How to make a massage table with your own hands: types, drawings, step-by-step instructions

A massage table for the home is not the most necessary thing. You can do without it by doing a massage while lying on the floor.But if one family member requires constant massage treatments for health reasons, then it is better to buy a table or make it yourself. The second option will be cheaper.

The content of the article:

Design requirements

There are 5 positions that must be taken into account when making a massage table with your own hands:

- The comfort of lying on the table top of the massage table. And this is regardless of the person’s build. He should lie relaxed without feeling any discomfort. The same goes for the massage therapist. It should be comfortable for him to work, and not conform to any posture.

- The massage table must be durable and withstand loads of 250 kg. This numerical indicator consists of 3 components: the patient’s weight, the force coming from the massage therapist, and the strength reserve.

- The face hole is an important design component. This especially worries women. More precisely, this concerns their makeup. If there is no hole, then it is difficult not to spoil the makeup.

- The surface of the tabletop should be soft. There are several materials that can be used for this. But the best is high-density polyurethane foam.

- What to choose - a folding or stationary model - it is better to give preference to the first. After completing the massage procedures, the folding table can be removed, and it will not interfere, taking up some, even small, space.This applies to the case when the structure is used at home.

What types of massage tables are there?

All models are divided into 2 groups: stationary and folding. They can be supplemented with various details, for example:

- with armrests;

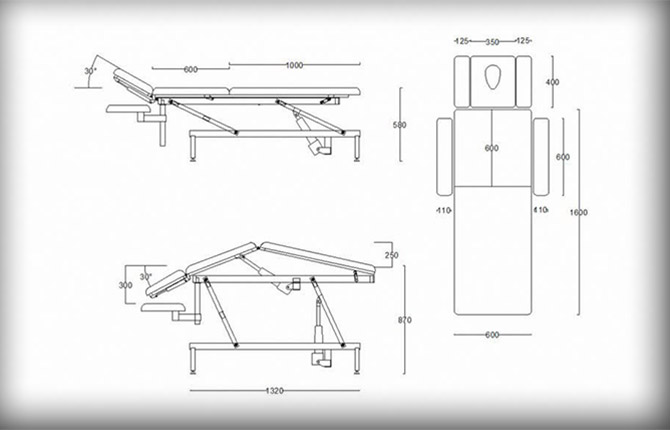

- with lifting headboard;

- with adjustable legs.

There are massive structures, and there are lightweight, portable ones. But they all represent a couch. That is, this is a tabletop and supports of different types.

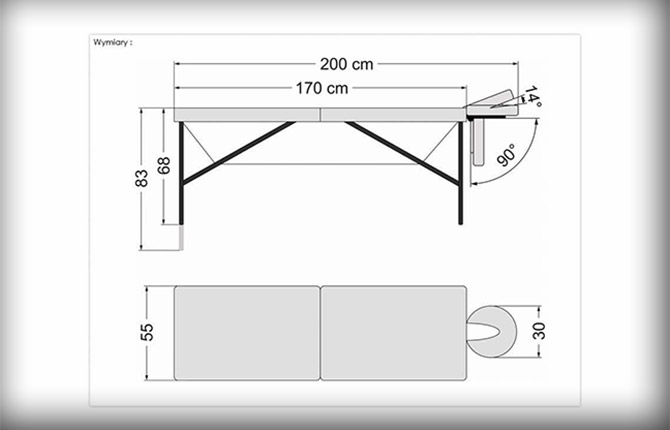

Drawing of a massage table

In this case, a drawing of the table is absolutely necessary, because it will show the dimensions of the structure. It’s good if it is done in detail, detailed. It shows all parts of the structure with dimensions. This will make them easier to make.

But before that, you need to imagine the massage table itself. It is rectangular in shape and has basic dimensions. But everything will depend on preferences.

Then you need to choose the type - stationary or folding. The first one is easier to do. In essence, this is an ordinary table, only lower than a dining table and longer. It is necessary to consider what the structure will be assembled from - metal or wood.

Step-by-step instructions for wood construction

A wooden table is easier to make because it does not require complex tools to assemble. Wood itself is a material that can be easily processed. But before you make a massage table, you need to prepare tools and materials.

What tools and materials will be needed

The tools you need to prepare are:

- wood hacksaw;

- drill and screwdriver;

- tape measure and pencil;

- knife;

- stapler with metal staples;

- construction square;

- brush.

From materials:

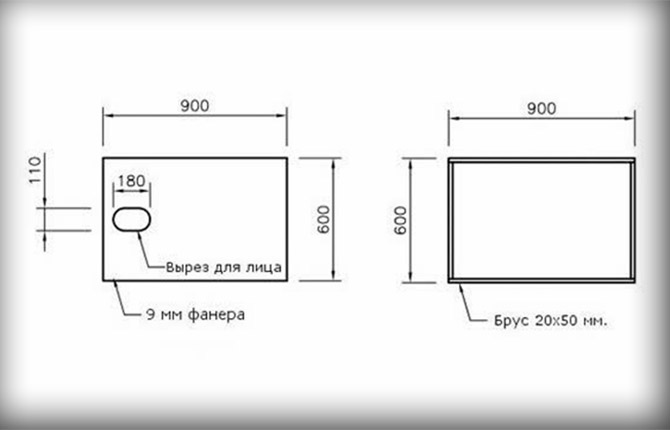

- wooden block with a section of 20x50 mm;

- plywood sheet with a thickness of at least 9 mm;

- self-tapping screws;

- fabric or leather substitute;

- sheet polyurethane foam;

- paint or clear varnish.

Assembling the table

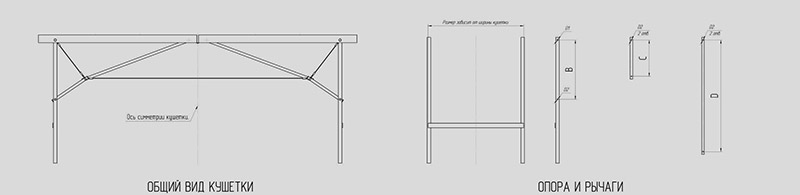

First of all, a tabletop is cut out of plywood, taking into account the dimensions indicated in the drawing. Next, the base is assembled. There are a large number of different design solutions here. The simplest one is a table with 4 legs.

There are 2 assembly options:

- take the tabletop as a basis, attaching the remaining elements of the massage table to it;

- a fellow table with legs, to which you can then attach a table top.

Both options are almost the same in terms of assembly method, they just have a different sequence of actions.

First way:

- Bars are installed around the perimeter of the prepared tabletop. They are attached with an adhesive composition both to the tabletop and to each other. Installation location: 5-6 cm from the edge inwards.

- Cross members are made from the same block. There should be 3-4 of them. The bars are laid across the rectangle and secured with the same glue.

- The structure is inverted. The frame elements are fastened to the tabletop with self-tapping screws. The distance between fasteners is 10-20 cm.

- The structure is being turned over again.

- Legs are installed. Installation location: corners of a rectangular frame. Fastening method - adhesive material and self-tapping screws. The latter are screwed into the frame elements. You can use perforated steel corners to increase strength.

- The legs are connected to each other by horizontal bars of the same section. Installation location – half the height of the massage table. The design can be supplemented with jibs. This is a beam connecting the leg and the frame under the tabletop. The jibs are installed at a slope, hence the name of the element.

Another assembly option is to first assemble the base, that is, the frame with legs. Then the tabletop is attached to it.

All that remains is to sand the wooden surfaces of the massage table using sandpaper. Some areas will need to be puttied to cover the wood defects. The last thing is painting or varnishing.

The massage table is almost ready. All that remains is to cover the tabletop with fabric or artificial leather, placing a porous slab material under it. To do this, the latter needs to be cut to the shape and size of the tabletop. Polyurethane material is placed on the surface of the massage table and outlined. Next, use a knife or scissors to cut off unnecessary areas

The prepared material is laid at its destination. Fastening is glue, which is applied along the perimeter in a strip and in a snake over the remaining area. Then the table is covered with fabric or leatherette, with which the plane is wrapped and secured on the reverse side with a fold. Fasteners are metal staples that are driven into plywood using a stapler.

Step-by-step instructions for metal construction

The technology for manufacturing and assembling a massage table made of metal is no different from a wooden one. Only in this case, the frame with legs is first assembled, and the plywood tabletop is attached to it.

What tools and materials will be needed

Here again you will need a plywood sheet, polyurethane foam padding, coating material, glue and paint. But the frame will be assembled from a metal profile. The most convenient one here is a profile pipe with a cross-section of 20x40 mm. To make it you will need:

- drill with drills;

- welding machine with electrodes;

- bolts with nuts and washers.

First of all, the frame under the tabletop is assembled. Here, as with wooden blocks, you need to assemble a rectangle with equal diagonals.4 profile pipes are laid out on a flat surface or on stands, the diagonals are measured, if they are equal, then the frame elements are welded together.

Now you need to make through holes around the perimeter of the frame through which the plywood tabletop will be attached to it. You need to make 3 holes on each side along the length of the frame, 1 or 2 along the width. The diameter of the holes is 8 mm.

Next, legs are installed at the corners of the frame, which are welded to it. Their location is strictly perpendicular to the frame structure. To increase the reliability of the massage table, the legs are tied with crossbars.

The frame is ready, you need to process the welds. The deposits of metal are knocked down with a hammer and cleaned with a grinder, onto which a steel wire grinding wheel is mounted. If there is a lack of penetration in any area, it must be filled, that is, additional welding is carried out.

The next stage is painting the frame structure. Metal surfaces must be inspected for the presence or absence of corrosion areas. If they are present, they must be removed. This can be done with the same grinder or cleaned manually with sandpaper. The pipe structure must be painted with metal paint. Usually these are enamels.

When the painted frame is dry, you need to install the tabletop. This is done like this:

- the tabletop is applied at the place of its installation;

- through the holes made on the frame, marks are made on it with a simple pencil or marker;

- Through holes are drilled according to the marks on the tabletop;

- it is re-laid on the frame and connected to it with bolts.

To fasten the tabletop to the frame, you need bolts with a diameter of 6 mm with a head not in the form of a hexagon, but with a rounded head, preferably a flat one. The bolts are inserted so that their heads are on the side of the tabletop plane.

All that remains is to lay the porous pad and cover the tabletop with fabric or leather substitute. Here, as in the case of a wooden massage table, fastening is done with metal staples using a construction stapler.

We bring to your attention the article - making your own inversion table.

Step-by-step instructions for a folding structure

A folding table has almost the same design as a stationary one. It is simply divided into 2 parts, connected by hinges or other hinge mechanisms.

What tools and materials will be needed

Here, too, everything depends on what material the massage table will be made of. If it is made of metal, then a welding machine is the most necessary tool. If it is made of wood, then most often a hacksaw will be used.

Assembling the table

The plywood sheet is cut exactly in half. 2 tables are assembled from wooden blocks or metal profiles with dimensions equal to half the length of the stationary table. For example, if the stationary model has dimensions of 1x2 m, then one part of the folding structure will have dimensions of 1x1 m.

This means that you need to make 2 frames with the same dimensions for the countertops. Starting from here, the step-by-step instructions for making and assembling a folding massage table change. Now you need to attach the legs not tightly to the frame structure, but with the help of hinges, because in the folding position they should fold along the tabletop. Therefore, loops need to be attached to the longitudinal parts of the frame, one for each leg.

If the structure is metal, then fastening is done using electric welding. If it’s wooden, then use self-tapping screws. In this case, the legs should fold inward, that is, under the tabletop. Therefore, first you need to attach the hinges correctly, only then attach them to the frame. All four legs are secured in this way. For rigidity and reliability, they can be connected in pairs with jumpers.

Now all that remains is to connect the 2 parts of the massage table with loops. Here you can use one long piano hinge or several door hinges. The installation of the hinged product is carried out with an indentation from the edge of the frame elements of the massage table. This gap is left on purpose so that the 2 parts of the structure can be folded without the edges resting against each other.

When unfolded, such a massage table can hardly be called stable. Unfortunately, the hinges do not create the rigidity that is necessary for any type of table, especially a massage one. After all, the patient lies on it, and the massage therapist works with his hands, creating both vertical and horizontal loads. Therefore, we need to add two more elements to the structure. These are props.

For example, the photo below shows a folding massage table, which has 2 spacers connected to each other by a regular furniture hinge. When the table is opened, the spacer straightens to its full length and prevents it from folding. If the structure needs to be folded, the spacer bends along a loop, folding under the tabletop. This is not the only option for spacers. There are plenty of examples of how to make them and what to use for this.

To prevent the massage table from opening when assembled, you can install 2 latches along the edges of the frame. You can attach 2 door handles to make it easier to carry.That is, many additions can be made to the design for more efficient and comfortable operation.

The extent to which the manufactured structure will be operational depends on the correctly selected dimensions, materials and a competently carried out installation process. When assembling, do not rush; trim the elements after carefully applying the exact dimensions. The stronger the structure, the longer it will last.

Video: homemade folding massage table

If any of the readers have already tried to make a massage table with their own hands, leave your comments. I would like to know what it was collected from, what size, what difficulties did you encounter? Your advice will also be interesting.

I made a massage table from a steel corner for my athlete’s son. I didn’t come up with anything, I found a drawing with full details on the Internet. Made exactly according to it. Stationary model. I used a used corner. I cleaned it well of dirt and rust, using a grinder. Then I treated it with a primer for metal and then painted it with spray paint. My son has been using the table for five years now.

You need to be careful with folding structures. Homemade ones are not as safe. If you do not strengthen the hinges, if you use weak hinges, the table will simply fold. Therefore, you probably need to first think through everything down to the smallest detail, and only after that proceed to manufacturing. It’s better to make a stationary model with your own hands.