How to properly insulate a wooden entrance door with your own hands: step-by-step instructions

For many owners, the problem of insulating a wooden entrance door often seems far-fetched.In the case of metal boxes and panels, everything is clear; without insulation, the steel will freeze the entire hallway; the outer doors begin to be intensively insulated only after rot, condensation or a layer of frost appears. If you do not insulate it in time, then in a couple of seasons the condition of the supporting box will deteriorate so much that you will have to replace the entire entrance block.

The content of the article:

Reasons for heat loss through doors?

Door blocks can be divided into two categories: inexpensive purchased ones and professional, homemade ones. Size and shape don't matter. The main thing is how well the supporting box and canvas are made and fitted.

If the entrance doors are assembled and fitted correctly, at a professional level, then for the first few years there will be no need to insulate them. And made from oak, larch or ash, properly processed, installed according to step-by-step instructions, door blocks may not require insulation for 10-15 years of service.

Reasons why you have to insulate entrance door blocks:

- Sagging door leaf.

- The appearance of gaps between the canvas and the block-box.

- Mistakes made by craftsmen when installing a wooden block in a wall opening. For example, without waterproofing and insulation of the threshold.

- Low quality protective coating.After moisture has accumulated, the wooden door leaf is bent by the propeller, resulting in cracks and cold bridges appearing.

- Destruction of the insulation installed in the gap between the entrance block and the wall.

- Moisture regularly gets on the entrance doors. For example, condensation drips or rainwater flows in if the owners saved on a canopy for the entrance area of the porch.

Any moisture, droplets or in the form of water vapor, falling on an unprotected wooden surface is absorbed by the wood. Because of this, the outer fabric “leads.” Therefore, in any case, before installing insulation, you need to figure out where the siphonites are, why and how to eliminate drafts.

How to find where the cold penetrates

To check the entrance doors for heat leakage, you can use your own hands, a remote thermometer, a flashlight and a hair dryer. You will also need an assistant, at least one. Investigating problems with insulating a wooden entrance door on your own can be inconvenient and time-consuming.

Checking the doorway

Often homeowners test the resistance of a wooden door to cold penetration with a wet palm. You just need to tightly close the outer flap and run your palm, previously moistened with water, along the supposed heat leak. The sensitivity of the wet skin of the palm is so great that with a little training you can feel a chill in places where the insulation is damaged.

It is best to check in the evening or at night. The assistant will illuminate the opening from the inside of the room with a flashlight in all places where there may be cracks, and he will need to carefully and slowly walk along the contour of the entire opening. Where the leaf does not fit tightly to the door frame, barely noticeable rays of light will appear.

Checking the box

To check, you will need a hairdryer and a non-contact infrared thermometer. The scheme for checking the effectiveness of insulation of an external door is quite simple:

- one of the workers heats the joint from inside the room with a hairdryer;

- the second person observes the seam using an infrared device.

In places where there are heat leaks, a small draft lowers the temperature by several degrees at once. Moreover, a black spot on the outer surface of the sash forms within a few seconds. This is clearly visible on the device screen.

The advantage of this method is that you can check the insulation of the entrance block without waiting for cold weather. Moreover, the method only works on wooden entrance doors. In the case of armored, steel, metal-plastic models, heat dissipates naturally very quickly, since the thermal conductivity of metal is much higher than that of wooden cladding.

Checking the canvas

Checking the door leaf is much more difficult. You can judge the effectiveness of insulation by subjective sensations, for example, if you put your hand on the surface from the inside. The palm will immediately feel the freezing cold.

The second way is to try to see cracks on the surface of the front door if the door is made of tongue-and-groove boards or slats. Sometimes, as insulation, thermal insulation such as mineral wool is placed inside the canvas, which easily absorbs condensation and sag so much that a void is formed inside. In this case, frozen water vapor appears on the cracks - frost.

But it is best to remove the panel from the hinges and disassemble the front door leaf, remove the wooden cladding and make sure that the thermal insulation of the leaf requires urgent replacement.

Which insulation to choose?

For insulation, you can use four thermal insulation options:

- Styrofoam — expanded polystyrene 25-50 mm thick;

- penoplex any thickness;

- mineral wool in rolls or slabs;

- mounting polyurethane foam.

To insulate wooden doors, you can also use felt, natural or synthetic, 4-6 mm thick, as well as roll insulation used for laminate flooring. All other options, for example, foam rubber, polyethylene foam, bamboo fiber mats, if used to insulate the front door, are only used in apartments.

For the front door of a private house, such thermal insulation is not effective enough. The doorway still loses heat. Most often, these materials are sewn over the outer door cladding to improve the sound insulation of the wooden panel.

Styrofoam

Low-density polystyrene foam produces fairly effective insulation. Sheets of P25 foam plastic up to 25 mm thick can be laid directly inside the door leaf.

But there is one limitation - the mechanical strength of polystyrene foam is extremely low. Moreover, low-density polystyrene foam absorbs water vapor well that enters the thickness of the front door, freezing inside and destroying the porous structure.

Therefore, if you use polystyrene foam to insulate a wooden door leaf, then only in conjunction with a vapor barrier of one-way conductivity. Steam should be discharged from the door towards the street. In this case, the outer cladding of the door leaf is made of boards or wooden slats. Warm water vapor will freely escape from the insulation of the front door.

In addition, to insulate the front door, it is better to use a package of several thin layers (10 mm) of polystyrene foam. In this way, it is possible to eliminate cold bridges in the event that one of the sheets bursts and a crack appears.

Penoplex

Today this is one of the best materials for insulating wooden entrance doors. Penoplex does not allow water vapor to pass through, has high strength, rigidity, does not break or crack under load, like polystyrene foam.

The only disadvantage of such insulation is low vapor permeability. That is, foam protection will trap water vapor inside the door leaf. This means that the wooden frame of the front door will absorb moisture, and the wood will swell and deform. In severe and very severe frosts, this can lead to destruction of the adhesive seam and tearing of the foam sheet from the wooden frame.

Minvata

For ordinary entrance doors with a leaf thickness of up to 50 mm, it is better not to use mineral wool. Rolled mineral wool is definitely not suitable for insulating wooden entrance doors.

The reason is that the rolled material needs to be somehow fixed inside the door leaf. Otherwise, the panel will go in waves, folds, and after swelling with water condensation, it will completely sag on the wooden frame.

Therefore, if you want to insulate with mineral wool, then you need to use dense hard mats made of pressed fiber. But another problem appears.

The thickness (height) of the cavity inside the wooden door is not enough to allow a dense mineral wool mat to be placed in it. Thermal insulation made from pressed fiber is usually made with a thickness of 50 mm or more.

Only then does the mat acquire sufficient rigidity to adhere to the wooden frame inside the canvas due to its own deformation. But in this case of insulation, the front door will become 30-40 mm thicker.

If increasing the thickness of the front door is not a fundamental problem, then it is better to choose mats made of mineral wool. This is the only correct decision if the frost outside in winter reaches minus 30-40OC. Mineral fiber insulation is the only option that will withstand any thermal load.

Using the same scheme, you can make insulation for a wooden door from the back entrance. In this case, it makes sense to additionally equip the door frame with a so-called bath seal, as in the video:

With such insulation of the front door, frosts and strong winds at minus 40 are not scaryOWITH.

Polyurethane foam

They are practically not used as independent insulation for wooden entrance doors. Polyurethane foam is used to fill the frame and individual cavities of the door leaf only during restoration work.

In theory, a wooden entrance door can be insulated with foam, but only for models that do not have their own thermal insulation inside. Instead, a stiffening frame is assembled from paper or wooden slats. In this case, insulation with polyurethane foam will be a technically competent solution. Just don’t forget to treat the surface with water and lay a vapor barrier lining.

Repairing the opening

All you need to do is remove the trim from the door frame and clean the old foam holding the block with the front door inside the wall opening.Typically, heat loss through the door block is due to the fact that when installing the front door, little foam was used or the foam cylinder was too hot, and the air temperature dropped below +2OWITH.

In this case, the foam expands poorly, cools quickly, and collapses, leaving channels for cold air to penetrate. Therefore, the old foam needs to be removed and cleaned. The walls of the opening are moistened and sealed with foam from a cylinder. If the entrance door is double, the gap must be blown out simultaneously from the outside and inside. So go along the contour.

You also need to pay attention to the condition of the threshold. The base of wooden entrance doors often rots because the condensate that flows down does not go away. Therefore, under the wooden threshold, it is advisable to lay not polyurethane foam, but a tile of pressed foam glass, provide waterproofing and, of course, protection from external moisture that gets on the outer lining of the door leaf.

Insulating a wooden door leaf - instructions

First of all, you need to correctly assess the thickness of the thermal insulation for the front door. There are two options for arranging an entrance with a wooden door:

- single wooden door with increased thickness of thermal insulation;

- double door block - two wooden doors on one frame.

The first option is used in cases where it is not possible to install a vestibule or double block at the entrance to the house. This does not mean that a single door will be inconvenient. It’s just that its thickness, taking into account insulation, will be a little larger than usual.

But even if you install a double entrance block, experts still recommend insulating the outer leaf as much as possible and installing additional vapor barrier on the inner door leaf.

What will you need?

To work, you will need a furniture stapler, polystyrene foam, mounting foam, and a vapor barrier membrane used for insulating roofing coverings.

In addition, you will need some materials to put the door leaf and frame in order. You will need to prepare a high-quality oil-based (polyurethane) varnish for exterior use; you may need a propane torch.

Since the insulation will be performed with foam plastic, the outer cladding will have to be replaced, made from boards or wooden slats. Therefore, to work with wooden blanks you will need to prepare:

- jigsaw;

- hand grinder and electric planer;

- screwdriver;

- a couple of clamps;

- carpentry fasteners - self-tapping screws 25-50 mm.

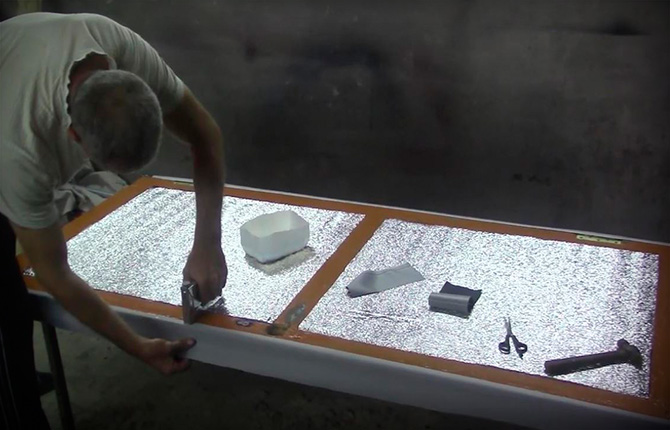

To insulate it yourself, it is best to remove the front door and place it on a table or workbench.

Step by step instructions

First of all, the door leaf needs to be disassembled, the top lining removed, and the old insulation removed. If there are glass inserts or windows, they will need to be removed. To obtain high thermal insulation characteristics, it is best to replace ordinary glass on the front door with a double-glazed window.

The old door block, leaf, platbands will first need to be burned to remove the old varnish and paint.

This will simplify the preparation for laying insulation, and will also dry the wood and at the same time destroy dry rot and pathogenic microflora.

Next you need to cut the foam into separate blocks. Each such insulation element is cut individually to size and placed in its own niche. It is important that the foam insulation “sits” tightly between the stiffeners, without a gap.

The last step is adding new wood cladding to the door.Since the vapor permeability of foam plastic is quite low, comparable in level to dry pine, the boards must be laid on the frame of the front door as tightly as possible, without gaps.

If necessary, tighten using clamps before fastening.

Immediately, as soon as new insulation was laid inside the front door, the wooden cladding was filled, the surface and the entire door leaf needed to be coated with polyurethane varnish at least twice and dried thoroughly. This is done in order to fix the natural moisture content of the wood. Now you can insert the double-glazed window, attach the lock, handles and install it on the hinges of the doorway.

Insulation with external upholstery

A fairly effective way to insulate a wooden door is to lay thermal insulation on the outer surface of the door leaf. There is no need to disassemble a wooden front door. It is enough to remove and lay the sash on a flat horizontal surface. The method is suitable for old apartments and country houses, where there is no point in installing a new wooden door.

The base is insulated with lining polyethylene foam, and the top layer of insulation is sheathed with felt and sewing leatherette. You can use a ready-made door kit or buy materials separately.

First of all, strips of dermantine are sewn around the perimeter of the door leaf, each 10 cm wide. The material is simply fastened around the perimeter, along the edge of the wooden leaf.

Next, you need to cut out and lay felt insulation on the outside.

The next stage is upholstery. A dermantine panel is laid on top of the felt insulation, the edges are turned inward, wallpaper nails can be driven into the corners, the rest is sewn evenly to the wooden base using staplers.

The last stage of insulation is to make a side around the perimeter of the front door. To do this, a rope is rolled up from scraps of insulation (felt), wrapped with a previously sewn 10 cm flange and nailed to the door with furniture nails. The soft edge performs decorative functions and at the same time, as a seal, closes the gaps between the wooden frame and the entrance door leaf.

The platbands must be covered with felt and dermantine. This is done not only for the sake of the appearance of the doorway. Insulating the contour of the door block significantly reduces heat loss on old blocks, those that have stood in the house for at least 10-15 years.

Results

It is quite simple to insulate a wooden entrance door if you do not skimp on material and choose the right thickness of thermal insulation. For most door blocks, foam plastic or penoplex is used. Mineral wool is recommended for use only in extremely cold climates.

Tell us about your experience of insulating entrance door blocks. What methods are best for an apartment? Also share the article on social networks and bookmark it.

Remove the door leaf and place it on the end. Using a cutter you need to select a groove from the end surface along the contour. A modern silicone or sponge seal is placed in the groove. That's all the insulation is. A wooden door itself holds heat well if assembled correctly. All problems are due to cracks.

Everything is insulated from the inside, the wood is still drying out, so what’s the point of building a fence around the garden. Install normal plastic.