How to get rid of condensation in a ventilation pipe: the subtleties of eliminating droplets from the air duct

Have you installed a ventilation system, but you still can’t breathe in the house, and it’s also damp? This means it’s time to think about how to get rid of condensation in the ventilation pipe and prevent its formation in the future. Agree, it is better to solve the problem immediately than to endure discomfort for a long time.

We will tell you what to do so that you don’t have to spend money on replacing ventilation pipes and fighting mold in living rooms. From our article you will learn how best to prevent and eliminate condensation. Our recommendations will help independent home craftsmen.

The content of the article:

- What is condensation and what harm does it cause?

- Removing condensate outside the ventilation ducts

- Requirements for thermal insulation materials

- Acceptable thermal insulation options

- Features of insulating the air duct from the inside

- The procedure for installing thermal insulation outside

- Fighting condensation using an example

- Construction of a new ventilation system

- Conclusions and useful video on the topic

What is condensation and what harm does it cause?

Air masses contain water in a vapor state. When cooled, the steam transforms into liquid water and settles on the internal surfaces of the air ducts in the form of droplets, which can flow down to form streams and puddles.

Reasons for condensation formation:

- errors in the design and installation of the ventilation system;

- increased humidity in the premises;

- proximity to bodies of water;

- large temperature difference between inside and outside the house.

Not only puddles on the floor should be of concern, but also rust on pipes, decreased flow of fresh air, and accumulation of moisture in walls and ceilings through which air ducts are laid.

Condensation is a source of dampness in the house.It serves as a breeding ground for the development of mold and other microorganisms that negatively affect human health. Metal air ducts are destroyed by ventilation condensation. Even concrete walls can “feel” the harmful effects of high humidity.

Removing condensate outside the ventilation ducts

Condensate collection in vertical and inclined sections of air ducts is carried out in their lower part. On horizontal air ducts, condensate collection can be organized almost anywhere, except for areas laid in the walls.

IN ventilation pipe a tee socket is installed so that the outlet is directed downwards. The outlet is equipped with a special container - a condensate collector.

You can find various types of condensate collectors for ventilation on the open market. They differ in design and materials of manufacture. They can be transparent, which makes it easier to control the filling, but are more often made of stainless or galvanized steel.

When filled with condensate, containers with a screw-on lid are emptied manually, which is not always convenient. Moreover, at an outside air temperature of -20º C and below, condensation forms especially abundantly and the container is filled in a short period of time.

In this case, a conical condensate collector-watering can would be a good option. It is easy to attach a hose to it and drain the condensate into the sewer. If it is necessary to organize liquid drainage in a hard-to-reach place, a model with a watering can is also used.

When organizing collection and disposal condensate take into account the configuration of the ventilation system. With multiple turns of pipes, you will have to install not one, but several condensate collectors.

Sorbents - moisture-retaining substances - also help to collect and remove condensation. They have the form of cassettes and are installed in the filtration section of the supply air duct. Periodically, the sorbent must be removed for drying, after which it is again ready for use.

Removing condensate is considered a temporary measure, primarily due to the possibility of ice jams forming in winter. Insulation of veterinary ducts helps to radically solve the problem.

Requirements for thermal insulation materials

To insulate air ducts in a ventilation system, materials with the following properties are required:

- low thermal conductivity;

- vapor tightness;

- fire resistance;

- noise absorption capacity;

- biostability.

Thermal conductivity coefficient is the most important parameter of a thermal insulation material.

The second most important indicator is vapor permeability. Many materials used for ventilation insulation have the ability to release moisture accumulated underneath them when the voltage limit for them is exceeded.

By filling the pores of the material, moisture increases its thermal conductivity, thereby reducing the effectiveness of insulation. To prevent this from happening, a waterproofing coating is mounted on top of the heat insulator - a membrane that can allow steam to pass out, blocking its access inside.

Fire resistance determines how fireproof the insulation will be. There are 6 fire resistance classes in total.

For air ducts, zero class insulation is required, that is, it has the highest fire resistance, and therefore the most fireproof. With multi-layer thermal insulation and a number of additional conditions are met, the use of materials of the first fire resistance class is allowed

As the air flows through the ducts, it creates noise. In forced ventilation systems, the operating fan also makes noise and vibrates. To prevent noise and vibrations from being transmitted through rigid structures and spreading throughout residential premises, damping devices and gaskets are used.

But most heat-insulating materials also have sound-proofing properties and, in addition to their main function, help protect the house from unpleasant acoustic effects.

The materials used should not be a favorable environment for the life of insects, molds, rotting bacteria and other harmful microorganisms.

Penetrating through air ducts into living spaces, they can cause diseases and also damage the material itself, which may require its premature replacement. There are microorganisms whose waste products are so aggressive that they can burn through steel sheets 1.5 mm thick.

The materials used in the installation of ventilation communications must comply with sanitary and hygienic standards. The insulation should not emit substances hazardous to humans and the environment. Environmental friendliness means the absence of a threat of contamination of the natural environment during disposal.

Acceptable thermal insulation options

Many mineral fiber materials, hydrocarbon polymers, and foam elastomers meet the above requirements, including:

- mineral wool;

- polyvinyl chloride;

- expanded polystyrene;

- polyurethane.

Foam elastomers are produced by extrusion and vulcanization. They have a porous structure, and the pores are vesicular, that is, closed, which reduces moisture absorption and makes them vapor-tight. By polymerizing hydrocarbons, insulation materials such as polyurethane and polyvinyl chloride are obtained.

Thermal insulators are supplied for sale in the form of rolls, sheets (mats), hollow cylinders (shells). Rolled materials and shells are suitable for thermal insulation of pipes and round air ducts. Rectangular air ducts can be insulated with sheet material.

Sheet and roll insulation is highly flexible, it is easy to give it the required shape, one side can be smooth. Thanks to the combination of these properties, the installation of thermal insulation is greatly facilitated. Many materials are not only fire-resistant, but also self-extinguishing, which increases fire safety.

Insulation is selected taking into account the environmental conditions in which it will be used, including operating temperature. For central Russia, materials that can withstand ambient temperatures in the range from -30° C to 60° C are suitable for insulating ventilation systems.

Polyethylene (PE) film and polyvinyl chloride (PVC) membrane are used as waterproofing protection.From external damage, insulated ventilation ducts are covered with boxes lined with boards, plywood or aluminum sheets.

Features of insulating the air duct from the inside

It is necessary to insulate all air ducts located outside heated rooms, including areas in the walls. It is possible to insulate both external and internal surfaces of air ducts.

If insulation is carried out from the inside, already at the design stage it is envisaged to increase the cross-section of the air duct in accordance with the thickness of the heat-insulating layer. Otherwise, its throughput will decrease.

Mineral wool fibers are strengthened using adhesives. This is necessary to prevent the fibers from peeling off under the influence of a stream of air. The adhesive used for this purpose should not affect the level of fire resistance of the insulation and its environmental friendliness.

Thermal insulation laid on the inside should not increase aerodynamic resistance, slowing down the movement of air masses. That is, it is necessary to make its surface smooth.

Due to the additional requirements for internal thermal insulation, its use is often impractical. Including if it is necessary to insulate an already built ventilation system with a given cross-section of air ducts. In such cases, the air ducts are insulated from the outside.

The procedure for installing thermal insulation outside

The most economical thermal insulation material for a private home is time-tested mineral wool.It comes in rolls of varying widths and may have one or two outer foil layers.

When determining the thickness of the heat-insulating layer, they are guided by SNiP 2.04.14–88. Heating engineers perform complex calculations taking into account the diameters of the pipes and the thermal conductivity coefficient of the heat-insulating material used.

They take into account the average annual air temperature and even possible heat loss through joints and fastenings, as well as other parameters, most of which can be found in reference books and the above-mentioned SNiP.

If we talk specifically about mineral wool, then when insulating ventilation systems in private houses located in central Russia, roll material 100 mm thick is usually used. You can buy mineral wool 50 mm thick and wrap the pipe twice.

To determine the required width of the insulation, measure the diameter of the pipe and add the thickness of the mineral wool multiplied by two to the resulting value. Multiply the resulting amount by 3.14 (Pi).

When starting work, prepare in advance a rubber spatula, a construction knife, a stapler, aluminum tape 7-8 cm wide, a marker and measuring tools - a square, a ruler and a tape measure (preferably metal). Be sure to wear protective clothing.

To work outdoors, choose a day without precipitation. Otherwise, the mineral wool may get wet. The roll is unrolled, marked and cut to obtain the required size. The foil is separated along the edge so that the pipe can be wrapped with mineral wool overlapping and the connecting seam can be covered with a foil layer.

Then the connecting seam is fixed in increments of 10 cm using a stapler and taped along its entire length. To fix the insulation to the pipe, both special fasteners and ordinary wire are used.

To protect the joints of the air ducts, the insulation is cut into fragments of the appropriate shape and size. Don’t forget to clean the pipe of any dirt before insulating it.

Insulation can also be done using segmental insulation. The monolithic casing has the shape of a pipe and is threaded onto the air duct. It is used mainly during the installation of a ventilation system from scratch.

Having measured the geometric parameters of the air duct, select a casing that is suitable in size and stretch it along the entire length of the pipe. Foil is wound over the top and secured with stainless steel or copper clamps.

The collapsible shell consists of two half-cylinders, which are applied to the pipe on both sides and fixed. In areas running through the wall, it is difficult to wrap the pipe in roll insulation, but putting on the shell is much easier. The collapsible shell can be placed on an existing air duct.

Fighting condensation using an example

Let's consider a specific situation. A one-story private house has a ventilation system that provides air exchange in the bathroom and kitchen. Metal ventilation pipes are connected to these rooms.

They are laid through the attic with subsequent access to the roof. With daily temperature fluctuations, condensation forms in the pipes.But a particularly large amount of it is observed in winter, when water drips from the hood, collecting in a puddle.

The problem is solved comprehensively. The exhaust and supply pipes are insulated. The pipes are insulated from the entrance to the ceiling to the exit to the outside. In areas passing through an unheated attic, pipes are insulated with rolled mineral wool 70-100 mm thick.

A shell is used in places where it passes through the ceiling and ceiling. A tee with a condenser collector is installed at the lowest point.

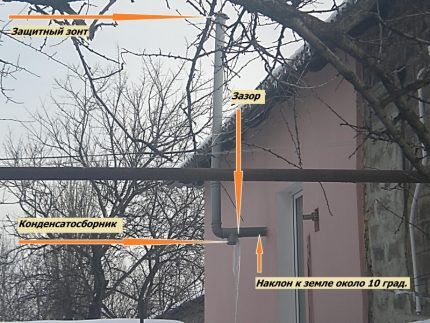

If the ventilation ducts do not pass through the roof, but through the wall, the section in the wall is insulated using the shell. Outside the house, a 90-degree tee is installed on the ventilation pipe, a condensate collector and an umbrella (deflector) are mounted.

Construction of a new ventilation system

Due to errors in design and installation, if low-quality pipes are used, all measures to combat condensate may be in vain.

In this case, it is economically feasible to shut down the old one and install a new ventilation system that would cope with its functions of removing contaminated air and supplying fresh air masses.

Design is carried out only after analysis of air exchange processes and calculations in accordance with the standards specified in SNiP, based on the characteristics of the ventilated premises and the number of residents. It may be necessary to abandon natural ventilation in favor of forced ventilation by changing the configuration of ventilation ducts and installing equipment for heating the supply air.

Conclusions and useful video on the topic

How to determine if condensation is forming in air ducts:

Discharging condensate from the ventilation system into the sewer system:

Installing condensate collectors in combination with insulation of ventilation pipes solves several problems simultaneously. The intensity of condensation formation is reduced.

That small amount of moisture that can still condense on the surface of the air duct is quickly removed beyond its boundaries, without having time to cause harm. The level of noise and vibration is reduced, which is especially noticeable in forced ventilation systems. As a result, the microclimate normalizes and the house becomes more comfortable to live in.

Do you have your own experience in dealing with condensation in ventilation pipes in a country house or country house? Do you know the technical nuances of its diversion or prevention that are worth sharing with site visitors? Please leave comments, post photos, and ask questions in the block below.

I have a ventilation system with a recuperator of 600 m3 per hour. Condensation persisted despite the insulation of all air ducts. Moreover, what surprised me: with the ventilation turned off, after 3 weeks I found condensation in the same places as with the ventilation system running... After analyzing this fact, I realized that the heat from the house rises through the air duct and falls into the condensate. Now I am installing reverse valves in front of each supply ventilation head, 5 pcs. At the same time I will install 2 pieces on the hood. In addition, I will equip drain valves...