Do-it-yourself setup and repair of gas water heaters: a guide for water heater owners

Isn’t it true that after spending money on installing a water heater, you want the house to always have hot water at a given temperature? But even the most modern equipment fails. What to do if an icy stream flows from the tap or, on the contrary, boiling water?

Is it possible to repair gas water heaters yourself or is it better to call a gas specialist? Let's decide together what problems with water heating equipment can be solved independently. Let us analyze and list for which problems a specialist is required.

From the article we presented, you will learn how to restore the performance of a gas unit and how to set it to optimal mode. We will introduce you to the typical design of devices running on blue fuel and their typical operational errors.

The content of the article:

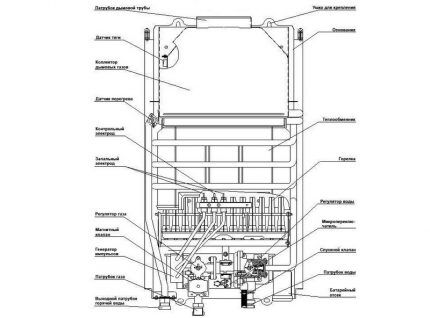

Construction of gas water heaters

To repair any equipment, you need to know its design features.

For municipal and domestic needs, gas water heaters of 3 main types are used:

- accumulative;

- flow-through;

- combined.

Most Popular gas instantaneous water heaters. Abbreviated as GPVN. GOST defines them as instantaneous water heaters. In such devices, water is heated only when the tap is turned on.

Technical requirements for household instantaneous gas water heaters equipped with atmospheric burners are established by GOST R 51847-2009. Their classification is also given there.

Features of diagnostics and repair

Manufacturers usually indicate in the accompanying documentation that repairs to the main air pump should only be performed by service company employees.

In accordance with labor safety requirements, such work is performed by adults who have undergone professional training and have a license from Gospromnadzor.

If you nevertheless decide to eliminate minor defects yourself, you should remember the explosion hazard and suffocating effect of liquefied and natural gas, be prepared for emergency situations, and be able to use fire protection equipment.

[adinserter name=”mobile: insert in text -2″]Please note that the same problem in equipment operation can be caused by different reasons. For example, you open a hot water tap, but the gas water heater does not turn on. This may be due to dirty filters, breakdown of controls and about a dozen other reasons.

Both home craftsmen and representatives of service companies face diagnostic difficulties. But gas workers have experience and professional equipment, which makes solving the problem much easier and faster. The home handyman is often armed only with a screwdriver and an adjustable wrench.

Before you begin self-repair, adequately assess your resources and weigh the pros and cons. This will help save time and avoid risks.

If the warranty period has long expired, you can perform the simplest steps to restore the functionality of the gas water heater yourself. When identifying the causes of malfunctions, there is no need to immediately dismantle and disassemble the device.

Proceed from simple to complex, first check:

- are the water and gas shut-off valves open?

- is there gas in the cylinder (if the dispenser runs on liquefied fuel);

- whether the batteries are installed correctly in the battery compartment and whether there is a charge.

This principle works for most common faults. In the future, we will not return to it, believing that you have already carried out the initial diagnosis, but were unable to get by with a little bloodshed.

Why doesn't water heat up well?

Over time, the burner channels accumulate dust, and soot is deposited on the fins of the heat exchanger. As a result, the actual heating output drops and barely warm water flows from the tap. Related problems: the column does not turn on, the burners smoke and go out spontaneously.

The thermal conductivity of stainless steel and copper, from which the heat exchangers are made, is 45 and 401 W/m2×K, respectively. These indicators vary slightly depending on the grade of metal. The thermal conductivity of scale is much less - only about 0.2 W/m2×K.

This means that even a small deposit on the walls of the heat exchanger leads to a decrease in heat transfer. As a result, the water heating time increases. Deposits reduce the diameter of the flow area, which reduces the flow of water.

How to clean the heat exchanger?

At home, the chemical method is mainly used. It is universal and suitable for both collapsible and welded/brazed heat exchangers. Special detergents are used that do not react with metal, but dissolve carbonate deposits.

Before cleaning you must:

- shut off the gas and water supply;

- drain the remaining water by turning on the tap;

- remove the protective cover;

- disconnect the supply pipes and wires;

- remove the heat exchanger.

Pour warm water with some dishwashing detergent into a deep basin. Place the heat exchanger and gas burner unit in the basin. Use a soft brush to clean soot from the radiator grille, rinse the parts with a stream of clean water, not forgetting about the channels through which gas is supplied to the burner.

The plate heat exchanger can be carefully disassembled before cleaning. At the same time, do not miss the opportunity to inspect it and assess its condition.If the wear of the plates is significant, it is better to replace them immediately. If there is a small layer of scale, instead of special liquids, you can use ordinary table vinegar or a solution of citric acid.

The washing time varies from 30 minutes to a day or more, depending on the properties of the detergent and the thickness of the deposits. After removing contaminants, the thermal performance indicators of the column must correspond to those specified in the passport.

Preventing scale formation

Using mixers in a water supply system involves mixing cold and hot water. This method leads to accelerated scale formation. It is recommended to use a separate tap for hot water, and a gas flow regulator will help to increase or decrease its temperature.

If, when heating water, its temperature often rises above 60 degrees, scale forms faster. Do not fill the bathtub with boiling water and then dilute it with cold water. Set up the device correctly, and water at a comfortable temperature will flow straight from the tap. The recommended temperature for baths and showers is between 37-42 degrees.

The rapid accumulation of soot is caused by prolonged heating of water at maximum burner flame, poor draft chimney, incomplete combustion of gas and the presence of impurities in it.

What to do if the speaker does not turn on?

Have you opened the hot water tap, but there is no spark and the instantaneous gas water heater does not ignite? It is possible that carbon deposits have formed on the electrodes of the spark plugs. In many models, these parts can be cleaned through the viewing window using a long-handled brush.

Sometimes water heaters do not work due to weak water pressure. Check the filter and, if necessary, clean it or replace it, rinse the heat exchanger.Open the shut-off valve completely. If the pressure remains weak, contact the management company (housing and communal services).

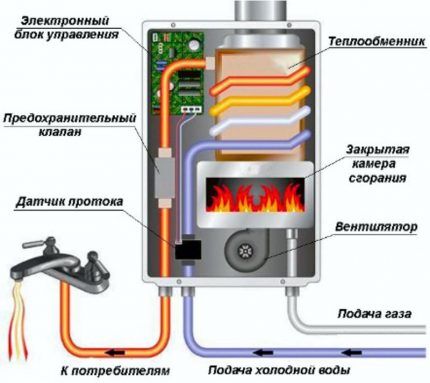

Difficulties in igniting a gas water heater are often caused by damage to the elastic membrane located at the beginning of the water circuit. When the tap is opened, a pressure difference occurs, which causes the membrane to bend and act on the gas valve through the rod. As a result, gas flows to the burners.

With repeated bending, the membrane wears out, stretches, tears and no longer performs its functions properly. Losing elasticity or integrity, it is not able to press on the rod with sufficient force. The gas valve does not open or does not open completely.

Due to lack of fuel, the water heater does not work. The membrane replacement algorithm is as follows:

- shutting off the water and gas supply;

- removing the casing;

- disconnecting pipes and wires;

- removing and replacing the membrane;

- reverse assembly.

Upon completion of work, use a soap solution to check the tightness of the detachable joints.

The burner goes out spontaneously

A water heater with an open combustion chamber turns on normally, but during operation its nozzles go out. This problem may be due to a lack of air, which is taken directly from the room where the device is located.

When plastic windows are tightly closed, air exchange with the street is difficult, which leads to the protection system being activated and the burner flame going out.

Open the window slightly, wait about 10 minutes and turn on the speaker. If it goes out again, check the combustion products path.For water heaters with atmospheric burners, these are the usual chimneyswith natural traction.

Gas workers check draft using an anemometer. The device allows you to determine the volume of air passing through the chimney. Home craftsmen use thin paper, which must be cut into strips about 2 cm wide and about 20 cm long and brought to the chimney inlet at a distance of 5 cm.

You must first turn off the column, remove the gas exhaust pipe and open the window. If the paper strips are not carried away by the air flow and do not touch the chimney inlet, then it is time to clean it.

Please note that in case of leaks, gas accumulates in the outlet shafts. Therefore, you should not tempt fate by testing your traction with a burning match, candle or lighter.

The burner operates with the tap closed

Have you turned off the hot water tap but the burner won't go out? Most likely, the gas or water circuit rod is jammed. This is the case when you cannot do without specialists.

But first of all, it is necessary to block the access of gas to the device by closing the shut-off valve on the gas main, and only then call the service department.

Leakage through detachable connections

The shut-off valve is installed on the cold water supply pipe using a union threaded nut. The pipe through which hot water enters the plumbing system is connected to the heat exchanger pipe in a similar way.

Before replacing the gasket, the column is turned off, the water in the water supply system is turned off, the nuts are unscrewed, the worn gaskets are removed and new ones are installed in their place.

The water heater is very noisy

Serviceable gas equipment operates very quietly and this is one of its advantages.

Increased noise levels indicate excessive water flow in the heat exchanger or overheating.

Measure the water temperature in the tap and, depending on the result, adjust the water or gas flow downward.

Security issues

To ensure that gas pumps meet safety requirements, manufacturers equip them with a variety of sensors. If the burner goes out for some reason and gas continues to flow, the gas-air mixture may explode.

This development of the situation helps to prevent the presence of a flame sensor. Ionization currents arise between its control electrode and the burner flame, on the basis of which discrete signals are generated. If there is no flame, the shut-off valves are activated and the gas supply is stopped.

If the sensor is installed in such a way that the electrode touches the burner parts or is located too far from the flame, its correct operation becomes impossible. This causes the speaker to turn off. To solve the problem, it is enough to change the location of the electrode.

To control the water temperature, an overheating sensor is installed on the heat exchanger tube. Usually it is a thermal relay with bimetallic temperature-sensitive elements.

When the water temperature approaches the boiling point (85°C), the shape of the temperature-sensitive elements changes, which opens the electrical power circuit of the electronic unit and the column turns off.

A breakdown of the overheating sensor or a break in the electrical circuit lead to premature shutdown of the column, even if the water has not had time to heat up.

Having ruled out other possible causes of the malfunction, use a multimeter to check the integrity of the current-carrying conductors of the electrical circuit. If there are no breaks, check the sensor and, if necessary, replace it with a serviceable one.

To do this, disconnect both wires from the sensor and unscrew the mounting screws that secure the device to the heat exchanger. Now all that remains is to remove the old sensor and install the new one.

Pressure testing of the water circuit

After repairing a gas water heater with disassembling the water circuit, you need to check the tightness of the pipes and joints. The most effective method is crimping. Fill the circuit with water, the temperature of which is from 5°C to 25°C. The air temperature in the room should be above 0°C.

Using a manual or electric pump, raise the pressure in the circuit to the test value. Hold for at least 5 minutes, monitoring the pressure using two pressure gauges pre-installed at two points in the system.

If the pressure has not dropped by more than 10%, the water circuit is considered tight. Otherwise, the faults are diagnosed again, and after they are eliminated, a leak test is repeated.

The test pressure is 1.5-2 times higher than the working pressure specified in the water heater passport. The exact values for different types of columns can be easily found in GOST R 51847-2009. They cannot be exceeded, therefore during pressure testing it is necessary to carefully monitor the operation of the pumping equipment.

Adjusting temperature and water flow

Speakers equipped with an electronic control unit and a display for displaying current information are becoming increasingly popular. Thanks to this technical solution, setting up a gas water heater consists of selecting the desired mode, which is then maintained automatically.

Speakers with a mechanical control system are equipped with rotating handles located on the front of the housing. One of them serves to regulate gas flow, the second regulates water flow. A number of models also have a third handle – “winter/summer”.

When the pressure in the water supply network is low, the water flow knob is set to minimum. If the inlet water pressure is normal, the knob can be set to maximum.

The temperature of the water entering the tap from the column directly depends on the gas flow. To reduce or increase it, gas consumption is reduced or increased accordingly.

The adjustment process is as follows:

- close the gas supply valve;

- set the gas flow knob to minimum;

- open the gas supply valve;

- turn on the hot water tap;

- Allow a few minutes to heat up;

- measure the temperature of the water coming from the tap;

- if the water is not hot enough, turn the gas flow knob one notch;

- Continue adjustment until the required water temperature is reached.

If the heating capacity of the water heater does not allow heating the water to the required temperature even at maximum gas flow, tighten the water supply shut-off valve a little. The volume of water entering the column will decrease and its temperature will increase.

The combination of minimum water flow and maximum gas flow can lead to overheating, tripping the protection system and shutting down the burner. In this case, you need to change the settings a little to achieve the optimal balance.

In winter, the water temperature in the water main can drop to 4 degrees, and in summer it can rise to 20 degrees or more. To avoid overheating or underheating of water during seasonal temperature changes, many modern columns are equipped with an additional handle. It must be promptly installed in a position appropriate to the time of year.

Conclusions and useful video on the topic

Owners of instantaneous water heaters sometimes encounter difficulties when igniting - they cannot light the spark plug the first time. You can solve the problem yourself:

If the solenoid valve fails, the gas supply to the burners is stopped, the security system is activated and the column is turned off. You can check the serviceability of this component yourself:

Owners of gas water heaters simply need to know the design of the devices in order to promptly understand what the problem may be and prevent its occurrence.It is worth familiarizing yourself with typical malfunctions that occur during operation. It is possible that you will be able to eliminate simple problems in your work yourself.

Please write comments in the block below, post photos related to the topic of the article, and ask questions. Tell us how you dealt with gas water heater problems yourself. It is possible that site visitors will be able to use your advice.