Hatches for storm drainage

Sewage hatches installed at the inlet of the collector well ensure safety. They protect people and animals from falling into the shaft and from falling into the wheel wells of vehicles.The depth of technical storm drainage wells in some projects reaches 6 meters. At the bottom of the underground structure there are metal reinforcement elements.

The content of the article:

Types of sewer manholes

The specific shapes of the hatch designs prevent foreign objects and debris from getting inside the gutters. Manufacturers of sewer manholes offer the main type of product - round. Square and other models are produced much less frequently. As a rule, the external structure is convex, but it can also be flat.

Round hatches

The classic version is suitable for most shafts with cylindrical necks. The main advantages of round structures:

- sustainability. During operation, it will not fall inward in any position, and will not give a large backlash when closing;

- strength. Thanks to the uniform distribution of the load over the entire surface, the risk of damage to individual areas is reduced;

- compactness. The absence of sharp corners makes transportation easier. A heavy product can be rolled to the installation site.

Functional round sewer manholes are economical. Up to 40% less raw materials are spent on such models than on products of similar sizes of other shapes.

Original forms

Square and rectangular sewer manholes are most often in demand specifically for stormwater structures. Standard side sizes are 300-800 mm.The products are unsuitable for installation in areas of heavy traffic.

They tried to install a triangular shape everywhere in American cities. The idea was to conveniently indicate the direction of rain flow. But they did not withstand the control of security requirements. Gradually, triangular models were replaced with regular ones.

Oval and other complex-shaped manholes are usually produced in small batches. They are not intended for massive urban projects. Such one-piece products are ordered for design solutions - they give the built-up area a unique, memorable look. Some exclusive products have decorative markings that attract the interest of collectors.

Functional details

The convex shape of the covers prevents the accumulation of rainwater, which, when frozen, destroys the structure of the device. The ribbed surface improves the grip of car tires and the soles of pedestrians.

The parameters of sewer manholes come in standard and special versions. The latter are distinguished by additional elements and devices. Some specific designs have:

- built-in fastening devices necessary when lifting covers with lifting machines;

- depressions on the surface for weighting with all kinds of polymer or concrete fillers;

- locking mechanisms that prevent unauthorized entry into wells and theft of hatches.

In storm drainage systems, structures with double covers are used. The upper, heavier one protects the engineering system. The lower one has shutter mechanisms with reliable fixation. The increase in weight is necessary to prevent spontaneous opening of sewer hatches on the roadway.

Material composition

Modern durable sewer manholes are manufactured for different storm sewer areas. The product material is selected in accordance with the application task. Marking of covers according to permissible load classes:

- L, LM (A15) - light and light small-sized, from 15 to 60 kg. Loads up to 1.5 tons are possible. They are used in public gardens, parks, and courtyards. They are characterized by low cost.

- C (B125) - medium, 60-80 kg. Withstands up to 12.5 tons. They are used in industrial and urban areas, roads with low traffic flow.

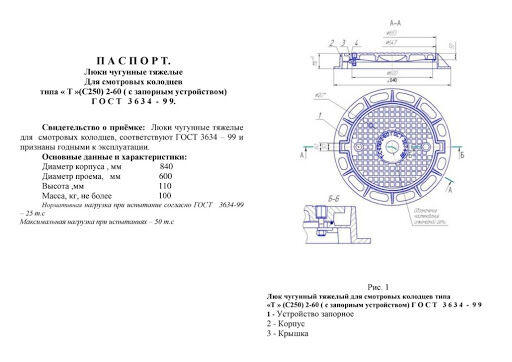

- T (C250) - heavy, weighing 80-120 kg. Designed for a load of up to 25 tons. Installed on industrial sites and parking lots of heavy vehicles.

- TM (D400) - heavy trunk, weight up to 140 kg. Designed for a load of 40 tons. Mounted in areas of heavy vehicle traffic.

- ST (E600) - super heavy, weighing from 150 kg. Maximum load 60 tons. Mounted on highways, gas stations, terminals.

- ST (F900) - super heavy, weight more than 150 kg. They are used in airfield areas and docks with extremely high loads of up to 90 tons.

Products made from different materials differ in price, technical parameters, and area of use. The universal cast iron composition is suitable for installing covers in different places in cities and countryside.

High strength cast iron

Gray cast iron SCh20 is used for the manufacture of lids. The alloy of iron and carbon includes graphite additives. High-quality products can withstand loads weighing up to 90 tons.

Advantages of cast iron sewer manholes:

- impact resistance, service life from 50 to more than 100 years;

- resistance to high temperature changes from -50 ºС to +90 ºС;

- neutrality to aggressive reagents, salts, acids.

The advantages of the products include a variety of weight categories. Wear-resistant cast iron models are produced more often than medium, heavy, super-heavy types. Their weight ranges from 15-150 kg, the range of diameters is 380-810 mm.

Floating hatches made of cast iron are not installed on the well neck, but directly on the road surface. This solution extends the service life of the engineering system due to the absence of subsidence of the road surface above the well. The design of floating sewer manholes consists of a body, a cover and a repair insert.

Plastic hatches

Lightweight products are used in places with low load. Their service life is more than 20 years. In all other characteristics, they are not inferior to cast iron - environmentally friendly, resistant to temperature changes from -40 ºС to +40 ºС.

Plastic lids are made from safe recycled materials. They do not emit harmful substances. Recommended for installation near residential buildings. Plastic models differ from cast iron:

- low cost;

- low weight in the range of 10-30 kg;

- impossibility of striking a spark.

Thanks to the variety of designs, plastic sewer manholes can be easily integrated into the landscape composition of a park area or cottage community. Plastic lids are not stolen for scrap metal. Therefore, they do not require expensive anti-vandal locks.

Polymer-sand

Progressive technologies make it possible to produce wear-resistant sewer manholes with attractive designs. Polymer-sand models are made by casting with hot pressing processing. Their weight is 40-50 kg. The following components are used in production:

- sand of different fractions;

- persistent industrial dyes;

- polymer thermoplastic elements.

The use of plastic bottles and similar waste as synthetic raw materials significantly reduces the cost. The service life of polymer-sand hatches is about 30-50 years. After the end of their service life, the lids can be easily recycled.

Polymer-sand models have popular standard sizes - 750x90 for the body, 690x55 for the lid. Values in mm indicate diagonal length and height. The parameters are optimal for stormwater underground engineering structures.

Withstanding a load of 1.5-12.5 tons, sewer manholes are installed in places of low and medium traffic intensity, in parking lots, and in pedestrian areas. The installation of lightweight products does not require the use of special equipment or additional labor.

Polymer-composite

Inexpensive, durable models are made by hot pressing at a temperature of 100 ºС. The innovative composition includes polyester resins, fiberglass, calcite, various fillers, and dyes. The material is much cheaper than cast iron, but more expensive than plastic.

The main advantages of polymer-composite products:

- optimal weight – from category L to TM;

- UV resistant, flame retardant;

- in winter they do not freeze to the necks;

- withstands changes from -60 ºС to +60 ºС.

The maximum weight of polymer-composite sewer manholes is 45 kg. They are used in conditions where all other materials except cast iron are categorically unacceptable. The products can withstand high mechanical loads on intracity roads, squares, and courtyard driveways. The service life of polymer-composite models is on average 40-50 years.

Regulations

The design and installation of storm sewer systems is carried out in accordance with construction and sanitary regulatory requirements. The documents regulate progressive technical solutions, factory-made hatch designs, and modern methods of construction and installation work.

When constructing a storm sewer, you can use a standard design with adjustments made to take into account the characteristics of a particular site. In case of a large water drainage area, additional wells for cleaning should be planned. It is necessary to include protective grilles in the design to collect large debris.

Requirements for hatches

The purpose and method of manufacturing sewer manholes from different materials are regulated by current standards. The technical characteristics of products are determined by GOST 3634-2019, which specifies the requirements for the manufacture of hatches, rainwater inlets and carpets for storm drainage.

The specified GOST contains markings for the purpose of utilities:

- K – sewerage for industrial and domestic purposes;

- D - sewerage system for drainage of rain and melt water.

In addition to the two main markings, there are markings on hatches for specific communications:

- covers for water supply are marked with the letter B;

- hydrant and fire water supply - G;

- gas main - GS;

- heating network - TS;

- telephone network - GTS.

When casting sewer manholes, the manufacturing company must indicate its trademark and year of manufacture. Designations are made in a random font on the top surface of the covers. It is not allowed for car wheels to slip according to the pattern and markings on the hatch in any weather conditions.

The manufacturer must attach a passport to each hatch or batch indicating the date of technical control.

Installation technology

The rules for installing storm sewer manholes are prescribed in documents SP 32.13330.2018, SNiP 2.04.03-85. Inspection wells with hatches are built on each branch of the storm sewer.

An additional well is needed in the local area to collect water from all receivers. Wells are constructed and arranged along roads and sites. The cast iron hatch is installed on a concrete slab or solid brickwork.

Installation of a plastic hatch

The installation process is similar to the implementation of engineering systems of conventional sewerage. The design of a hatch of any shape consists of a cover and formwork, which is sometimes called a shell. Installation of the product is carried out in the following sequence:

- Fastening the formwork to the well neck. Work is carried out strictly according to the level, in order to avoid deformations during operation. Plastic sewer manholes are equipped with special holes in the formwork for easy fastening.

- Pouring cement mortar. Typically, reinforcement or a retaining device is used to prevent the viscous mixture from entering the well. For example, a car tube inserted into a hole is inflated.

- Installing the hatch cover. The holding device or inner tube is removed after the solution has dried. The cover is inserted into special grooves in the formwork.

- A hatch mounted with a protrusion above the surface of the well neck must be equipped with a blind area. Typically, soil is excavated at a distance of 1-1.5 m from the cover. The prepared depression is filled with sand and compacted. The upper part of the blind area is filled with concrete.In the green zone, sewer manholes are decorated with artificial stones or using other techniques.

Installation of road hatches

When constructing roads, models with precise geometry are included in projects. The seat must ensure that the pressure of the hatch on the base plate is no more than 7.5 MPa. When installed on a leveled slab, there is no need to adjust the level of the hatch to the road surface. A device installed in this way will last for many years without replacement.

When repairing with building up the roadway, a support ring is additionally installed between the ceiling and the sewer hatch. The purpose of the element is to increase the level of the hatch and reduce the load on the floor slab. The support ring reduces the specific load by more than 10 times.

Model selection criteria

For installation near houses in areas with low traffic flow, sewer manholes made of polymer materials are better suited. They do not produce noise under the car tires.

In any case, before choosing a specific type of product, it is necessary to take into account climatic conditions and load level. A correctly selected and installed model will last for many decades. You also need to rely on the information provided in the relevant regulatory documents.