Batch switch: what is it and what is it for + connection diagram

There is hardly a mature person who has not seen a packet switch in his life, although not everyone knows what it is called.Several decades ago, such devices were installed in every entrance and in all apartments.

They were used as switches, with the help of which the power supply was turned on and off. Over time, packet machines were replaced by modern machines, but not everywhere.

The content of the article:

What is a packet switch?

Packers are devices designed for switching (i.e. turning on and off) small load currents. They are connected to DC and AC power networks of 440-660 V.

The devices can hardly be called convenient, since their design does not provide automatic de-energization systems in case of overload.

In addition to the lack of automatic protection, the devices have another significant drawback: they quickly break down due to frequent voltage surges. For this reason, they began to be used much less frequently.

But it’s still too early to talk about the irrelevance of packet networks while they are cheap and their switching resource is satisfactory. The devices are still convenient for use in switchboards and control panels.

Package switches have not been installed in the entrances of high-rise buildings for a long time. They were replaced with modern two-pole circuit breakers, which are characterized by better wear resistance, durability and greater current carrying capacity. New devices are connected to the electrical network of each individual apartment, and not the entrance.

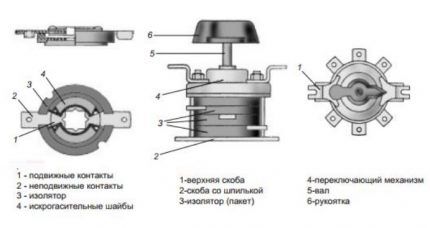

Design features of the bag

The package design includes a contact group and a switching mechanism. They are enclosed in a shell, which also contains movable contacts fixed on a square sleeve made of electrical insulating material.

The device is equipped with fixed contacts, the terminals of which extend from the housing and are shaped like knives. The contacts are connected and disconnected using a spring. It is controlled by a switch.

Turning the handle winds the spring of the switching mechanism. It turns the figured washer and movable contacts a quarter turn. The stroke of the washer is limited by a stop located in the cover.

The moving contacts are attached to plates made of fiber. When the material heats up, it releases gas, which moves under pressure through the openings of the bag. Instead of gas, non-ionized air enters the housing and extinguishes the arc.

Due to their simplicity of design and ease of use, bags are widely used in the following areas:

- as input switches;

- for switching control circuits;

- as electric current distributors;

- for controlling electric motors.

There are many different types of models designed for use in different conditions: in dry and wet rooms, for installation in panels and technological niches.

5 undeniable advantages of devices

The popularity of package switches for many decades is due to the undeniable advantages of these devices:

- Compactness. Due to their small size, the devices are easy to install and convenient to use.

- High arc extinguishing speed. Package switches are rationally designed, so both extinguishing the electric arc and turning off the device occur almost instantly.

- Easy to maintain. Baggers do not require any special care or maintenance. The main thing is that they are inspected on time and replaced if necessary.

- Resistant to damage. The devices are difficult to break. They cope well with mechanical loads and do not suffer from vibration.

- Wide range of applications. Package switches are not afraid of high and low temperatures (from -40 to 70 degrees). Devices housed in sealed housings are resistant to dust and moisture.

The service life of the bag directly depends on the condition of the protrusions of the fixing washer.

If the main working part wears out, the device fails.It is because of this feature that there are complaints about the devices regarding their short service life.

Package switches cannot be repaired. If they break, they have to be replaced. But throughout the entire period of operation, the devices do not need to be maintained. It is enough to clean them from dirt and check their functionality once every six months.

Main types and types of bags

Bags are classified according to different criteria:

- at the location where external electrical cables are connected to the panel (front, rear connection);

- according to the degree of protection of internal structural elements from negative environmental factors (open, protected, sealed devices are distinguished);

- according to the design features of the switches (packet-cam, drum).

Despite the wide variety of package switches and switches, they have common technical and operational characteristics and similar disadvantages.

Thus, the resource of the spring mechanism is designed for approximately 103 power outages. There are wear-resistant models that perform 203-1000 shutdowns. The main condition: the frequency of operation of the mechanism should not exceed 50 within 1 hour.

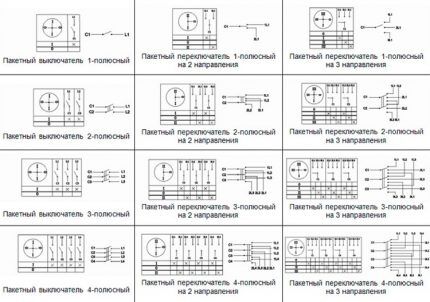

Product markings may include the following alphabetic and digital symbols:

- “B” – switch;

- “P” – switch;

- “P” – batch;

- “G” – sealed;

- numbers 1-4 – number of poles;

- “N” – direction (2, 3, 4, and also “R” – reverse).

The marking of devices indicates the degree of protection, type of placement, installation features, rated current. Sometimes you can find abbreviations “sil.” and "pl."

They are used to indicate the housing material (silumin, plastic). For example, the marking of the device GPPM-2-60/N2 stands for 2-pole 60-amp sealed packet switch for 2 directions.

More modern analogues of the device

The old package switches have been replaced almost everywhere with automatic machines. This is logical, because the requirements for energy consumption and durability of devices have changed. Nowadays, RCDs (residual current devices), automatic and differential circuit breakers, and contactors are widely used.

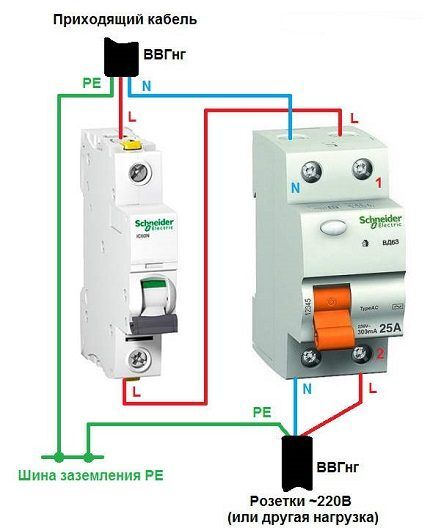

Option #1: residual current device

The device is designed to prevent current leaks. It reacts to differential current, which contributes to overheating of electrical cables, which can lead to a short circuit and fire of the wiring. Leaks can also cause electric shock to a person.

An RCD must be installed to avoid the risk of electric current leakage if it begins to pass by consumer devices. The device functions as a leak indicator, which simply turns off the electricity in case of problems.

By itself residual current device does not protect against overloads or short circuits. This is only possible if it is connected in combination with a circuit breaker.

Option #2: circuit breaker

These devices replaced the package switch.They perform the same functions, but are more convenient to use, durable and wear-resistant.

Automatic switches can also be one-, two-, three-, four-pole. They differ in the type of drive (it can be manual, spring, motor), type of connection and other technical and operational characteristics.

Offered for sale circuit breakers mark and are classified in accordance with GOSTs 9098–78 and 14255. These documents establish requirements for the technical characteristics of devices.

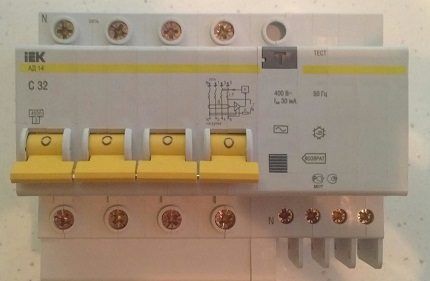

Option #3: differential machine

This is a combined machine that simultaneously performs the functions of two devices - an RCD and a circuit breaker. Differential automatic perfectly replaces the bag, is suitable for household electrical networks and is successfully used in enterprises.

Functional and design differences between the diffautomatic device and the RCD are given here, we recommend that you familiarize yourself with very useful information.

The differential circuit breaker prevents leaks, short circuits, and minimizes the risk of electric shock. The design of the device includes thermal and electromagnetic releases. The first prevents overloads in the network, and the second is needed to turn off the electric current in the event of a short circuit.

Option #4: contactor - a type of electromagnetic relay

The device is necessary for remote control of on/off modes of electrical circuits. Electromagnetic relays do not operate in the event of a short circuit and are designed only for rated currents. This is their main difference from circuit breakers.

In modern residential buildings, outdated package switches are rarely installed. Almost universally practiced installation of automatic machines or RCD connection in combination with a circuit breaker. But there are cases when a good old bag can be indispensable, for example, if you need to turn off the current supply during electrical installation work.

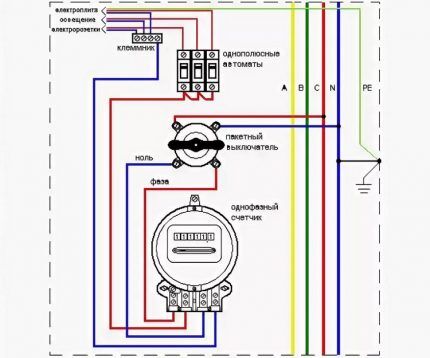

Packet connection diagram

Due to its compactness, the package switch can be installed in a panel. To do this, use a DIN rail. If you choose an old model, you need to take into account that it is unlikely to have a latch and will require screws for installation. There are no problems when installing modern packagers.

The two input terminals of the packet are connected to the phase and zero wires that come from the electric meter. And the output terminals are connected to the circuit breakers in the panel.

On domestic diagrams, the zero and phase wires are marked in blue and red, respectively.

If the product is imported, the cable colors may be different, so be sure to read the technical documentation and manufacturer’s recommendations. Don't experiment blindly.

Conclusions and useful video on the topic

We offer a thematic video selection that will help you understand the design, purpose, and operating principle of package switches of various types.

Design features of the Soviet batch switch:

Modern models of the CA25 series:

How the PVM 2 10 package works:

Video instructions for connecting an RCD and a circuit breaker:

Although the popularity of package switches decreases every year, manufacturers continue to produce them. New models are much more convenient and have fewer disadvantages than outdated ones.

When choosing a suitable bag, you should pay attention to several brands: Legrand (France), Iek (Russia), ABB (Sweden, Switzerland). These are reliable brands and their products are of high quality.

Tell us about how you selected or installed a batch disconnect device with your own hands. Share technological nuances that will be useful to site visitors. Please ask questions, post photos related to the topic of the article, and leave comments in the block below.

Packets were often used not for their intended purpose (for switching), but for simple switching on/off, due to sealed housings, when installed outdoors and in damp rooms.

I'm interested in how safe it is to use packet switches. I have heard stories more than once about how they exploded when worn out.

Good afternoon, Leonid.

A batch switch, an automatic switch, or any electrical device are safe if they are used in accordance with the passport data and are operated as required by the PEEP.

Here, for example, are the passport details of the “PV” packet:

— designed for control circuits of electrical installations, asynchronous motors;

— allows infrequent switching on/off – switching is limited to 120 operations per hour;

— operating modes – long-term, intermittent-short-term, intermittent-long.

During operation, the contact resistance of the contacts, insulation resistance (cold state/heated by current), and other parameters specified in the Operating Rules must be monitored.

Here's something interesting about the installation:

— packets for 16~40 A. The ends of the connected wires are soldered;

— packets for 63~100 A. The ends of the wires are terminated with lugs, which are soldered. I have attached a screenshot of this extensive and interesting fragment of the passport.