How underground gas storage facilities work: suitable methods for storing natural gas

It would seem that knowledge of how underground gas storage facilities are designed has no practical significance for the average user.But humanity is too dependent on “blue” fuel and we really want to be sure that there will never be any interruptions in its supply. Isn't that right?

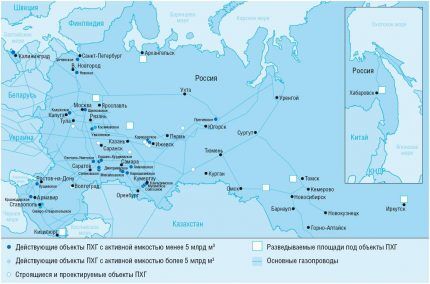

And every compatriot can be reassured by the information about gas storage facilities located underground (UGS) - as long as they are full, there will be no problems with gas supply. Read more about the storage structure and storage features in our article.

The content of the article:

Construction of underground gas storage facilities

If owners of private houses use gas to store gas for domestic needs gas tanks, then on a national scale we are talking about completely different storage options. Thus, officially, underground gas storage facilities are complexes of engineering structures that serve for the injection, storage and withdrawal of “blue” fuel. They consist of above-ground and underground components.

TO ground relate:

- gas distribution point, which serves to distribute the gas flow into several technological processes;

- compressor shopwhere fuel is prepared (by increasing pressure) for injection into wells;

- Gas purification plants.

Underground UGS components are: wells, workings, tanks. And the last point (containers) is the most interesting - how the gas storage itself is arranged depends on where the “blue” fuel is stored.

Review of gas storage tanks

With the same weight, gas occupies much larger areas than any solids. And since it is used in huge quantities, the same containers are needed to store it.

Moreover, experts abandoned gas storage in man-made above-ground reservoirs a century ago.

The reason is that this would require:

- occupy vast areas of the planet with complexes for storing low-pressure “blue” fuel;

- use expensive and explosive high-pressure gas tanks.

As a result, in order to neutralize the negative aspects listed above, the choice was made in favor of underground storage facilities, and these are considered to be containers located at a significant depth. Which, in most cases, ranges from 300 to 1000 meters. And you can store fuel there in tanks created by nature.

In total, engineers have learned to successfully use 7 types of natural gas storage tanks:

- formed in water-saturated porous formations;

- preserved after the production of carbohydrates, namely gas, oil;

- formed in rock salt deposits;

- created in the workings of mines;

- created in durable permafrost rocks;

- with a low-temperature ice shell;

- formed after underground atomic explosions.

Although there are many options, only the first 4 methods of gas storage differ in practicality.The remaining tank options are suitable only theoretically.

The reason the remaining three options are impractical is as follows:

- Gas can be stored in frozen rocks, as evidenced by several existing storage facilities in the northern regions of the planet. But their volumes are extremely insignificant, therefore they do not have any industrial significance today.

- Containers formed by underground nuclear explosions are quite suitable for storing significant gas reserves, which has already been proven experimentally. But the point is that powerful weapons were tested away from where people lived. Therefore, there are usually no consumers or utilities there.

As a result, these types of containers are simply unsuitable for use.

Although underground gas storage facilities are called storage facilities, in fact, gas conservation is not their primary task. Since what is in them is mostly used to smooth out unevenness of consumption. Which can be daily, weekly, seasonal. Only as a last resort are UGS facilities created to mitigate the consequences of force majeure circumstances.

Next, we will consider in more detail each of the options for storing gas underground.

Option #1 - storage in water-saturated formations

Storage facilities in water-saturated formations are designed to level out the effects of seasonal unevenness in gas use. And also to create strategic reserves.

An important feature of the design of such storage facilities is the minimal human participation - most often at the stage of creating wells necessary for gas injection.

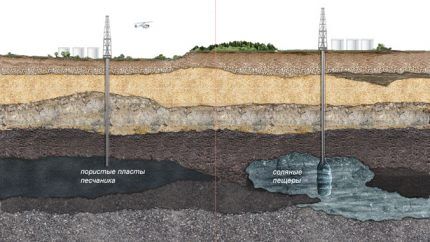

These containers are searched for in artesian formations. Gas storage facilities are created where the rock structure is permeable and porous. The remaining liquid is removed by gas, which compresses it and then squeezes it out.

The so-called fuel storage tanks themselves are not actually such. More precisely, they are not there at all - they are used as storage space voids in porous layers. And the whole procedure for creating a gas storage facility consists of displacing part of the water to the periphery. They do this in order to create space for “blue” fuel.

The procedure described above can only be completed if a number of factors contribute to this:

- The porous permeable layer is covered with a dome (cover) of gas-impermeable rocks, which are usually compressed clays.

- The aquifer extends from the boundaries of the storage facility for tens of kilometers. And it’s even better if it has access to the surface. All of the above allows the gas to successfully squeeze out the water in the formation.

- The length of the dome is sufficient to provide the ability to store significant volumes of gas.

- The porosity and permeability of the rock ensures acceptable gas capacity and the ability to release it during development.

If at least one of the conditions is not met, then it will be impossible to create an underground storage facility.

The operating principle of modern underground storage facilities is simple. The features can be examined using the example of large underground gas storage facilities used to smooth out seasonal irregularities.

So, usually in the warm season the required amount of gas is pumped into them. Which begins to be taken away only with the onset of the heating season. Moreover, it is not some huge amount of gas that is sent into the main pipe, but an average one, known from operating experience in past winters.

And, if suddenly the temperature drops sharply and daily consumption becomes an order of magnitude higher, then a large underground gas storage facility will still not increase the volume of withdrawal. And the shortage will be covered by small storage facilities designed to smooth out daily and weekly consumption. The reason is that it is easier and faster to select from them.

The advantage of UGS facilities in water-saturated formations is their significant capacity. A disadvantage is that geologists, when studying the characteristics of the aquifer, may not identify or take into account some important factor. As a result, the storage will be unusable.

And the worst thing is that this is often revealed after huge investments in the construction of above-ground and underground infrastructure. Quite often there are also less significant troubles, from which the operation of underground gas storage facilities in water-saturated rocks is accompanied by significant unplanned costs.

Option #2 - containers after hydrocarbon production

Engineering complexes that belong to this type serve to smooth out seasonal fluctuations in the consumption of “blue” fuel. And also to create strategic reserves.

The design of storage facilities of this type is the same as in the case of analogues created in water-saturated formations. That is, the fuel is stored in the voids of porous rocks.

UGS facilities created in rocks where hydrocarbons were once located are the most abundant in the world. So, their number reaches a significant 70%, the reason for this is a number of advantages.

These include: significant capacity and savings on capital investments in exploration, creation of infrastructure or at least part of it, drilling - oil and gas production has already been carried out at the site of the creation of such underground gas storage facilities.

But containers preserved after hydrocarbon production cannot be called ideal.

They have many disadvantages:

- problems with the tightness of old wells - this is especially true for former oil fields;

- insufficient porosity, permeability of rocks;

- mixing gas with oil residues - which sometimes leads to significant losses, since the resulting mixture can no longer be used.

And also, gas often develops a dangerous impurity in the form of hydrogen sulfide in oil fields. Which is harmful to human health, and also destroys all kinds of steel structures, even those related to stainless steel.

The operation of underground gas storage facilities based on areas of depleted hydrocarbon deposits is possible due to the fact that gas, when injected, displaces the remaining oil from the desired formation. In addition, like water, it has the effect of compressibility and mobility, which facilitates the task of arranging the container. Sometimes oil under gas pressure is not squeezed into the rock, but rises to the top, which becomes an additional source of profit.

Option #3 - reservoirs in rock salt deposits

Such containers with gas serve to smooth out the daily and weekly unevenness of its use, and also take part in leveling the seasonal one. In addition, storage facilities in salt formations successfully cope with the role of a backup source for important consumers.

The specified UGS facilities are created by washing out part of the salt deposits in order to create a cavity of the required size. For this purpose, several wells are initially drilled, through which water is supplied for a long period of time.

Although the described procedure is lengthy and expensive, it pays for itself, since the injected natural gas is stored without losses. The reason is that salt caves are airtight. In addition, they have the effect self-healing — tectonic and other cracks are quickly overgrown with salt deposits.

The advantage of constructing such underground gas storage facilities is that the required volume of fuel is withdrawn with virtually no speed restrictions. Which is several times higher than when performing the same operations in containers of other types. And also an important advantage of UGS facilities built in salt caves is the high percentage of gas extraction - one of the highest among all its types.

But the number of caverns in salt layers does not exceed 2% of the total number of storage facilities.

This indicator is affected by a number of negative aspects:

- Presence of huge amounts of salt water after washing out the caves to save gas. As a result, if there is no sea nearby or at least salt processing plants, there is nowhere to put the liquid. What is the main reason for the small amount of this kind of UGS.

- Reduction of useful volume during operation. This phenomenon is caused by the evaporation of salt in places with higher pressure and accumulation where it is lower.

- The appearance of impurities in the gas, which often become the remains of liquid previously used to wash out the cave.

- Minor volumes, which does not allow creating reserves in sufficient quantities.

As a result, salt storage facilities are usually used only where it is not possible to use the types of containers listed above.

Option #4 - UGS in mine workings

Their volumes are insignificant. Nevertheless, the Swedes and Norwegians store part of their strategic gas reserves in containers of just this type.

PVC in mine workings is the only gas storage facility completely equipped by humans. So, in one of the mines, explosions create a container, which is then lined with steel sheets.

Although it is profitable to operate underground gas storage facilities in abandoned mines due to the high percentage and rate of withdrawal, their number will not increase significantly in the near future. The reason is that the described storage facilities are difficult to build. Since it is not always possible to achieve complete tightness, which leads to significant losses.

This happens due to the fact that during the operation of the mine they try to supply the maximum amount of air there. Why is a ventilation system created with a lot of exits to the surface, which cannot always be sealed when arranging a storage facility?

As a result, today there are only a few successful examples of implementing the idea of storing gas in abandoned mines (in Sweden, Norway, Germany).

Are the storage facilities airtight?

Fuel leaks are common processes that cannot be avoided. Because there are too many reasons.

For convenience, they are divided into 3 categories:

- geological;

- technological;

- technical.

To the group geological reasons include the heterogeneity of UGS cover, the presence of tectonic faults, as well as features of hydrodynamics and geochemistry. For example, gas can simply migrate through the formation, and specialists will not influence this in any way.

Technological causes are among the most common since errors regularly occur when assessing any facts. For example, the effectiveness of hydrotraps, gas reserves, and ongoing physical and chemical processes.

Technical reasons are most often associated with the condition of the wells used, through which gas is injected.

Features of creating underground gas storage facilities

In 95% of cases, underground storage facilities are created squeezing out water with gas, oil residues from porous formations. In this way, “containers” for storing “blue” fuel are created.

And the most important feature is that the volume of gas used to squeeze out liquids cannot subsequently be used for delivery to consumers. Its task is to prevent water and hydrocarbon residues from returning to their old place. Otherwise, the repository will simply cease to exist.

That is, the specified gas is buffer. As a rule, it is no less than half of the total volume pumped into underground gas storage facilities. And in some cases, there is 3 times more buffer gas than what can be used for supply to consumers, which is called active.

It is interesting that the amount of buffer gas cannot be calculated in advance.That is, everything is tested exclusively experimentally. Which in many cases takes years. But still, when the result obtained is unsatisfactory, the buffer gas can be pumped out in full.

Procedure for filling the storage

After geologists have studied a formation and decided that a gas storage facility can be created in the right place, gas producers build an engineering complex.

And then the injection of “blue” fuel into the future underground gas storage facility begins, which is supplied from the nearest main pipeline. And it goes to the cleaning site, where all kinds of mechanical impurities are removed.

Clean fuel is supplied to the metering and metering point. And after that, to the compressor shop, where compression is carried out - this is the name for preparing gas for pumping into storage. It represents an increase in gas pressure to the desired value.

It is then transported to gas distribution points. Where the total flow is divided into several and supplied to different technological lines. From there it is sent through plumes to wells for injection.

Throughout the entire process, specialists monitor a number of parameters, including gas pressure and temperature, and the productivity of each well.

Conclusions and useful video on the topic

The video attached below is dedicated to the topic of creating underground gas storage facilities to smooth out the uneven consumption of fuel that will be supplied by the Power of Siberia gas pipeline.

Underground gas storage facilities are the most reliable and profitable way to level out uneven gas consumption and ensure its stable supply in case of force majeure. And the most interesting thing is that for this we need to thank not the human genius, but nature, which prudently created the rock layers suitable for this.

Have you personally taken part in the creation of underground gas storage facilities and want to supplement the above material with useful information? Or noticed a discrepancy in the facts? Leave your remarks and comments - the feedback block is located below the article.

Good article, but it’s unlikely that the photo shows Hungary. The car numbers are more similar to Russian ones and advertising of Meat and Baltic too)