Coagulant for wastewater treatment: how to choose + rules of use

There are many ways to purify wastewater.When installing autonomous sewer networks, in addition to installing the usual filters that can filter out harmful substances and at the same time make the water cleaner, a precipitation treatment method - coagulation - is increasingly being used.

We will tell you on what principle the coagulant works for water purification. The article offered for review describes in detail all the varieties used in practice. You will learn what to consider when choosing a product and how to use it correctly.

The content of the article:

How coagulants work

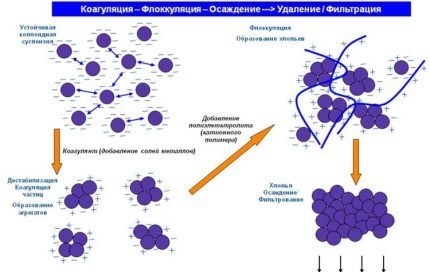

Coagulation is a method of water purification by adhesion of dispersed pollutants for subsequent removal by mechanical method, filtration. The combination of polluting particles occurs due to the introduction of coagulating reagents, creating conditions for the simplest elimination of bound pollutants from the purified water.

The term "coagulatio" translated from Latin means "thickening" or "coagulation". Coagulants themselves are substances that, through a chemical reaction, can create insoluble and slightly soluble compounds that are simpler and easier to remove from water than dispersed components.

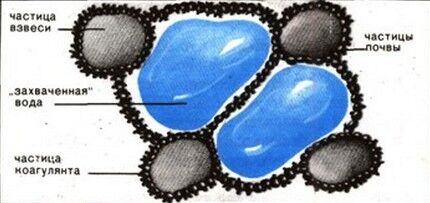

The principle of operation of substances is based on the fact that their molecular form has a positive charge, while most contaminants have a negative charge. The presence of two negative charges in the structure of the atoms of dirty particles does not allow them to join together. For this reason, dirty water always becomes cloudy.

At the moment a small portion of the coagulant is added to the liquid, the substance begins to attract the suspensions present in it.As a result, as the intensity of the scattered light increases, the liquid becomes cloudier for a short period of time. After all, one molecule of coagulant can easily attract several molecules of dirt.

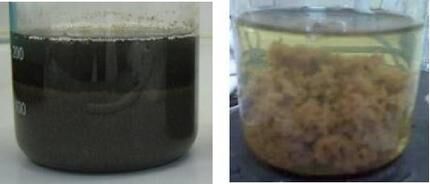

The attracted dirt molecules begin to react with the coagulant, as a result of which they combine into large complex chemical compounds. Slightly soluble highly porous substances gradually settle to the bottom in the form of a white sediment.

The owner’s task is only to remove the sediment in a timely manner, using any of the types of filtration available to him.

The effectiveness of the drug can be judged by the formation of sediment at the bottom in the form of white flaky formations - flocs. Due to this, the term “flocculation” is often used as a synonym for the concept “coagulation”.

In addition to wastewater treatment, coagulants are used in pool water treatment, in water treatment of industrial and drinking water in regions with limited water resources. We recommend that you familiarize yourself with the capabilities of coagulating chemical compositions, the features of which are described on our website.

Use of reagents: pros and cons

The effectiveness of modern equipment for neutralizing impurities in wastewater is not able to reach its maximum level without the use of reagents.

Modern coagulants can significantly increase the intensity and quality of the wastewater treatment process. The high cost of the reagents is compensated by a number of advantages that they possess.

Among the undeniable advantages of using synthetic coagulants, it is worth highlighting:

- efficiency;

- affordable price;

- high quality cleaning;

- versatility of application.

Wastewater is a persistent aggressive system. And coagulation helps to destroy it, forming large particles so that they can subsequently be removed by filtration.

The use of reagents gives good results in removing suspended and colloidal particles from wastewater.

But the precipitation method using reagents is not without its drawbacks. These include:

- the need for strict adherence to dosage;

- the formation of a large volume of secondary waste that requires additional filtration;

- the complexity of setting up the process on your own.

On an industrial scale, coagulation processes are used everywhere, they are put on stream. To set up the system at home, you will have to purchase special installations, the cost of which is quite high.

Most owners solve this issue by using separate household-type coagulants, which are sold in small-volume containers.

In some cases, coagulation can be carried out directly in mechanical filtration system. To do this, the reagent is introduced into the section of the pipeline with the liquid to be treated before the point where it is supplied to the filter. And in this case, foreign particles enter the filtration system and are “converted” into flakes.

Main types of coagulants

There are many types of coagulants. We will not list their formulas in detail in the article. Let's consider only two main groups, which, depending on the feedstock, are divided into organic and inorganic.

Today, many domestic and foreign companies are engaged in the production of coagulants. The new generation reagents they produce differ from the coagulants produced during the Soviet Union by improved technical characteristics.

Organic natural substances

They are specially created reagents that, by accelerating the adhesion of aggressively unstable particles present in water, help facilitate the processes associated with their separation and sedimentation. Organics help stimulate the combination of pollutants into dense suspensions and emulsions, facilitating the process of removing them from the water.

When interacting with pollutant molecules, organic coagulants significantly decrease in size. Upon completion of the reaction, they precipitate as a small amount of precipitate.

By minimizing the volume of sediment that accumulates at the bottom of the container, it is much easier and faster to filter. At the same time, the reduced amount of sediment does not in any way affect the quality of cleaning.

Due to the limited raw material base, natural reagents have not found widespread use in wastewater treatment on an industrial scale. But they are often used for household purposes.

Synthetic coagulating compounds

These types of reagents are created on the basis of mineral and synthetic elements. The polymers promote the formation of a high cationic charge, thereby stimulating the rapid appearance of flocs. They interact well with water, having a complex effect on it: softening its structure, as well as getting rid of coarse impurities and salts

The most widely used salts are polyvalent metal salts based on iron or aluminum. Iron is used for rough cleaning.

Among the iron compounds, the most popular are:

- ferric chloride - hygroscopic crystals with a dark metallic luster, excellent at removing large particles of contaminants and easily removing the smell of hydrogen sulfide;

- Ferrous sulfate is a crystalline, hygroscopic product that dissolves well in water and is effective in cleaning sewage.

Due to the low level of viscosity and low molecular weight, such reagents are perfectly soluble in any type of liquid being processed.

Of the coagulants created on the basis of aluminum, the most widely used are:

- aluminum oxochloride (OXA) – used for treating water with a high content of organic natural substances;

- aluminum hydroxochlorosulfate (HCHA) - copes well with natural wastewater deposits;

- Aluminum sulfate - an unrefined technical product in the form of gray-green pieces is used to purify drinking water.

In previous years, polymers were used only as an additive to inorganic coagulants, using them as stimulants to accelerate the formation of flocs. Today, these reagents are increasingly used as basic ones, replacing inorganic ones.

If we compare organic and synthetic substances, the former win in that they act much faster. In addition, they are able to function in almost any alkaline environment and do not interact with chlorine.

Organic active compounds also benefit from the fact that they do not change the pH in the water.This allows them to be used to purify water where plankton colonies are present, algae and large microorganisms grow.

Recommendations for choosing funds

The choice of coagulant for wastewater treatment must be approached very carefully. After all, although the substance does not pose a danger to human health, its action has a rather narrow specialization.

When choosing a coagulant for wastewater treatment, you can also use reference books, but before purchasing consumables, you should still consult with professionals specializing in the field of water treatment.

To protect yourself from disappointment in case of low efficiency of using a coagulant, we recommend that you first submit your water for analysis. Laboratory studies will give an idea of the composition and help determine the most suitable type of treatment.

Coagulants are quite specific substances. In some cases, they are able to reject elements from water, in others, on the contrary, they enhance their effect. For example, the use of an active substance based on aluminum and iron sulfate can have a triple effect: cleanse the contents, as well as deferrize it and significantly soften it.

When using any type of coagulant, the main thing is to adhere to the dosage recommended by the manufacturer. Too small a portion of the active substance will provoke a reaction, but it will not proceed as intensely as necessary for proper cleaning. The sediment will fall out slowly, and the liquid will not be cleared of harmful impurities.

In addition, if the dosage is violated, the flakes begin to settle unevenly.In this regard, many microflakes are formed in the water, which, due to their small size, are not captured by filters.

To simplify the task of calculating the required volume of active substance, manufacturers produce coagulants in packages equipped with dispensers, not forgetting to include detailed instructions for use.

Conditions for the process to occur

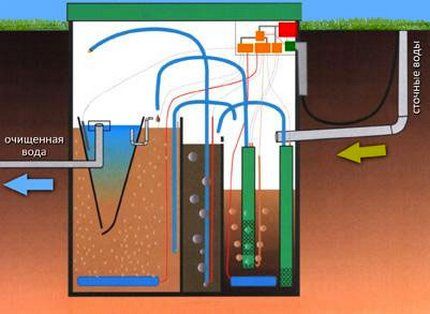

Maximum efficiency of wastewater treatment is achieved through an integrated approach to solving the problem. Therefore, when constructing autonomous treatment facilities, coagulation is used in combination with mechanical and biological treatment.

For this purpose, structures are erected consisting of vertical settling tanks separated by partitions. Thanks to this, the wastewater undergoes multi-stage treatment. First they settle, then they are purified by processing bacteria, after which they enter a chamber where they enter into the coagulation process and are finally filtered.

It is better to entrust the installation of specialized equipment, calculation of the approximate dose of consumables and initial control at all stages of the wastewater treatment process to professionals.

The coagulation scheme includes three main stages:

- Adding a coagulant to a contaminated liquid.

- Creating conditions for maximum interaction of the active reagent with impurities.

- Settlement followed by filtration of settled particles.

A necessary condition for coagulation to occur is the equality of particles with opposite charges. Therefore, in order to ensure the achievement of the desired result, obtaining the greatest reduction in effluent turbidity, it is so important to maintain the concentration of the reagent used.

When using coagulants for wastewater treatment, it should be taken into account that these substances only work at above-zero temperatures.

Therefore, it is so important to ensure stable heating of the treated water.

To speed up the coagulation process, you can add substances to the water that can form colloidal dispersion systems - flocculants. For this purpose, the following are most often used: starch, polyacrylamide, activated silicate. They will be adsorbed on the coagulant flakes, turning them into stronger and larger aggregates.

The flocculant is introduced into the contact medium zone 1-3 minutes after the coagulant is introduced. By this time, the processes of formation of microflakes and the subsequent sorption of precipitating substances are completed.

The amount of sediment deposited in contact tanks depends on the type of reagent used and the degree of pre-treatment of the wastewater to be treated.

On average, after mechanical treatment, the volume of sludge per person per day is about 0.08 liters, after passing through biofilters - 0.05 liters, and after treatment in an aeration tank - 0.03 liters. It only needs to be removed in time as the tank fills.

Conclusions and useful video on the topic

The principle of operation of the coagulant:

Video presentation of household coagulating products:

By using the coagulation technique, you will have an excellent opportunity to achieve high results with little investment. By choosing a reagent wisely and creating the necessary conditions for its operation, it will not be difficult to purify wastewater from many impurities and contaminants at once.

Did you have any questions while reading the information we provided? Do you know the intricacies of using coagulants in practice? Please share your knowledge and impressions, and also ask questions in the block below.

This is a labor-intensive process and if you violate the dosage, you may not get the expected result. And much more depends on the choice of coagulant. Before I started cleaning, I had the water analyzed in a laboratory, which told me which coagulant to use. Modern reagents even have dispensers, so you just need to carefully read the instructions and you can’t go wrong. I will say, the hassle is worth it. We simply dump the wastewater that has settled in the septic tank into the drain; it is very clear and odorless.

I’m not sure that the coagulant for wastewater treatment can be selected correctly on your own. We sent the sample to the laboratory, where they selected the right one based on the characteristics of the drain. We are glad. We looked at the water after purification - a little cloudy, but without odor or foreign impurities. We buy a special coagulant in a container with a dispenser, it is very easy to use and the dosage is chosen correctly.

Is aqua aura beneficial?

Yes, Aqua Aurat is very good.Works even at low water temperatures, high coagulation stability. Removes odor and color well. But it is important to carefully follow the instructions regarding dosing, etc.

It is better to use Bopak coagulant, as it is made on the basis of harmless components, in particular aluminum polyoxychloride!

The coagulant is truly a great solution. The Hydraizer turned out to be the best of all that we tried; they didn’t even have to submit a sample to the laboratory. They came themselves, did the analysis and sorted everything out.