Film infrared heater: device, principle of operation, overview of types of IR systems

Heating systems for non-residential and residential premises are presented on the market in huge quantities.And among all this variety, the film infrared heater stands out for its high efficiency, long service life and increased operational safety.

The article we presented describes in detail the operating principle of the equipment used to form radiant heating. Advantages and disadvantages are listed, technical characteristics are given. We will introduce applications and methods of constructing popular film systems.

The content of the article:

Electrical appliances for IR heating

Abbreviation PLEN means “film radiant electric heater” or simply “film electric heater”. It is permissible to use IR heating film as both an additional and the main source of heat.

In fact, it is a film with internal heating elements that emit infrared waves as a result of the passage of electric current through them.

Advantages of the infrared principle

Heating of air masses in a room from one source or another can be carried out due to:

- thermal conductivity;

- convection;

- thermal radiation.

The first two principles of heat transfer are used in water and oil radiators, as well as fans with heating coils.

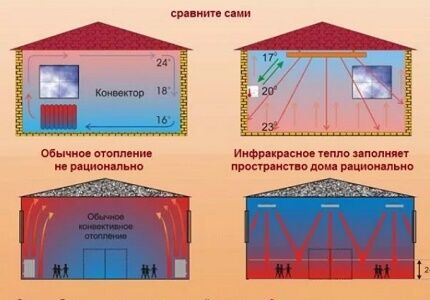

In them, first, using a coolant or heating element a certain working surface is heated, from which the room air is then heated in its immediate vicinity. Then, using natural or forced convection, air exchange occurs throughout the room.

Thermal radiation involves the transfer of heat from a source using electromagnetic radiation in the infrared spectrum. Air cannot be heated directly by infrared rays.

They can only heat surfaces made of solid materials. That is, first as a result of work heating systems PLEN the furniture and decoration in the room are heated, and then they give off heat to the air.

Infrared heat is electromagnetic waves in the range of 0.74–2000 microns. If you look at the Sun, about 40% of its radiation to the Earth comes from visible light, and about 10% and 50%, respectively, from UV and IR rays.

IR-type film electric heaters generate thermal energy, having a wavelength in the region of 9.2 microns. For humans, such rays are completely safe and natural, since they most closely resemble “sunlight.” After all, the human body itself emits heat in the infrared spectrum with a wavelength of 9.6 microns.

Film heating system design

IR film electric heaters include three main elements:

- heating;

- transmitting;

- radiate.

The first converts electrical energy into thermal energy. The second distributes the generated heat over the entire area PLEN, and the third emits infrared rays.

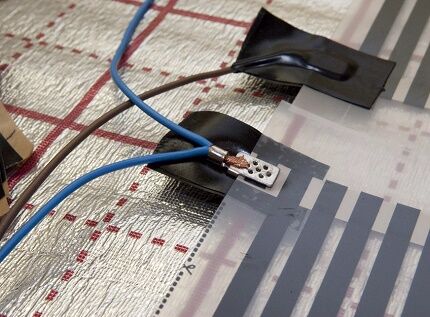

Heating element in PLENe made from high resistance conductor. Usually this is a thin strip of nichrome (spirals are made from it in heating elements) or carbon. At the same time, almost all manufacturers of film IR heaters have now switched to the second option. Carbon is more economical, cheaper and more efficient.

The transmitting element is a layer of aluminum foil, which has high thermal conductivity. It is located on one or both sides of the IR film. Also, a number of manufacturers do not use aluminum at all, relying only on the emitting material.

The top layer of the film heater in question on both sides is made of PAT (polyethylene terephthalate). Film from this thermoplastic has a high IR emission coefficient and can easily withstand temperatures up to +2000C and is an excellent dielectric.

The film cleans the internal heating elements from condensation and moisture, forms a single heating system from disparate components, and also reduces the risk of electric shock to almost zero.

Calculation and installation of an IR film heater are made taking into account that the film will not heat continuously, but at short intervals from several seconds to several minutes.

That is, such an infrared heater quickly raises the temperature of the surfaces in the room to the required values, and then turns off the thermostat. And then again energized from the mains only from time to time as the room air cools.

Scope of application of infrared PLEN

Film radiant electric heaters are most often used as an add-on to water heating. In southern regions they can serve as the main heating system. You just need to correctly calculate the area of infrared film required for the required situation.

Infrared film heaters can be installed in:

- residential country houses;

- city apartments;

- baths and saunas;

- production and warehouse premises;

- yards for keeping animals;

- garages with and without heating;

- greenhouses, etc.

There are no fundamental restrictions on the use of the low-temperature electric heaters under consideration. The only limitation for the device infrared heating – the room must have height dimensions of up to 3 meters. If the ceilings are higher, then you will need to install high-temperature and more expensive models of infrared heaters.

Characteristics and types of IR films

Infrared electric heaters are divided into two types - low temperature and high temperature. The first ones can heat up only to +50 0C, and the second even up to 200 0C. In everyday life, only options of the first type are used in the form PLEN or lamp or panel devices designed to operate from a 220 V electrical network.

The technical characteristics of low-temperature film IR heaters are as follows:

- Rated voltage – 220 Volts.

- Maximum film heating temperature – 40–550C depending on the model and manufacturer.

- IP protection degree – from “22” to “67”.

- Heating fabric weight – about 500 grams/m2.

- Specific power – 150–300 W/m2.

- Current load – 0.68–1.4 A/m2.

- Length – 0.25–7 m.

- Width – 0.5–1 m.

Manufacturers provide a 10–15 year warranty on infrared film. However, in fact, such heating systems last up to half a century.

According to the installation method, film IR heaters are divided into:

- wall-mounted – “warming pictures” (for additional local heating);

- ceiling – behind suspended and suspended ceilings;

- floor - "warm floor".

The floor-standing analogue is slightly inferior to the ceiling-mounted counterpart in terms of efficiency. Film heated floor It cannot be placed under cabinets, beds or sofas. And furniture always takes up a lot of space in a living room. “Paintings” and just films behind decor on the wall are the worst way to use IR film heaters.

Infrared heating films are available in the following forms:

- models of given sizes (for example, "ZEBRA" or "NIRVANA");

- canvases for individual cutting according to design dimensions; they are produced in widths from 50 to 100 cm.

The first option cannot be cut at the installation site. Such systems are produced ready-made; you just need to connect the wires with terminals. They must be especially carefully selected from the size range available from the manufacturer, so that installation does not cause problems later.

The second version of films is sold in rolls up to 7 meters long. This option infrared heated floor can be cut to the required dimensions directly on the premises using ordinary scissors.

Advantages and disadvantages of film heaters

The advantages of heating IR films are as follows:

- High safety and reliability.

- Minimum installation time for an electric heating system.

- The fastest and most comfortable heating of a room.

- Aesthetic appearance of the heating system, which is completely covered with decor.

- Full automation of the heater operation, resulting in no need for maintenance.

- High efficiency.

- Zero risk of water (coolant) leaks from the batteries.

- No problems with drying and oxygen burnout in room air.

- Absolutely silent operation.

- No convection - no dust settling everywhere.

- The ability to install a different microclimate in each room in the house in accordance with the specified parameters.

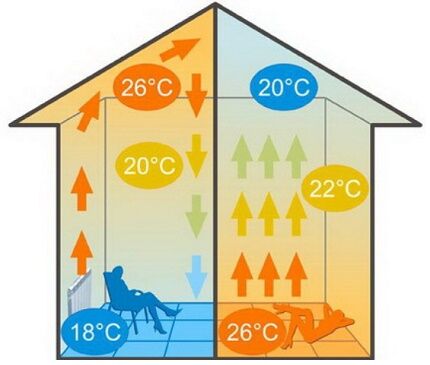

- No sudden temperature changes in height (the difference between the floor and the ceiling will be within 2–3 degrees).

The conductors and heating elements in the infrared heater are securely sealed in PAT film in the factory.Plus, there are no moving parts in such a heating system at all. wear out, break and corrode nothing.

In a house with an area of 100 square meters, the IR film system, along with wiring and protection in the electrical panel, is installed in 2–3 days. The main thing is that the network is designed for the required loads.

The electric heater is turned on/off thermostat, which monitors the temperature in the room using built-in sensors and itself supplies power to the heating elements. There are also programmable thermostats that allow you to set different modes for different rooms and times of day.

Among the disadvantages of film IR electric heaters it is worth mentioning:

- Large electricity bills.

- The need to have sufficient power at the electrical input into the house.

With the same area of a cottage or apartment, energy costs will be 1.5–2 times higher than expenses for gas heating from the main system. But a gas boiler, its connection to the main line or gas holder and installation of batteries with pipes is also a significant amount of money.

Installation of a radiant heating system will cost several times less than this option. And solid fuel boilers it benefits even more in terms of fuel consumption and installation costs.

Features of installation of film IR heating

Flexible film heaters can be installed with your own hands without much difficulty. The main thing when transporting and cutting is not to bend the film at an angle of more than 60 degrees.Its cut is made in the places indicated by the manufacturer on the canvas.

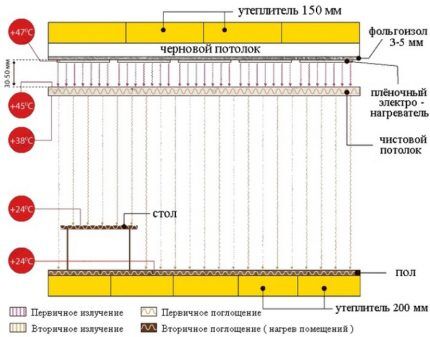

It is best to place it under film as insulation. isolon or penofol with a foil layer that reflects IR rays. And the thermostat should be installed away from direct sunlight, radiators and drafts.

To achieve maximum effect, the area of the film heater should reach 60–70% of the square footage of the heated room. At the same time, IR film cannot be placed under furniture on the floor and above high cabinets near the ceiling. Such heating will be of no use to people, but local overheating points will appear in the room.

Also, the strips of the infrared flexible electric heater need to be moved 15–20 cm away from the walls. In order to correctly calculate and lay out the film, you need to draw up a room plan in advance with all the required indents and places for placing furniture.

Any finishing material is a screen for infrared radiation. The only question is the degree of its transparency, the weakening of IR rays and the heating of this finish or cladding. Some cladding options allow radiant heat to pass through, while others do not.

Option #1 – on the floor

The infrared IR heater in the floor version is installed on a flat rough base made of concrete, wood boards or drywall. It cannot be placed in a concrete screed or a layer of tile adhesive, polymer film not designed for alkaline exposure from the cement used.

As a finishing coating, it is permissible to lay on top:

- laminate (without cork backing);

- thin carpet over chipboard or plywood flooring;

- linoleum without a heat-insulating sublayer.

It is not recommended to lay parquet on top of IR film. The wood of the parquet blocks will begin to crack and creak from overheating.

By SanPiNam the floor in living rooms is allowed to be heated only to +26 0C. However, if there is severe frost outside the window, the IR underfloor heating system will have to be turned on at full power in order to achieve comfortable air temperatures in the room.

And in this case, walking on it with bare feet will become uncomfortable. This is the main disadvantage of the floor-mounted version of infrared film heating.

Option #2 – on the ceiling

Infrared film heaters in ceiling design are allowed to be closed:

- eurolining, MDF And GKL with a thickness of up to 12 mm;

- stretch ceilings (PVC or fabric);

- hanging systems of the type "Armstrong" or "Grilyato».

You can also use plastic panels, but only on condition that their manufacturer allows the heating of their decor to +500WITH.

If the IR film heater is mounted together with a suspended ceiling, then the heating film should be laid directly along the frame of the system. It cannot be fixed to the ceiling, as there will be too large an air gap between PLEN and finishing.

You cannot install any metal, mirror or glass finishing structures on top of the infrared film. You should also avoid using glass-magnesium panels.

Conclusions and useful video on the topic

Video #1. About the advantages and installation of ceiling PLEN:

Video #2. Types of infrared heating films:

Video #3. Pros and cons of IR heating:

Infrared radiant heat in your home is an effective and safe way to heat your home. Installation of electric IR films pays for itself within 2–3 years due to savings on solid fuel for boilers and the cost of boiler equipment.

Even with heating using gas from the main line, the heaters in question win in the end. You just need to calculate them correctly for a specific room and have sufficient specifications for the power of the electrical network.

Would you like to talk about how you chose or installed a radiant film heating system with your own hands? Do you want to share technical nuances and technological subtleties that will be useful to site visitors? Please write comments in the block form below, ask questions, post photos on the topic of the article.