What to do if the gas meter squeaks during operation: the main causes of noise and methods for eliminating them

Agree, sharp and creaking sounds are annoying and interfere with concentration.Especially if the noise stays at the same level for a long time or occurs many times during the day. Such troubles often arise in everyday life. Imagine, your new gas meter creaks during operation, what should you do when you can’t get your money back and the sound is unbearable? Is it worth changing it? Can it be repaired, and where should I go for it?

If you are the owner of a squeaky meter, then you don't have to worry too much. You are not alone, and some gas meters cannot operate silently. In the article we described all the reasons why a gas meter may squeak. Here you will find options for action in such a situation.

The meters begin to work more actively when gas equipment is turned on. Sometimes a specific creak and even a whistle appears. Sometimes the strength of sound does not depend on the speed of gas movement. The condition of the device also has its influence, as do the features of its structure. Even before purchasing, you can find out how the product performs during operation. If an old meter is noisy, then on the one hand this should not cause concern, but on the other hand, it may indicate an imminent breakdown.

The content of the article:

Operating principle of gas meters

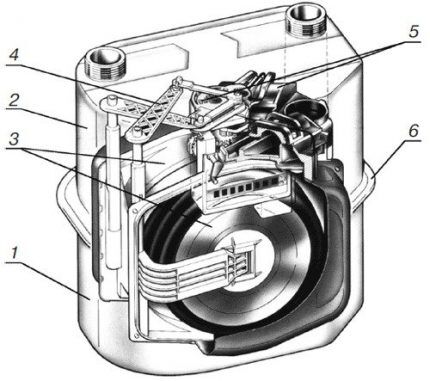

Gas meters show the volume of gas consumed, less often the mass. Among the measurement methods, 2 options are used: direct and indirect.

The direct method means counting the amount of gas through cycles of filling the chamber/chambers. In the indirect method, volume determines flow rate. Sensors detect the movement of rotating parts.Unpleasant noise is observed primarily in low-quality devices, more often in mechanical ones.

Manufacturers test device protection for resistance to moisture, sunlight and temperature contrasts. No laboratory tests guarantee 100% correct operation. During the 2nd period of verification, problems often arise with loud noise during operation, especially with meters with rotors.

Causes of noise when the gas meter operates

The squeak of the meter interferes with everyday life. The noise is usually long-lasting and resembles the sound of unlubricated parts. The meters can last the entire period, despite the creaking. For rotary flowmeters, noise is normal.

Meters are noisy due to several factors:

- debris and foreign particles;

- design features;

- problems with joint tightness, tightness;

- wear.

Normal pollution leads to the formation of extraneous sounds. Dirt sometimes gets inside, insects, leaves and debris get stuck on the outside of the housing (if the meter is not located indoors). Due to the vibration of the device, foreign objects may be completely pushed inside.

The quality of work depends on type of device. Meters with converting elements in the form of eight-shaped rotors produce squeaking noise at low temperatures. These gas meters are cheap, so they are in demand.

The sealing problem also causes noise. A complete inspection will indicate a lack of insulation. If there are no foreign objects inside or outside, then the cause of the squeak is a leak in the internal parts in the case.

Problems arise due to initial defects or rapid temperature changes. The escaping gas will emit a characteristic squeak. The insulation of the device is also affected by housing deformations. Damage occurs due to improper installation and impacts.

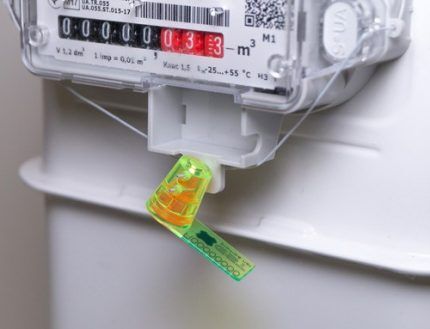

Due to depressurization in the dial area, they resort to urgent replacement. Subscribers are sometimes forced to pay based on clearly inaccurate data, and if the figures are too low, the supplier charges amounts based on consumption in the first months of the year.

Also, users often encounter a situation when the gas meter begins to record too high a gas consumption. This can happen by several reasons.

A grinding sound in the gas meter indicates a temporary problem, failure, or the likelihood that the meter will break down in the near future. With old and almost expired equipment, wear of parts, friction and loss of power are observed, which leads to unpleasant sounds.

Meters also squeak if too wet fuel enters a cold room. Sometimes sound occurs due to oxidation of the wires that go to the electronic display. Some gas meters make sounds immediately after gas-using appliances are turned off. The excess noise then goes away on its own or continues to appear periodically. In some cases, after the squeak, a problem with gas movement occurs.

How to remove disturbing sound?

You can get rid of the squeak on your own only if there is an external problem. The device is inspected closely, and the crevices are cleaned with a thin brush. The smell of gas in the air indicates an internal problem.

The devices become explosive, and several careless inhalations of poisonous gas during inspection can sometimes lead to loss of consciousness.

If there is a hardware problem, call gas companies. These organizations are usually parties to maintenance agreements. The operator will accept the request if the problem is only noise. The gas technician will inspect the gas meter inside and out, determine why it is noisy, and try to fix the problem. Emergency service personnel will soon respond to a gas leak call.

Before the gas engineer arrives, you should do the following:

- shut off the fuel supply to gas-using appliances;

- turn off all gas meters, as well as electricity meters that are located nearby.

If the problem was in the rotary meter itself, then it should be replaced with a membrane one. Type 2 devices make less noise and have better insulation.

Soundproofing the meter using a cabinet

There are metal and plastic products on sale. In order to reduce noise and simply at home, it is better to assemble the cabinet yourself, from plasterboard. Metal profiles are used, which are connected and then sheathed. The box will almost completely absorb the noise if it does not touch the flow meter itself.

Install 2 sheets of drywall on each side and make a soundproofing layer between them. The cabinet door is made on the entire facade or only in the form of a closed window. The second option is better in terms of sound isolation.

The disadvantage of a soundproof cabinet is the possibility of gas accumulation. The likelihood of an explosion will increase, and the vents will not help you hear the smell in time.

Gas workers have the right to issue fines for such installations. The option with a closet will be useful primarily for those who find sound disturbing to sleep. The structure should be kept open most of the time.

Alternative options for eliminating noise

If external cleaning, inspection of the gas operator and repairs do not bring results, and the cabinet cannot be installed, you will have to choose one of the alternatives.

If the device is still buzzing, there are 4 ways out of the situation:

- Move flow meter.

- Reduce noise by insulating the gas pipes through which it travels.

- Organize soundproofing of the kitchen or other room.

- Buy another meter, which can be more economical than repairs and reinstallations.

A creaking counter will not cause discomfort if you move it outside. Technical feasibility depends on the pipeline design. You will need to contact the gas distribution company. The level of complexity of the operation determines whether the organization agrees to the work or not.

A gas meter on the street also requires additional protection, a visor or the same locker, as well as insulation of gas pipes. The likelihood of a meter breaking down on the street will increase. The idea has modest economic benefits and only if the gas meter lasts for some time. You will need a thermal corrector and, in addition, the recorded indicators will increase.

The sound from the meter also travels through pipes. The problem will become less noticeable after they are thermally insulated. As a result, gas consumption will also decrease. In practice, a blanket is often used, and close to the meter. Ideally, they resort to reliable 3-layer insulation.

The base is formed from 2 layers, including a primer and a primer as an adhesive. Initial coatings protect against peeling of the polymer from the steel pipe. Extruded plastics are used directly as insulation. These measures also reduce the risk of humidity and temperature changes in the pipes, which is good for the meter.

Sound can be isolated from spreading throughout the apartment, while at the same time softening its strength in the kitchen or technical room. Soundproofing foam rubber or polyurethane foam is attached to the walls and installed on a frame. Sound-absorbing panels are mounted on top. The finishing is then done with plaster. There is not enough sound insulation for 1 wall with a meter. To enhance the effect, it is better to also process the opposite.

Without adherence to technology, the end result will be weak. The first layer of sound insulation must be made with a ventilated structure, the second - heavy and dense. You cannot leave gaps between soundproofing panels, but also do not make a rigid joint with a wall, floor or ceiling.

Repairing or moving the meter will take a lot of money if the subscriber lives in a small town, at a considerable distance from the organizations that deal with this. A humming meter should be replaced with another model, and you can read how to do this correctly in this material.

The essence of the work is to compare the speed of ultrasonic flows directed along and against the movement of fuel.

Conclusions and useful video on the topic

The noise from the gas meter goes to the pipes:

What meters should you buy, and what they don’t say in stores:

Gas meters fail for various reasons. It’s bad if all the savings “disappear” because of this. If the gas meter is simply buzzing or whistling loudly, then you will be able to find a way out. The first step is to eliminate the cause of the noise.

Employees of the organization with which the agreement for the maintenance of gas equipment was signed will help with this. They must inspect everything and determine when and why the meter beeps, whether the gas boiler and stove are working normally. If something happens, an emergency team will need to come out. If there were no technical problems, no extraneous sounds, but the meter continues to hum, then you will have to reduce the noise itself.

If you have encountered a problem with noise from a gas meter, then write how you managed to solve the problem. Ask questions about the operation of gas flow meters to our experts and exchange information with other readers of our site. The contact form is located below.

The meter was changed in 2019. We have a private house and in addition to the stove there is also a gas boiler. All was good. In 2021 there was a massive gas outage for 12 hours.After turning on the gas, the meter began to creak and when reading the meter, it was discovered that the gas consumption had tripled. I called Gorgaz and they told me to change the meter. We bought it, called a gas worker, connected it, the creaking did not go away. What to do?