How a thermal blanket for gas cylinders works: features of the device and use + tips for choosing

The option of supplying gas in a cylinder is very relevant for owners of private houses and buildings, fishing trips and tourists, in a word, everywhere where there is no possibility of connecting to a central gas pipeline. And most users consider a gas cylinder to be a rather primitive device that will always work, because it has “nothing to break.” Do you agree?

But you should be prepared for the fact that in the winter season problems may unexpectedly occur when the propane in the vessels begins to freeze, and the connected devices, including the stove or burner, simply stop functioning. The use of artificial insulation for gas cylinders violates safety standards, affects the fuel supply conditions and worsens the heat exchange of the device with the environment. A weak burner flame may simply disappear after such manipulations. But what should users do in such a situation if they cannot refuse to use bottled gas?

We will help you sort out this issue - in the article we will talk about how a thermal blanket for gas cylinders, which is considered one of the safest insulation materials, is designed and works. Let's consider the technical characteristics, as well as the features of using such devices. We also provide basic recommendations for choosing a thermal blanket.

The content of the article:

The design and principle of operation of a thermal blanket

In the cylinder, the gas is in a liquid state and under high pressure.Capacity run approximately 80%. In case of expansion of the fuel, caused, for example, by heating, an explosion will not occur.

First of all, during operation, the vapor phase of the gas is used, which rises upward. The liquid phase is transformed into a vapor state as fuel is consumed. This process is accompanied by the consumption of so-called fast molecules.

As a result of this process, the liquid loses energy and cools down. The rate of temperature decrease depends on evaporation, as well as the presence of liquid in the cylinder. The gas supply will stop at a critical temperature level. To prevent this from happening, users use special heating devices - thermal blankets. We will consider their features in more detail below.

When is additional cylinder heating needed?

Blankets for domestic gas cylinders should be used at temperatures close to -15 degrees Celsius. When the thermometer reaches -30 degrees, operating the cylinder without a thermal blanket becomes impossible. This process becomes especially complicated in the winter season, since as the air temperature drops, the freezing of the container accelerates.

Even in a room with an air temperature below zero, the butane in the cylinder does not evaporate. The combustion of propane causes the boiler, convector and other gas-using devices to go out. The remaining butane can be burned out, but only at above-zero temperatures, or you will have to change the cylinder to a refilled one.

On the surface of the vessel can also frost will form due to poor fuel quality, especially if gas stations in the cold season do not use a special type of propane-butane. In such a mixture (“winter”) propane should predominate, since it is this gas that evaporates even at sub-zero temperatures.

We examined the types and characteristics of gas mixtures in more detail in this article of ours: Types of gas mixtures in cylinders for a gas stove.

The device ensures heating of the gas cylinder to a safe level - +40 degrees Celsius. Under such conditions, complete evaporation of the mixture of propane and butane is achieved.

This operating principle guarantees stable operation of water heaters, convectors, boilers and stoves in the cold season, even at sub-zero temperatures.

Characteristics and advantages of insulation

To heat a propane cylinder, you must use only safe devices, including a special thermal blanket.

Its main technical properties include the following:

- Heating is carried out to a temperature of +40 degrees Celsius, maximum deviation +/- 5 °C.

- The device operates from a 220 network.

- Its power is 160 W.

- At a temperature of -15 degrees Celsius, it consumes electricity about 80 W per hour.

- Size when unfolded: 108*45*2, 116*103.2 cm.

- The thermal blanket weighs only 1 kg.

- Volume: 27, 40, 50 l, also suitable for Ragasco cylinder 33.5 l.

- Helps save electrical energy up to 30%.

- Service life – at least 3 years.

- There is an indicator of the presence of power from the network.

The cost of purchasing a heater will pay off in the first season, because the device allows you to save on the purchase of additional gas cylinders.

Uniform fuel consumption ensures stable operation of burners and stoves. The thermal blanket also normalizes the pressure inside the vessel and allows you to avoid dangerous situations due to sudden temperature changes in winter.

The thermal blanket has other advantages:

- does not lead to the formation of hazardous condensate;

- suitable for use at any time of the year;

- convenient to use;

- ensures complete evaporation of the liquefied fraction;

- robust design;

- quick removal and reinstallation;

- It is possible to manufacture according to individual orders - with certain dimensions and power;

- operational safety is ensured by explosion-proof cable entry;

- eliminates the need to use multiple heat sources simultaneously.

The thermal blanket is suitable for heating cylinders and special cabinet. A galvanized protective structure must be used for storing cylinders with a volume of 12 liters or more.

Classification and configuration of thermal blankets

Several types of heaters are produced:

- Category "C" This type of thermal blanket is fire and frost resistant. The surface of the product is made of tarpaulin, the density of the material is 380 g/m2.Safety is ensured by the fire-resistant mixture used on the top of the blanket. The kit includes a frost-resistant cable and plug.

- Category "B" — a moisture-resistant type of thermal blanket. Its upper part is made of jacket fabric. A nichrome heating wire in silicone insulation is used as the inner layer. Thermal insulation is 300 g/m2 voluminous padding polyester.

For storage and transportation there is a convenient case that comes included.

After disconnecting the plug, you must remove the heater from the cylinder and place it in the protective cover.

The thermal blanket must also be unplugged while being carried. The cylinder should be stored in a place regulated by the Rules for the Design and Safe Operation of Pressure Vessels PB 10-115-96, approved by the Resolution of the Gosgortekhnadzor of the Russian Federation.

Recommendations for using the heater

We looked at how a thermal blanket for a gas cylinder works and what it is. Now let's talk about how to use it correctly.

Before using the thermal blanket, you should check the tightness of the cylinder, as well as gas-using equipment. If impermeability violations are detected, they should be eliminated. If external signs of heater malfunction are detected, including a defective power cord, the device should be disconnected.

We also recommend that you read the rules safe use of cylinders at home.

Depending on the need, the thermal blanket can be connected for the entire period of operation or used intermittently.

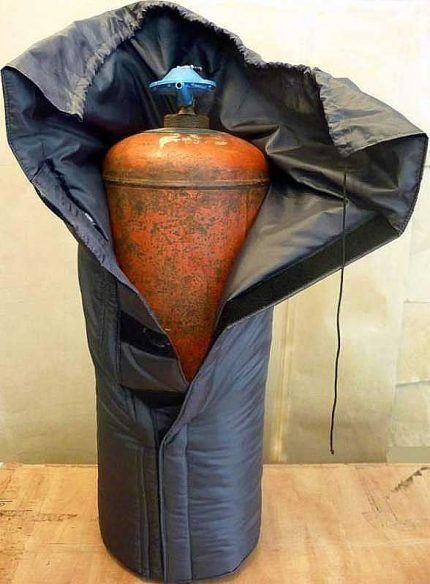

In working condition, the heater is wrapped around the cylinder. The thermal blanket covers the entire surface of the container; Velcro is provided for fixation. A cord that cinches at the top provides access to the tap. To get started, just plug it into a power outlet.

The heater must not be used if sparking, a smell of smoke or damage to the insulation of the connecting cable is detected. Do not use folded or wrinkled, or wash the product.

How to choose a thermal blanket?

Before purchasing, you should decide type of cylinder, which needs to be warmed. It is important to consider circumference, volume and dimensions.

As mentioned above, heaters come in special designs - moisture-resistant and fire-freeze-resistant; they are distinguished from conventional models by additional functions.

The quality of a device can also be determined by several criteria:

- by heating time;

- maintain the desired temperature if possible;

- for uniform heat distribution;

- the tightness of the blanket.

It should also be kept in mind that the cord should not protrude from the top of the end of the blanket, otherwise this may cause the cable to bend continuously and cause further failure.

A blanket for heating a gas cylinder of standard sizes can also be used for plastic containers with a volume of 18 liters. This will allow you to save on ordering insulation in standard sizes.

But not only a thermal blanket will help to insulate the cylinder. We have considered other safe methods in the next article.

Conclusions and useful video on the topic:

The following videos will show you how to decide on the type of heater for a gas cylinder and install them correctly.

Review of Electric Vaporizer for Gas Cylinder:

Why does gas freeze and how to avoid freezing of the cylinder:

How to make a heater with your own hands:

The thermal blanket allows you to save about a third of the contents of the gas cylinder. Using the device eliminates the hassle of moving heavy gas containers into a heated room. Caring for insulation does not require much effort. It is enough to use the case that comes with the kit. If used correctly, the device will last for many years, but if any problems occur, you should definitely seek help from specialists.

Do you have any questions about using insulation, have you found inaccurate information about how a thermal blanket works, or would you like some advice? Leave your wishes, express your opinion, share your experience of use - the feedback form is located below the text.