Choosing a check valve with a mesh - main characteristics

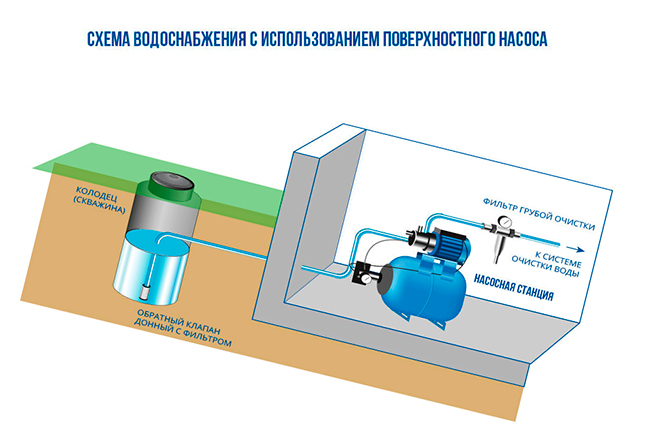

A check valve with a mesh is one of the types of shut-off valves.Usually it is installed on a vertical pipeline, or more precisely, on its end located in a well or borehole.

The content of the article:

What functions does it perform?

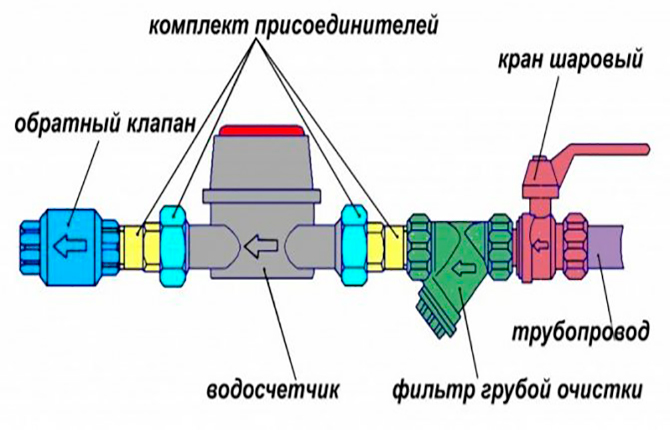

The purpose of the part is to prevent the reverse flow of water downwards when the pumping station is turned off. An additional purpose is to protect the water supply and pump from large, solid particles of debris. The first task is performed by a valve located in the body of the product. The second is a mesh made of stainless steel.

The essence of using a check valve is that stopping the pump is a constant matter. And this happens not only due to a power outage. As soon as the water supply system is filled and the required pressure inside it is reached, the pumping station will automatically turn off.

To ensure that the water main does not remain without water, they carry out valve installation with mesh. All liquid located above it will be clogged in pipes and plumbing fixtures. That is, there is no need to fill the pipelines and pump with water when turned on. Because some of them are not self-priming, and they cannot lift liquid from great depths without water.

Check valves with mesh are installed only on surface pumps. Borehole and submersible ones are in water, so they have no problems with turning on and raising the liquid. But the grid is necessarily present in such models. Protection from debris is always needed.

Another point that affects the effective operation of an autonomous water supply network is the absence of water hammer, which often occurs when the pump is turned on and water is supplied to the pipelines. This happens if the pipes are empty and not filled with liquid. Installing a check valve solves this problem. Plumbing fixtures, containers and other plumbing equipment often suffer from water hammer.

In what systems is it used?

Systems may be different. The basic requirements are the absence of aggressive liquids, temperature no more than +50 ℃, pressure no more than 0.25 MPa.

Systems that require a check valve:

- Autonomous water supply. The valve is mounted on the end of a pipe, which is lowered into a well or deep well (more than 8 m). The connection is made via thread. That is, a threaded model is used.

- House sewerage. A flanged check valve with a mesh is used here. It is installed at the end of the sewer pipe that goes into the septic tank. In this case, installation is carried out on a vertical section. Such a valve with a mesh works in the opposite direction and protects the sewer line from runoff, which sometimes rises due to flooding of the area or rainwater entering the septic tank.

- Heating.

In industry, check valves with mesh are also used. For example, in oil production (the fittings are installed at the end of a pipe that is lowered into the well), in plants and factories where large containers with the necessary liquids are used. They are pumped out using pumps installed outside the tanks.

Check valve in the water supply system in the video.

Types of valves

Classification of check valves with mesh:

- According to the method of attachment to pipes.

- According to design features.

Based on the first criterion, there are three groups:

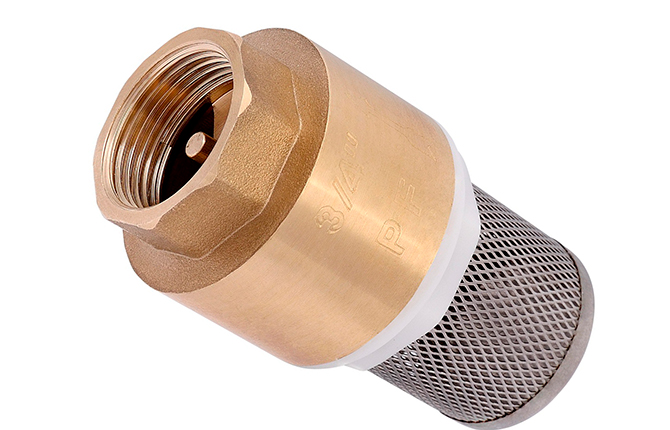

- coupling, they are also threaded;

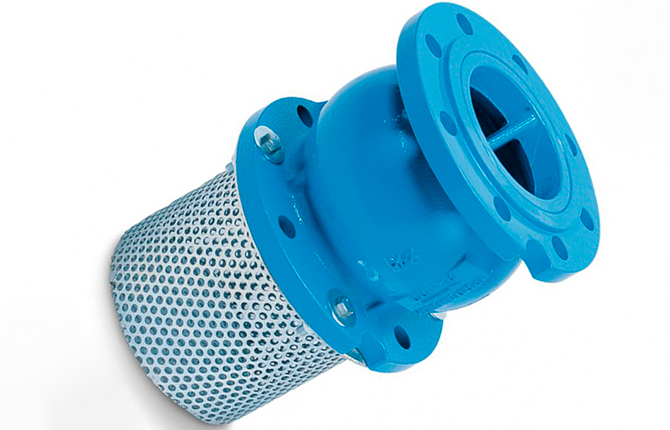

- flanged;

- wafer.

The first are devices that are installed on water supply networks, so their diameter is small. It is clear that the pipe must also be provided with a thread, so a bend is welded to it in advance.

The second are fittings, one end of which, opposite the mesh, is equipped with a flange. With its help, it is attached to a pipe, to which a flange of the same diameter as on the valve is welded in advance. The connection requires bolts and nuts, as well as a gasket, which ensures the tightness of the joint.

The third group is check valves, which are mounted between two flanges, hence the name. A flange is welded to the end of the pipe. Then a second one is attached to it using bolts, but with the condition that there is space between them where the valve can be placed. Gaskets are placed at the joints, then the bolts are tightened.

Devices from the last two groups are more often used in sewer systems. And also in water supply systems, where large diameter pipes are used.

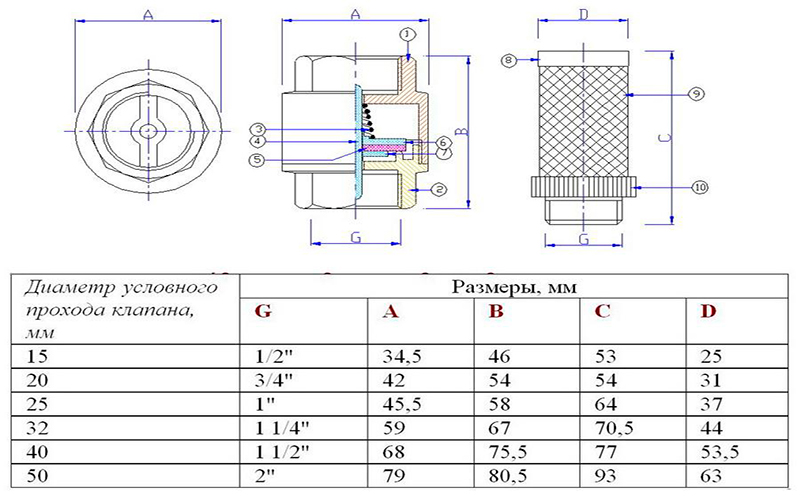

As for the design features, a flat disk is installed inside the coupling models, also known as a plate, supported on one side by a spring (always located on top of the disk). It performs the functions of a valve - it closes the space of the device across. For tight closure, the design includes a seat precisely adjusted to the dimensions of the valve.

When the pressure of water, which is pumped out from below by a pump, increases, the spring compresses, the disk moves upward, opening a gap between itself and the seat. The liquid penetrates the pipe and further into the house to the plumbing fixtures.As soon as the pump stops working, the water pressure drops, the spring expands, returning to its original position and pressing on the disk. The latter is tightly connected to the saddle, blocking the passage.

There is one more design feature by which coupling models with meshes are divided:

- with internal thread;

- from the outside.

The first are connected to the drives, the second - to the bushings in which the internal thread is cut.

Flange and wafer models have exactly the same disk in their design. But they don't have a spring. The process of closing and opening is carried out by a disk that rotates around an axis passing exactly in the middle in a horizontal plane. That is why small particles of debris (including feces) easily pass through the valve with a mesh. Therefore, this variety is installed in sewer systems.

What parameters should you pay attention to when choosing

Technical parameters that you need to pay attention to when choosing:

- water pressure created by the pump;

- the bore diameter of the device, which must correspond to the diameter of the installed pipe (measured in millimeters and designated - DN);

- throughput, which depends on the diameter;

- tightness class.

There are difficulties with the first point. Experts recommend that the pressure that a suction return valve with a mesh can withstand be twice as high as what the pump creates. For example, if a pumping station pumps water under a pressure of 0.12 MPa, then it is necessary to install a device that can withstand 0.25 MPa. In sewer systems this is an insignificant indicator.

Two more parameters to pay attention to:

- The material from which the valve with mesh is made. Coupled ones are made of brass, flanged ones are made of cast iron or steel.The mesh is always made of stainless steel or polymer.

- Sealing element between seat and plate. There are three options: rubber, polymer, paronite.

And one more point that you need to pay attention to when choosing is the production date. Overall dimensions, DN and other parameters do not change over time. But the sealing gasket may deteriorate. This will affect the technical and operational characteristics of the check valve with mesh. The device will “prime” during operation, which means that inside the pipeline, when the pump stops, the water will flow back into the well or borehole. In the case of sewerage, wastewater will begin to penetrate higher through the pipes, approaching the house.

The date of manufacture and expiration date also affect the manufacturer's warranty. A check valve with a mesh that has been in storage for 5-7 years will stop working effectively after a year. It will not be possible to make a claim to the manufacturer. The warranty period has expired. The store will also not accept a used device back.

How to install correctly

The first thing you need to pay attention to is the arrow on the valve body. It shows in which direction the pumped liquid should move. For example, if a valve is installed in a well, then its arrow should be directed towards the pipe, and accordingly, towards the pump.

Installation rules for the coupling model:

- FUM tape or thread is wound onto the thread of the drive.

- A check valve is screwed onto the outlet so that the arrow points towards the pipeline.

- A mesh is screwed onto the opposite pipe of the device, which has the shape of a closed cylinder.

- The pipe is lowered into the well or borehole to the required depth.

- The opposite end of the pipe is attached using an American to the pump nozzle.

The flange model is installed like this:

- A valve is installed on the flange welded to the pipe.

- Bolts are inserted into the flanges, and nuts and washers are screwed onto them. Better add Grover washers. There should be four or six fasteners, depending on the number of mounting holes.

- A sealing gasket is placed between the flanges.

- The bolts are clamped crosswise. This is how uniform pressing of the connection planes is achieved.

- A mesh is installed on the opposite side of the device, which is attached to it with four screws (fasteners on the side).

There are models in the design of which there are two flanges on two opposite sides. One is attached to the pipe, and the mesh is bolted to the second.

The wafer model is mounted as follows:

- A separate flange is attached to the flange that is welded to the pipe.

- They are connected to each other with bolts. The length of the latter is 5 cm greater than the thickness of the check valve without mesh.

- The device is installed between the flanges. Seals are installed at the joints.

- The bolts are clamped crosswise.

- A mesh is attached to the free pipe.

In an autonomous water supply system, a check valve with a mesh plays an important role. With its help, problems that relate to the efficient operation of the network are solved. Installing the device is simple and does not require special skills or additional tools. And one more positive point - this type of shut-off valves is relatively inexpensive.

Quality largely depends on the manufacturer. But if the device works for two to three years without failures, then this is its normal resource. This is especially true for the sewer flange model, the service life of which is at least 5 years. In an active aggressive environment, even cast iron corrodes.

Have you installed such a device at home? Write in the comments.Share the article on social networks and save it in bookmarks so as not to lose it.

We also recommend watching selected videos on our topic.

Check valve for water: types, advantages and disadvantages, how to choose?

Check valve of the pumping station.

Sources:

- https://santehstandart.com/poleznye-materialy/klapan-obratnyy-s-setkoy

- https://mechanicinfo.ru/klapan-obratnyj-s-priemnoj-setkoj-16ch42r-razmery-ves-cena

The brass valve worked for a year, then just jammed. I had to change it.

It all depends on who the manufacturer is. If China is cheap, then that's it. Buy a German one, this one will last at least 6-7 years. But this pleasure is not cheap.