Purifying water from a well: a review of the best and most effective methods

A well is one of the most affordable ways to supply water to a suburban area.It provides life-giving moisture for the natural needs of households, their household needs and watering plants on the site. Therefore, the water in it must be free of all kinds of impurities. Contaminants must be removed immediately. Do you agree?

From the article we have proposed, you will learn what stages are involved in purifying water from a well, and also whether it can be done on your own. We will tell you by what signs water pollution is determined. We will present in detail effective ways to eliminate mineral and organic inclusions.

The content of the article:

Main causes of well water contamination

The opinion that well water is a priori clean is erroneous. The depth of this water source is not so great. The groundwater that feeds the well often contains impurities in a dissolved or suspended state.

Various types of bacteria often live in perched water, which multiply, create colonies and decompose over time, forming hydrogen sulfide-containing compounds. Such compounds give water an unpleasant odor and make it toxic, and therefore dangerous to human health.

The causes of water pollution are conventionally divided into two types:

- Natural phenomena. These may be changes in the aquifers supplying the source or seasonal phenomena. For example: contact with a source of organic matter, sunlight...

- Problems caused by man. They occur when the installation technology of a structure is violated and errors occur during its operation. For example: close proximity of septic tanks, depressurization of seams, corrosion of metal elements...

When arranging a hydraulic structure, it is important to monitor water renewal. So, if taken irregularly, it will stagnate and become cloudy. If the head of the source is open, then leaves and branches, insects and rodents can easily enter it.

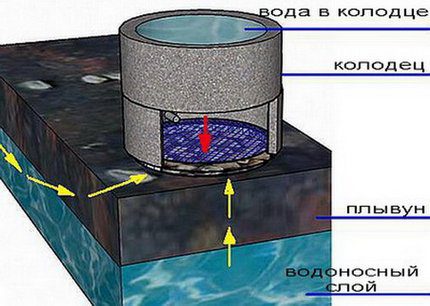

If the well is installed on quicksand, then there is a high probability of the presence in the water of an increased content of colloidal impurities, organic and chemical substances. All these processes must be controlled and eliminated in a timely manner.

You can read all about the reasons for cloudiness and yellowing of well water in next article.

Main signs of water pollution

Tests of water from a well should be carried out annually, since its composition in an underground source, depending on seasonal changes and other external factors, can change constantly.

This is especially important if the source is used only in the summer.A number of signs will indicate the need to purify water from a well.

How to take water from a well and submit a sample for analysis is described in detail in the article we presented.

Water turbidity and sedimentation

The opacity of the water indicates that too many silty small particles and suspended dust grains have accumulated inside the walls of the structure. This happens if the well rings have lost their tightness due to erosion of the seams or when the elements are displaced relative to each other.

A clear sign of a violation of the tightness of the walls of the structure is cloudiness of the water after heavy rainfall. Mechanical cleaning of the shaft, supplemented by work on sealing seams and sealing joints, helps eliminate the deficiency.

The appearance of an oil film over the water surface indicates the presence of petroleum products. This may occur due to depressurization of the mine.Or for the banal reason of improper cleanliness during the operation of a hydraulic structure.

Natural color change

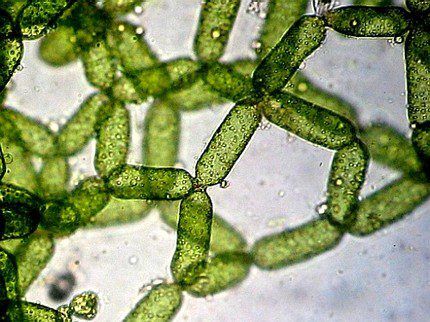

The color of the water in the well depends on the type of pollution. A change in color to green indicates a bloom in the water. The reason for this may be direct sunlight entering the mine.

The problem is solved by disinfecting water using chemicals and then installing carbon filters.

Brown and yellow shades indicate that the water has a high iron content. Disinfection in this case is not effective. Only the arrangement of a water treatment system and the installation of additional filters will help solve the problem.

Water acquires a black color due to organic contaminants, which infect it during the process of decomposition and rotting. To remove decaying organic matter with a simple source disinfection no longer possible. To obtain water that can be consumed, you will have to perform multi-stage purification.

Appearance of a strange odor

The clayey or earthy odor is due to the presence of organic natural compounds in the liquid such as 2-methylisoborneol and geosmin. They are formed during the life of soil bacteria and blue-green algae present in water.

Mechanical cleaning of the structure, followed by the installation of household reverse osmosis and the installation of filters equipped with activated carbon, helps eliminate the cause.

Water containing sulfur bacteria has the smell of rotten eggs. They produce hydrogen sulfide.

The smell of phenol and other unnatural aromas indicate that sewage and other human products likely entered the well shaft through underground aquifers. The problem can be solved by mechanical cleaning and installing a carbon filter.

Unusual taste of water

The salty taste appears due to the increased salt content: NaSO4, NaCl, MgSO4. It can be removed by performing additional purification of water, passing it through household reverse osmosis.

A metallic taste indicates the presence of iron in the water. Iron removal methods help correct the situation. For example, installing a compressor that will saturate the water with oxygen, a circulation pump and an iron removal filter.

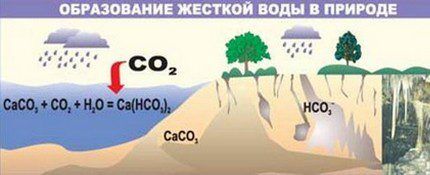

The sour taste of water, which has a blue-green tint, indicates a high content of carbon dioxide. This phenomenon occurs due to the reaction of water upon contact with copper and bronze elements of the system.

Increased hardness indicates the presence of calcium and magnesium salts in the liquid. Stiffness is not a constant value. It fluctuates depending on the season and reaches its peak in the summer.

The situation can be corrected by installing softening systems. Reagent and reagent-free complex purification filters are capable of demineralizing and softening water.

Well water quality analysis

The listed “symptoms” indicate serious water contamination.And until it is cleaned, it is not recommended to operate the structure. To find out the cause of pollution and find the optimal solution to eliminate it, it is necessary to take water samples and submit them for analysis.

The sequence of actions when collecting fluid for research:

- A plastic or glass container with a volume of 1.5 liters is thoroughly washed with running water, without using detergents. A plastic bottle of mineral or distilled water is perfect for taking a sample.

- The container is gradually filled with water so that excess oxygen does not form in the bottle due to excessive pressure. If there is an automatic water supply system from the well, you should first drain the water from the tap, and then fill the bottle to the neck at low pressure.

- The filled container is tightly closed and wrapped in a dark plastic bag.

- Within three hours from the moment the sample is taken, the container with the liquid is delivered to the laboratory.

Keep in mind that after two days from the moment the liquid is taken, the results will no longer be reliable.

It is not possible to perform a water quality analysis on your own. Obtaining accurate results cannot be achieved without the use of special equipment.

Research of this kind is carried out by:

- sanitary and epidemiological stations;

- state laboratories at geodetic centers;

- licensed private centers;

- accredited laboratories of Rospotrebnadzor.

The price of the service depends on the type of analysis.It can be shortened, focused on identifying a specific group of substances, or complete, including chemical and microbiological research.

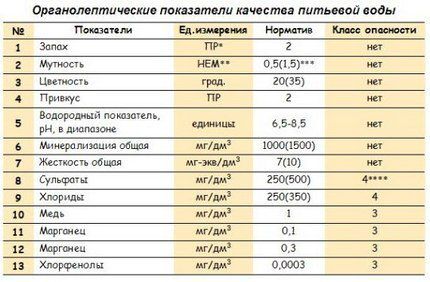

The results obtained are recorded in a protocol in which the permissible percentage of impurities and substances is indicated in accordance with current sanitary standards. The protocol will be accompanied by a conclusion on the suitability of the water and the presence of microorganisms and substances potentially hazardous to health.

If the customer wishes, specialists can also give recommendations on how best to purify the water in a particular well and what filtration systems to use in the future.

Effective cleaning methods

If the results of the study show that the fears are not groundless and the water contains impurities hazardous to health, the situation should be corrected as quickly as possible.

The choice of method depends on the cause of contamination. If debris has accumulated inside the structure and mucus has formed on the walls, it is worth using a mechanical method when cleaning the structure.

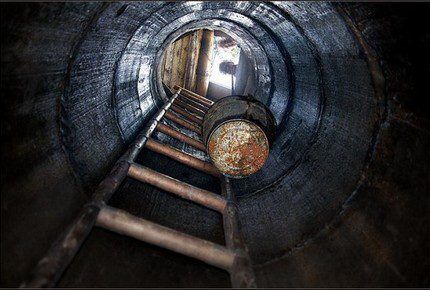

Mechanical cleaning of the mine

The method involves cleaning the walls and bottom of a hydraulic structure by washing or scraping off accumulated deposits. Mechanical cleaning It is best to do it in late summer or early spring before the snow melts. During the off-season, the groundwater level is at its lowest.

The mechanical cleaning procedure includes several main steps:

- Pumping water. Before performing mechanical cleaning, the structure is first emptied by pumping out the liquid with a drainage pump. Keep in mind that it will not be possible to completely drain the well shaft; a small amount of water will still remain at the bottom.

- Cleaning the walls and bottom. The cleaning worker, wearing a protective suit, lowers himself into the well. The assistant remains on the surface and takes the filled buckets. Debris and sludge residues are removed manually using a metal brush or a regular scraper. The crushed stone and sand that covers the bottom of the structure and serves as a bottom filter are replaced with new ones.

- Repair and strengthening of well rings. If necessary, to prevent the rings from moving relative to each other, they are reinforced with metal brackets.

- Sealing seams. If cracks are detected in the seams between the rings, the defects are repaired with cement mortar to which liquid glass has been added.

When replacing bottom filter Instead of crushed stone, you can use natural sorbents such as shungite or zeolite. They not only mineralize water, but also protect it well from heavy metals and petroleum products. The thickness of the newly laid layer must be at least 15 cm.

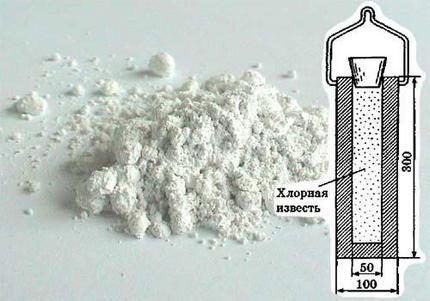

Carrying out disinfection work

Water disinfection is carried out after completion of mechanical cleaning and eliminating leaks at the joints. It is performed by applying the solution to the walls of the structure with a fur roller or a wide brush. For this purpose, bleach is used.

To prepare a 2% solution, bleach is diluted with water at the rate of 20 g of powder per 1 liter of liquid.When using pure chlorine, a solution of the required concentration is obtained by diluting the powder at the rate of 3-5 g per 1 liter of water.

The prepared solution is infused for 1-2 hours in a container with a tightly closed lid. The settled mixture is poured into another container. The top layer that rises to the surface is used for disinfection.

Disinfection of a well using chlorine is performed in the following sequence:

- A diluted 2% solution is applied to the inner walls of the well using a wide brush or roller, covering them evenly over the entire surface. The remainder of the preparation is treated with the bottom filter.

- After applying the product, the well is filled with water. A new portion of the solution is added to the poured water, but prepared in a ratio of 1:5.

- The solution poured into the well is thoroughly mixed with a long pole or by alternately scooping up the liquid with a bucket and then pouring it back.

- The neck of the treated and filled with water well is covered with a lid with plastic film and left for a day. This is necessary because chlorine tends to evaporate quickly. For chlorine to have the desired effect, it is important to keep the mine cool.

- After waiting 24 hours, chlorinated water is pumped out of the well and waiting for it to fill. The next day, the disinfection procedure is repeated.

An average of 500 g of solution is required per cubic meter.

Water that has been purified cannot be used. Before putting the structure into operation, the well will have to be drained and wait until it is filled from scratch. If there is a smell of chlorine in the water after filling, you will have to repeat the procedure. Within 5-7 days after completion of chlorination, the water is boiled.

If we consider other available means, then disinfection of the structure can also be performed using the same potassium permanganate. To do this, potassium permanganate is diluted in water at the rate of 1 teaspoon of powder per 10 liters of liquid. The solution is poured into a mine with water.

After waiting a day, they empty the well and wait until it is filled again. After cleaning is completed, a small bag made of synthetic fabric and filled with potassium permanganate is lowered into the shaft. It should be left in the well permanently.

There are also special chlorine-containing preparations such as “Aquatabs”, “Septolite-DHC”, “Ecobreeze-Oxy” on sale. They are available in liquid, powder or tablet form.

Based on these concentrates, disinfectant solutions are diluted in accordance with the instructions, which are used using the same technology as when working with bleach. Any of these means improves water quality and extends the life of the structure.

Application of dosing cartridges

In case of severe water contamination, when simple cleaning methods do not give the desired result, experts recommend using more radical measures - using dosing cartridges.

Cartridge body volume from 250 to 1000 cm3, made of ceramic, the porous walls of which freely allow active chlorine into the water. The number of cartridges required for disinfection depends on the volume of water in the mine and the degree of its contamination.

Disinfection using dosing cartridges should be carried out under the guidance of SES workers, while monitoring the quality of water in relation to microbiological and sanitary-chemical indicators.

The containers are suspended into the well shaft, immersed in the water column and placed at a height of 20 to 50 cm from the surface of the bottom filter. The concentration of the active substance in water is monitored 6 hours after the cartridge is immersed. It should be 0.5 mg/l. If the indicators are lower than required, another cartridge is buried.

In the future, concentration monitoring is performed every seven days. Cartridges are replaced every 3-4 weeks.

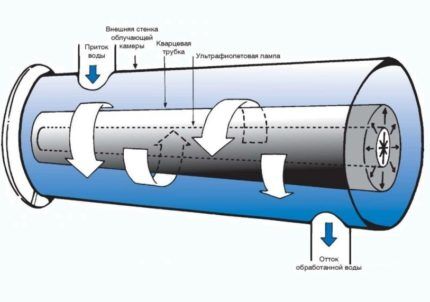

Alternative method of ultraviolet cleaning

The contents of a well can also be disinfected by irradiating it with ultraviolet light. This method is less labor-intensive, but more expensive. Disinfection with ultraviolet light is performed only after preliminary mechanical cleaning.

UV rays, the wavelength range of which is 200-295 Nm, are capable of destroying pathogenic microorganisms. The higher the radiation dose, the less time is required to disinfect the mine contents. A radiation dose of 15 mJ/cm² is sufficient to destroy most pathogenic bacteria.

The main advantage of water purification by ultraviolet irradiation is that it does not change the taste of drinking water.

Preventing water pollution

Cleaning and disinfecting water in a well requires a lot of time and effort. To minimize the occurrence of this kind of trouble in the future, do not forget to carry out preventive disinfection measures.

Following a number of simple rules will help prevent water contamination in the well:

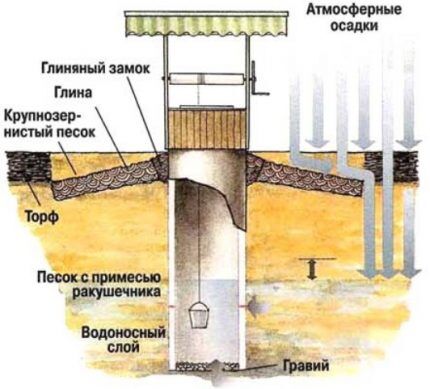

- At installation of a hydraulic structure take care of the construction of the clay castle. To do this, dig a trench around the well, 1.5-2 meters wide and 50-100 cm deep. It must be covered with clay and compacted tightly. The constructed clay castle will simultaneously perform two functions: prevent the penetration of moisture and prevent contamination of the structure through the seams between the rings.

- When arranging a bottom filter, use flint gravel, which has the property of softening water, or zeolite, which acts as a natural sorbent.

- Equip the well head with a lid or canopy. They will prevent dust and small debris from entering the mine, and will also protect well water from direct penetration of sunlight.

- To reduce the risk of leaks during the operation of a hydraulic structure, use stations with remote ejectors and submersible pumps.

Proper arrangement of the water source will eliminate the need for frequent disinfection work.

If your summer cottage does not yet have its own water source and you have not decided on its type, we recommend that you read the information in the article comparing well and well, assessing the pros and cons of both options.

Conclusions and useful video on the topic

Video review of tablet disinfectant Aquabreeze:

Video presentation of a lamp for an ultraviolet disinfection system:

Don't wait for a bolt from the blue. After all, water is something we use every day. And that’s why it’s so important to be sure that it does not contain harmful substances. To protect yourself and your loved ones, do not neglect the operating rules and regularly check the composition of the water, even if it seems crystal clear.

We are waiting for your stories about self-cleaning and disinfecting well water. Please write in the comment block. Here, ask questions, share your impressions, useful information and thematic photos.

Last summer we cleaned a well on my father’s property. The water had an unpleasant taste and the color became less clear.

I wanted to say that cleaning a well is a difficult and time-consuming job. The problem was pumping out water: although the bottom was covered with silt and dirt, the pumped volumes in the well shaft quickly resumed. They pulled out a fair amount of dirt, ten buckets. We also had to tinker with the sludge on the walls; we sorted through and washed the bottom filter.

The result was not long in coming! After just a couple of days, the taste of the water has improved and cloudiness no longer appears.

I believe that cleaning the well is absolutely necessary once every five to seven years, provided that the well is well enough covered and protected from direct contact with dust and rainwater. No super purified drinking water can compare with well water from a clean source!

I have a well on my property. To avoid contamination of water from the outside, I updated the above-ground part made by the log house and closed it with a lid. Reinforced concrete rings sometimes turn green, and to prevent the water from spoiling, my neighbor and I clean the walls of the well. I take a stiff brush and go down the walls. I usually do this in the middle of summer, when there is not much water. If there is a lot of water, I pump it out first. Usually cleaning lasts for a year.

Cleaning the well every year is clearly overkill. Even according to the standards, if I remember correctly, this is done once every two years.