Electronic ballasts for fluorescent lamps: what they are, how they work, connection diagrams for lamps with electronic ballasts

Are you interested in why an electronic ballast module is needed for fluorescent lamps and how it should be connected? Proper installation of energy-saving lamps will extend their service life many times over, right? But you don’t know how to connect electronic ballasts and whether it is necessary to do so?

We will tell you about the purpose of the electronic module and its connection - the article discusses the design features of this device, thanks to which the so-called starter voltage is formed, and the optimal operating mode of the lamps is maintained.

Schematic diagrams for connecting fluorescent light bulbs using an electronic ballast are provided, as well as video recommendations for the use of such devices. Which are an integral part of the gas-discharge lamp circuit, despite the fact that the design of such light sources may differ significantly.

The content of the article:

Designs of ballast modules

Industrial and domestic structures fluorescent light bulbs, as a rule, are equipped with electronic ballast modules. The abbreviation reads quite clearly - electronic ballast.

Old style electromagnetic device

Considering the design of this device from the series of electromagnetic classics, one can immediately note an obvious drawback - the bulkiness of the module.

True, designers have always sought to minimize the overall dimensions of EMP.To some extent this was successful, judging by modern modifications already in the form of electronic ballasts.

The bulkiness of the electromagnetic design is due to the introduction of a large inductor into the circuit - a mandatory element designed to smooth out the mains voltage and act as ballast.

In addition to the inductor, the EMPR circuit includes starters (one or two). The dependence of the quality of their work and the durability of the lamp is obvious, since a defect in the starter causes a false start, which means an overcurrent on the filaments.

Along with the unreliability of the starter, fluorescent lamps suffer from the strobing effect. It appears in the form of flickering with a certain frequency close to 50 Hz.

Finally, the ballast provides significant energy losses, that is, it generally reduces the efficiency of fluorescent lamps.

Improvement of the design to electronic ballasts

Since the 1990s, fluorescent lamp circuits have increasingly been supplemented with an improved ballast design.

The basis of the modernized module was made up of semiconductor electronic elements. Accordingly, the dimensions of the device have been reduced, and the quality of work is noted at a higher level.

The introduction of semiconductor electronic ballasts led to the almost complete elimination of the shortcomings that were present in the circuits of devices of outdated format.

Electronic modules show high-quality stable operation and increase the durability of fluorescent lamps.

Higher efficiency, smooth dimming, increased power factor - all these are the advantageous characteristics of new electronic ballast modules.

What does the device consist of?

The main components of the electronic module circuit are:

- rectifier device;

- electromagnetic radiation filter;

- power factor corrector;

- voltage smoothing filter;

- inverter circuit;

- throttle element.

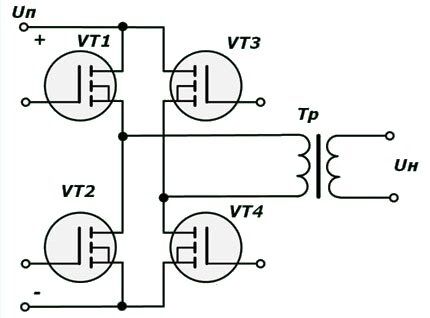

The circuit design provides for one of two variations - bridge or half-bridge. Designs that use a bridge circuit typically support high-power lamps.

Meanwhile, mainly modules built on the basis of a half-bridge circuit are used as part of fluorescent lamps.

Such devices are more common on the market compared to pavement ones, since for traditional use, lamps with a power of up to 50 W are sufficient.

Features of the device

Conventionally, the functioning of electronics can be divided into three operating stages.First of all, the function of preheating the filaments is turned on, which is an important point in terms of the durability of gas light fixtures.

This function is seen as especially necessary in low-temperature environments.

Then the module circuitry starts the function of generating a high-voltage impedance pulse - a voltage level of about 1.5 kV.

The presence of a voltage of this magnitude between the electrodes is inevitably accompanied by a breakdown of the gaseous medium of the fluorescent lamp cylinder - the ignition of the lamp.

Finally, the third stage of the module circuit is connected, the main function of which is to create a stabilized gas combustion voltage inside the cylinder.

The voltage level in this case is relatively low, which ensures low energy consumption.

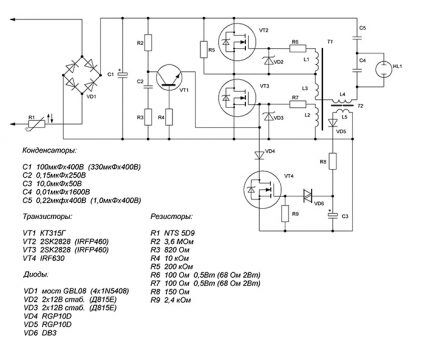

Schematic diagram of the ballast

As already noted, a frequently used design is an electronic ballast module assembled using a push-pull half-bridge circuit.

This scheme works in the following sequence:

- The mains voltage of 220V is supplied to the diode bridge and filter.

- A constant voltage of 300-310V is generated at the filter output.

- The inverter module increases the voltage frequency.

- From the inverter, the voltage passes to a symmetrical transformer.

- At the transformer, due to the control keys, the necessary operating potential for the fluorescent lamp is formed.

Control keys installed in the circuit of two sections of the primary and on the secondary winding regulate the required power.

Therefore, the secondary winding generates its own potential for each stage of lamp operation. For example, when heating the filaments one, in the current operating mode the other.

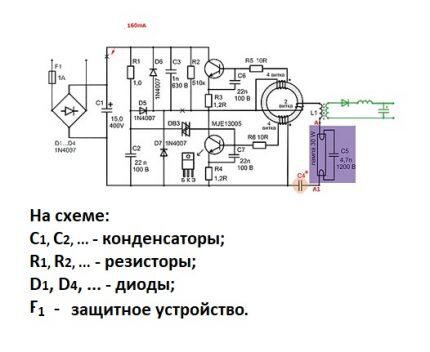

Let's consider the schematic diagram of a half-bridge electronic ballast for lamps with a power of up to 30 W. Here the mains voltage is rectified by an assembly of four diodes.

The rectified voltage from the diode bridge goes to the capacitor, where it is smoothed in amplitude and filtered from harmonics.

Next, through the inverting part of the circuit, assembled on two key transistors (half-bridge), the voltage coming from the network with a frequency of 50 Hz is converted into a potential with a higher frequency - from 20 kHz.

It is already supplied to the terminals of the fluorescent lamp to ensure operating mode.

A bridge circuit operates on approximately the same principle. The only difference is that it uses not two inverters, but four key transistors. Accordingly, the scheme becomes somewhat more complicated, additional elements are added.

Meanwhile, it is the bridge version of the assembly that ensures the connection of a large number of lamps (more than two) on one ballast. As a rule, devices assembled using a bridge circuit are designed for load power of 100 W and above.

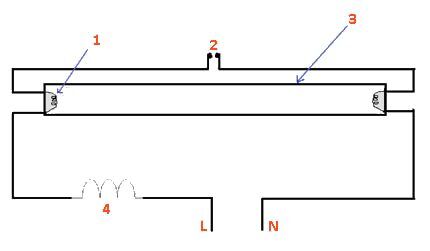

Connection options for fluorescent lamps

Depending on the circuit solutions used in the design of ballasts, connection options can be very different.

If one device model supports, for example, connecting one lamp, another model can support the simultaneous operation of four lamps.

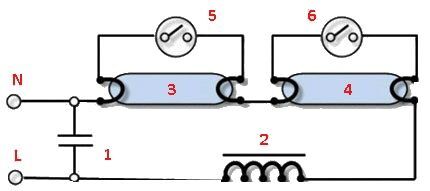

The simplest connection seems to be the option with an electromagnetic device, where the main elements of the circuit are only throttle and starter.

Here, from the network interface, the phase line is connected to one of the two inductor terminals, and the neutral wire is connected to one terminal of the fluorescent lamp.

The phase smoothed at the inductor is diverted from its second terminal and connected to the second (opposite) terminal.

The remaining two lamp terminals that remain free are connected to the starter socket. This, in fact, is the entire circuit, which was used everywhere before the advent of electronic semiconductor models of electronic ballasts.

Based on the same schematics, a solution is implemented with the connection of two fluorescent lamps, one choke and two starters. True, in this case it is necessary to select a choke based on power, based on the total power of gas lamps.

The throttle circuit option can be modified to eliminate the gating defect. It quite often occurs on lamps with electromagnetic electronic ballasts.

The modification is accompanied by the addition of a diode bridge to the circuit, which is switched on after the inductor.

Connection to electronic modules

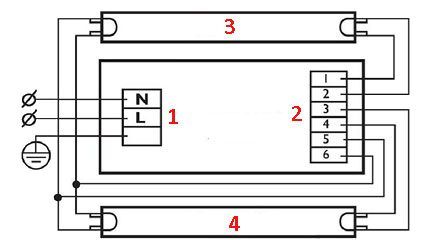

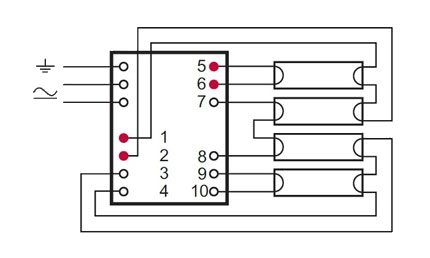

The connection options for fluorescent lamps on electronic modules are somewhat different. Each electronic ballast has input terminals for supplying mains voltage and output terminals for load.

Depending on the electronic ballast configuration, one or more lamps are connected. As a rule, on the body of a device of any power, designed to connect the corresponding number of lamps, there is a circuit diagram for switching on.

The diagram above, for example, provides for powering a maximum of two fluorescent lamps, since the diagram uses a two-lamp ballast model.

The two interfaces of the device are designed as follows: one for connecting the mains voltage and ground wire, the second for connecting lamps. This option is also one of a series of simple solutions.

A similar device, but designed to work with four lamps, is distinguished by the presence of an increased number of terminals on the load connection interface. The network interface and ground connection line remain unchanged.

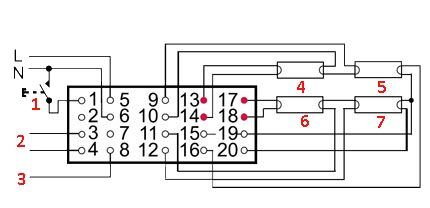

However, along with simple devices - one-, two-, four-lamp - there are ballast designs, the schematics of which provide for the use of the function of adjusting the glow of fluorescent lamps using.

These are the so-called controlled models of regulators. We recommend that you familiarize yourself with the operating principle in more detail. power regulator lighting fixtures.

How do such devices differ from the devices already discussed? The fact that, in addition to the network and load ones, they are also equipped with an interface for connecting control voltage, the level of which is usually 1-10 volts DC.

Thus, the variety of configurations of electronic ballast modules allows you to organize lighting systems of different levels. This refers not only to the level of power and area coverage, but also to the level of control.

Conclusions and useful video on the topic

The video material, based on the practice of an electrician, tells and shows which of the two devices should be recognized by the end user as better and more practical.

This story once again confirms that simple solutions look reliable and durable:

Meanwhile, electronic ballasts continue to be improved. New models of such devices periodically appear on the market. Electronic designs are also not without drawbacks, but compared to electromagnetic options, they clearly show better technical and operational qualities.

Do you understand the principles of operation and connection diagrams of electronic ballasts and want to supplement the above material with personal observations? Or would you like to share useful recommendations on the nuances of repairing, replacing or choosing a ballast? Please write your comments on this entry in the block below.