Do-it-yourself gas convector: steps for installing factory-made appliances + assembling homemade products

Gas convectors are justifiably popular.They operate on a commonly available type of fuel, which is attractive due to its low price, minimal volume of combustion products and high efficiency. Without any problems, you can install and even mount a gas convector with your own hands, if you know the specifics of performing this work.

We will tell you how to install a gas heating device that provides convective heating. Let us introduce you to the principle of its operation and design features.

In our article you will find a guide to the installation and production of proven homemade products. Our advice will undoubtedly be appreciated by independent home craftsmen.

The content of the article:

Secrets of the popularity of a gas convector

Convectors that use gas are used to equip residential, industrial and commercial facilities. They are especially in demand in private homes, small workshops, and cafes not connected to centralized heating systems.

Gas convectors are often used for heating large vehicles: campers, trucks, buses. They are more convenient to use than solid fuel stoves and diesel heaters, and more economical than electrical appliances.

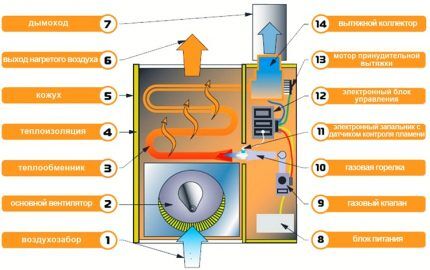

Job convective type devices is based on the natural movement of heated air passing through a combustion chamber located inside with a heat exchanger.The heat exchanger is heated by a gas burner, into which gas is supplied through a nozzle through a hose or pipe.

Almost all models of gas convectors can operate both on main gas and on a liquefied combustible mixture of propane and butane. They can be connected to the gas supply network, and to a cylinder or gas holder. It all depends on the technical conditions of the facility being developed.

Gas-powered convectors come with open and closed combustion chambers. The former are cheaper both in price and in terms of operating costs. The latter are more expensive, but much safer, which is why people buy them more willingly. Let's look at the operating principle of just such a device.

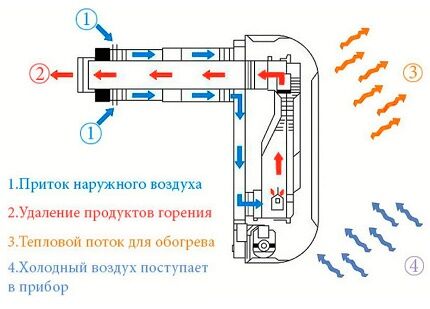

The air required for combustion enters the combustion chamber of the gas device through coaxial chimney. If we imagine a coaxial structure in a simplified way, then these are two pipes of different sections, one of which is installed inside the other. Due to the features of the device, the coaxial system performs two important actions.

The gap between the pipes draws air into the combustion chamber, which is required to stimulate and maintain the combustion process. Through the central pipe, the few but extremely toxic products of blue fuel processing are discharged outside, i.e. outside the heated object.

A convection gas heater has absolutely nothing to do with the air space in the room. A fresh portion of air is taken from the street, and flue gases, soot and fumes that accompany gas combustion are also sent there. During operation, the gas convector does not burn oxygen in the object being processed and does not threaten users with carbon monoxide poisoning at all.

The movement of air through gas convectors can be natural or forced. In the first case, the cold flow spontaneously displaces the warm flow from the heat exchanger into the room. In the second, the movement and change of cooled and heated air mass is accelerated by a fan that needs power.

Blue fuel is supplied to the burner through the gas valve.It doses the supply and performs the function of a kind of climate system that maintains the temperature background in the room required by the owners. Volatile devices are also equipped with automation.

Automatic protection systems guarantee safe operation. They interrupt the supply of gas to the chamber in the event of pressure fluctuations in the gas network or the flame in the burner extinguishes. Deflectors are installed on the coaxial pipes of gas convectors, which prevent the nozzles from being blown out by gusty winds.

The author of the video will clearly introduce the operating principles and design features of a gas convector heater:

Craftsmen develop and assemble unique models gas heaters, taking into account the principle of their operation and the features of the device. Their homemade products take into account the basic rule - you just need to ensure safe and efficient heating of the air passing through the device with a gas burner.

We will definitely consider models of homemade gas convective heaters that have been proven in practice, but first we will understand the rules for installing and connecting ready-to-use equipment offered by the trade.

Standards for the location of gas convectors

Gas convectors are installed inside heated residential, utility and industrial premises. They can be used in warehouses, garages and other explosive facilities, subject to the rules of use.

The number of devices is calculated based on the cubic capacity of the room to be processed. It is believed that on average 1 kW generated by a device can provide heat to 20 m³.Of course, average values are not enough for an accurate selection; besides, the calculations are influenced by climatic conditions and the actual heat loss of the building, but you can get an idea of the approximate number of required convectors.

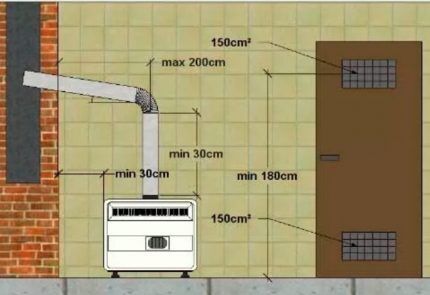

Either a home-made or a factory-made gas convector is mounted on a permanent wall. It is recommended to place it directly under the window, but not in a niche that impedes the movement of air flow. It is necessary to install the device so that nothing interferes with operation and maintenance.

Most manufacturers of gas convection appliances recommend maintaining the following distances from building structures:

- At least 150 mm from the plane of the floor with a flammable coating.

- From the plane of the floor with a non-flammable coating, 100 mm.

- From a window sill or other similar structure rising above the convector, at least 100 mm.

- 150 mm from structures and objects located on the left/right/behind.

- From the front wall of the gas convector to the nearest obstacle from 500 mm.

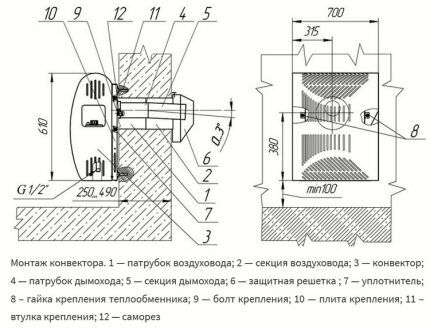

The gas convector must be equipped with coaxial chimney, brought to the street through a main wall or through a roofing system. The thickness of the wall crossed by the chimney can be 600... 800 mm.

When exiting through a wall, there cannot be less than 300 mm between the coaxial pipe and the ground surface. If it comes out at a height of more than 2000 mm from the ground surface, protection should be provided against atmospheric negativity and unauthorized entry.

Steps for mounting and fixing on the wall

To bring a coaxial pipe through the wall, you need to drill a hole in it, the radius of which will allow you to bring the chimney out, insulate and seal the gap between the pipe and the wall. According to the position of the drilled hole, the fixation points of the convector on the wall are marked.

Let's consider the process of preparing a hole for the output of a coaxial pipe in the wall of a frame building:

Naturally, the first thing you need to do is secure the brackets on which the device will be hung. Upon completion of their fixation, they begin to install the unit and connect it to the chimney and gas pipe. But first you need to prepare it for installation.

At dachas and in cabins, the walls of which do not have a load-bearing capacity sufficient to load a device with a cast-iron heat exchanger, it is better to place the heater on supports, for example, as in the following gallery:

The casing is removed from the convector, and an o-ring is put on the hole located on the back side. Then the device is tilted towards the wall, as a result of which the coaxial pipe is inserted into a hole equipped with a seal at the back of the unit. After which the connection must be strengthened with a mounting coupling.

Now you need to connect it to the gas supply pipe or hose. It is advisable that if connected to the main gas, the pipe should already be connected to the installation site of the convector. Before entering the gas channel into the device, there must be a tap so that you can shut off the supply if repairs, replacement or cleaning are planned.

Please note that connection to the pipe of a centralized gas system can only be made by representatives of the organization with which contract signed for the supply of gaseous fuel and maintenance of gas equipment. The technician must have certification from the manufacturer with the right to carry out installation work.

The responsibilities of a gas engineer called to install a gas convector include connecting to the gas supply system and checking the connecting unit for leaks. After completion, the worker must give the owners a report that lists all the actions he has performed.

You can connect the convector to the gas cylinder with a hose yourself. But it should be remembered that the connection must be made using a reducer and a gas valve. You also need to know that the nozzles for supplying main gas and a liquefied gas mixture differ in diameter.

It is advisable to arrange the opening for the coaxial pipe using a flange that ensures the tightness of the external unit. But before installation, the usual version needs to be slightly modified depending on the mounting method. Let's look at an example of preparing and installing an external seal on a wooden wall:

After finalizing the flange installed on the coaxial pipe from the street side, proceed to its installation:

If the device was sold with nozzles designed for main gas, before carrying out installation work they should be replaced with those whose size and model are specified by the equipment manufacturer. All injectors in the device must be replaced.

Don't forget that gas cylinder Any container cannot be placed above basements or placed in the basement or basement levels of the house. It is prohibited to install it directly next to the heater. A distance of at least one meter must be maintained between the device and the cylinder. It’s better to have a larger one so that the heating of the cylinder by the heater is completely eliminated.

Rules for proper operation

Only adult users who have carefully studied the manual and operating recommendations can turn the gas convector on and off and adjust its operating modes. It is unacceptable for the younger generation or incapacitated people to participate in these processes. If it is impossible to protect the gas convector from their interference, then it is better to refuse to install the device in advance.

Remember that if a specific gas smell is detected in the room, the tap at the entrance to the convector should be closed immediately. Under no circumstances should you “spark” in such a situation: strike matches, turn on the lights, use a lighter, etc. If these requirements are not followed, a seemingly small leak can cause a devastating explosion.

The room in which a leak was discovered must be immediately ventilated by opening the windows and door wide. You should immediately call the employees of the gas organization that connected your device to the centralized mains, or the emergency service. It will be possible to operate the gas heater only after the leak has been completely eliminated or the device has been repaired.

Homemade gas convectors

Among the developments of homemade convectors that convert gas into thermal energy, there are not too many different solutions. This is due to the danger of errors in the construction of devices operating on blue fuel. The slightest miscalculation can lead to an explosion, poisoning, or fire.

However, there are a few interesting designs worth considering. They can be useful in heating cottages, country houses, trailers, tourist tents, and garages.

Option 1. Heater based on IR burner

In essence, this is just a modification of the usual infrared gas burner brand Solarogas. The device operates on bottled gas. The inventor and implementer of the idea used the GII-2.3 model, the working panel of which can be installed horizontally.

On this working panel, which normally heats the space by flameless processing of gaseous fuel, an original heat exchanger was simply welded and installed. It is a metal cube with metal tubes installed inside the body.

The heat exchanger does not have a bottom; it would prevent the passage of heat waves. At the top there is a pipe for connecting the chimney. A pair of computer fans are installed at the back to speed up air flow.

Structurally, this model resembles a heater for air heating systems. By the principle of action - too. The air drawn into the tubes of the device is heated by a gas burner, then displaced from the tubes by a fresh portion of cold air.

According to the owner of the invention, the modified burner heats the tent much faster than the same burner, but without a heat exchanger. All gaseous fuel processing products are discharged through a pipe connected to the pipe. It does not burn oxygen and uses gas sparingly. This is a real find for fishermen, hunting enthusiasts and tourists.

Option #2. Using a decommissioned heater

This option is generally extremely simple, it was invented to save money on heating the garage. The entire modification consisted of repairing a decommissioned convector and removing the casing. The result made it possible to significantly increase heat transfer and heating rate, but it has safety problems.

Firstly, the seal is broken. If it accidentally goes out, the heater gas valve will, of course, stop supplying.

However, with constant combustion, oxygen from the air mass in a confined space will be burned out, so it will be necessary to regularly ventilate the garage in one gulp or construct fresh ventilation.

Secondly, an open heat exchanger can easily cause a burn. But where children don’t run, this can’t be considered a minus. An adult is unlikely to forget that the casing has been removed from the heater and that if you move carelessly near the device, you can get burned.

The following video will introduce you to a similar solution, but used for heating a trailer:

A convector without a casing heats a garage of 30 m² in about five minutes. Gas consumption amounts to no more than 500 rubles per winter month. In autumn and spring he works less often, which means that expenses are further reduced.

Option #3. Modernization with a duct fan

The essence of the modification is to install an air duct with an exhaust fan on the front grille. The heat generated by the convector is directed into the owner’s work area. There are no special tricks, but there is a significant reduction in heating costs.

Features of the design and operation of the modernized gas convector are presented in the video:

Combustion products are removed outside the facility as usual - through a coaxial pipe, through which fresh air is supplied to the burner to maintain the flame. This homemade product is significantly safer than the previous model, but you will still need to periodically ventilate the room being treated. After all, without a doubt, it will “drive” clouds of dust.

conclusions

Undoubtedly, gas convectors are the most popular type of heating appliances today for small residential, household facilities and even vehicles. The difficulty is that the most affordable and affordable type of fuel can be dangerous if the operating instructions are violated.

If the rules of use are strictly followed, there will be no threats to life, health, or property. Homemade products will not create any risks if the gas moves through sealed circuits. However, if there are doubts that you can ensure tightness, it is better to buy a factory-made device and not tempt fate.

Would you like to talk about how you installed and connected your own gas convector? Perhaps you have an interesting idea for assembling or upgrading a gas heater? Please leave comments in the block form below, ask questions and post photos on the topic of the article.