Switch insulation: requirements for insulation of household and industrial appliances

The safe operation of all types of electrical equipment directly depends on the actual condition of the insulating materials that are incorporated into the design of the live parts of each installation product.If the insulation of the switches is broken, there may be a power failure, fire, or even an accident.

We will tell you everything about the types of insulation that ensure complete safety of using switching devices. The article we have proposed describes in detail natural and synthetic, conventional and enhanced options. Features of labeling are given and advice is given to buyers.

The content of the article:

Insulation protection of electrical equipment

Insulating materials provide protection to surrounding people and animals from electrical shocks. There is only one condition: you need to choose the right consumable dielectric, its shape, thickness, operating voltage parameters (it can be different, as well as the design of the device).

In addition, the production or domestic operating conditions of a complex electrical device can have a significant impact on the quality of insulators. The quality of insulation, thickness and degree of electrical resistance must correspond to the actual environmental influences and standard operating conditions.

Information on how to check the voltage in an electrical outlet is contained in next article, which we recommend that you familiarize yourself with.

The composition of electrical insulation can include both a dielectric layer of a certain thickness and a structural form (housing) made of dielectric material. The dielectric covers the entire surface of current-carrying elements of equipment or only those current-carrying elements that are isolated from other parts of the structure.

Types of insulating materials

Manufacturers producing modern electrical switches, which are used in residential, office and industrial buildings, distinguish the following types of electrical insulation: working (main), additional, double, reinforced.

Working (basic) insulation

This, in its essence, is the main protection of electrical installations, which ensures their normal and stable operation, without short circuits, and protects consumers from direct contact with live parts.

Working insulation, according to standards, must cover the entire surface of wires, cables, and other elements through which electric current passes. For example, electrical cords are always covered with insulation.

It must guarantee resistance against all potential external influences that may arise during the operation of electrical switches in the event of synchronous exposure to force fields, thermal heating, mechanical friction, and aggressive environmental manifestations.

The listed factors negatively affect the electrical characteristics of dielectric (insulating) materials; they can also lead to an irreversible deterioration of useful qualities, that is, the insulation will be subject to rapid wear.

If we are talking about the industrial operation of switches, then the enterprise personnel must periodically check the wear rate of insulating structures and timely carry out preventive measures to monitor their protective properties.

Responsibly maintaining a high level of insulation resistance reduces potential ground faults, frame faults, and electrical shocks.

In small, sparsely branched electrical networks, insulation resistance is a major safety factor. Inspection of the main insulation can be acceptance testing, carried out immediately after installation work or repairs, or periodic, carried out during the operation of the equipment at least once a year.

In very wet workshops, control is carried out 2 to 4 times a year on a continuous basis. Measurements are carried out using a digital measuring device for insulation control - a megohmmeter.

Periodic monitoring of insulation resistance on installed switches is carried out at production sites, where equipment over time is exposed to the negative effects of caustic chemical vapors, moisture, dust and elevated temperatures. In this case, the insulation of the switches may be damaged. Devices with damaged insulation are dangerous to human life.

Industry PUE (Electrical Installation Rules) adopted in Russia require regular measurements of insulation resistance, which is present in power supply networks from 1 kV and above.

The resistance of dielectric materials in the network of lighting installations in the area between 2 adjacent fuses, between any wire and ground, as well as between any two wires should not be < 0.5 MOhm.

This indicator is not applicable in practice to overhead wires of external electrical devices, to installations that are located in extremely humid rooms, because the resistance in them is not constant and depends on air humidity.

It should be especially noted that if there are no insulation standards for such installations, then enterprise management must take this factor into account and take all measures for the safe operation of the devices and more closely monitor the current condition of the insulation materials.

According to the PUE, measuring electrical insulation resistance should be carried out with a voltage of at least 500 V, and testing the insulation of multi-core cables with a voltage of 6-10 kV.

Determining the integrity of the current-carrying cable cores and checking them with a megger for phase compliance must be carried out by at least 2 people. The rules require that one of them must have a clearance of no lower than group IV, and the second: no lower than group III.

Reasons for additional protection devices

Additional insulation is placed in electrical installations with an operating voltage of up to 1 kV. This is independent insulation, which will be mounted together with the main insulation of the equipment in order to protect switches in difficult and dangerous cases of operation in case of indirect contact with damaging elements.

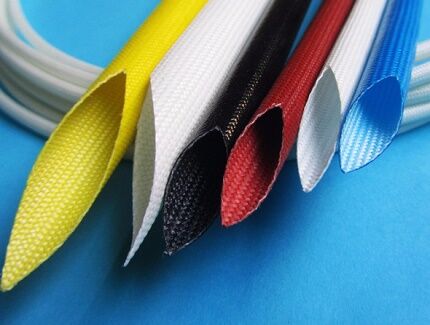

Mainly, it performs the function of counteracting electrical shocks if the main insulation layer is damaged. A practical example of additional insulation is the plastic switch housing, insulator bushings, casings, plastic tubes and other types of dielectrics.

For this type of insulation, materials are used that differ in their physical properties from standard forms of dielectrics, which are the main insulation of electrical appliances.

This is done taking into account the fact that even in the most unfavorable operating conditions or storage methods of electrical equipment, it would be unlikely that the main, working and additional insulation would be damaged simultaneously.

Advantage of double insulation

Such potential danger to people as electric shock during indirect contact with equipment elements can be significantly reduced by installing double insulation.

These durable protective materials are used in electrical devices where voltages up to 1 kV are present. There are 2 degrees of protection here - basic and additional. Manufacturers install double insulation in various electrical devices: hand-held lamps, hand-held electric tools, and isolating transformers.

The practical meaning of double insulation lies in the fact that in addition to the main, dielectric layer. place the second insulating layer on the current-carrying parts of the switches. It protects a person from touching metal that conducts current, which may well be under high voltage.

To avoid this, the metal housings of high-tech electrical equipment are covered with a layer of insulator; handles, buttons and control panels are made on the basis of dielectrics.

In household appliances, buttons, wires and a housing shell made of metal are also insulated. The disadvantage of this type of coating is its relatively high mechanical fragility: there is a theoretical possibility of destruction of the insulating layer from repeated mechanical impacts.

Because of this, metal, non-current-carrying parts of electrical devices may become live. Therefore, it is very important to measure the physical state of the insulation with appropriate instruments, in accordance with the electrical diagram.

It should be noted that the destruction of the second layer of insulation cannot in any way affect the main operation of the devices and, as a rule, is not detected at the time of testing. It makes sense to use double insulation for those types of electrical equipment that in domestic use will not be subject to mechanical shocks and pressure on live parts.

The most reliable protection for people will be provided by double insulation on equipment whose housing is made of non-conductive insulating material: it serves as a guarantee against dangerous electric shock.

The non-conductive housing of the devices will protect against current not only in the event of dielectric breakdowns inside the product, but in the event of accidental human contact with current-carrying elements. If the housing is destroyed, the structural arrangement of parts and elements will be disrupted, and the device will stop working.

If it has protection, it will work automatically and disconnect the faulty product from the network. In the metal casing of the devices, special bushings perform the function of additional insulation.

Through them, the network cable passes into the housing, and insulating gaskets separate the electric motor of the equipment from the housing. The nameplate of a double-insulated electrical device bears the image of a special symbol: a square located inside another square.

Why is reinforced insulation needed?

In production conditions, there are times when double insulation is quite problematic to use due to the design features of electrical devices.For example, in switches, brush holders, etc. Then you have to use another type of protection - this is reinforced insulation.

Reinforced insulation is installed on electrical installations with a rated voltage of up to 1 kV. It is capable of providing a degree of protection against electric shock that is equivalent to the properties of double insulation.

According to the requirements of GOST R 12.1.009-2009 SSBT, reinforced insulation can have several layers of dielectric, each of which cannot be tested separately for short-circuit breakdown, but only in its entire form.

Natural and synthetic dielectrics

Insulating materials, otherwise known as dielectrics, are divided by their origin into natural (mica, wood, latex) and synthetic:

- film and tape insulators based on polymers;

- electrical insulating varnishes, enamels - solutions of film-forming substances made on the basis of organic solvents;

- insulating compounds that harden in a liquid state immediately after application to conductive elements. These substances do not contain solvents; according to their purpose, they are divided into impregnating (processing the windings of electrical appliances) and potting compounds, which are used to fill cable couplings and cavities of devices and electrical units for the purpose of sealing;

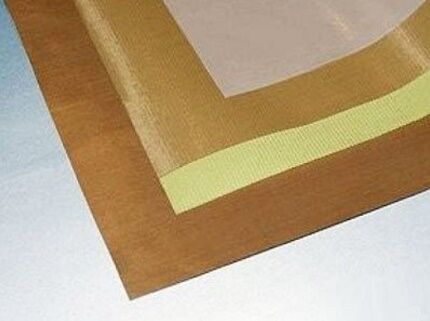

- sheet and roll insulating materials, which consist of unimpregnated fibers of both organic and inorganic origin. It can be paper, cardboard, fiber or fabric. They are made from wood, natural silk or cotton;

- Lacquer fabrics with insulating properties are special plastic materials on a fabric basis, impregnated with an electrical insulating composition, which, after hardening, forms an insulating film.

Synthetic dielectrics have electrical and physical-chemical characteristics that are important for the reliable operation of devices, determined by the specific technology of their production.

They are widely used in modern electrical engineering and electronics industries to market the following types of products:

- dielectric shells of cable and conductor products;

- frames of electrical products, such as inductors, housings, racks, panels, etc.;

- elements of electrical installation fittings - distribution boxes, sockets, sockets, cable connectors, switches, etc.

Electronic printed circuit boards are also produced, including panels used for wiring conductors.

Classification of insulating materials

Electrical insulation in household appliances is divided into corresponding classes:

- 0;

- 0I;

- I;

- II;

- III.

Devices with insulation class “0” have a working insulating layer, but without the use of grounding elements. Their design does not have a clamp for connecting the protective conductor.

Devices with class “0I” insulation have insulation + a grounding element, but they contain a wire for connecting to a power source that does not have a grounding conductor.

Appliances with Class I insulation contain a 3-wire cord and a 3-prong plug. Electrical installation devices of this category are subject to installation with connection to grounding.

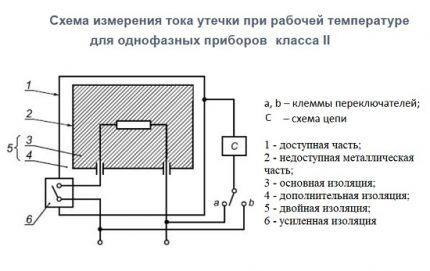

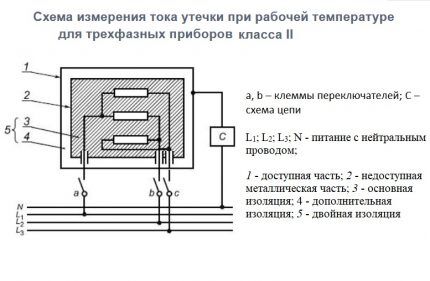

Electrical appliances with class “II” insulation, that is, double or reinforced, are often found in household use. Such insulation will reliably protect consumers from electric shock if the main insulation of the device is damaged.

Products equipped with durable double insulation are designated in power equipment by the sign B, meaning: “insulation in insulation.” Devices containing such a sign must not be neutralized or grounded.

All modern electrical devices with class III insulation can operate in power supply networks with a rated voltage of no higher than 42 V.

Absolute safety when activating electrical equipment is provided by proximity switches, the article we recommend will introduce you to the features of the device, operating principles and types.

Conclusions and useful video on the topic

The video contains instructions on how to use a popular brand of megohmmeter:

A short video review of insulating materials and methods of protecting current-carrying parts of electrical installation accessories:

Special types of insulation are used when equipping industrial switches, for example, air or oil type. They are not used in everyday life. If you have encountered a malfunction of the insulation of switches in production, you should contact specialists who service electrical installations.

Please write comments in the block below. Share useful information on the topic of the article that will be useful to site visitors.Ask questions about controversial and unclear points, post photographs.

I wanted to mention the importance of choosing insulation for electrical conductors. Climatic operating conditions and installation method are very important here. How will the insulation behave, suppose in a fire, will it release toxic substances, how long will it withstand open burning? Someone’s life, and often our own, may depend on all these moments. I think we need to approach this issue very carefully.

In fact, a very small percentage of people ask such questions when it comes to wiring, much less the quality of its insulation. If the electrician is arranged by the developer, then this is often done with minimal compliance with GOSTs and SNiP. In this case, no one will spend money on insulating materials that can withstand temperatures up to 900 degrees.

As for the release of toxic substances during combustion, this indicator can be ignored, since in the event of a fire in a residential area there will already be a lot of things that will release toxins.

Otherwise, you are absolutely right - wiring requires a lot of attention, and savings and violations are fraught with negative consequences.

I categorically do not use devices where I notice even the slightest damage to the electrical insulation. Even if it’s just a small wire peeking out from under the insulation, although it shouldn’t, I won’t touch anything. I'm terribly afraid of all these moments. I immediately either ask my husband or call an electrician to get it fixed as soon as possible. As a child, I was shocked by 220 volts a couple of times, and I remember these sensations for the rest of my life.