How to choose fiberglass pipes: production specifics and review of leading manufacturers

Thanks to the combination of the positive characteristics of glass and polymers, fiberglass pipes have almost unlimited application prospects - from arranging ventilation ducts to laying petrochemical routes.

In this article, we will consider the main characteristics of fiberglass pipes, markings, manufacturing technologies of polymer composites and the compositions of binding components that determine the scope of operation of the composite.

We will also present important selection criteria, paying attention to the best manufacturers, because an important role in product quality is played by the technical capabilities and reputation of the manufacturer.

The content of the article:

General characteristics of fiberglass

Fiberglass is a plastic material that contains fiberglass components and a binder filler (thermoplastic and thermosetting polymers). Along with their relatively low density, fiberglass products have good strength properties.

Over the last 30-40 years, fiberglass has been widely used for the manufacture of pipelines for various purposes.

The highways combine the qualities of glass and polymers:

- Light weight. The average weight of fiberglass is 1.1 g/cc. For comparison, the same parameter for steel and copper is much higher – 7.8 and 8.9, respectively. Due to its lightness, installation work and transportation of material are facilitated.

- Corrosion resistance. The components of the composite have low reactivity and therefore are not subject to electrochemical corrosion and bacterial decomposition. This quality is a decisive argument in favor of fiberglass for underground utility networks.

- High mechanical properties. The absolute tensile strength of the composite is inferior to that of steel, but the specific strength parameter is significantly superior to thermoplastic polymers (PVC, HDPE).

- Weather resistance. Boundary temperature range (-60 °C..+80 °C), treatment of pipes with a protective layer of gelcoat ensures immunity to UV rays. In addition, the material is resistant to wind (limit – 300 km/h). Some manufacturers claim that their pipe fittings are seismically resistant.

- Fire resistance. Non-combustible glass is the main component of fiberglass, so the material is difficult to ignite. When burning, the poisonous gas dioxin is not released.

Fiberglass has low thermal conductivity, which explains its thermal insulation qualities.

As the inner walls are abraded, the fibers become exposed and break off - particles can get into the transported medium.

Technologies for manufacturing fiberglass pipes

The physical and mechanical characteristics of the finished product depend on the production technique. Composite reinforcement is produced by four different methods: extrusion, pultrusion, centrifugal casting and coiling.

Technology #1 - extrusion

Extrusion is a technological process based on the continuous pressing of pasty or highly viscous material through a forming tool. The resin is mixed with crushed fiberglass and a plastic hardener, and then fed into the extruder.

A high-performance extrusion line makes it possible to obtain frameless composite products at a low price, but demand for it is limited due to low mechanical properties. The basis of the polymer matrix is polypropylene and polyethylene.

Technology #2 - pultrusion

Pultrusion is a technology for manufacturing long composite elements of small diameter with a constant cross-section. Passing through a heated forming die (+140 °C), parts made of fiberglass material impregnated with thermosetting resin are “pulled out”.

Unlike the extrusive process, where the determining influence is pressure, in a pultrusive unit this role is played by the pulling action.

Technological process:

- Fiber threads from spools are fed into a polymer bath, where they are impregnated with thermoplastic resins.

- The treated fibers pass through a preforming unit - the threads are aligned and take on the desired shape.

- The unhardened polymer enters the die. Using several heaters, the optimal mode for polymerization is created and the drawing speed is selected.

The cured product is pulled by a drawing machine and cut into segments.

Distinctive features of pultrusion technology:

- polymers that can be processed — epoxy, polyester resins, vinyls;

- drawing speed — the use of innovative optimized “pultrusion” polymers allows speeding up broaching to 4-6 m/min. (standard – 2-3 m/min.);

- work area run-up: minimum – 3.05*1 m (pulling force up to 5.5 t), maximum – 1.27*3.05 m (pulling force – 18 t).

The output is a pipe with perfectly smooth external and internal walls, high-level strength characteristics.

The disadvantages of the method relate not to the quality of the initial product, but to the technology itself.Arguments against: high cost and duration of the production process, impossibility of manufacturing large-diameter pipes designed for significant loads.

Technology #3 - centrifugal casting

Swiss company Hobas developed and patented the centrifugal formation technique. In this case, production is carried out from the outer wall of the pipe to the inner wall using a rotating mold. The pipeline contains: crushed glass strands, sand and polyester resins.

Raw materials are fed into a rotating matrix - the structure of the outer surface of the pipeline is formed. During production, solid components, filler and glass fiber are mixed into the liquid resin - under the influence of a catalyst, polymerization occurs faster.

Additional advantages:

- high accuracy of dimensions of the initial product (the internal cross-section of the rotating mold corresponds to the external diameter of the finished product);

- the ability to cast a wall of any thickness;

- high ring rigidity of the polymer composite;

- obtaining a smooth surface outside and inside pipe fittings.

The disadvantage of centrifugal production of fiberglass pipes is energy intensity and high cost of the final product.

Technology #4 - progressive winding

The most popular technique is continuous winding. The pipe is created by alternating the mandrel with fiberglass and polymers with cooling processes. The production method has several subtypes.

Spiral ring technology

The fiber stacker is a special ring, around the circumference of which there are dies with threads.

The working element continuously moves along the axis of the moving frame and distributes the fibers along the helical lines.

Main advantages of the method:

- uniform strength over the entire surface of the highway;

- excellent tolerance to tensile loads - cracks are excluded;

- creation of products of variable diameters and sections with complex configurations.

This technique makes it possible to obtain high-strength pipes designed for operation under high pressure (pump and compressor engineering networks).

Spiral tape winding

The technique is similar to the previous one, the difference is that the stacker feeds a narrow ribbon of fibers. A dense reinforcing layer is achieved by increasing the number of passes.

The production involves cheaper equipment than the spiral-ring method, but “tape” winding has a couple of significant disadvantages:

- limited performance;

- Loose laying of fibers reduces the strength of the pipeline.

The spiral-tape method is relevant for the manufacture of pipe fittings under low, moderate pressure.

Longitudinal-transverse method

Continuous winding is carried out - the stacker places longitudinal and transverse fibers simultaneously. There is no reverse movement.

Characteristics of the method:

- used primarily when creating pipes with a cross section of up to 75 mm;

- there is the possibility of tensioning the axial threads, due to which strength is achieved, as with the spiral method.

Longitudinal-transverse technology is highly productive. The machines allow you to change the ratio of axial and ring reinforcement in a wide range.

Cross-layer cross-longitudinal technology

The development of Kharkov engineers is in demand among domestic manufacturers. With oblique winding, the stacker produces a “veil” consisting of a bundle of connecting threads. The tape is fed onto the frame at a slight angle, overlapping with the previous turn - a ring reinforcement is formed.

Upon completion of processing of the entire mandrel, the fibers are rolled with rollers - the remaining binding polymers are removed, and the reinforcing coating is compacted.

Features of oblique knurling:

- density of glass fibers;

- unlimited diameter of produced pipes;

- high dielectric properties due to the absence of continuous reinforcement along the axis.

The modulus of elasticity of “cross-layer” fiberglass is inferior to that of other techniques. Due to the risk of interlayer cracks, the method cannot be implemented when creating pipelines under high pressure.

Parameters for choosing fiberglass pipes

The choice of glass composite pipes is based on the following criteria: stiffness and design pressure, type of connecting component, design features of the walls and connection method.Significant parameters are indicated in the accompanying documents and on each tube - abbreviated markings.

Hardness and pressure rating

The rigidity of fiberglass determines the ability of the material to withstand external loads (heaviness of the soil, traffic) and pressure on the walls from the inside. According to ISO standardization, pipe fittings are classified into several stiffness classes (SN).

The degree of rigidity increases as the wall thickness of the fiberglass pipeline increases.

Classification by nominal pressure (PN) displays the gradation of products relative to the safe liquid pressure at a temperature of +20 ° C throughout their entire service life (about 50 years). The unit of measurement for PN is MPa.

Some manufacturers, such as Hobas, indicate combined characteristics for two parameters (pressure and hardness) using a fraction. Pipes with a working pressure of 0.4 MPa (class PN - 4) with a degree of hardness (SN) of 2500 Pa will be marked - 4/2500.

Type of binder material

The performance properties of the pipe largely depend on the type of binder. In most cases, polyester or epoxy additives are used.

Features of PEF binders

The walls are formed from thermosetting polyester resins reinforced with fiberglass and sand additives.

The polymers used have important qualities:

- low toxicity;

- curing at room temperature;

- reliable adhesion to glass fibers;

- chemical inertness.

Composite pipes with PEF polymers are not subject to corrosion and aggressive environments.

Characteristics of epoxy resin

The binder gives the material increased strength. The temperature limit of composites with epoxides is up to +130 °C, the maximum pressure is 240 atmospheres.

An additional advantage is almost zero thermal conductivity, so the assembled lines do not require additional thermal insulation.

Wall design of composite pipes

According to their design, they are divided into: one-, two- and three-layer fiberglass pipes.

Characteristics of single-layer products

The pipes do not have a protective lining, due to which they are low in cost. Features of pipe fittings: impossibility of use in regions with difficult terrain and harsh climate.

Also, these products require careful installation - digging a large trench, arranging a sand “cushion”. But the cost of installation work increases because of this.

Features of double-layer pipes

The products are lined from the inside with a film coating - high-density polyethylene. The protection increases chemical resistance and improves the tightness of the line under external loads.

However, the operation of valves in oil industrial pipelines has revealed the weaknesses of two-layer modifications:

- insufficient adhesion between the structural layer and the lining - violation of the solidity of the walls;

- deterioration of the elasticity of the protective film at sub-zero temperatures.

When transporting a gas-containing medium, the lining may peel off.

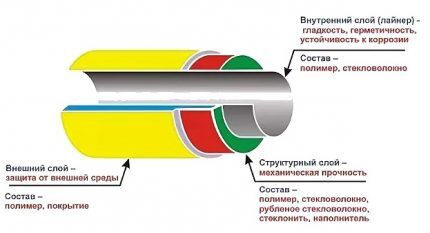

Parameters of three-layer pipe

Structure of fiberglass pipe:

- Outer polymer layer (thickness 1-3 mm) – increased mechanical and chemical resistance.

- Structural layer – a structural layer responsible for the strength of the product.

- Liner (thickness 3-6 mm) – inner shell made of fiberglass.

The inner layer provides smoothness, tightness and smoothes out cyclic fluctuations in internal pressure.

Method of joining fiberglass mains

Based on the connection method, the range of composite pipe fittings is divided into 4 groups.

Group No. 1 - socket-tenon joint

Elastic rubber gaskets are mounted in reciprocal grooves on the end spikes of the pipes. The seat rings are formed using electronically controlled equipment, ensuring precise placement and dimensions.

Group No. 2 - bell-tenon with seal and stopper

When constructing an above-ground pipeline, it is necessary to compensate for the effect of axial forces on the pipeline. For this purpose, in addition to the seal, a stopper is placed.The element is made of metal cable, polyvinyl chloride or polyamide.

Group No. 3 - flange connection

Joining a composite pipeline with shaped fittings or metal pipes. The connecting dimensions of fiberglass flanges are regulated GOST 12815-80.

Group No. 4 - adhesive fixation

Permanent connection method - a composition of reinforcing glass materials with the addition of a “cold” curing polyester component is applied to the ends. The method ensures the strength and tightness of the line.

Marking of the protective inner layer

The method of production of pipe products makes it possible to produce products with different compositions of the inner layer, which determines the resistance of the pipeline to the transported medium.

Domestic manufacturers use the following markings for protective coatings.

The letter designation reflects the permissible scope of use:

- A – transportation of liquid with abrasives;

- P – supply and removal of cold water, including drinking water;

- X – use in chemically aggressive gas and liquid environments is permissible;

- G – hot water supply systems (limit 75 °C);

- WITH – other liquids, including those with high acidity.

The protective coating is applied in a layer of up to 3 mm.

Review of products from leading manufacturers

Among the variety of products presented, there are reputable brands with many years of positive reputation. These include products from the following companies: Hobas (Switzerland), Steklokompozit (Russia), Amiantit (a concern from Saudi Arabia with production facilities in Germany, Spain, Poland), Ameron International (USA).

Young and promising manufacturers of composite fiberglass pipes: Poliek (Russia), Arpipe (Russia) and Fiberglass Pipe Plant (Russia).

Manufacturer #1 - HOBAS brand

The brand's factories are located in the USA and many European countries. Hobas group products have earned worldwide recognition for their excellent quality. GRT pipes with a polyester binder are manufactured using centrifugal casting technology from fiberglass and unsaturated polyester resins.

Characteristics of Hobas composite pipes:

- diameter – 150-2900 mm;

- SN-hardness class – 630-10,000;

- PN pressure level – 1-25 (PN1 – non-pressure pipeline);

- the presence of an internal lining anti-corrosion coating;

- resistance to acidic environments over a wide pH range.

The production of shaped parts has been established: elbows, adapters, flanged pipes and tees.

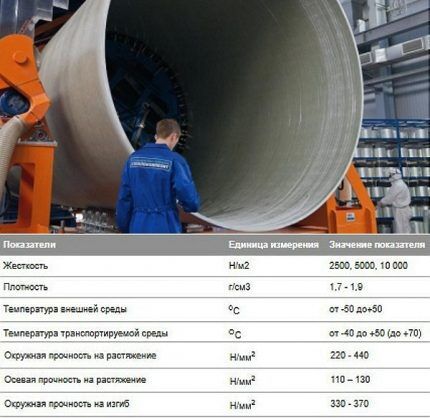

Manufacturer #2 - Steklokompozit company

The Steklokompozit company has set up a line for the production of Flowtech fiberglass pipes; the production technique is continuous winding.

Equipment with double supply of resinous substances is used.High-tech resins are used to lay the inner layer, and cheaper compositions are applied to the structural layer. The technique allows you to rationalize material consumption and reduce the cost of products.

Manufacturer #3 - Amiantit brand

The main components of Amiantit Flowtite pipes are: fiberglass, polyester resin, sand. The technique used is continuous winding, which ensures the creation of a multilayer pipeline.

The fiberglass structure includes six layers:

- external winding made of non-woven tape;

- power layer – chopped fiberglass + resin;

- middle layer – fiberglass + sand + polyester resin;

- re-layer power;

- lining of glass threads and resin;

- protective coating made of non-woven fiberglass.

The studies carried out showed high abrasive resistance - over 100 thousand cycles of gravel treatment, the loss of the protective coating amounted to 0.34 mm.

Manufacturer #4 - Poliek company

Poliek LLC produces various modifications of Fpipes pipe products made of fiberglass. The manufacturing technique (continuous oblique longitudinal-transverse winding) allows the creation of three-layer pipes up to 130 cm in diameter.

Polymer composite materials are used in the creation of casing pipes, links of water-lifting columns, water supply pipelines and heating systems.

In addition to fiberglass pipes, the market offers many products made from other materials - steel, copper, polypropylene, metal-plastic, polyethylene, etc. Which, due to their more affordable price, are actively used in various areas of domestic use - installation of heating systems, water supply, sewerage, ventilation, etc.

You can familiarize yourself with the characteristics of pipes made of various materials in our following articles:

- Metal-plastic pipes: types, technical characteristics, installation features

- Polypropylene pipes and fittings: types of PP products for pipeline assembly and connection methods

- Plastic ventilation pipes for hoods: types, their characteristics, application

- Copper pipes and fittings: types, markings, features of copper pipeline arrangement

- Steel pipes: types, range, overview of technical characteristics and installation nuances

Conclusions and useful video on the topic

Manufacturing technology and feasibility of using fiberglass pipes:

Comparison of continuous and periodic fiber winding techniques:

In private housing construction, fiberglass pipes are used quite rarely. The main reason is the high cost compared to plastic counterparts. However, in the industrial sphere, the quality of the composite is appreciated, and worn-out metal lines are being replaced en masse with fiberglass ones..

After reading our article, do you still have questions? Ask them in the comments block - our experts will try to give a comprehensive answer.

Or maybe you want to supplement the presented material with relevant data or examples from personal experience? Please write your opinion under this article.

At one time, I chose the wrong fiberglass pipes for the water supply and problems, of course they caused me a lot. They complained about particles of something unknown in the water, but they flowed constantly.

Has anyone used the products (fiberglass pipes) of this plant? — https://ntt.su

What can you say about the quality?

The article contains many inaccuracies regarding both methods and final characteristics. I hope the author did not allow them intentionally