Requirements for air humidity in a catering unit: norms and rules for arranging ventilation in a catering unit

Rospotrebnadzor has developed strict standards and requirements for air humidity in the food department of public catering outlets.After all, you must agree that a comfortable microclimate has a positive effect and contributes to the efficient work of bakers and cooks, and provides visitors with a good appetite. The rules are quite strict and clearly rank the limits of acceptable values.

Violating them can provoke a deterioration in the health of catering staff and create an ideal environment for the rapid growth and reproduction of microbes and pathogenic bacteria.

In this article we will look at the basic requirements of Rospotrebnadzor for the humidity of all catering premises and introduce you to control and accounting methods.

The content of the article:

What is a catering unit?

When talking about a catering unit, many people imagine a room in which food is prepared and products are heat-treated. But this is not entirely true.

First of all, it is worth knowing that the catering department is not only the kitchen and dining rooms, but also other premises directly or indirectly related to the organization of public catering.

The catering complex includes:

- washing;

- kitchens;

- linen, food warehouses;

- refrigeration rooms;

- dressing rooms, etc.

Offices and various administrative premises are also part of the catering unit.

Most of the food department premises are equipped with equipment that, during operation, has a direct impact on the temperature and humidity of the air.

Humidity level in the catering unit

In each catering unit, optimal air temperature and humidity must be maintained, taking into account the equipment used. For example, in hot shops, constantly running electrical equipment has a great influence on humidity. gas stoves.

During operation, not only they themselves heat up, the temperature of the working surfaces increases, and the air dries out quite strongly.

This can adversely affect the health of workers in these workshops, since dry air dries out the mucous membranes and contains very little oxygen.

The strongest influence on the microclimate of the catering unit is exerted by:

- continuous cycle of food preparation, its heat treatment;

- drying;

- washing;

- heating pipes and radiators during the cold period.

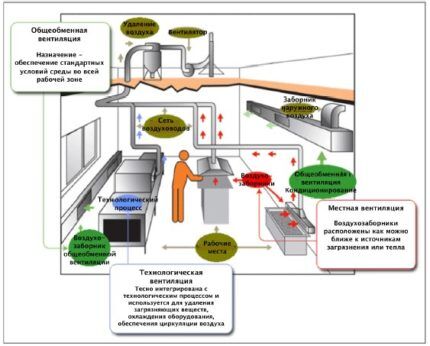

The negative impact of equipment, as a rule, is neutralized by installing local exhaust systems and supply ventilation.

Sanitary requirements for air humidity

Sanitary rules 2.3.6.1079-01 “Sanitary and epidemiological requirements for public catering organizations, the production and circulation of food products and food raw materials in them,” SanPiN 2.2.4.548-96 “Hygienic requirements for the microclimate of industrial premises” make it clear that the optimal humidity in the catering unit should not go beyond 40-60%.

The law requires adherence to this humidity indicator in premises for all purposes, except for pantries where food or equipment is stored.Not only the quality of the food supplied by the catering outlet, but also the safety of the working conditions of kitchen workers depends on this indicator.

Understanding that not all premises of the catering department have the technical ability to maintain the microclimate at the required level, Rospotrebnadzor suggests taking into account two humidity values - optimal and permissible.

In catering units that are equipped with air conditioning systems, the air humidity in the premises must correspond to the optimal value, because it is as comfortable as possible for a person. If the premises of the catering unit are equipped only with a ventilation system with mechanical or natural air exchange, then the humidity level should not fall below the permissible level.

Only these two quantities are considered working. The optimal value means that at this air humidity the worker is physically comfortable working for an 8-hour shift. Also, maintaining an optimal humidity level is a prerequisite for good performance.

The permissible value is the limit - the body of a catering worker at this level of humidity can function normally without threat or harm to health. But being in a room with a maximum level of humidity can cause discomfort and negatively affect the well-being of the employee.

An indoor microclimate that does not meet SanPiN standards can cause injuries and serious physiological disorders.

The very concept of “food department microclimate” is a composite definition, which consists of the following quantities:

- indoor air temperature;

- surface temperature;

- humidity;

- air circulation, its speed;

- thermal radiation, its intensity.

SanPiN recommendations are aimed, among other things, at maintaining a balance of all values of these quantities.

All these measures, to one degree or another, contribute to maintaining a microclimate in the premises suitable for work.

Humidity standards in the kitchen

A special and, probably, the most important place in the catering unit can be safely called the kitchen. The work process and working conditions of cooks involve the use of numerous equipment that generates heat, which negatively affects temperature and humidity.

The speed of air movement and its circulation is an equally important indicator - when it corresponds to the norm, the risk of heat stroke for kitchen staff is reduced.

When the temperature in the kitchen is 25 °C or more, the optimal humidity values should not exceed 70% and fall below 55%.

For different times of the year, SanPiN provides certain indicators of the microclimate of kitchen premises.

In the cold season, when the average daily temperature outside is below +10, it is recommended to adhere to the following indicators in the workshops:

- Meat, poultry and vegetable. The temperature in the workshop is 17-19 °C, humidity is 40-60%, surfaces are 16-20 °C.

- Hot. Indoors - 17-19 °C, humidity - 40-60%, surfaces - 16-20 °C.

- Cold. Temperature - 19-21 ° C, humidity - 40-60%, surface temperature - 18-22 ° C.

All kitchen areas must be equipped with ventilation systems in order to ensure the required air circulation rate.

The speed of air movement in the kitchen in the workshops throughout the year should be at least 0.2 m/s. This is typical for all premises of the catering unit, with the exception of service rooms, linen, dressing rooms and administrative premises. There the speed of movement is different - 0.1 m/s.

During the warm period, when the average daily street temperature is from +10 °C and above, the following indications for workshops are recommended:

- Meat, poultry and vegetable. It is recommended 19-21 °C with a humidity of 40-60% and with a surface temperature of 18-22 °C.

- Hot. Maintain 19-21 °C, relative humidity 40-60%, surface temperature 18-22 °C.

- Cold. Temperature 20-22 °C, humidity - 40-60%, surface temperature 19-23 °C.

The kitchen is not the only room in the catering department. All rooms, halls and utility rooms are connected in one way or another, and in all of them it is necessary to maintain normal humidity levels.

All requirements for humidity, air and surface temperatures developed and recommended by Rospotrebnadzor and prescribed in SanPiN are intended to ensure safe working conditions for the personnel working there.

The microclimate in the halls intended for visitors to eat must comply with the standards for industrial premises.

Humidity standards in washing and laundry rooms

No less important is the air humidity in the laundry room of the catering unit and in the washing rooms. Unlike the kitchen, there is virtually no heating equipment in these rooms, but there is a lot of water, including hot water.

This increases the level of humidity, which worsens the sanitary and hygienic conditions in the catering unit. The norm in these rooms is 60-40% humidity at any time of the year.

Also, to normalize humidity, the rules require that routine wet cleaning and surface treatment using special disinfectants be carried out strictly according to schedule.

What are the consequences of non-compliance with the instructions?

The norms and rules defining the optimal and permissible temperature and air humidity were developed for a reason. By observing their values, a microclimate is maintained in the production area that is safe for the normal functioning of the human body throughout the working day.

Supervision of compliance with humidity standards is aimed, first of all, at the safety of life and health of catering department employees, as well as at the sanitary and hygienic compliance of food products with GOST standards.

Rospotrebnadzor requires compliance with the temperature and humidity conditions in the catering department, primarily in order to ensure the safety of working conditions for enterprise workers and sanitary and hygienic control of the conditions for preparing and eating food.

Control and recording of humidity in the catering department

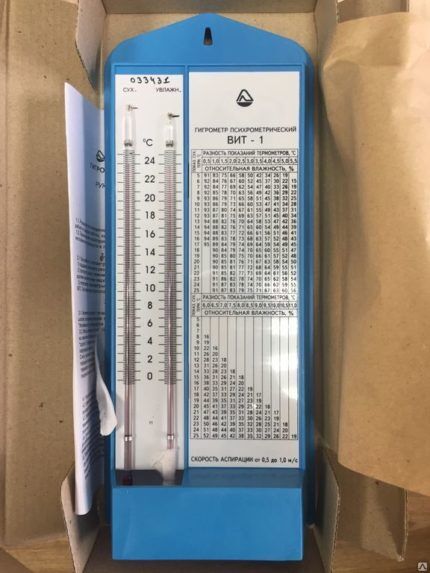

Used to measure indoor humidity psychometric hygrometer, which contains two thermometers in one device - dry and wet.

By calculating the difference in the readings of both thermometers using a special formula, you can obtain the most correct value of relative humidity.

Relative air humidity is measured every day, and the obtained values are necessarily recorded in a journal for recording temperature and relative air humidity and certified by the signature of the person responsible for keeping records.

The columns required to fill out are the air temperature in the room, the values of the dry and wet thermometer, the relative humidity of the air, as well as the date and time when the measurement was taken.

The journal can be maintained either electronically or in paper form.

Such scrupulous monitoring of temperature and humidity indicators of the microclimate makes it possible to monitor adherence to the regime and promptly identify deviations or trends towards them.

Also, thanks to accounting, the person responsible for production control can make the necessary adjustments in a timely manner to improve the temperature regime - add system equipment to the room ventilation and air conditioning or vice versa, working for heating.

Conclusions and useful video on the topic

Cleaning ventilation systems in the food department

Diagnostics of the exhaust ventilation system in the catering department

The microclimate in the room where a person works or eats is very important, because... has a positive effect and maintains the psychophysical state of a person at a normal level. For a clear feeling of discomfort or the occurrence of health problems, a violation of any parameter that is part of the microclimate is enough. Therefore, the rules so clearly prescribe the balance of indicators.

If you have questions about the topic of the article, you can ask them in the block below.

What formula can you use to subtract the humidity in the pantry?

I didn’t see what percentage of humidity and temperature should be in the vegetable pantry and the food pantry. Please tell me.