Vacuum valve for sewerage: operating principle + installation of a vent valve

An unpleasant odor emanating from the sewer is a fairly common occurrence in our houses and apartments.Therefore, it is important to know that there is an easy way to improve its performance without resorting to major repairs.

A vacuum valve for sewerage (or as it is also called an air valve, aerator, ventilation duct, vent valve) allows you to improve the system, and in some cases even abandon the construction of a vent ventilation riser.

In our material we will talk about the design and purpose of the aerator, as well as how to independently install it in the sewer system.

The content of the article:

Signs of problems with the sewer system

Irregularities in the sewer system can be identified by characteristic signs.

These are:

- presence of extraneous sounds;

- spread of unpleasant odors.

In houses with a long-established sewer network, it is necessary to first check all elements of the network for damage. Deviations in the operation of the new system may indicate that it was installed incorrectly.

If during the inspection it was possible to exclude causes of possible damage such as cracks in pipelines, clogs in drain pipes or ventilation ducts, incorrect pipe slope, then the cause of the problems is most likely insufficient air flow. In this case, installing a vacuum valve will help troubleshoot the system.

Operating principle and purpose of a vacuum valve

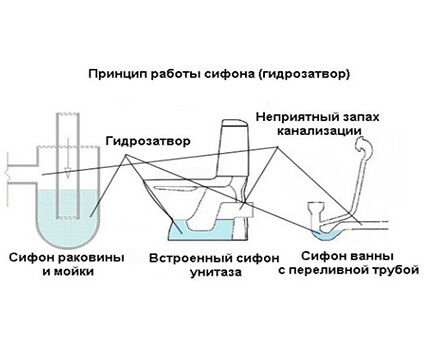

During hours of maximum drainage and during the draining of large amounts of water, air vacuum may be created in the sewer system and water from siphon water seal is sucked out, and odors, harmful gases and vapors enter the room.

A vacuum valve is installed to compensate for pressure in the sewerage system. It prevents water from being sucked out and odor from entering from siphons.

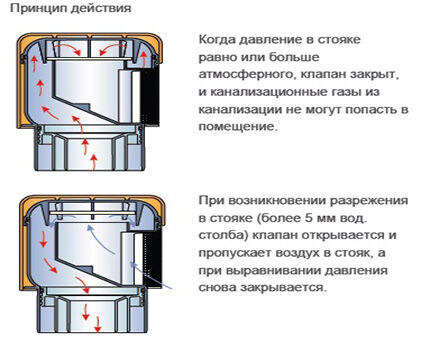

This happens as follows. The vacuum valve begins to operate when pressure drops in the sewer network. When a large volume of waste liquid is drained (for example, when using a toilet or several plumbing fixtures), the pressure in the system dilutes and the valve membrane automatically opens, allowing air inside the pipeline until the pressure equalizes.

If the sewerage system is not in use, the valve remains closed and prevents vapors and gases from entering the room.

Main Applications:

- Unventilated sewer networks. In systems in which it is not possible to connect an exhaust part to the pipeline, an air valve can be used. A device is used for aerating toilets and sinks, where the flow of a large amount of waste water can lead to the creation of a pressure imbalance and drawing water out of the water seal.

- Long horizontal sewer networks with a large number of plumbing points and a high probability of volley drainage. For example, in public toilets. In such places, to prevent the water seal from breaking, an aerator is installed every three plumbing points.

- Systems in which the plumbing is located far from the riser, and the product sewer pipe slope (expressed in mm/m) exceeds the height of the hydraulic valve.

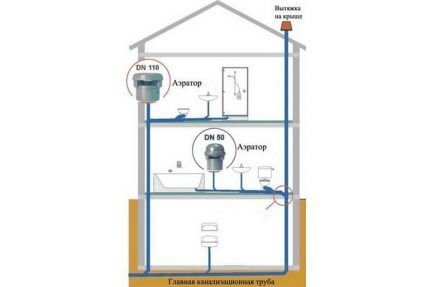

A vacuum valve (aerator) allows you to save materials and money when constructing utility networks in low-rise buildings by eliminating the need to install a ventilation pipe.

In multi-storey buildings it can only be used as additional equipment used to optimize the operation of the sewerage system.

Pros and cons of using a vent valve

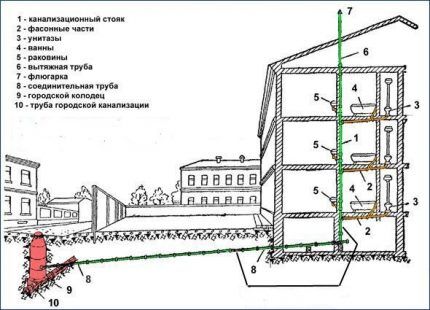

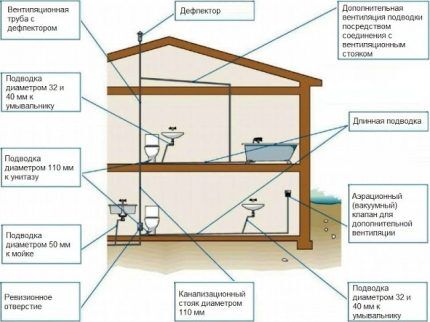

To prevent gases, vapors and odors from the pipeline system from entering the house, ventilation is provided, which will facilitate their removal from the system.

The principle of ventilation is based on the flow of air from the ventilation pipe of the septic tank, the passage of air flows through external and internal sewer networks and their exit through the ventilation duct leading to the roof.

Thus, the air passing through the septic tank and sewerage system carries with it all the odors, exits along with them through the ventilation riser in the roof and then dissipates. If there is no ventilation system, unpleasant odors and volatile substances from the septic tank and pipes can enter the room through broken hydraulic valves.

The presence of a ventilation system in the building ensures that odors do not penetrate into the premises even if the siphons break or dry out. But sometimes setting up a fan channel is impossible or causes great difficulties.

This may occur due to the characteristics of the roofing material, due to the roof being used, or the impossibility of locating the outlet of the exhaust riser away from balconies, windows, and ventilation systems. In this case, the exhaust part is taken out into the attic, and an aerator is mounted on its top.

A vacuum valve cannot be a complete replacement for ventilation risers, but its use can be justified by the following advantages:

- easy and quick installation;

- saving money;

- impossibility of installing a fan riser;

- minimizing heat loss through ventilation risers;

- improved operation of the sewer network and greater freedom in its planning.

Simply put, the ventilation valve solves only one problem - it prevents the vent valve from breaking, while fan boner equalizes the pressure in the network, and also ventilates the septic tank and the internal sewage system.

When installing a non-ventilated system or replacing the ventilation riser with an aerator, it is necessary to correctly calculate the throughput of the network in order to eliminate the possible breakdown of siphons or failure of fan valves.

It should also be taken into account that if the building is not inhabited all year round, it may happen that the hydraulic valves will not be filled with water (dry out) and air from the sewer will flow into the premises, which will not happen when installing a ventilated riser.

Design and operating conditions of the device

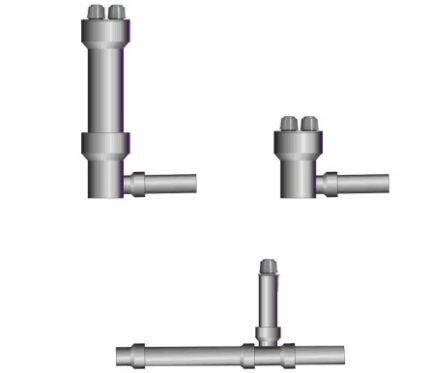

The body of the vent valve for sewerage installations is made of propylene. The internal mechanism can be equipped with a rubber membrane or rod that allows air to pass into the system without releasing it back into the premises. The rod valve is considered more reliable, since its working part wears out more slowly.

When choosing a valve, pay attention to the following characteristics:

- for open or closed installation;

- required diameter of the connecting outlet;

- with a regular or double thermally insulated riser wall;

- what kind of locking mechanism is used - membrane or rod;

- for vertical or horizontal (T-connection) connection.

Vacuum valves for sewerage are subject to strict requirements, each of them is tested for tightness and reliability - during operation they can withstand more than 800 thousand operation cycles without loss of performance.

General rules for installing a vent valve

Before installation, you must first check the valve for leaks.The easiest way to do this is to fill it with water from the side from which air should not flow into the housing and check this part for leaks.

The aerator is installed exclusively in a vertical position. When placed horizontally or installed at an angle, the manufacturer does not guarantee its correct operation. To achieve the desired location when installing the valve, you can use tees and elbows that will help install it vertically.

Although the device does not require regular technical inspection, it is still necessary to provide access to it for cleaning if necessary.

During installation, it is necessary to ensure free flow of air to the aerator, since water when drained can carry with it air, the volume of which is 25 times greater than the amount of waste liquid itself.

It is especially important to take this feature into account when installing a hidden aerator for a sewer system.

It is installed above the connection level of the outermost drain point (in the place furthest from the riser). To exclude the possibility of splashes and dirt getting on the sealing membrane - the main working element - the aerator is installed above 300 mm from the junction with the riser.

The device is mounted in places accessible to air intake. This could be an attic, a technical floor or a bathroom on the top floor of the house. All rooms must be ventilated or equipped with hoods.

The operating temperature range of different device models can vary from –50 °C to +95 °C. When installing an aerator in an unheated part of the house, the sewer riser (pipe) is insulated. The valve body does not need to be protected from negative temperatures, since there is an air cavity between its cover and the body, which can serve as insulation.

Step-by-step installation instructions

Most air valves are produced by manufacturers to connect to DN110 pipes. If the connecting size of the device does not correspond to the size of the pipe, a special adapter is used. For pipes DN50 or DN75, aerators with the corresponding diameter of the connecting outlet or equipped with a reducing insert are used.

It must be remembered that a valve designed for pipes with a diameter less than 110 mm can be installed for a maximum of two plumbing points.

In areas of transition from a pipe of a larger diameter to a valve with a smaller diameter, reducer inserts and various adapters are used. To install the aerator on cast iron pipe There are also special adapters that provide a reliable connection plastic with metal.

At the beginning of the work, the installation location of the valve is determined, taking into account the installation rules and its accessibility for further maintenance.

Next, perform the following steps:

- The water supply in the house is turned off.

- If the installation is carried out on a previously installed pipeline, then a tie-in is made and a special adapter is installed.

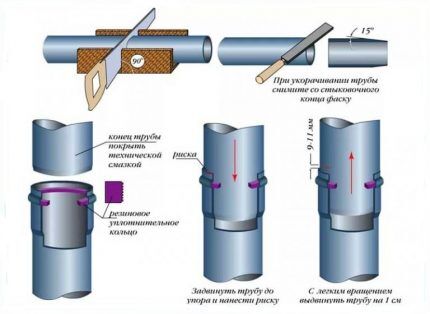

Most aerator models have a bell-type connection.

The assembly of such connections is carried out in the following sequence:

- The outer surface of the smooth part and the surface inside the socket are cleaned of dust.

- Wipe the sealing ring from possible contamination and place it in the bell groove.

- The surfaces that come into contact during connection are lubricated to reduce friction. To do this, use a silicone-based sealant or soap solution, glycerin.

- Place the smooth end of the valve into the socket up to the mark. The quality of the connection is checked by rotating the parts relative to each other, followed by returning to their original position.

If necessary, the area with the connected vacuum valve is secured with a clamp. Upon completion of work, it is necessary to check the joints for leaks.

For hidden installation, special models of vacuum valves are used. If the riser is hidden in a fine or protective box, then measures must be taken to ensure the flow of air into the sewer valve. To do this, a ventilation hole is made according to the size of the aerator mesh.

The aerator body is buried in the wall, the fastening element is adjusted so that its outer edge is flush with the wall surface. The only visible element remains the decorative grille, which can be attached using self-tapping screws or inserted manually. For aesthetic reasons, it is available in the most popular color options - white, gray, black and chrome.

Some valve models can be used as openings for sewer cleaning. To do this, remove the decorative cover, take out the internal mechanism of the fan valve and a cable is brought inside.

Conclusions and useful video on the topic

Operating principle and purpose of the fan valve:

Installing a drain valve can certainly significantly improve the operation of the sewer network. But its installation should not be considered as a panacea for all possible troubles associated with poor performance of the drainage system.

If you have installed an air valve in a sewer system yourself or have the necessary knowledge and skills, please share them with our readers. Leave your suggestions and ask questions in the block below.

Please tell me which valve is suitable for a 9-storey apartment building if the solution with an unventilated riser has already been made by the developer? At the same time, the water seals are torn off and the risers stand open on the technical floor, making living on the top floor impossible. Are there vacuum aerators of sufficient power or should you immediately contact Rospotrebnadzor and demand that they be installed in the roof?