The washing machine drum does not spin: 7 possible reasons + repair recommendations

You loaded the laundry as usual, turned on the machine, it filled with water and started working. But after some time it suddenly stopped.The program is not completed, things are inside, panic sets in, the world turns upside down at the mere thought of hand washing.

Let's figure out how to get rid of a breakdown if the washing machine drum does not spin - the causes, consequences and options for solving the problem.

The content of the article:

What can you do right away?

We calm down, turn off the machine with the button on the panel and unplug the cord from the outlet. We cover the floor with rags, find the drain filter on the front panel below, place a container (scoop, suitable container) under it, open it and drain the water. We take the laundry out of the machine and figure it out further.

We determine when the drum stopped. If during the spin cycle, the laundry will remain simply wet, without any signs of soapiness. If you wash it, things will be powdery.

You need to try to spin the drum by hand. Did not work out? Rotation is physically interfered with by a foreign body or a failed part. When the drum spins while the machine is turned off, the reason is hidden in the electronics.

And one moment. A common consequence of drum immobility is the usual overload.Try splitting the laundry in half and restarting the wash with less “work.”

Modern washing machines are equipped with special sensors that monitor the weight: if it is exceeded, they stop the process. On some models this information is displayed on the display.

Don't forget to check the external conditions that affect the operation of the machine. Some washing machines are equipped with sensors that are sensitive to water pressure parameters.

While the user is disassembling the device and changing parts, a pinched hose, a burst gasket or a dirty filter will not alert you to attention.

What faults lead to the problem?

Machine breakdowns are divided into rare and typical. Stopping the drum belongs to the second group. The causes of failure can be mechanical, technical, or household problems.

If the washing machine has been operating within its capabilities for a long time and without proper preventative maintenance, technical faults appear. They require specialist intervention. The rest you can handle on your own.

Failure #1 - foreign object in the tank

Take a flashlight and examine the inside of the drum. It is important to carefully inspect everything to see if there is a foreign object there.

We take out other foreign objects:

- Pull out the machine to provide access from all sides.

- Remove the bolts on the back panel that hold the top cover in place.

- Slide the cover back to remove it.

- Unscrew the screws of the back cover and remove it.

- Take out the heating element, this will make it easier to remove foreign objects.

- Disconnect the wires that go to the heating element, unscrew the fastening nut. The heating element is easy to pull out if you pick it up with a screwdriver.

- We get a hole - shine a flashlight into it.

- Did you see the problem? We twist the wire to a sufficient length and use it to remove the stuck object.

- Installing the heating element into place, make sure the fit is perfect, tighten the nut.

- We assemble the machine.

When an object is in the space between the drum and the tank from above, it cannot be seen through the hole in the heating element.

We block the pulley with a block of wood, unscrew the fastening bolt, remove the pulley, screw the bolt, but not all the way. Now we hit the bolt with a hammer, trying to preserve the thread.

As a result of the impacts, the shaft and drum will move forward slightly, and the excess object will fall down, where it is convenient to reach it. We return the pulley to its place, tighten the bolt until it stops. We install the back wall of the machine, fasten all the bolts.

Failure #2 - vertical doors opened

In vertical machines, the tank flaps often open during the spin cycle. The reason is sometimes not related to a leaky latch.

Perhaps a too smart child got there and turned the drum while the doors were open. Or an adult loaded too much laundry and a piece of fabric got caught in the fastener.

The problem doesn't look serious. But the severity of the consequences depends on the moment when exactly the doors opened. If you use a delicate wash, in most cases nothing bad happens.

But during a strong spin, the open blades can turn into meat grinder knives and ruin everything that gets in the way.

The doors break through the protective barrier at speed. The heating element is the first to be hit, and the walls of the tank itself and the drum flaps are also damaged. When all three elements break, repairs are expensive. It's cheaper to buy a new washing machine.

Let's try to solve the problem differently. You need to try with minimal effort and carefully return the drum to its original position.

If that doesn't work, try closing the doors. You will need a strong, elastic steel wire with a diameter that fits into the holes of the drum.

Using pliers, bend the end of the wire about half a centimeter to form a hook. Carefully insert it into the hole. Using a flashlight in one hand and a wire in the other, we try to close the doors.

If successful, you will be able to spin the reel. When it is not possible to hook the doors with wire or they cannot be held when rotating and they still open, you will have to disassemble the washing machine.

General procedure:

- We unscrew the latches of the rear panel and set it aside.

- We move the side to the side and remove it too.

- We photograph the location of the wires and disconnect them.

- Unscrew the screw holding the shaft.

- Close the loading hatch and take out the tank.

- We separate the halves of the tank and take out the drum.

- We clean parts from dirt and debris.

Now we try to close the doors several times. If the retainer is broken, this part can be ordered from the manufacturer and replaced.

We inspect the doors themselves, the integrity of the tank, and damage to the heating element. Significant deformations are a reason to think about buying a new washing machine.

Failure #3 - rusty bearing jammed

Bearing wear is another malfunction that causes the drum to stop. We have it disassembled, let's check the bearing. Carefully knock out the part with a handy tool.

In addition to the bearing itself, the seals also need to be replaced. We treat the bearing installation site with lithol and return the elements back. Secure with a hammer.

If you have a horizontal machine, the order of work is as follows:

- Unscrew the fasteners and remove the back and top covers.

- We dismantle the dispenser.

- Remove the control unit by first unscrewing the fasteners.

- Open the loading hatch, unscrew the rubber cuff, and insert it into the drum.

- We remove the blocking.

- We remove all fasteners and remove the front panel.

- Loosen the clamp and remove the counterweight.

- Now you need to pull out the heating element.Here we pay attention to the order in which the wires are connected, disconnect them, and remove the heating element.

- We remove all remaining obstacles that connect the tank and the body - pipes, drive.

- Unscrew and remove the engine.

- After this, nothing prevents you from removing the tank along with the drum.

To make it more convenient to work, the tank can be moved to a good-quality table. Next, we do everything similarly to the algorithm with a vertical machine: knock out the bearing, remove the seals, lubricate the seat, install new parts.

When assembling the drum, perform the installation very carefully. Treat the joint area with sealant to avoid leaks. There are models of cars with non-dismountable tanks; it is reasonable to entrust their repair to a specialist.

Detailed instructions for replacing bearings in a washing machine are given in this material.

Failure #4 - the drive belt has fallen off or deteriorated

Remove the back panel of the machine and look at the condition of the belt. If it just slipped off, put it back in place, close the lid, turn on the washer and check its operation. In case of complete wear or damage, replacement will be required.

They are made of chloroprene rubber, polyester cords, and cotton material, due to which they are elastic and have increased strength characteristics.

The V-belt is tensioned when moving the engine, so you need to loosen the fastenings. When the adjustment stroke of the engine is small or such a maneuver is excluded by the design of the machine, the belt needs to be replaced.

We install the V-belt like this: we wind it around the pulley, then we place the strip in the drum groove and seat it completely there, rotating the pulley.

The V-belt has a toothed section. The parameters are also marked on the outside. It changes in exactly the same way as the wedge one. But it requires careful position control after final installation.

We measure the middle of the mating part of the engine pulley and drum - the belt is installed strictly along this line. V-ribbed belts are tensioned less than V-belts.

We also recommend that you read the detailed instructions for selecting and replacing the belt in the washing machine.

Failure #5 - the electric motor brushes are worn out

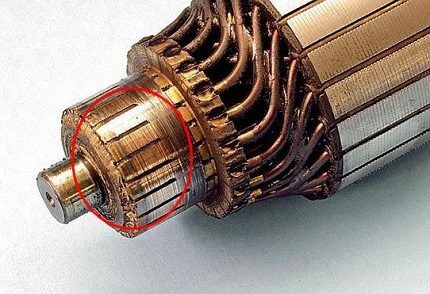

When worn brushes do not provide the required electromagnetic field, the motor rotor stops rotating. During operation of the washing machine, this part is shortened and no longer reaches the collector. Need a replacement.

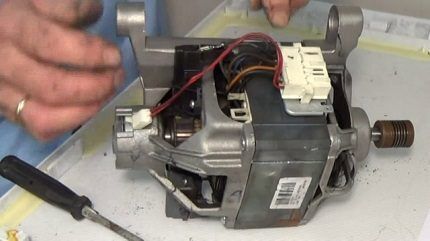

If the machine is assembled, remove the back wall and belt. We disconnect the engine from the power supply by pulling out the connector with the wires. We dismantle the engine itself.

Next, we lay the engine on its side so that the brush housing is on top, and unscrew the mounting bolts and pull out the spare part from one side and the other.

Do not rush to change, inspect the elements.Measure the rods: if they are longer than 1.5 cm, the brushes are not causing the drum to stop.

Also, do not forget to clean the collector from black deposits; remove scratches with sandpaper. That's it, now you can install new elements and tighten them with bolts.

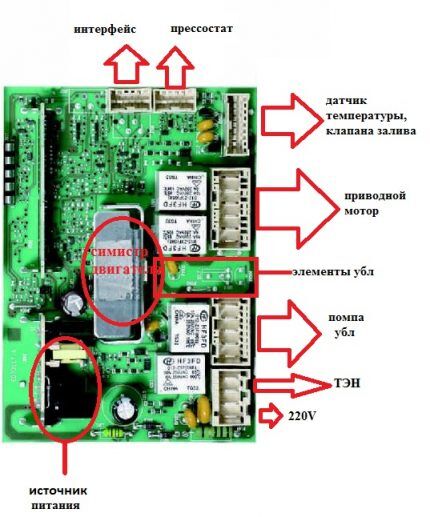

Failure #6 - the control module is broken

The drum may remain motionless due to the lack of a signal from the “brain” to start washing. Most often, the control board fails due to voltage surges or natural wear.

There are three options to solve the problem - reset the programs, flash the firmware, or replace the module.

Some models have a self-test function. It allows you to determine the source of the problem. How to enable this feature? They don’t write in the instructions, but the starting method depends on the manufacturer and the specific model.

As an example - Ardo it is tested like this: drain the water, the tank should be empty, set the mechanical program switch vertically down, set the temperature to zero. To start the test mode, press all the buttons at once.

If there is still a need to remove the board, it can be removed quite simply. We remove the top panel, dismantle the upper part of the machine, remove the fixing strips and take out the module.

Repairing the control unit requires special skills - you need to check the parameters of the elements and monitor the chains. We carefully inspect the board.

4 signs that serious intervention is needed:

- The paths darkened, the color changed in some places, and scorch marks appeared.

- Bumps are visible on the caps of the capacitors.

- The varnish coating on the damping coils has faded.

- The main processor has darkened at the installation site.

If any of the above is found and you have no experience with a soldering iron or multimeter, entrust the repair to a specialist.

Failures associated with sensor problems can be resolved independently. Contact groups become greasy and clogged over time; they just need to be cleaned. Remove the program regulator, disassemble the handle and clean it.

If there is a layer of soot on the power coils of the surge protector, brush it off with a dry cloth and brush. We free the hatch lock block from soap deposits.

Failure #7 - engine burned out

The motor is usually reliable and it takes a lot of effort for it to break. But there are a couple of cases where this happens. The winding short-circuits or it breaks off at the stator and rotor.

A characteristic sign of the first situation is that the empty drum rotates normally, but during a full wash the plugs are knocked out. When the second situation occurs, the drum stops rotating altogether.

Repair is possible if the drum has stopped, but the machine is humming when turned on. Full engine replacement It is needed when there is no start at all, there is a smell of burning, dark smoke is coming out, the washing machine is sparking. First, let's remove the electric motor and see what can be done.

The motor is removed in the same way as when replacing the belt. If it is clamped by the tank, slightly lift the tank and free the engine. Sometimes you have to remove the side wall as well. There are three main faults - brushes, lamellas, windings.

We have already looked at how to replace brushes. You can check the performance of the windings with a multimeter by probing adjacent lamellas one by one. The discrepancy must be less than 5 ohms.

We will also check the short circuit of all windings: we will place one probe on the body, and with the second we will go through the lamellas. If everything is fine, the resistance will be high.

If the windings are faulty, it is better to find the same part and replace it. Rewinding will cost more. Minor peeling of the lamellas can be turned on a lathe.

But such an event will not be a panacea; you cannot return them to their factory appearance and quality. Conclusion: we replace the parts with new ones.

Methods to prevent future problems

Empty pockets thoroughly before washing. Place all small items (baby socks, handkerchiefs) and bras in special mesh bags.

Connect the washing machine through an uninterruptible power supply or at least an extension cord with a surge blocker if you live outside the city or simply have problems with power surges.

This is especially true for models with many programs and an overly smart “brain”. Pay attention to the correct grounding of the machine.

In addition, it is necessary to regularly carry out preventive drum cleaning - this will protect the washing machine from damage and unpleasant odors.

Conclusions and useful video on the topic

More details about repairing faults can be found in videos presented by service center technicians and ordinary users.

Disassembly diagram for a front-loading machine:

Removing and opening the washing machine drum is discussed in the following video:

Removing the belt, motor, replacing brushes in the video:

When you change everything, install it, close the machine, be sure to check the operation of the equipment. Start your normal program. The washing machine operates in the usual mode or sounds louder than usual - everything is fine, everything is done correctly. Creaking, chattering, or too loud noise from the washing machine is a reason to contact a service center for help.

Have you ever encountered a problem when the washing machine drum stopped spinning? Please tell us how you managed to cope with this problem and what caused it. Write your comments, share your experience, ask questions - the contact block is located under the article.

When I started cleaning the filter of my washing machine, I didn’t find anything there. Starting from pebbles and ending with coins. Now I try to do prevention at least once every 3 months. I also encountered the problem of a stuck bra wire, but the drum continued to spin, only there was an extraneous sound. I had to turn it off, take out all the laundry and use tweezers to remove the bone. There were no more problems. It turns out that most problems can be solved independently and it is not necessary to contact the service.

Just yesterday I watched a program where they showed how a belt comes off, and that this is a common cause of failure of washing machines. But still, I wouldn’t risk repairing it myself or trusting my husband to find the reasons for the machine’s breakdown. I would rather entrust this issue to the master, since he knows what spare parts are needed for repairs and where to quickly get them. After all, staying without a washing machine for several days is very, very difficult.

The article is useful. And the problem turned out to be a simple one - engine brushes! The car, Siltal SL348X, is 22 years old (!), over the last year a situation with the drum stopping began to appear. Then I could continue working again, and the other day I stood up completely. It pours, heats, doesn’t turn, drains :)

The brushes were worn out to the limit, they simply hung over the commutator. Replaced without removing the engine. The machine is in the “on its side” position, do not forget to turn off the water, disconnect the water hose and unplug the machine from the outlet!

Hello, yesterday the Bosch maxx 4 washing machine broke down; 2001 release - there was a pop/click, the machine turned off, and the machine on the dashboard turned off. The electrician on duty said that everything was fine from the panel to the socket, the socket was working, but it still didn’t turn on. Further, after unloading the laundry and draining the water, I noticed that the drum began to turn with effort. What could have happened? Is there any point in repairing it and how much could it cost?! Thank you in advance.

Hello. It is very similar to a short circuit in the electric motor of the device. In your case, a diagnosis from a service specialist is necessary, since the problem can be both significant and completely fixable.

Very useful article. I replaced the brushes and filter and cleaned the filter myself. Everything worked! Thank you!

Model Candy Alise g04w264 (Italian assembly). The wash is in progress but the drum does not spin. Recently, the sounds of rubbing rubber appeared during the spin cycle. It turns by hand too easily; before, you had to apply a little effort. Please tell me what the most likely problem could be?