How to make a vacuum cleaner with your own hands: detailed instructions for assembling a homemade device

“He has golden hands” - this is what they say about craftsmen who are able to assemble a miracle of modern technology from scrap materials.Despite the abundance of inexpensive ready-made equipment in stores, self-taught craftsmen successfully design and create household appliances, units for the garden plot and very effective devices for the workshop.

It turns out that you can also assemble a vacuum cleaner with your own hands. The main thing is to understand the design, find the necessary parts and allocate some free time. We offer three interesting models for independent experiments.

The content of the article:

Construction vacuum cleaner from an old household one

If you constantly deal with technology, the design features and operating principles become clear.

And if necessary, you will no longer spend money on branded construction vacuum cleaner, and in a couple of evenings you will make a device whose characteristics are not inferior to the promoted “cleaner”.

This is what the author of the construction model, based on the failed Whirlwind vacuum cleaner, did. We invite you to get acquainted with the manufacturing process of a construction vacuum cleaner.

When making a homemade product, you should take into account the characteristics of the room and some nuances of the selection and fastening of individual structural elements. The following are useful guidelines for assembling a vacuum cleaner.

What will be needed for the remodel?

Literally all the products involved in the modernization have already been used and therefore do not require acquisition costs. If you don’t have any parts on hand, you can buy them for pennies on an online sales site or find them in a landfill.

True, it is still recommended to use a new filter - for high-quality operation of the vacuum cleaner, and also to buy some little things: a socket, parts for the electrical board, wires, fasteners.

The total cost of purchasing new parts was 800 rubles, and the most expensive element was the socket - 350 rubles. Parts for the board cost 250 rubles, the filter – 200 rubles.

In addition to the listed parts, you will need a socket, a piece of rubber car mat for laying, and a tool for the job:

- drill with a set of crowns and drills;

- screwdriver;

- jigsaw;

- pencil with ruler, compass.

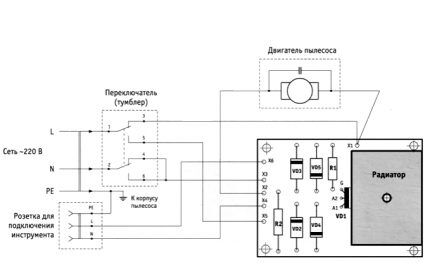

The fastening elements will be not only self-tapping screws, but also bolts, so to tighten the nuts you will need wrenches of the required size. To connect individual elements - switch, electronic board and network cable - you need to draw a diagram in advance.

In order for the improvement of an old device to please you with a successful result, you need to know how the vacuum cleaner is working. This way it will be clearer to the home craftsman what he is upgrading and for what purpose.

Step-by-step manufacturing instructions

When all the parts of the future unit and tools are prepared, you can begin assembly. But first you need to comply with safety standards - wear special clothing and work gloves.

Operating procedure:

- Step 1 - installing an outlet. Using a bit with a diameter of 42 mm, we drill a hole in the upper part of the lid. Between the socket and the body we place a rubber gasket cut from a car mat. For fastening we use self-tapping screws.

- Step 2 - installation of the electrical circuit. On the lid we drill small holes for the toggle switch and for attaching the circuit. The board should not touch the body, so we install it on stands cut from a fountain pen.

- Step 3 - attaching the toggle switch. As a result, a switch and socket for power tools must be installed on the outside of the cover, and an electronic board on the inside.

- Step 4 - Connecting the Power Cable. It is better to solder the cable, with two wires going to the switch, and the third grounding wire goes to a large mounting screw, to which the “ground” from the socket is already connected. This is necessary to ground the device.

- Step 5 – fixing the filter. We cut 95 mm holes in the bottom of the dust collector and in the lid of the tank, drill holes for screws around the circumference, cut out a plug from plywood, and tighten all the parts with screws. We fix the filter with a pin on the bar.

- Step 6 - installing the suction pipe. Use a 57 mm bit to drill a hole in the top of the tank. We insert into it a pre-assembled pipe with a flange, which can be constructed from a piece of sewer pipe.

- Step 7 – assembling the vacuum cleaner. We install a waste collection tank and close it with a lid so that the filter is inside. Then we attach part of the old vacuum cleaner with the motor and tighten it with a metal clamp.

- Step 8 - connecting the hose. Instead of a hose, you can use a plumbing corrugated pipe. We insert it into the connecting pipe, then turn on the unit. Testing can be done by removing sand or sawdust.

During testing, you need to pay attention to the suction power and tightness of the garbage container. If the parts do not adhere tightly to each other, the power of the unit will noticeably decrease.

But it is necessary to carry out one more test - with a power tool.

We insert the plug of the jigsaw or circular saw into the socket on the body and turn on the tool. Together with it, the vacuum cleaner should also start working automatically.

Cyclone vacuum cleaner for workshop

Another option for a construction vacuum cleaner, but with a more complicated design. This replacement for a commercial model is made from an old vacuum cleaner, a plastic container and cyclone filter.

The peculiarity lies inside the design - it is a metal casing to protect the filter.

The cost of homemade products is determined by spending on individual parts. An old, but working, household vacuum cleaner was found in the pantry, a plastic tank was purchased for 500 rubles, a filter for a Gazelle car - 180 rubles. It's easy to calculate the total cost.

About how to do cyclone for vacuum cleaner, you will learn from the article we propose. It describes the assembly process in detail.

Assembly order:

To check the functioning of the homemade unit, all that remains is to connect to the power supply. The suction power of the unit should be the same as that of the old vacuum cleaner, if the engine has retained its performance.

If you don’t have an old vacuum cleaner, you can buy a used model from an ad – online shopping portals offer many options. Most likely, an outdated device will cost no more than 1 thousand rubles.

Rated cyclone vacuum cleaners industrial production will be introduced in the following article, which is worth reading for both home craftsmen and future buyers.

Do-it-yourself portable “cleaner”

As an experiment, you can assemble a miniature vacuum cleaner, which will be useful for cleaning crumbs, dust or debris from tables, shelves, and window sills.

Tools and materials required for work: construction knife, hand jigsaw, glue gun, hot melt glue, marker, compass.

When manufacturing all components, it is necessary to adjust the parts to size so that there are no gaps after gluing - tightness is necessary for good suction.

To attach the fan, you need to cut off a piece of the syringe with a central needle and glue it in the center of the side opposite to where the blades are installed.

To check the operation of the device, pour crumbs, scraps of paper, and cereal onto the table. When turned on, the hose begins to suck in debris, which ends up in the lower can - the dust collector.

To clean it, you need to disconnect the cyclone part - essentially unscrew the bottle from the cork, and then simply remove the cap.

Conclusions and useful video on the topic

Another option for a mini vacuum cleaner:

Features of assembly and operation of homemade products:

An excellent replacement for the branded model made of plastic buckets and plumbing pipes:

As you can see, making a powerful construction unit or mini-vacuum cleaner yourself is not so difficult. The main thing is to be patient, study all the stages of manufacturing and find some free time for a home experiment.And the devices, as practice has proven, fully cope with their functions.

Please write comments in the block below. Ask questions about unclear and controversial issues, post photos related to the topic of the article. Tell us about how you assembled or upgraded a vacuum cleaner with your own hands; it is possible that your advice will be useful to site visitors.

I liked the portable handheld vacuum cleaner option. I might have used this if my husband had done it. But a homemade vacuum cleaner would hardly be useful to me, since I’m sure the quality would be poor. When cleaning it would definitely fall apart. Modern vacuum cleaners are assembled in factories and factories, that is, the parts are sealed tightly. And a homemade vacuum cleaner can fall apart at any moment.

Well, the factory versions are also very conditionally airtight; very high airtightness is not required there. And having the necessary equipment and skills, a vacuum cleaner can still be made no worse than a factory one, it’s more a matter of expended effort, time and money...

Well, this, of course, is more of a pampering or some kind of challenge - to make a vacuum cleaner with your own hands. I don’t think that in practice anyone would prefer a homemade vacuum cleaner to a store-bought one. Although, of course, situations in life are different and even such specific skills as the ability to make a vacuum cleaner can also come in handy somewhere. In any case, it is useful to understand how the equipment works; it can come in handy if repairs are needed.

Well, why, right now I’m going to make some kind of simple installation for assembling sawdust in the workshop. I will, of course, collect it not from scratch, but using an old Uralets vacuum cleaner.It has been sitting in the garage for ten years now because my parents bought a modern model at one time, and it was a pity to throw away a working item. I plan to adapt a cyclone type container to it.