Which dowel to choose for drywall: types, load, installation

Wall cladding with plasterboard sheets today confidently holds first place, far ahead of traditional plaster, and even more so plastic, lining, all kinds of slats and panels. Therefore, you have to deal with the problem of selecting dowels for drywall quite often. From simply hanging a book shelf to having to attach heavy furniture to drywall.

The content of the article:

Requirements for fasteners to drywall

Of all the options for facing materials, plasterboard sheets are the most difficult to install fasteners. The main problem is the soft structure of the gypsum core. There is no strong and rigid support for the fasteners, as in the case of brick or concrete. Any excessive contact pressure on the drywall material will immediately cause the gypsum core to chip.

Therefore, plasterboard dowels are designed based on the following requirements:

- fastening is done through, the sheet is always drilled through so that the back side of the material can also be used;

- the load should be distributed evenly over the surface of the drywall;

- for fastenings under light loads, cutting (threading or notching) into the gypsum sheet is allowed.

The main requirement for dowels is related to the amount of load they can withstand. For simple fastenings on a single sheet, it should be at least 15 kg for pulling out, and 20 kg for cutting. For complex prefabricated dowels 30 and 45 kg respectively.If you need to make high-strength fastenings for drywall, then the limits should be 60 kg and 80 kg, respectively.

The fastening design must stably hold the self-tapping screw or screw in a horizontal position under load. That is, a correctly installed dowel should reliably hold the fastener in its original position throughout its entire service life.

Varieties

The requirements for installing fasteners on drywall are quite strict. Therefore, in order to securely “fit” the dowel-cork into the sheet, it is necessary to use special collapsible structures with additional support on the back, and often the front surface of the drywall. Only for the lightest fastenings is it allowed to use self-tapping dowels similar to a self-tapping screw (dowel), but with a different profile of the screw surface.

The most common types of fastening dowels, designed specifically for installation in soft plaster:

- specialized models for installing fasteners on thin plates;

- universal dowel plugs;

- “Auger” or “Driva” type fasteners;

- fastenings with breakable cork frame walls - “Butterfly” or “Molly”4;

- Fisher system;

- clamp Hartmut Knauf.

All drywall dowels, except Driva, are disposable. Re-installation is not permitted, even if the external body and main structural elements appear intact. Therefore, when covering walls with plasterboard, it is better to buy dowels with a reserve. In addition, some of the fasteners will be used up when mastering the installation method.

Useful:

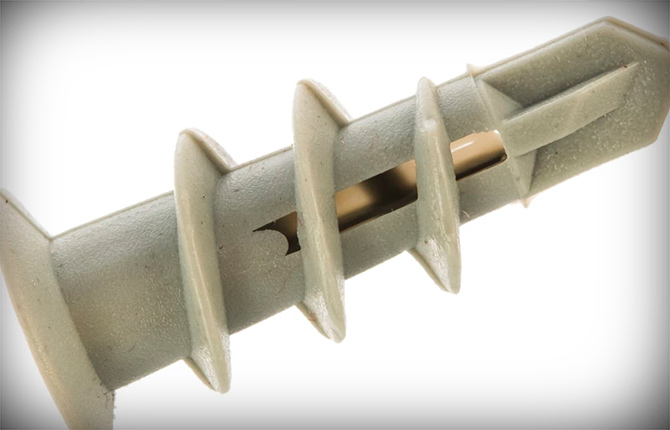

Driva

A small dowel made of nylon, polypropylene or zinc alloy. Due to the huge helical spiral on the surface, it is sometimes called an auger or drill fastener.

Essentially, this is a plastic plug that, once screwed into the drywall, will additionally be screwed with a hex head screw. Metal auger dowels are typically used to join two sheets of drywall into one package. This scheme is used if you need to hang a heavy cabinet or shelf on the wall. A double sheet, accordingly, will withstand double the load.

If the sheet is too thin, from 6 mm to 8 mm, then the number of spiral turns that cut into the wall does not exceed 2-3. This is not enough, so Driva is either coated with PVA-M glue, or a small piece of plasterboard sheet is additionally glued to the back side of the drywall, a piece of 40x40 mm is enough.

The strength of the screw fastening is small, for horizontal load the limit is 20 kg, for shear load - 35 kg. A package of two sheets contains 40 kg and 70 kg, respectively.

If necessary, Driva can be reused, especially for metal screws. But the number of repeated installations is also limited, for plastic - no more than three, for zinc-aluminum - up to 5 times.

There is one limitation for Driva type dowels.If the diameter of the fastener is almost always equal to the thickness of the drywall, this means that when screwing the screw, you need to hold the screwdriver so that the axis of rotation of the chuck is strictly perpendicular to the plane of the sheet. A slight misalignment causes the sharp edges of the spiral to cut out the soft plaster, and the dowel falls out of the hole.

In addition, you need to pre-adjust the clutch on the chuck so that the screwdriver tightens the Driv into the drywall with a force of no more than 3-5 N*m. Then, when screwing the self-tapping screw into the dowel, the Auger itself will fall into place with the required force.

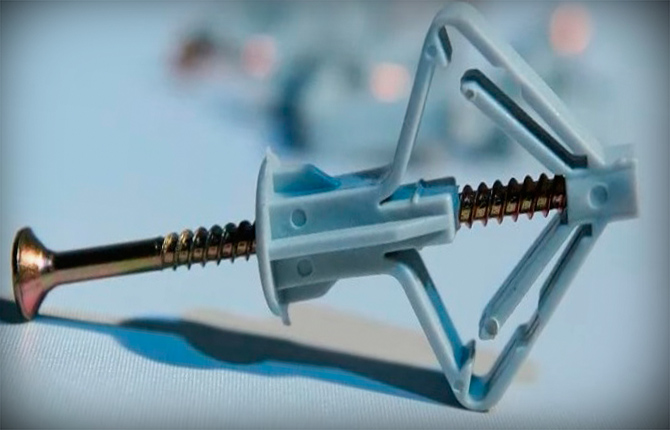

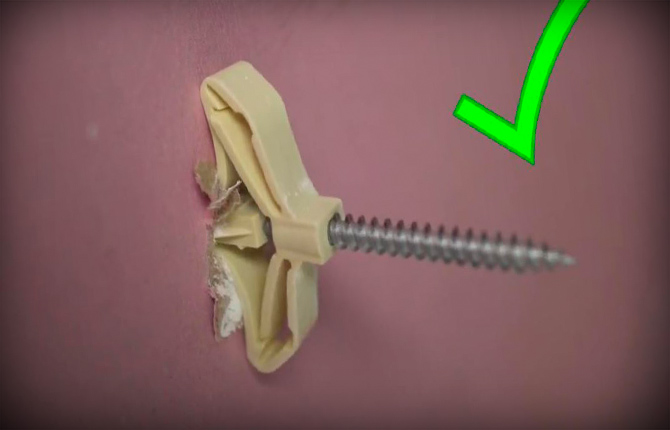

Butterfly

Specialized dowel for mounting on drywall. Often they try to use it for fastenings for brick or concrete. This is not a very good option. Installation results are much better on light blocks - foam concrete and aerated concrete.

To install the Butterfly, you first need to select a point and drill a hole equal to the diameter of the frame.

Next, squeezing the frame with your fingers, you need to push it inside the hole until it stops, the ring side should “sit” on the drywall.

Only after this can you wrap a self-tapping screw or screw into the dowel. But you need to ensure that at the moment of tightening the frame on the back side is positioned vertically, otherwise the fastening will turn out to be fragile.

Inside the plastic frame there are two additional plastic “antennae”. When screwing the self-tapping screw into the dowel, the mustache unclenches and fits into the corner grooves. This way the dowel is fixed in a compressed position.Even if you tighten the fasteners with extreme force, this will not lead to breakage of the plastic frame.

The butterfly is one of the few structures that can withstand vibration loads.

The deformed plastic frame acts as a spring, so you can safely attach wall-mounted kitchen cabinets to the Butterfly. As a rule, opening and closing the door creates additional load on the fastening. Butterfly copes with it best. Whereas the Molly Auger breaks the drywall pretty quickly and falls out of the hole.

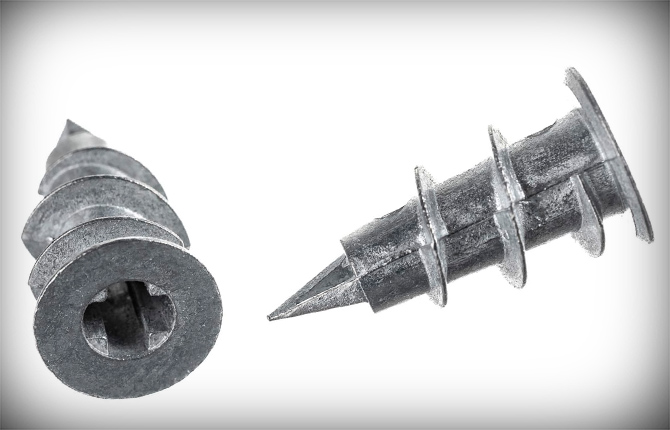

Molly

The dowel is made of soft annealed steel with zinc coating. In design and principle of operation, Molly strongly resembles a Butterfly. The central bushing is made of thin-walled with four longitudinal cuts.

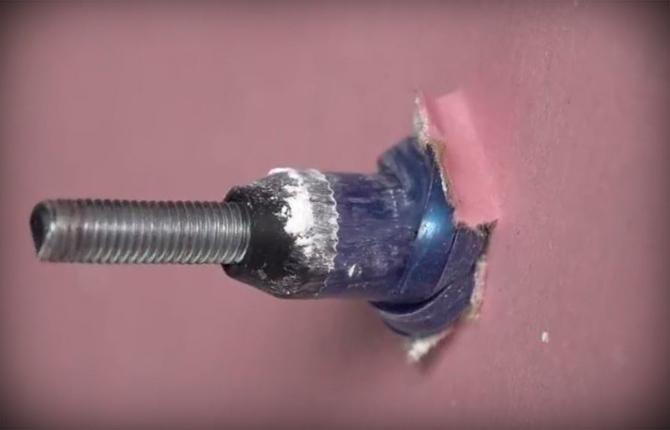

At the end there is a sleeve with a threaded screw. When twisted, it breaks the frame and folds it into a pyramid shape. Molly is one of the best options for attaching objects weighing up to 25-30 kg to drywall.

Molly has one more flaw. The metal of the sleeve, even of small thickness, is very difficult to deform at the initial stage. When tightening with a screwdriver, you have to turn the screw with quite a lot of force. The dowel manufacturer installed an additional toothed washer on the side to prevent the dowel from turning in the drywall when tightening the screw.

But still, tearing off the petals of the sleeve and making them begin to deform is quite difficult; often the first turn of the screw in the dowel has to be done while holding the screwdriver with both hands.

If you don’t have a screwdriver, then the first turn of the screw can be done in the following way:

- after installing the sleeve in the drywall, you need to screw the screw all the way in, and then turn it back out so that there is a gap of 1.5-2 mm between the toothed washer and the head;

- we take side cutters (for biting off wire) with cutting edges beveled by a wedge;

- open the side cutters, place them under the head and, using the tool as a lever, push the screw “towards you” by 1-2 mm.

You can repeat the procedure, after which the screw on Molly is tightened with a regular screwdriver with one hand with medium force.

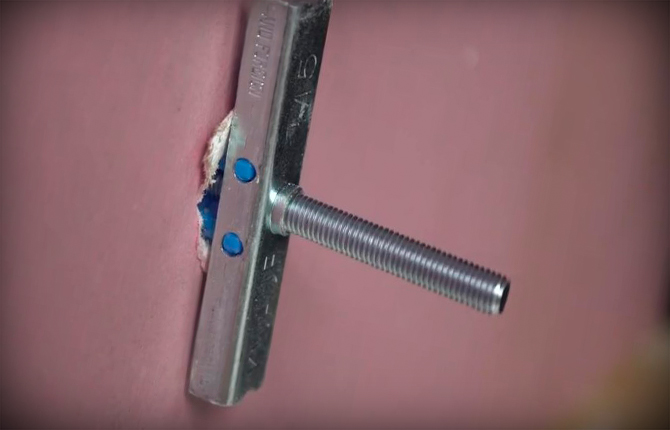

Hartmut Knauf

An original development by Knauf, a world leader in the production of sheet plasterboard, putties and various types of auxiliary fasteners. The company has developed a specialized dowel specifically for attaching heavy objects to sheets of drywall. In this case, the main emphasis was placed on simple and quick installation of the dowel. The Hartmut Knauf system is considered the most popular among cladding masters.

The mount consists of four parts:

- profiled steel U-shaped strip with a central threaded hole and two pairs of holes on the side shelves;

- two flat polypropylene strands;

- plastic sleeve;

- screw

Plastic bundles are fixed on a U-shaped bar so that all parts can simultaneously unfold in one line.Hartmut Knauf, subject to the installation technology on plasterboard, can withstand a load of up to 100 kg. Moreover, the installation process itself does not require additional preparation and can be performed simultaneously with laying sheets of drywall on the wall.

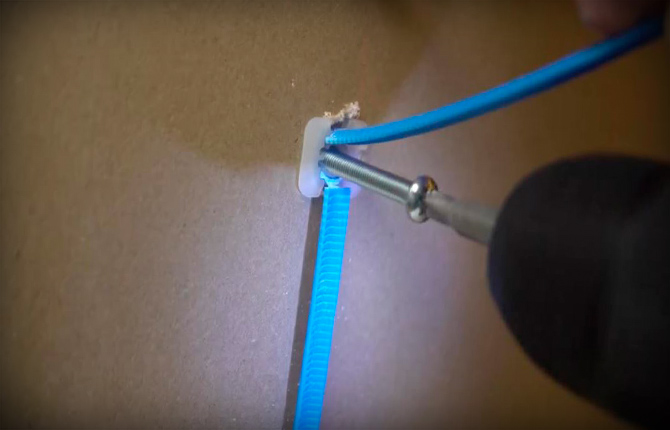

Initially, you need to drill a hole in the drywall; the diameter of the drill can be read by the markings on the profiled strip. Next, the dowel is folded into one line and pushed forward into the hole with the steel bar.

The next step is to hold the transparent sleeve in the hole and pull both harnesses towards you at the same time with your other hand. The U-shaped strip will be pulled up and placed on the back of the sheet, directly in front of the hole in the drywall.

All that remains is to bend the harnesses, insert the screw and, holding the dowel by the sleeve, tighten the fastener with a screwdriver. After installing the fastener into the drywall, the “whiskers” are cut off.

If necessary, you can shorten the length of the screw, but you need to cut it very carefully so as not to damage the threads on the rod, otherwise it will not be possible to tighten the fastener.

Builders often call Hartmut fasteners for the lazy. Its installation requires 2-3 times less effort and time than any other fastener of similar strength.

Sometimes the harnesses are not broken off, but are used for temporary (or permanent) fastening of wiring, pipes, guides, and various fittings. The length of the harness after installation in drywall is 120-140 mm. In order to secure the wiring to the drywall, you just need to wrap the cables in bundles and secure them with a stapler.

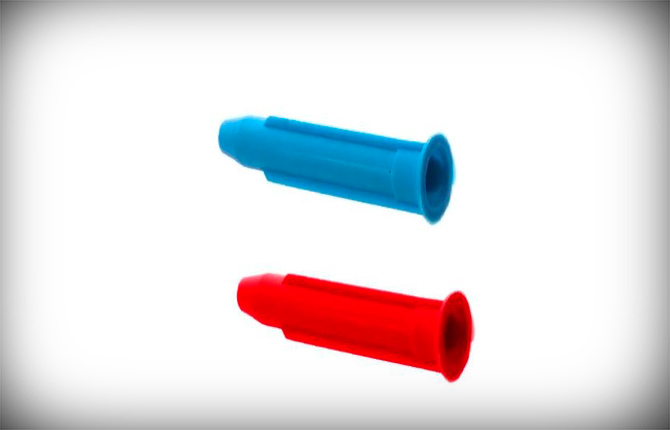

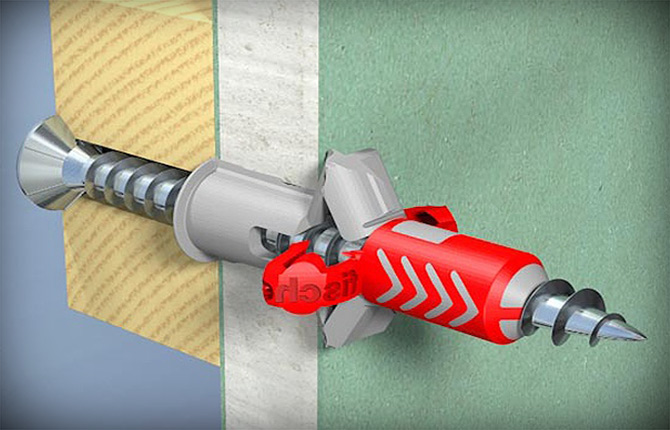

Fisher

This is a whole line of dowel models from a well-known manufacturing company. Dowel plugs are easily recognizable by the characteristic color of the plastic plug.

Single-color, gray - these are universal dowels for fastening in materials with voids. When you tighten the self-tapping screw from the back, a knot is formed due to the plastic being compressed. At the same time, the side has 6-8 pieces of additional ribs, which cut into the drywall material and prevent the plug from turning when tightening the screw.

Advice! When choosing a dowel for drywall, you need to pay attention to the markings and description of the fastener. There are quite a few models offered on the market, including gray-red colors, and not all of them are suitable for mounting on drywall.

Unlike the universal Fisher versions, when installing a self-tapping screw, special dowels are not twisted into a knot, but take the shape of a cross-shaped pyramid. It looks very similar to the deformed Butterfly dowel frame. The cross-shaped pyramid has a much larger support area than the knot, so the fastening strength is quite high, 35 kg for horizontal load and 40 kg for shear load.

The only drawback of Fischer is that branded dowels are massively counterfeited. A real Fisher costs much more than a Butterfly, and if you look closely you can see how well the cork is made.

Counterfeits, as a rule, can be distinguished by the low quality of polymer inserts, multiple defects and casting residues on the dowel body.Otherwise, Fischer is worthy of leading the ranking of fasteners for plasterboard sheets.

Universal dowels

Specially designed fasteners designed specifically for plasterboard sheets are relatively inexpensive. One dowel with a self-tapping screw costs between 20 rubles and 300 rubles (Hartmut Knauf), but in practice homeowners often save.

For some reason, it is considered normal to simply screw a carpentry screw directly into the drywall, without any dowel. Not the best solution, especially when you consider that the strength of such fastening is no more than 0.5 kg on 6 mm thick plasterboard and 0.8-1.2 kg for a 8-10 mm sheet.

Classic dowel in plasterboard

But the problem is not even the maximum load. If necessary, the number of screws can be increased. But in order to hang any object, the screw head must be turned out 3-4 mm, otherwise the loop or bracket simply will not fit onto the fastener. In this position, the fastening becomes loose quite quickly, so it is better to immediately install dowels, even the simplest ones.

Quick dowels

In terms of design, they differ from universal models in the absence of annular grooves and longitudinal cuts. But three longitudinal edges have been added along the dowel body. When installed, they cut into the drywall and hold the fasteners well. The maximum shear load is up to 20 kg.

Fastening for heavy objects

If the solution is obvious for light objects, then for a radiator or a massive shelf you have to look for a special version of the dowel. For example, you can use dowels for fastening to thin cladding (plate), including chipboard, OSB and plasterboard.

Important! This fastener can be used on 12 mm thick plasterboard.

The dowel is sold assembled with a hook and a polypropylene support washer. There are several spiral cuts on the body, which should make it easier to twist the plug while screwing the hook. Typically, dowel manufacturing companies paint them in specific colors.

Gray plugs are the weakest. They can withstand a maximum of 20 kg and 35 kg for pulling and cutting respectively.

Blue plugs can be placed under heating radiators. They can withstand horizontal forces of up to 50 kg and shear forces of up to 60 kg.

All three types of dowels are mounted in a 10 mm hole. The cork is inserted inside along with a screwed hook. Otherwise, you won’t be able to insert it; the too soft and flexible material of the case bends and deforms.

When the hook is screwed in all the way, a locking knot is formed on the back of the drywall. But, since there is not a spiral winding on the surface of the hook, but a full-fledged M6 thread, if necessary, you can unscrew the fasteners from the plasterboard sheet.

According to the manufacturing company, after several months the plastic hardens and the assembly acquires additional rigidity. Therefore, if the hook in the dowel sits too “softly,” then this is not a reason to panic; after a few months, the rigidity of the fastener will increase significantly.

In many cases, craftsmen apply a small amount of glue to the leading edge before installing the dowel. Once screwed in, the glue dries and locks the thread. That is, the fastener turns out to be non-separable, the same as hammering a nail.

Is it possible to glue dowels into drywall?

It is clear that a screw-on cork can be glued into a plasterboard sheet, as is often done to install fasteners on gypsum plaster. Homemade dowels are used for packages of two sheets or on plasterboard with a thickness of at least 12 mm.

The material used is wood blanks. Acacia or oak is best. You need to cut a cylindrical plug 30-45 mm long. The diameter of the homemade dowel is selected depending on the load on the drywall.

For example, for a shelf weighing 5-10 kg, two plugs with a diameter of 25 mm will be sufficient. On the back side of the “dowel” two axial cuts are made to a depth of 15 mm. Two drills are made in the center. The first is done with a through drill of 3 mm, the second with a diameter of 4 mm to a depth of 20 mm from the front side.

A hole in the drywall is cut with a ring drill exactly to the diameter of the plug. Before installing the dowel, freshly diluted alabaster or plaster is applied to the surface of the plug and the edge of the hole. After which the fastener is recessed into the hole, only a small edge of 3-5 mm remains outside, by which it can be held with pliers or a key.

The self-tapping screw is tightened, not reaching the wood 3-4 mm. The protruding remains of the cork are cut off with a hacksaw blade, and after 10-15 minutes you need to tighten the screw to the desired position.

The fastening strength of a homemade cork is 40-45 kg.

Is it possible to use models for foam blocks?

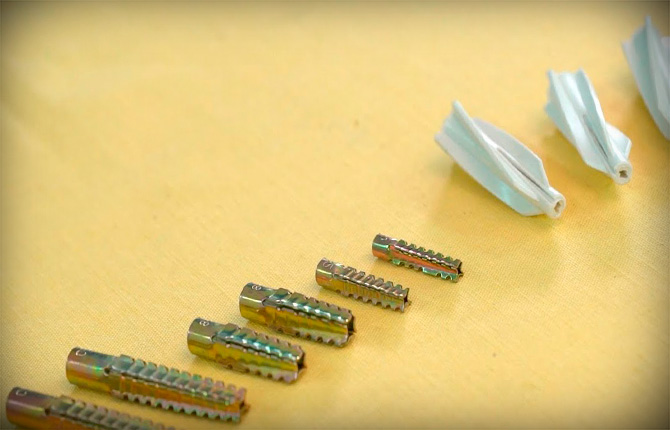

Of all the options for dowels for foam concrete, two types can be used as fasteners:

- sleeve split plugs;

- polypropylene screws.

Both options are installed in drywall in the same way as in foam concrete. Holes for fasteners are drilled with a diameter slightly smaller than the size in the smallest section of the sleeve or screw.

Before installing it in the hole, the plug must be dipped in diluted alabaster. This will strengthen the adhesion of the steel sleeve to the walls of the hole. When tightening a screw dowel, it is better to use glue; PVA-M or any other water-based glue will do.

In both cases, the fastening strength is approximately at the Driv level. If it is necessary to increase the load-bearing capacity of the fastener, then a plastic washer is glued under the plug. It increases the bonding area of the dowel and strengthens the edges around the hole.

Results

The choice of a specific model of drywall dowel directly depends on the required fastening strength. If the load on the fastener is small, then universal dowel models can be used. For heavy and large items, it is better to choose reinforced plugs or fasteners for thin cladding plates.

Tell us about your experience in selecting fasteners. Which option do you think is the most successful? Leave comments, share the article on social networks and bookmark it.

Fischer is best for drywall, I don’t know why they praise Knauf, they are inconvenient to work with, there are a lot of defects. The plastic bursts, the strands tear out of the steel strip, it’s just a hassle.

Lots of frank marriage. You buy a pack, it contains 50 pieces of dowels, only half of them still hold something, the rest is some kind of defect.Take imported ones, so at least everything fits true to size.