Biogas plant for a private home: recommendations for arranging a homemade project

A thrifty owner dreams of cheap energy resources, efficient waste disposal and obtaining fertilizers.A DIY home biogas plant is an inexpensive way to make your dream come true.

Self-assembly of such equipment will cost a reasonable amount of money, and the gas produced will be a good help in the household: it can be used for cooking, heating the house and other needs.

Let's try to understand the specifics of this equipment, its advantages and disadvantages. And also whether it is possible to build a biogas plant yourself and whether it will be effective.

The content of the article:

Specifics of biogas production

Biogas is formed as a result of fermentation of a biological substrate. It is decomposed by hydrolytic, acid- and methane-forming bacteria. The mixture of gases produced by bacteria is flammable, because contains a large percentage of methane.

Its properties are practically no different from natural gas, which is used for industrial and domestic needs.

Biogas is an environmentally friendly fuel, and the technology for its production does not have much impact on the environment. Moreover, waste products that need to be disposed of are used as raw materials for biogas.

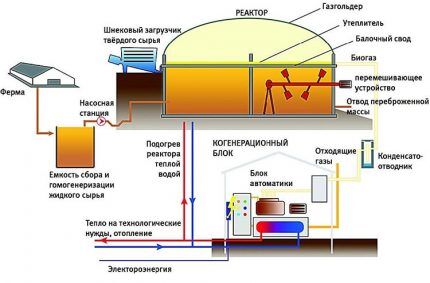

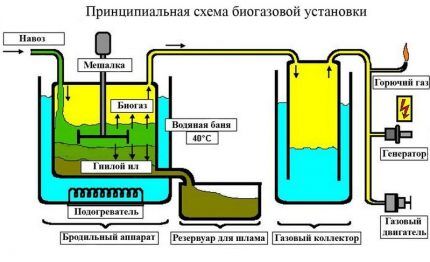

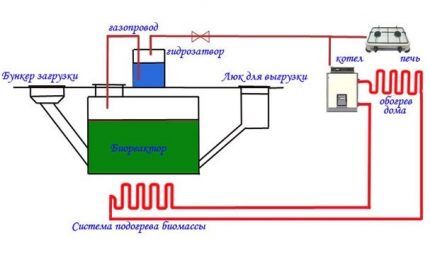

They are placed in a bioreactor, where processing occurs:

- the biomass is exposed to bacteria for some time. The fermentation period depends on the volume of raw materials;

- As a result of the activity of anaerobic bacteria, a flammable mixture of gases is released, which includes methane (60%), carbon dioxide (35%) and some other gases (5%). Fermentation also releases potentially dangerous hydrogen sulfide in small quantities. It is poisonous, so it is highly undesirable for people to be exposed to it;

- the mixture of gases from the bioreactor is purified and supplied to a gas tank, where it is stored until it is used for its intended purpose;

- gas from a gas tank can be used in the same way as natural gas. It goes to household appliances - gas stoves, heating boilers, etc.;

- Decomposed biomass must be regularly removed from the fermenter. This is additional labor, but the effort pays off. After fermentation, the raw material turns into high-quality fertilizer, which is used in fields and vegetable gardens.

A biogas plant is beneficial for the owner of a private house only if he has constant access to waste from livestock farms. On average, from 1 cubic meter. You can get 70-80 cubic meters of substrate. biogas, but gas production is uneven and depends on many factors, including biomass temperatures. This complicates calculations.

In order for the gas production process to be stable and continuous, it is best to build several biogas plants, and add the substrate to the fermenters with a time difference.Such installations operate in parallel, and raw materials are loaded into them sequentially.

This guarantees a constant production of gas, so that it can be continuously supplied to household appliances.

Homemade biogas equipment, assembled from scrap materials, is much cheaper than industrial production installations. Its efficiency is lower, but it is well worth the investment. If you have access to manure and the desire to put in your own effort to assemble and maintain the structure, this is very profitable.

Advantages and disadvantages of the system

Biogas plants have many advantages, but there are also a lot of disadvantages, so before starting design and construction you should weigh everything:

- Recycling. Thanks to a biogas plant, you can get the maximum benefit from waste that would otherwise have to be disposed of. This disposal is less hazardous to the environment than landfilling.

- Renewability of raw materials. Biomass is not coal or natural gas, the extraction of which depletes resources. When farming, raw materials appear constantly.

- Relatively small amount of CO2. When gas is produced, the environment is not polluted, but when it is used, a small amount of carbon dioxide is released into the atmosphere. It is not dangerous and is not capable of critically changing the environment, because... it is absorbed by plants during growth.

- Moderate sulfur release. When biogas is burned, a small amount of sulfur is released into the atmosphere.This is a negative phenomenon, but its scale can be seen in comparison: when burning natural gas, environmental pollution with sulfur oxides is much greater.

- Stable work. Biogas production is more stable than work solar panels or wind turbines. While solar and wind energy cannot be controlled, biogas plants depend on human activity.

- Multiple settings can be used. Gas always carries risks. To reduce potential damage in the event of an accident, several biogas plants can be dispersed throughout the site. If a system of several fermenters is properly designed and assembled, it will operate more stable than a single large bioreactor.

- Benefits for agriculture. Some types of plants are planted to obtain biomass. You can choose ones that improve the condition of the soil. For example, sorghum reduces soil erosion and improves its quality.

Biogas also has disadvantages. Although it is a relatively clean fuel, it still pollutes the atmosphere. There may also be problems with the supply of plant biomass.

Irresponsible plant owners often harvest it in such a way that they deplete the land and upset the ecological balance.

Calculation of installation profitability

Cow dung is usually used as a raw material for biogas production. One adult cow can produce enough to provide 1.5 cubic meters. fuel; pig – 0.2 cubic meters; chicken or rabbit (depending on body weight) – 0.01-0.02 cubic meters. To understand whether this is a lot or a little, you can compare it with more familiar types of resources.

1 cubic meter biogas provides the same amount of thermal energy as:

- firewood – 3.5 kg;

- coal – 1-2 kg;

- electricity – 9-10 kW/h.

If you know the approximate weight of agricultural waste that will be available over the coming years and the amount of energy required, you can calculate the profitability of a biogas plant.

To put it into the bioreactor, a substrate is prepared, which includes several components in the following proportions:

- manure (best cow or pork) – 1.5 t;

- organic waste (this can be rotten leaves or other components of plant origin) – 3.5 t;

- water heated to 35 degrees (the amount of warm water is calculated so that its mass is 65-75% of the total amount of organic matter).

The calculation of the substrate was made for one laying for six months, based on moderate gas consumption. After about 10-15 days, the fermentation process will give the first results: gas will appear in small quantities and begin to fill the storage. After 30 days, you can expect full fuel production.

If the installation is working correctly, the volume of biogas will gradually increase until the substrate rots. The performance of the structure directly depends on the rate of biomass fermentation, which in turn is related to the temperature and humidity of the substrate.

Instructions for self-construction

If you have no experience in assembling complex systems, it makes sense to select online or develop the simplest drawing of a biogas plant for a private home.

The simpler the design, the more reliable and durable it is. Later, when you develop skills in building and handling the system, you can redo the equipment or install an additional installation.

When calculating the volume of the fermenter, you should focus on 5 cubic meters. This installation allows you to obtain the amount of gas necessary to heat a private house with an area of 50 square meters, if a gas boiler or stove is used as a heat source.

This is an average figure, because The caloric content of biogas is usually not higher than 6000 kcal/m3.

The construction of a biogas plant can be divided into several stages.

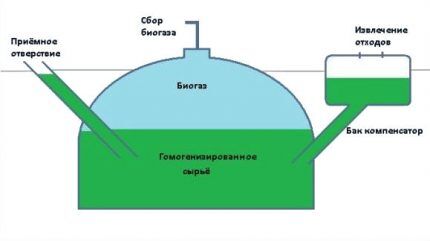

Stage 1 - preparing the pit for the bioreactor

Almost the entire biogas plant is underground, so a lot depends on how the pit was dug and finished. There are several options for strengthening the walls and sealing the pit - plastic, concrete, polymer rings.

The optimal solution is to purchase ready-made polymer rings with a solid bottom. They will cost more than available materials, but no additional sealing will be required. Polymers are sensitive to mechanical loads, but are not afraid of moisture and chemically aggressive substances. They cannot be repaired, but if necessary they can be easily replaced.

Stage 2 - arrangement of gas drainage

Purchasing and installing special mixers for biogas plants is an expensive proposition. The system can be made cheaper by installing gas drainage. It consists of vertically installed polymer sewer pipes, in which many holes are made.

When calculating the length of drainage pipes, you should focus on the planned filling depth of the bioreactor. The tops of the pipes must be above this level.

You can immediately load the substrate into the finished bioreactor. It is covered with a film so that the gas released during the fermentation process is under slight pressure. When the dome is ready, this will ensure a normal supply of biomethane through the outlet pipe.

Stage 3 - installation of the dome and pipes

The final stage of assembling the simplest biogas plant is the installation of the dome top part. At the highest point of the dome, install a gas exhaust pipe and stretch it to gas holder, which you can’t do without.

The bioreactor container is closed with a tight lid. To prevent biomethane from mixing with air, a water seal is installed. It also serves for gas purification. A release valve must be provided that will operate if the pressure in the fermenter is too high.

Read more about how to make biogas from manure in this material.

Methods for heating a bioreactor

Microorganisms that process the substrate are constantly present in the biomass, but for their intensive reproduction they need a temperature of 38 degrees or higher.

For heating during cold periods, you can use a coil connected to the home heating system or electric heaters. The first method is more economical, so it is used more often.

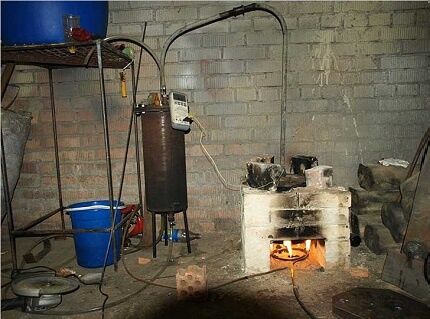

The biogas plant does not have to be buried in the ground; there are other options for arrangement. An example of the operation of a system assembled from barrels is shown in the video below.

Conclusions and useful video on the topic

Although there is nothing complicated in assembling and arranging biogas equipment, you need to be extremely attentive to details. Errors are unacceptable, because may lead to explosions and destruction. We offer video instructions that will help you understand the design of the plants, assemble them correctly and supplement them with useful devices for more convenient use of biogas.

The video describes how a standard biogas plant works and works:

An example of a homemade biogas plant. Video tutorial on how to set up a system with your own hands:

Video instructions for assembling a biogas plant from a barrel:

Description of the manufacturing process of substrate mixers:

Detailed description of the operation of a homemade gas storage:

No matter how simple the biogas installation chosen for a private home may be, you should not skimp on it. If possible, it is better to buy a collapsible industrial bioreactor.

If not, make it from high-quality and sustainable materials: polymers, concrete or stainless steel. This will allow you to create a truly reliable and safe gas supply system at home.

Have questions about the topic of the article, found any shortcomings, or have valuable information that you can share with our readers? Please leave your comments, ask questions, share your experience.

Did I understand correctly that it is best to install a biogas plant on a livestock farm? There are plenty of raw materials and space for installing the device itself. Dad once worked on a sheep farm as a shepherd. There were also night shifts, and it was cold in the room where people slept. I don’t even know if the sheep pens were heated. And so the idea is quite feasible, with the right hands and head it can be implemented.

Still, it’s good that humanity is slowly coming to the idea of maintaining a clean environmental situation, responsibility, consciousness and the desire to search for alternative sources are waking up. After all, our children live here. I liked the idea of a biogas plant. It seems like nothing complicated at first glance, but it will be very profitable if we take into account our gas prices. But there are, of course, disadvantages that should not be overlooked.

Question 1 (probably the most important) - there is a plot of land (dacha) with an area of approximately 0.5 hectares. I want to build such an installation (hands grow from where necessary). How comfortable will it be for a person to be in the immediate vicinity of such an installation - in other words, will there be a stink “per hectare”? I understand that a lot depends on the design and build quality, but let’s assume that everything is done as it should.

Question 2: How, exactly, should such an installation be cleaned of recycled materials? And again, a sub-question: do you need a closed gas mask or can you get by with an open type?

And the last question 3: Are special bacteria required for the fermentation of biomass, or is this just a commercial move?

P.S.: As for gas prices YES-A_a - (it takes a long time to type obscenities in relation to you know who and where...) - I have a one-room apartment insulated according to all the rules, but for gas heating the bill turns out to be equal (or even more) than for all other utilities - electricity, water supply, utilities for “Utrimuvannya budinka and pribudinka territory” and the Internet - TAKEN TOGETHER!!!

Draw your conclusions, Ladies and Gentlemen!

It will be much more comfortable for a person in the immediate vicinity of such an installation than in the immediate vicinity of a stinking heap of derm and garbage in an open space.

In any case, shit emits gases (methane and others), and if you need vermicompost, then you have to wait 2-3 years for the shit to rot and all the harmful gases to evaporate. But biogas plants are a solution to a global problem. It’s good if you make a system, then there won’t be any stink. The sound of some units operating in this system will not even be heard. You just need to think it through carefully.

The result is fair waste disposal, free bioenergy, free fertilizers. I think so, every farmer is simply obliged to install such a reactor just to dispose of waste.

I came across this topic for one reason, because... I started thinking about starting a mini chicken farm. I planned everything clearly and settled on the shit - it will stink, the neighbors will complain. I studied the sanitary standards - you can’t build a chicken farm in the village. “This is an obstacle,” I thought, and somehow out of nowhere it appeared to use the waste... but the question is - how? I thought a lot and heard from somewhere about a biogas plant. Total. If you are working with a farm, then you must work with a biogas plant. If you don’t have a farm, then dealing with biogas is not profitable.

I will answer Alena and Vadim.

All this crap can be done! But no one answered my questions. After all, the whole point is that ALTERNATIVE ENERGY SOURCES are absolutely unprofitable/unprofitable for Oil/Gas Industry! And our fucking lousy government will do everything possible to kill attempts to give birth to such technologies in their infancy. I’ll keep my mouth shut about financial support for such enterprises.

Well, in general, a biogas installation is possible even on a summer cottage plot of 0.25 hectares. But it all depends on the specific requirements/opportunities. I heard (I’m not saying) that at one of the dachas in the Poltava region, excess biogas was stupidly burned so as not to stink, since the compressors could not cope with refueling the battery of series-connected cylinders for storing biogas.

If there is no manure, but there are empty corn stalks and cobs or wheat (rye) straw, tops, leaves, etc., then how much of such raw materials will be needed to produce one cubic meter of gas?

Hello. I will try to answer each raw material that you have questions about. The numbers will not be accurate, with some error, since they depend on many factors that cannot be calculated “by eye”.

So, according to preliminary data, a ton of straw will produce about 300 cubic meters of gas. Regarding the leaves, everything is not so simple here, since there is no specific mention on your part of which trees you are talking about. But even now, experimental (amateur) installations make it possible to obtain 50 cubic meters of gas from one ton of leaves.

I think that this information will be enough to calculate the approximate performance of the future installation. You can also consider producing biogas from organic waste. For your reference, I also attach a plate with data on other types of raw materials.

I have read all the comments and will respond to everyone at once. One of the examples above is exactly my experimental setup. Based on operating experience, the installation is sealed, therefore there is no smell; if there is a smell, then logically there is no seal, which means there is a loss of gas. After processing, the raw materials have a slight odor, but it is not like manure, slop or analogues, it has a slight bitter odor. The waste from the reactor is a high-quality vermicompost, which after aeration can be safely poured onto the beds. Aeration with air is necessary to kill all methanogens.

The reactor is best made in a continuous cycle, because to make a reactor - fill it up, wait two weeks, the gas is produced for a week and then everything is drained, I think it’s not practical.The most optimal thing is to add 5-7% of fresh raw materials every 1-2 days and drain the same amount, then the reactor will produce gas continuously.

The volume of gas per day is on average equal to one and a half volumes of the reactor. Just do not confuse liquid and gaseous gas. The bioreactor produces gas.

If you have your own home, then for heating you need a bioreactor with a volume of at least 5 cubic meters. And yes, the bioreactor must be insulated and part of the gas must be spent on heating it in winter.

In principle, everything is clear to me, except for how to remove everything rotten. If you make 2 reactors of 3 cubes each, what are the proportions of the contents in one reactor? Is it possible to add substrate while the reactor is running? Thanks in advance for your answer.

what about security? Gas cylinders sometimes explode, but this won't explode?

what I read and saw was at the level of a circle of young chemists, electricians and mechanics, maybe someone else. no concept, no calculations, no concept.