The washing machine does not spin or makes noise when spinning: analysis of the causes of failure and repair instructions

During the operation of washing machines, users repeatedly encounter various malfunctions in the operation of the equipment.There are often a lot of reasons when the washing machine does not spin or has a system failure in the electronic control.

In order to prevent or promptly eliminate such situations, it is necessary to understand the prerequisites for their occurrence, don’t you agree? In the article, we examined the most likely reasons for the lack of spinning and the appearance of strong noise, and also suggested ways to restore the functionality of the washing machine.

The content of the article:

- Reasons for lack of spinning and their elimination

- No. 1 - washing clothes without twisting

- No. 2 - imbalance of loaded laundry in the drum

- No. 3 - problem with the drain pump

- No. 4 - malfunction or wear of the pressure switch

- No. 5 - malfunctions in the control system

- No. 6 - failure of the electric motor

- No. 7 - clogged sewer drain

- No. 8 - debris in the drainage device

- Possible causes of noise and troubleshooting

- Problem #1 - shipping bolts not removed

- Problem #2 - foreign objects in the drum

- Problem #3 - wear of the bearings in the machine

- Problem #4 - problems with drum mounting

- Problem #5 - Tank counterweights are poorly secured

- Problem #6 - Incorrect installation

- Problem #7 - high noise level of a specific model

- Preventing breakdowns in washing machines

- Conclusions and useful video on the topic

Reasons for lack of spinning and their elimination

The washing machine has a simple design, but parts often wear out and fail. As a result, a number of breakdowns can occur when the equipment stops performing the functions inherent in its electronic system.

One of the main problems that may arise during operation is poor-quality spinning or its complete absence.Even owners of brand new washing machines can encounter the problem of lack of spin. Let's look at the possible reasons in more detail.

No. 1 - washing clothes without twisting

Modern machine models are equipped with a large number of options and innovative technologies that allow you to remove washed items from the drum completely dry or, conversely, wet.

If you discover that things have not gone through the twisting procedure, you need to check the “no spin” button. It is possible that the no-twist function was accidentally turned on when selecting a program.

No. 2 - imbalance of loaded laundry in the drum

Expensive washing machines have more functions and capabilities for economical and efficient washing. One of the additional functions is the distribution of loaded items inside the drum, which helps prevent things from bunching up into a single lump.

In the absence of such a function, washing machines may malfunction during the execution of a running program.

No. 3 - problem with the drain pump

In this case, the spinning process occurs, but the waste water is not poured into the sewer. Thus, things remain wet after twisting. To fix the breakdown, you need to make pump replacement (pump).

Let's look at how to replace the pump in branded machines Samsung, Whirpool, LG, Ariston, etc.

To do this you need:

- Disconnect equipment from all sources: power, water supply and drainage.

- Place the product body in a side position.

- Detach the bottom to gain access to the pump.

- Unscrew the screws and pull out the pump by pressing it from the side of the drain valve.

- Disconnect the wires from the pump.

- Remove the clamps and drain the remaining water into a prepared container.

After this, it is necessary to disassemble the pump, remove and clean the volute (if it is suitable), and replace the pump. At the end, you should reassemble all the parts in reverse order.

No. 4 - malfunction or wear of the pressure switch

The spinning mode may not turn on if the water inlet and outlet sensor is broken.

If the wrong signal is given, then the spin will not turn on and the sensor will need to be replaced.

No. 5 - malfunctions in the control system

The electronic or mechanical control system may malfunction after sudden changes in electrical power, due to the long service life of the equipment, or failure of the stabilizer.

A breakdown of the speed control sensor is quite rare, but if it occurs, the machine performs a poor-quality spin. In this case, you will need to reflash the control system or replace the board.

No. 6 - failure of the electric motor

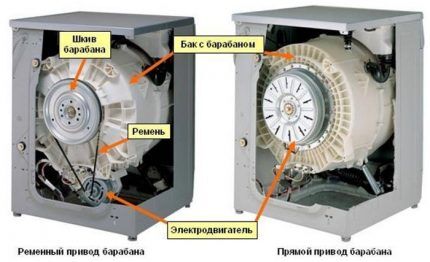

If the motor breaks down, the spin function in the product does not turn on at all. The cause of engine failure may be a malfunction of the windings, their breaks, wear of the lamellas or brushes. To repair this unit you will need disassemble the washing machine, remove and inspect the motor.

How to determine engine failure:

- if the engine sparks during inspection, then urgent replacement of the brushes is necessary;

- in the presence of strong noise and overheating of the equipment, the cause may be a violation of the integrity of the winding;

- Peeling of the lamellas and the appearance of burrs on them can also lead to the appearance of sparks.

The lamellas must be checked during disassembly at the same time as the graphite brushes.

Failures are eliminated in the following order:

- It is necessary to turn off the machine - disconnect the drains, water pipes and the electrical network.

- Disassemble the product body: remove the back panel and straps.

- Remove all bolts that secure the engine.

- Disconnect the terminals and wiring that connect to other components.

- If the tank prevents free access to the engine, you need to lift it slightly.

- Different models have different structures from each other, so you will need to remove the side walls of the machine to successfully remove the engine.

Next, you should replace the broken parts or tighten their fastenings for normal operation.

After the manipulations have been performed, you should install the repaired motor, assemble the washing machine in the correct sequence and check its operation.

No. 7 - clogged sewer drain

If the reason is not a breakdown of parts or a malfunction of the electronic control system, then the waste water drain pipes into the sewer may be clogged.

You may need to clean the pipe with a cable. If a breakdown is found, then the machine will work correctly, and the stagnant debris will come out of the tube.

No. 8 - debris in the drainage device

If the spin function in the washing machine does not work or any malfunctions occur during the process of starting the procedure for unscrewing things, you need to check for the presence of foreign objects in the drain element.

The part is located at the bottom of the machine. Recommended clean the drain filter at least twice a year. If any problems are detected in the operation of the equipment, cleaning should be carried out immediately.

If you detect malfunctions in the washing machine related to the spin function, it is recommended to immediately diagnose the product.

Please note if:

- the equipment has stopped twisting clothes well (remains wet);

- water remains in the tank even after turning on the pump;

- The spin cycle is quite noisy.

It is also recommended to carry out regular cleaning the washing machine, all components and filters to prevent possible damage or clogging.

Possible causes of noise and troubleshooting

In addition to poor-quality spinning or its complete absence, equipment can signal a breakdown in another way, namely, by making unusual loud sounds - noise, humming, ringing, etc.

The following recommendations will help you figure out what the cause may be and how to eliminate it.

Problem #1 - shipping bolts not removed

After the selected equipment is delivered home, buyers, as a rule, save on the cost of installing the machine and deal with the procedure themselves.

Connecting the product to the water supply and sewer system is quite simple. But they forget to remove the mounting bolts that secure the drum during transportation.

After discovering this problem, you should unscrew the remaining bolts and check the operation of the equipment again.

Problem #2 - foreign objects in the drum

When placing items to be washed in the drum, it is imperative to check for various items in your pockets - keys, coins, receipts or receipts.

When they get into the drum or tank of the machine, you can hear a tapping sound.

Also, items that are decorated with metal rivets, large zippers with fasteners, chains, etc. can make noise when washing. To prevent them from knocking on the drum, you should turn the items inside out and then just place them in the washing machine.

Problem #3 - wear of the bearings in the machine

The drum in the washing machine rotates thanks to bearings. If parts are damaged, the drum stops rotating correctly and makes uncharacteristic noise.

To check whether this is the cause, you need to rotate the empty drum from side to side. When bearings wear out and fail, they prevent free rotation and play is felt. During washing, the equipment makes a lot of noise and may vibrate.

If the reason is determined correctly, bearings should be replaced.

To do this you will need to perform the following list of actions:

- Disconnect the washing machine from the sewer, water supply, and turn off the power.

- Disassemble the rear and top panels according to the instructions.

- Remove the dispenser and control unit by unscrewing the screws.

- Loosen the clamp, remove the counterweight, heating element, pipes and other parts that prevent access to the engine.

- Remove the motor.

- Remove the drum tank.

- Unscrew the drum to remove the pulley and unscrew the shaft.

- Knock out the bearing using a special tool - a knockout.

- Replace the seals.

- Install the new bearing into the seat.

- Reassemble the equipment in reverse order.

It is better to coat the tank connection points with a sealant. For convenience and to remember the order of the procedure, all steps taken can be recorded using photos or videos.

Problem #4 - problems with drum mounting

A characteristic sign of a weakened pulley is the presence of a click when the drum rotates. The identified problem is resolved quickly enough.Disassembling the washing machine is performed in the same manner as when replacing bearings.

After completing the procedure, you will need to check whether the washing machine makes noise during the spin cycle. It is better to run a short wash program with twisting to make sure it works correctly.

Problem #5 - Tank counterweights are poorly secured

In order to hold the tank while washing, the machine is equipped with counterweights. If you hear a loud noise during operation, you should check whether the fastenings of this unit are loose.

If the unit fails, you will need to remove the panels of the machine and unscrew all the parts that prevent free access to the counterweights. Next, you need to check their integrity and secure the fastenings more tightly.

Problem #6 - Incorrect installation

At installing a washing machine Users do not always pay attention to the quality of the floor surface and the presence of unevenness on it.

As a rule, tiles are quite slippery and the machine can move on the floor. To do this, you need to glue rubber tips to the legs if they are missing.

Stores also sell special rubber installation mats.

Problem #7 - high noise level of a specific model

Increased noise levels may not cause any damage. Some budget cars are very noisy.

When purchasing a product, you should definitely be interested in this characteristic. The indicator in the equipment passport is indicated in dB. More quiet models do not exceed the level of 54 dB during washing and 65 dB during twisting.

If a problem with increased noise is detected, you must check the product specifications specified in the documentation.

Preventing breakdowns in washing machines

It is possible to anticipate the occurrence of problems associated with increased noise levels, strong vibrations, and lack of a spin function if you adhere to the basic recommendations for the care and operation of equipment.

Experts advise doing the following with washing machines:

- load the volume of things without exceeding that specified in the machine’s passport;

- check for foreign objects in pockets;

- use covers for washing small items;

- less often include programs that involve working at high speeds and using hot water;

- clean filters regularly;

- Use only high-quality detergents and water softeners for washing.

In case of power surges, it is advisable to connect equipment to the network through surge protectors with a fuse or use a stabilizer.

If problems are identified, it is necessary to diagnose the product and replace failed components for the correct operation of the machine.

Timely and correct replacement of parts will extend the life of the equipment and prevent more serious breakdowns.

Conclusions and useful video on the topic

The proposed videos will help you independently determine the cause of increased noise in the machine or lack of spin, as well as replace components and parts with your own hands.

Instructions for replacing the oil seal and bearing yourself:

How to replace brushes in a motor:

Eliminating the reason for the lack of spin in the machine:

Repairing a washing machine usually does not take much time, but initial skills are required to identify the cause of noise and other problems, as well as to replace spare parts or even basic cleaning.

If you doubt your abilities, it is better to contact a service center, where, after an initial diagnosis, they will quickly determine the cause of the breakdown and indicate the cost of repairs.

Have you ever repaired a washing machine yourself? Please tell us what kind of breakdown you encountered and whether you were able to fix the equipment. We are waiting for your comments, questions and advice on repairing your washing machine - the contact form is located below.

In the vast majority of cases, when the machine makes a lot of noise and vibrates during the spin cycle, it was simply installed incorrectly. Often the bathroom floor is uneven and the tiles are slippery. Therefore, it is quite normal to adjust it to the building level. The second most popular source of noise is foreign objects caught in the drum.Be sure to check pockets before washing. But if the machine does not spin at all, then this is a more complex problem and it is better to contact a specialist.

There are quite different problems with spin washing machines. Maybe your things are just bunched together, which is why the washing machine detects an uneven distribution of things and gives an error; you should also pay attention to the overload of things. In my case, the drain pump failed, and therefore the machine simply could not pump water into the sewer.

Somehow my machine stopped spinning. It buzzed and that was it. As much as it cost me to repair it each time (our old one is already 10 years old), it was already possible to buy a new one for that money. I called the technician and thought: well, that’s it. If the price goes too high, I’ll spit and go for a new one. The technician came, did some digging, and after all, it turned out that an ear cleaning stick was stuck in the hose that was connected to the pipes. How she ended up there, I have no idea. The wand was pulled out, and the machine continued to work like a clock.

The spin does not work, after draining the water, the drum stops spinning and makes sounds?