Gas analyzer: principle of operation, what to look for when choosing + review of manufacturers

The device, functionally built on the principles of measuring gas mixtures, allows you to timely determine the excess of dangerous toxins.A gas analyzer is a small device that will warn of the danger associated with the unauthorized release of harmful volatile substances and the appearance of a leak in the pipeline.

We will talk about all types of gas mixture analyzers used in practice. The article we presented describes in detail their design features and operating principle. Taking into account our recommendations, you can choose the most suitable device.

The content of the article:

How does an automatic gas analyzer work?

In terms of performance, there are manual and automatic gas analyzers. Hand-held analyzers include absorption models, which use the technology of absorbing a gaseous environment with reagents. Devices that operate automatically usually operate using the technology of constructing the physical and chemical characteristics of a substance.

Almost all gas environment analysis devices that support automatic measurement are, from a methodology point of view, conditionally divided into three groups:

- Chemical reaction analyzers.

- Analyzers of physical and chemical processes.

- Analyzers of physical processes.

Physical methods of analysis performed using chemical reactions are the first to be supported. Here, as a rule, the range of instruments consists of volumetric manometric and chemical apparatus.

Using mobile devices, the volume or pressure of a gas mixture is measured.

The second group of devices also supports physical methodology, but with the addition of a physical and chemical process.

Such processes may include:

- electrochemistry;

- thermal chemistry;

- photocolorimetry;

- photoionization;

- chromatography.

Naturally, depending on the specific process, the result is obtained in different ways. For example, electrochemistry determines the concentration of a gas mixture based on its electrical conductivity. Or, by measuring the thermal output of the catalytic oxidation reaction, the degree of concentration of combustible gases is obtained.

The third group of gas analyzers, built exclusively on physical methods, is represented by magnetic, optical, densimetric and other devices. This group includes, for example, thermal conductometric instruments for analyzing gas mixtures, thanks to which results are obtained by measuring the degree of thermal conductivity of substances.

The basic operating principle and design of gas analyzers allows the analysis of multicomponent mixtures by measuring the concentration level of one component present in the mixture.

Principles of classification of gas analyzers

All currently existing analyzing devices are classified based on their design and technological details. The classification characterizes the specific functionality of gas analysis instruments.

For example, an indicator and a signaling device may be somewhat similar, but are classified as different meters. The same applies to leak detectors and gas analyzers.

The design classification determines properties such as mobility and portability. The ability of devices to measure a certain number of components is classified as a single-component or multi-component device.

Similarly with the number of measurement channels, where there is a classification according to single-channel or multi-channel gas analyzers.

Finally, there is one more criterion that shows the specific purpose of the devices. For example, there are gas analyzers for monitoring car exhaust gases, and there are devices that control technological processes.

The most common devices

The most common devices included in the three noted groups are optical and electrochemical models. Their attractiveness is due to the possibility of making measurements in real time.

At the same time, technologically the devices support multi-component analysis with the ability to save results in a memory chip.

For the industrial sector, such devices are indispensable equipment.Especially where continuous emissions monitoring or process analysis is required.

In such cases, gas analyzers often act as systems for continuous monitoring of the industrial production process and are used in environmental studies. For selection for use in a domestic environment, gas analyzers of the indicated types are also preferable.

Choosing a device for gas analysis

When trying to make a choice of device, it is advisable to decide what task will be assigned to the device. Based on the intended tasks, it is easier to find the required equipment. In addition, the financial issue with the exact selection of equipment will be resolved in favor of the buyer. The fewer parts in the kit, the lower the cost.

The following operating criteria are usually considered when choosing:

- list of supported gases;

- concentration measurement limit values;

- the ability to analyze volume and mass fractions;

- continuous operation time;

- the ability to take measurements at several points at once.

Of course, external performance plays a certain role in the equipment selection process. The presence of protective properties, such as a waterproof housing, blocking the penetration of dust and soot - all this is also important if you count on the longevity of the analyzer.

Considering the saturation of the Russian market with foreign-made gas analyzers, one has to choose with an eye to adaptation to domestic conditions.It is clear that if the information part of the device is in a foreign language, it is more difficult to use such a device. True, over time you can get used to it.

Any gas analyzer is equipped with working sensors (sensors). As they are used, these elements lose their properties, lose sensitivity and must be replaced.

How frequent replacements should be and how things go with the acquisition of spare parts is also a matter of choice that requires a careful approach. And the warranty period is not the last detail that you should pay attention to.

Review of gas analyzer manufacturers

Among the foreign companies whose products have gained popularity in the domestic market, the German company Testo AG stands out. It produces a wide range of control and measuring equipment, including various types of gas analyzers.

The company has existed for more than half a century and over this period of time has learned to create truly high-quality equipment that is sound in all respects.

Specifically regarding gas analyzers: Testo AG supplies the market with devices capable of measuring, analyzing, and providing characteristics of various flue gases generated heating equipment.

The domestic company Politekhform-M also provides a decent selection of gas analyzers. This is one of the major manufacturers of instrumentation and analytical equipment.The enterprise has its own experimental and laboratory base, which ensures the successful development of modern devices.

The range of Polytechform-M is represented by models of gas alarms from the “Signal” and “Sigma” series, including multi-channel designs. The company also produces a series of DMG detectors and other equipment. Among specific examples we can note: “Signal-033”, “Sigma 1M”, “DMG-3”.

The St. Petersburg company Informanalitika has developed and produces a series of devices under the “Hobbit” brand. The Hobbit-T series covers a wide range of substances with which the instruments can work and perform analysis.

Almost all types of gases used in industrial production and the domestic sphere are analyzed using a device developed by a company from St. Petersburg. True, Hobbit-T is equipment that belongs to the category of stationary devices. This factor somewhat limits user choice.

Another German company, Fessen, through its subsidiary WITT, supplies fast, accurate, multifunctional gas analyzers. Moreover, the choice for the consumer is practically unlimited in terms of the design of the devices.

The WITT assortment is filled with stationary and mobile devices designed for selective or in-line inspection. All types of gases can be analyzed with WITT technology, and the range of possible applications starts from the food sector and ends with metallurgy.

Devices from the Promekopribor company are interesting to choose from. A relatively young Russian company (2009) develops and promotes modern analytical technology for environmental purposes on the domestic market.

It is noteworthy that the company's products fully comply with regulatory documentation for domestic use. The list of the company's products is headed by devices of the Polar and Test series. These are portable multicomponent gas analyzers designed for industrial process control systems.

Easy-to-use household appliances are supplied to Russia by the Italian company Seitron s.r.l. Italians have been working on the Russian market for more than 15 years and during this time they have managed to supply more than 450 types of control and measuring equipment.

For the domestic sphere, it may be of interest, for example, the development of “Seitron RGDMETMP1” - a gas indicator for natural gas supplied main gas pipeline.

This is just one isolated example of Italian equipment. In general, Seitron technology is capable of meeting demand in a wide range of needs. Here you will find, for example, mobile gas analyzers for routine adjustment of gas and solid fuel boilers and stationary alarms for indoor gas contamination.

A gas analyzer is an electronic device that is increasingly becoming a necessary accessory for many aspects of modern life. Scientific and technological progress has given people many useful things and products, but at the same time it has brought a lot of harmful production technologies and operating conditions.

Conclusions and useful video on the topic

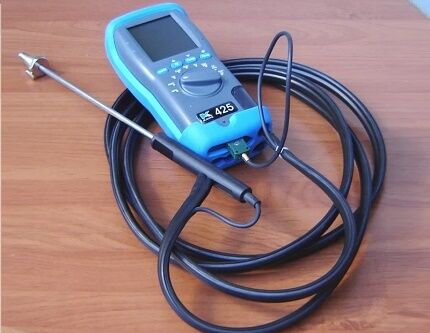

Using the mobile model as an example, you can understand the operating principle of a gas analyzer:

Accurate analysis of the environment makes it possible to protect nature and make places where people live clean. Analyzers reveal a complete picture of the state of the surrounding atmosphere, make it possible to assess the situation and immediately take action if there are deviations from standardized standards.

Please write comments in the block below, ask questions and post photos. Tell us about your own experience in using a gas analyzer. It is possible that your recommendations will be useful to site visitors.

I came across such a device when I was working on setting up gas turbines. There, a gas analyzer was used to check fuel combustion.And the labor protection engineer had such a portable device; he measured the state of emissions in the workshop. Electronics, everything is clear, the readings were recorded, then entered into the passport, after adjustment - into the acceptance certificate. We had a stationary Russian version, and the engineer had a small portable German one. A necessary thing.

Human waste and garbage pollute the environment much more than a leaky gas pipe. But the device is still necessary. First of all, to prevent tragedy. I'm thinking of installing a stationary version at home, although the price, of course, is high. Portable ones in everyday life, in my opinion, are useless to ordinary people. Aren't you going to check the gas every hour? But a stationary one will warn you about a leak on its own and will definitely help you avoid trouble.

You think correctly, installing a stationary sensor is the right decision. And it’s best to consider options that run on regular AA batteries rather than on mains power. I think there is no need to explain why sensors using AA batteries are more reliable.

In principle, one sensor in the kitchen is enough, but you can play it safe and install it in all rooms just in case. The price of the issue is not high - only $10 for one sensor, there are cheaper options, but I would not recommend considering them.

If your budget allows, then take the autonomous gas detection sensor Atis HX-2008EX, a model that I personally tested. For the future, I also advise you to get a carbon monoxide detector. For example, the Kronos KXL 601 model, but it costs more than the gas model, about $60.