Press fittings for metal-plastic pipes: types, markings, purpose + example of installation work

The connection of metal-plastic pipes is made using compression fittings for clamping and their analogues for crimping. Installation of pipelines in both cases does not require sophisticated equipment or highly qualified specialists.

The first method is easier to implement, but not as reliable. But press fittings for metal-plastic pipes make it possible to create a durable system with minimal risk of rupture.

Let's figure out what types of connecting elements are on sale, how to choose the right press fitting and install it.

The content of the article:

General description of couplings for crimping

A press fitting connection is one of the most reliable methods of joining metal-plastic pipes. As a result of this installation, the pipeline turns out to be one-piece, but very reliable. If after assembly you need to change its circuit, you will have to redo a lot from scratch, but leaks are practically excluded.

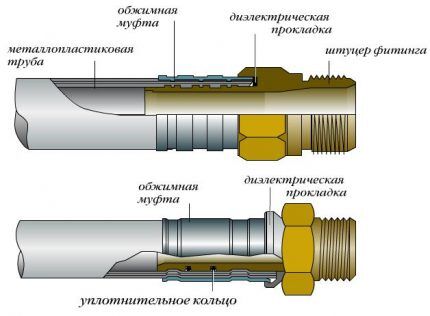

Press fittings are a permanent type of connection, obtained in this case by compressing a metal sleeve around an o-ring. In this case, as a result of the crimping performed, the ring is irreversibly deformed. It cannot be removed and then reused. The geometry of the pipe itself also changes slightly.

For metal-plastic pipes, fittings for crimping are made from the following materials:

- brass;

- stainless steel.

The first option is more preferable. It is more reliable and durable in conditions of high humidity.

Unscrupulous manufacturers often use aluminum and other soft metals to make the fittings in question. They can be easily identified by weight - brass in your hands is obviously heavier than these fakes.

It is strictly not recommended to use such products for crimping metal-plastic pipes. By definition, they are not able to tightly compress the fitting and pipe plastic.

Each manufacturer of metal-plastic pipes recommends purchasing its own set of press fittings. And for good reason. Pipe products and fittings from different manufacturers can vary in diameter by literally a millimeter.

Quite a bit, but this is enough to reduce the reliability of the connection. It’s better not to save money here, risking a break and leakage.

There is no single standard for the outlines and exact dimensions of fittings. Each manufacturer independently selects these parameters for their products.

Some sellers offer universal press fittings, but this is a banal advertising ploy. The use of such connecting parts is inevitable and will result in leaks in the near future after installation.

Types of press fittings for metal-plastic pipes

The connecting elements in question on the plumbing market are presented:

- crosses;

- tees;

- squares;

- couplings with a union nut;

- adapters with external and internal threads.

This variety of fittings allows you to assemble a metal-plastic pipeline of any configuration and purpose. There are no restrictions here.

According to the method of crimping the sleeve, press fittings are divided into crimp and push-in. In the first case, the ring is crimped with special pliers. In the second, it is pulled onto the fitting using a hydraulic or manual press.

Depending on their shape, press fittings are used for various purposes.

Type #1: Crimp

The sleeve on such a press fitting can be a separate element or a part immediately attached to the body.After the nozzle, the metal-plastic pipe is crimped onto the fitting press jaws. This tool is specialized and is not intended for other purposes.

It can be used exclusively for installing pipelines by squeezing a metal ferrule.

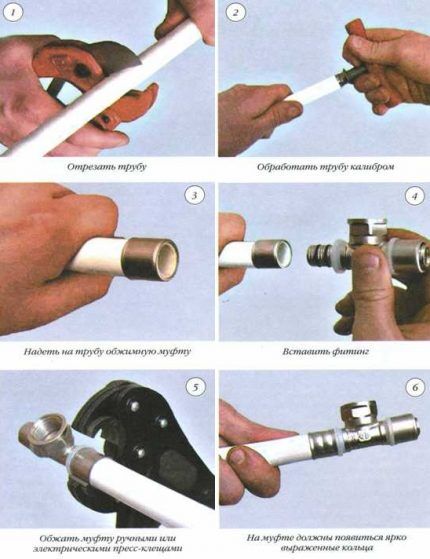

Installation of metal-plastic pipes using crimp press fittings is carried out as follows:

- The required pipe length is prepared - used for cutting pipe cutter for metal-plastic pipes.

- An internal chamfer is removed from the end of this segment.

- To get rid of ovality, which occurs as a result of squeezing the plastic with a cutting tool, a gauge is used.

- A crimp ring is placed on the pipe.

- A dielectric gasket and O-rings are placed on the fitting, and then it is pressed into the pipe.

- The metal coupling is crimped using press jaws.

If everything is done correctly, then two pronounced depressed stripes should form on the ring along the entire circumference. Moreover, these zones of maximum compression should not coincide with the places where rubber O-rings are located on the fitting.

When performing crimping, it is extremely important to avoid the formation of excess stress in the sealant material. It should not be excessively compressed.

Sealing gaskets are designed to compensate for temperature deformations in the pipe walls.If you squeeze them when crimping a press fitting, the rubber will lose its elastic properties, and then when the water temperature changes, the plastic will gradually begin to collapse.

As a result, instead of the 20–30 years declared by manufacturers, the press connection will last 5–10 at most.

The pipe must be pushed onto the fitting until it stops. To prevent the plumber from making a mistake here, many crimp couplings have small holes through which the white plastic is clearly visible. You just need to apply a little force and then crimp the fitting with pliers.

The resulting connection can be safely embedded in concrete. It will last as long as the metal-plastic pipes themselves without leaks.

Type #2: Press-on (slide-on)

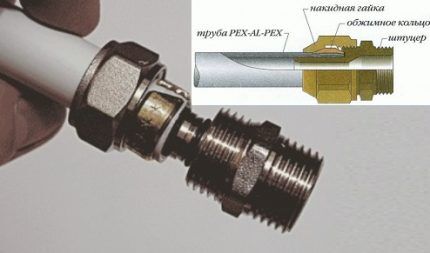

The second version of press fittings does not involve compressing the ring, but pulling it onto the pipe into which the fitting is inserted. Such a connection is no less strong than in the first case with crimping.

Only for the installation of metal-plastic pipes with fittings using the pressing method, not pliers, but a special press are used.

To connect metal-plastic pipes with press fittings, you need to perform four steps in sequence:

- Place a metal ring on the pipe.

- Expand the diameter of the pipe by treating its end with an expander.

- Insert the fitting into the place intended for it until it stops.

- Clamp the sliding coupling with the press jaws and press it onto the fitting.

This method involves using, in addition to a press tool, an expander. It is designed to expand the pipe at the cut point.Without this, it is impossible to pull it onto the fitting. All diameters are calculated in such a way that it is impossible to do this manually without prior preparation.

The reliability of the connection is ensured on the one hand by a sliding ring, and on the other by the properties of cross-linked polyethylene from which metal-plastic pipes are made. After expansion and attachment to the fitting, this plastic tries to return to its original dimensions.

There is an inevitable and tight compression of the fitting connector. And from above all this is still tightened with a metal ring.

For the installation of push-on press fittings, the tool is available both manually, battery-powered, and electric from the mains. If you have to connect a lot of pipes, then you should choose the second option. For one-time work, a cheaper manual analogue is quite sufficient. There is no special effort required when crimping this fitting.

Differences from compression analogues

Due to inexperience and ignorance of all the nuances of installing metal-plastic pipes, press fittings can be confused with compression fittings. They also have a fitting and a sleeve. Only the latter is crimped not with a tool, but using the union nut included in the design.

The main difference between these parts is the different type of connection resulting from installation. The compression version can be disassembled if necessary, but this cannot be done with a pressed version. The press fitting can only be cut off from the pipe to be replaced with a new one.

However, the likelihood of a leak in the press connection is practically zero. It is not for nothing that this installation method is recommended for use when installation of heated floors under the screed and when embedding pipelines into the wall.

Cases when such fittings begin to leak in concrete occur extremely rarely in the practice of plumbers.This is more of an exception to the rule.

On the other hand, installation of both types of press fittings requires specialized tools. And to tighten the nuts of compression products, you only need a pair of wrenches.

As a result, on one side of the scale there is “expensive tools + higher reliability of the joint”, and on the other “no extra expenses + a slightly higher risk of leaks”. The choice here is only up to the master and the owner of the house where the pipeline is being laid.

Features of installation and selection of fittings

Metal-plastic pipes made of cross-linked polyethylene are not initially intended for welding and gluing. The welds on them will still crack and come apart after a couple of months. And glue is not used due to the resistance of this plastic to solvents and its low adhesion. It remains to use only specialized fittings for installation.

When choosing a press fitting, the main attention should be paid to the crimp ring. It must be made of durable metal. And no seams on this metal surface, just seamless stamping. Any seam is a point for destruction.

It is better to immediately reduce or completely eliminate the likelihood of a pipeline rupture resulting in flooding of the house. There's no point in chasing cheap prices here.

The standard sizes of the press fitting are indicated in the markings both on the ring and on its body. Similar information is contained on the pipe. Everything must match.

Once again, you should not purchase fittings and metal-plastic pipes different manufacturers.In most cases, such inconsistency leads to problems both at the installation stage and then during operation.

After crimping the fitting, the pipe must not be bent near the latter. This may place unnecessary stress on the connection. It is also unacceptable to apply any lateral force to the press fitting. It itself will not be damaged, but the plastic nearby may collapse.

Additional information on installation and crimping of metal-plastic pipes is provided in the articles:

- Do-it-yourself installation of metal-plastic pipes: connection technology + wiring examples

- Pressure testing of metal-plastic pipes: instructions and tips for performing the work

Conclusions and useful video on the topic

Installation of the fittings in question should not cause problems. However, there are still nuances when connecting metal-plastic pipes with them. And before starting work, we recommend watching the video instructions below to avoid beginner mistakes.

Comparison of crimp compression fittings and press fittings:

Step-by-step instructions for crimping press fittings:

Review of the pros and cons of compression fittings:

Manufacturers of metal-plastic pipes provide a guarantee for their products for up to half a century. However, a pipeline system made from them will work properly all these decades only if the fittings are installed correctly. Don't skimp. To assemble a metal-plastic pipeline, you should purchase only high-quality connecting parts.

Press fittings must be compatible with the pipes being installed. The best option is when all components are made by one manufacturer. Fortunately, there is a wide choice of them on the market now, there is plenty to choose from.

Do you have anything to add or have any questions about the use of press fittings for metal-plastic pipes? Please leave comments on the post. The contact form is located in the lower block.

What specific fittings for metal-plastic pipes can you recommend? The price is not important (within reasonable limits), the main thing is the quality.

If you are interested in specific manufacturers, then everything is not so simple. The rule, the more expensive, the better, in this case it is better not to apply. And for a lot of money, believe me, you can buy a frankly bad fitting.

It is still not entirely clear what type of connection you are interested in:

- compression fitting;

— coupling;

- saddle insert;

- corner fitting, etc.

Metal or propylene? What is the material of the fitting? If you just need to recommend normal manufacturers in terms of price/quality ratio, then these are: Koer, Klondajk.