Which corner valve for a radiator is better to choose - types, advantages, installation rules

Angle valves for heating radiators are the type of shut-off valves that are responsible for regulating the supply of coolant to heating radiators. With their help, you can increase it, which leads to an increase in the temperature of the radiators. Or reduce to reduce. This is convenient not only in terms of maintaining a comfortable indoor microclimate, but also in saving fuel on which the heating system operates.

The content of the article:

Why are corner taps needed?

There are three qualities of the corner device that affect the purpose of this type of shut-off valve:

- If there is a need to repair the radiator or need to replace it, you can use it to turn off the coolant supply. Since two corner valves are installed on the radiator - one for supply, the second for return - both are turned off.

- If it is necessary to change the temperature regime inside the building, the volume of supplied coolant is regulated.

- Angle valve is an option for draining coolant, as well as for removing air from inside radiators.

What are the advantages of an angle faucet?

All described properties are advantages. An additional advantage is that with such shut-off valves you can regulate the temperature of each radiator, regardless of the heating system. For example, if you need to reduce the temperature in a room that is rarely used, you simply need to reduce the supply of coolant in the radiator batteries installed in it. Or vice versa.

More often, angle-type valves are installed in cases where the pipe supply to the radiators is located at an angle of 90º.

Other advantages:

- Compactness. A small device with enormous functionality - this was the task set for the manufacturers. It should not stand out and fit even in inconvenient places.

- Typically, radiators are connected to pipes that are laid parallel to the walls. Today, many pipelines are recessed into the same walls to make the pipework invisible. The radiator can be connected using bends, and then a direct coolant regulator can be mounted. It is easier to install an angle tap, which combines two elements in the design.

- High reliability. The corner taps offered on the market are high quality products. And this despite the simplicity of the design.

- Easy to install. Since corner locking devices are installed in limited space, it was the issue of installation that faced the developers as a component of quality. Hence the speed and reliability of fixation.

- They are convenient to use. To do this, you need to turn the locking mechanism to one side.

- Appearance. More often than not, this type of shut-off valve is visible, so manufacturers try to pay a lot of attention to its design.

We have to give credit to the companies that are always working on corner cranes. This is not only about design, but also about increasing their functionality. For example, models with a thermometer installed on one of the pipes. A convenient option is that it can be used to monitor the temperature of the coolant.

How does an angle tap work?

Before considering the principle of operation of corner control valves for heating radiators, you need to know that they are all divided into three groups depending on the type of locking device:

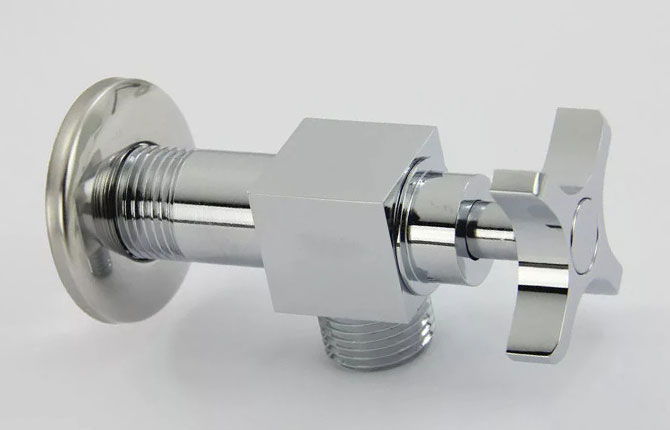

- Ball. Inside the body there is a ball with a through slot. When it is turned 90º, either the coolant supply is closed or opened. With their help, it is easy to regulate the flow passing inside them. They are most often used in heating systems of apartments and houses. This option refers to manual types.

- Throttle. These are standard valves, the design of which includes a stem with a valve at the end. When the first one is rotated clockwise, the second one decreases. It blocks the hole through which the coolant moves. And vice versa. It is with these corner valves that it is easy to manually adjust the movement of the coolant.

- Thermostatic. This is essentially the same first option, only the kit includes a thermal head. The adjustment process occurs automatically.

What you should pay attention to when choosing an angle tap

Attention must be paid to the heating system in which it will be installed. There are three of them:

- centralized;

- autonomous;

- heating in the form of boilers installed in multi-storey buildings directly next to or inside the building.

Each system has its own characteristics in terms of temperature and coolant pressure. Hence the norms of choice in accordance with these parameters. For example, in houses with more than five storeys, the coolant pressure is 5-12 atm. Less than five – 2-3 atm. In an autonomous system - no more than 2 atm.

The coolant temperature depends on the average temperature of the region:

- at -20 ℃ – the coolant temperature should be 65-80 ℃;

- at -40 ℃ – 95-105 ℃.

You cannot install an angle valve on a radiator in a multi-story building if it is designed for a pressure of 2 atm. It's the same with temperature.

The second point is the diameter of the shut-off valves. This size must be indicated on the product itself. When selected, it must be identical to the diameter of the pipe to which it is attached.

The third position is the material from which the locking device is made. There are three options here:

- stainless steel;

- brass;

- polypropylene.

The first is expensive, but reliable, with a long service life - up to 50 years. The second is cheap and less reliable. Will last no more than 7-8 years. But this period is not bad either. The most popular is the third option:

- service life – 15 years;

- withstands pressure up to 10 atm, temperature up to +90 ℃.

Today on the market you can come across corner taps made of silumin. It is an alloy of aluminum and silicon. It is difficult to distinguish it from stainless steel by appearance. Product characteristics are low. For example, the service life does not exceed 12 months. The price of silumin faucets is low.

The fourth selection criterion is the installation method.

There are four positions here:

- with internal thread on two tap pipes:

- with external thread;

- combined version - one pipe has an external thread, the other has an internal thread;

- Angle valve with American connection for radiator.

The latest model is preferred. The thing is that it allows you to install the tap without changing the location of the pipe and the shut-off valves themselves. To do this, you need to unscrew or tighten the union nut, which is attached to the radiator using a threaded pipe fitting. This is especially important when it is necessary to dismantle the radiator battery. There is no need to cut something and then weld it.

The fifth selection criterion is the ability to pass a certain amount of coolant through it.

| Type of corner device | Throughput, % |

| Full bore | 100 |

| Partial bore | up to 50 |

| Standard | 70-80 |

For heating radiators, it is better to choose a full-bore option. It will ensure the free passage of coolant without any problems. This type of shut-off valve can only reduce the passage of the pipe through which hot water moves to the radiator. He cannot increase it.

How to install an angle tap depending on operating conditions

Before installing a corner tap, you need to know some of the nuances of its installation:

- There must be free access to the installation site.

- The adjustment knob should be positioned so that it can be used without difficulty.

- If there is an arrow on the body of the corner radiator tap indicating the direction of movement of hot water, then it should become a guide at the installation site.

- Threaded connections, especially for radiators, must be equipped with materials that create a tight joint. Fum tape or thread work well for this. They are screwed in against the thread so that when the American pipe fitting is screwed clockwise, the material does not fluff up.

The installation process itself is carried out like this (for example, a faucet with an American):

- The locking device is disassembled into two parts - the tap itself and the nut with the pipe.

- A FUM tape is wound around the end of the latter.

- The same end is used to connect the pipe to the radiator.

- The union nut must have a cuff: rubber or plastic.

- The corner valve is connected to the heating system pipe: soldering, threading.

- The nut is screwed onto the tap pipe by hand.

After assembling the entire heating system, the joints are checked - it is filled with water and each connection is checked for leaks.

Set of corners radiator taps – a common shut-off valve. Ball models are especially popular. But experts recommend paying attention to the material of manufacture when purchasing. Stainless steel is the priority here. But brass and plastic also performed well in operation. Moreover, these two materials are several times cheaper than stainless steel.

Radiator taps: video.

Share your experience using corner radiator taps in the comments. Did you choose and install it yourself? Save the article in bookmarks so as not to lose useful information.

In my house, all the heating system pipes are recessed into the walls or floor. Therefore, I didn’t even think about what type of shut-off valves to use when connecting pipes to radiators. The only question was the choice of material. I gave preference to plastic ones - inexpensive. It's been five years now and no problems.

I had a choice between ball and valve. I decided to buy both options and install them on different radiators. The second ones flowed quickly. But with them it is more convenient to regulate the coolant - the result is more accurate.