Insulation of the ceiling in a private wooden house from the inside and outside: choosing the best material and installation nuances

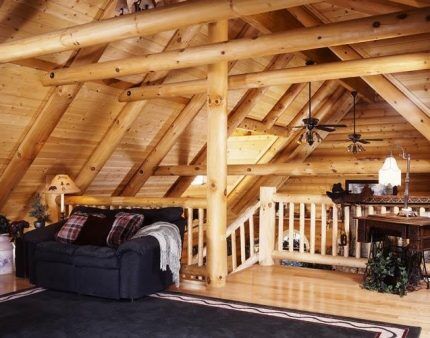

Although a wooden house is warm in itself, the upper enclosing structure in it is the weak link, unless the attic is heated, but this happens extremely rarely. Therefore, it is important to timely insulate the ceiling in a private home, which will help reduce heat costs and save on heating your home.

There are several options for thermal insulation of the ceiling. To decide on the optimal insulation and the method of installing it, you need to evaluate the pros and cons of each method, don’t you agree? We suggest that you look into this issue in order.

In the article, we examined in detail the technologies for carrying out thermal insulation work using different types of insulation, and outlined the characteristics and operational features of the materials. In addition, they told us when it is better to use external and when internal ceiling insulation, and provided advice on choosing a thermal insulation layer.

The content of the article:

Methods for insulating a wooden ceiling

Based on the location of insulation installation, all existing thermal insulation technologies are divided into two categories: internal and external.

Each of them has its pros and cons.The first method is more economical, but you will have to sacrifice the useful volume of rooms. And in the case of external insulation, the floor is usually reinforced, and then the attic flooring is installed.

Insulation on the outside is a risk of damage from any mechanical influences, so additional protection is necessary. In this case, you cannot do without vapor and waterproofing, which will also entail an increase in the cost of the insulating layer.

The best materials for external insulation

The industry produces a wide range of insulation materials. Each of them has its own properties, positive and not quite qualities. First of all, environmental friendliness is important - they should not harm health.

It is important that the insulating layer does not create excessive load on the ceiling structure and copes well with the task of retaining heat. Also, it should not accumulate condensation on itself and be resistant to fire.

The material used for insulation is divided into 4 categories:

- bulk — this group includes ecowool, expanded clay, sawdust;

- slab — these are expanded polystyrene, dense mineral wool sheets, cork plates;

- roll — all types of mineral wool;

- sprayed or poured — here we are talking about penoizol.

Let us consider in detail the characteristics of the main materials used as insulation.

Sawdust as insulation

Despite the fact that there are a great many new materials, the relevance of sawdust remains the same. They are easily accessible, cheap, and the quality is not inferior to expensive thermal insulators.

You need sawdust that can be stored for no more than a year, dry, odorless and mold-free, of medium size. The volume of material is determined based on the area to be insulated.

Alternatively, sawdust is soaked in a solution of copper sulfate. Afterwards, drying will be required, and then a mixture of wood material and cement will be prepared.

Make a cement mortar in a ratio of 1:10 - for every one and a half buckets of liquid add 10 buckets of sawdust. The result is a bright gray and wet mixture. It is subsequently distributed along the plane of the ceiling. The recommended height of the insulation layer is 20 cm.

To improve the adhesion of the thermal insulation to the ceiling surface, the layer can be lightly trampled, it will become compacted and will retain heat better. When the solution of shavings and cement dries, you can walk on it.

Sometimes, before mixing sawdust with cement mortar, lime or gypsum is added. This makes the insulation invulnerable to rodent attacks and increases its fire safety.

Ceiling insulation with expanded clay

Another old, but not completely forgotten method of insulation is a layer of expanded clay on the ceiling. The complete environmental friendliness of the material is attractive, since expanded clay is simply high-strength balls made from baked clay.

The material is durable, resists deformation well, absorbs moisture, which subsequently evaporates. An attic insulated in this way is always dry, which is why wooden structures last longer.

The thermal insulation characteristics of expanded clay are still lower than those of the latest generation of insulation materials.

Fine and medium fraction material is better suited. Before laying it, the surface is cleaned of anything foreign and covered with glassine or a special membrane.

Expanded clay is poured over the hydro-vapor barrier layer. Next, it is advisable to cover the surface with board or plywood. You can also use OSB boards. Another suitable option is a cement screed.

Expanded polystyrene boards for ceilings

The heat-retaining properties of polystyrene foam are much higher than those of bulk materials. Since the slabs are lightweight, they place minimal load on the ceiling structure.

It is easy to work with this material. It cuts easily, so it is not difficult to fit it to the openings. Sheets of different thicknesses are available for sale.

Since this insulation does not allow air to pass through well, it must be separated from wooden structures with a vapor barrier material. Otherwise, condensation will certainly appear.

Gaps at the joints are also a disadvantage of this insulation method. Heat is lost through them, so you cannot do without using polyurethane foam.

Lay the material as follows:

- The base is cleaned and a vapor barrier is placed on it.

- They give sheets of expanded polystyrene the desired geometry and dimensions.

- Lay out the material, pressing it tightly to the base.

- Fill the joints with polyurethane foam.

- Remove excess frozen foam.

If the attic is going to be used, a finishing coating in the form of a reinforced concrete screed of at least 50 mm thickness is laid on the slabs.

Although polystyrene foam is of unnatural origin, it does not emit harmful substances during operation. This material does not rot, does not corrode, and does not contribute to the appearance of fungus or mold.

The average service life of the material is 20 years. Negative property - fragility, instability to chemical reagents.

Rolled mineral wool

Mineral wool in rolls has the lowest density - 1-11 kg/m3. This is explained by the fragility of the fibers. If you make the material dense, it will not curl into a roll. Mineral wool is a non-combustible material.

Since it is easy and convenient to install, this material is most often used. With its help, you can insulate the ceiling in a wooden house both outside and inside. It won't cost very much.

The fibers in glass wool are arranged randomly, which provides both high thermal protection and noise insulation. There are separate lines of materials that absorb sound vibrations.

As a minus, low moisture resistance can be noted.This material cannot be compacted, since the air contained between the fibers will escape and the thermal conductivity will be significantly reduced.

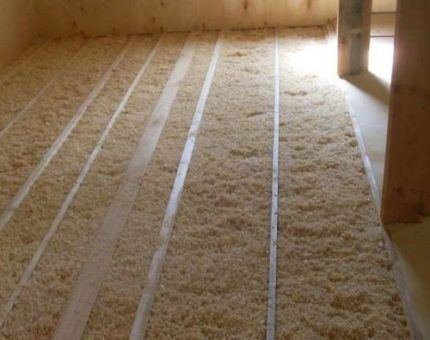

The installation technology is also simple:

- The surface of the ceiling is cleaned, and nails protruding from wooden structures must be removed or hammered in over the entire length.

- Lay a vapor barrier film.

- Lay the mineral wool, trying not to leave any gaps.

- Cover the mineral wool with a polymer film or foil material.

If you plan to periodically walk through the attic, you need to arrange a wooden flooring, securing it in such a way that it does not put pressure on the insulation layer.

Some types of mineral wool contain phenol. However, if you do not go beyond the accessible temperatures, this dangerous substance will not be released.

Features of insulation with foam insulation

Penoizol is foam plastic in liquid form. It belongs to those materials that cannot be used without special equipment. It is poured or sprayed, depending on the type of installation.

In addition to equipment, you need a protective suit. It is difficult to do the job without professional skills.

The main advantage is that the material fills not only all the cracks, but also microcracks. In addition, it is safe, non-flammable, and rodents are not interested in it. The structure of the material contains many air bubbles, which guarantees excellent insulation.

Schematically the technology looks like this:

- a vapor barrier is laid on the surface;

- fill the gaps between the beams with foam insulation with a layer of about 25 cm;

- lay a layer of roofing felt or other similar material;

- lay a plank finishing covering.

Negative quality - fragility, mechanical stress on the material is contraindicated. High cost also cannot be attributed to the advantages of penoizol.

Internal ceiling insulation

It is easier to insulate the ceiling of a wooden house from the outside; internal insulation work is somewhat more complex.

This method is attractive because less materials are consumed, the work can be done together with finishing and at any time. This reduces financial costs.

Although the method of internal insulation of a ceiling structure is effective, it is not worth implementing it if the ceiling has recently been repaired in the house.

Option #1 - insulation from the inside with mineral wool

Rolled mineral wool will be used for insulation.

The process consists of 11 sequential steps:

- Marks are placed on the ceiling in the corners. The best solution is to use a laser level for this.

- The marks are transferred to the walls to the desired height, taking into account the height of the profile and the thickness of the roll.

- A line is drawn along the marks using a cord.

- The profile is fastened along the line with self-tapping screws.

- Apply the CD profile to the ceiling, measure the required length, and install it at a distance of 40 cm from each other.

- For each profile, U-shaped hangers are attached at a distance of 70-90 cm.

- Pull the fishing line from the edge of every third profile.

- The profile is screwed to the suspension along the fishing line. The remaining profiles are fixed using a level or rule, based on the previously fixed profile.

- Mineral wool is placed between the profile. The panels are fixed using hangers.

- Using self-tapping screws, screw the sheets of drywall in a checkerboard pattern. A 5 mm gap is left around the perimeter of the ceiling.

- The joints in the places left free are reinforced with a profile, and then covered with pieces of plasterboard.

Metal or wooden frame - additional costs. But this method of attaching insulation opens up wide possibilities for decorative finishing of the ceiling.

Option #2 - insulation with polystyrene foam

To obtain a perfectly smooth surface layer that retains heat well, polystyrene foam is used for insulation.

Method 1. To insulate the ceiling using the frame method, you need to prepare: wood screws, washers with a large outer diameter and foam plastic about 300 mm thick.

Sequencing:

- The ceiling is coated over the entire surface with a deep penetration primer and allowed to dry.

- They make markings.

- The foam is secured using self-tapping screws.

- The insulation is puttied with the application of a reinforced mesh with a mesh size of 2.5 mm.

- Apply a layer of finishing putty, then paint the surface.

Method 2. The foam is not screwed to the ceiling, but glued. For this purpose, use a polymer adhesive mixture or ordinary starting gypsum plaster. The main thing is not to knead a large amount at once, since the latter has a limited time of use.

The mixture is applied to one side of the foam sheet, placing it in slides in the corners, between them and in the center.

The sheet is pressed against the ceiling surface, its spatial position is adjusted using a building level. Having finished laying the first row, begin installing the second. At the same time, they try to avoid continuous seams.

If a full-size sheet is laid at the beginning of the first row, then a half-slab should begin the second row. Next, this entire structure is plastered twice, then covered with finishing.

Instead of polystyrene foam you can use extruded polystyrene foam — the material is characterized by high thermal efficiency, good strength and resistance to negative influences.

Option #3 - installing penofol on the ceiling

Penofol is an excellent option for insulating the ceiling from the inside of a wooden house. It consists of polyethylene foam and polished foil.

The installation sequence is as follows:

- Install a strong sheathing on the wooden ceiling.

- Attach penofol with the foil side facing the room. The material can be fixed with nails.

- Gaps are left on both sides of the insulating layer for ventilation.

- They arrange another crate.

- Attach drywall. Instead, you can use a suspended ceiling.

The thermal resistance of this material with a thickness of 0.3 cm is identical to the corresponding parameter of extruded polyurethane foam, which has a thickness of 3 cm. Penofol is used as an independent insulation and in combination with other insulation.

The two substances included in the structure of penofol are non-flammable, so they can be used indoors without any restrictions. It is a good sound absorber and does not allow moisture to pass through, so there is no need for additional moisture protection.

The disadvantages include the lack of rigidity, as well as the fact that it does not stick well. It has to be fixed with nails or staples, which reduces its performance properties. To compensate for this shortcoming, manufacturers began producing self-adhesive foam foam.

If the installation technology is violated, fungal or mold spores may develop in the insulation.

Option #4 - a combination of penofol and mineral wool

In order to perform such double insulation of the ceiling from the inside, a structure is assembled as if under plasterboard. Mineral wool is placed between the profiles. Penofol is fixed on top of the frame and secured to the supporting profile using self-tapping screws.

The strips are laid without overlap, but end-to-end. The joints are taped with foil tape. At the next stage, the sheathing is done with plasterboard, then the final finishing is performed.

Which insulation is better?

The quality of insulation of a wooden ceiling structure depends on which insulation is chosen and how well its installation is done.

The effectiveness of thermal insulation is best seen in cold weather. Everything is simple here - if it gets warmer, it means the thermal insulation is working.

Doubts can be dispelled with a little snow.It is left in the attic, if after a while it melts, everything is in order with the protection. When the snow has not yet fallen, you can place ice cream or ice from the freezer in the attic.

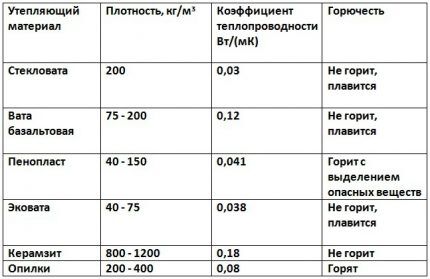

Based on the price of the material, then the best option for both external and internal insulation is mineral wool. As for the price tag, more economical options are sawdust and expanded clay, which are only suitable for installation outside.

To make your choice easier, you can use the table.

Polystyrene foam is also a relatively inexpensive material, but it is not entirely reliable from an environmental point of view.

It is also worth worrying in advance about the insulation of the floor in the house to prevent heat leakage through the lower ceiling. Practical recommendations for choosing the optimal thermal insulation material are given in this article.

In addition to using traditional insulation technology, you can use a more progressive and practical solution - install heated floors. Such a system can completely replace standard heating or become an effective addition to it.

Conclusions and useful video on the topic

Interesting ideas for ceiling insulation:

Nuances of insulating a timber ceiling:

If a wooden house does not have a living or insulated attic, you cannot do without insulating the ceiling. The ideal case is to insulate the floor during construction.

Installing an insulating layer in an already built house is somewhat more difficult, but still possible.It is important to follow the technology and take into account the features of the selected heat insulator.

Do you have personal experience insulating the ceiling in a wooden house? Do you want to share your accumulated knowledge, talk about the nuances of performing work, or ask questions on the topic? Please leave comments and participate in discussions - the feedback form is located below.

Does insulation with sawdust really do anything else? I understand, it’s cheap (maybe even free if you know someone at a sawmill or furniture shop somewhere), but still there are so many new materials.

Why not? The method is proven and has its advantages. Although sawdust has many disadvantages compared to modern materials. A high fire hazard is that they accumulate and absorb moisture. These disadvantages are partially mitigated if you make a mixture of sawdust with clay or gypsum and treat it with an antiseptic.