Gasification of industrial facilities: options and standards for gasification of industrial enterprises

What makes it necessary to lay a gas supply system to a plant, factory, plant or power plant? First of all, gasification of industrial facilities provides them with uninterrupted heating.

Secondly, it is the possibility of continuous supply of hot water. Thirdly, gas can be used in various technological processes as a fuel, and some enterprises require a steam supply.

We will talk about how water supply systems are organized at manufacturing enterprises. The article we presented describes in detail the options for installing gas supply systems and their popular varieties. The costs allocated for the construction of main gas supply circuits are considered.

The content of the article:

Gas fuel options

The main consumers of gas are factories and power plants. They use gas as an efficient fuel. Enterprises in the chemical, metallurgical, and mechanical engineering industries also use gas when carrying out technological processes. In cities, the food industry is actively switching to gas use.

Gas supply to an industrial enterprise, depending on the fuel sources, can be carried out in various ways. Large industrial enterprises use their own gas sources. In most cases, this is generator, coke oven or blast furnace gas. When processing coal, artificial gases are released: illuminating gas, coke oven gas and others.

The interaction of chemical elements in production processes causes the release of gas as a by-product. If insufficiency and shortage of a resource is detected, then industrial enterprises are often connected to the main gas pipeline, which supplies natural gas: standard or associated petroleum.

Natural gas is considered the best fuel option for gas supply.

This is due to the following advantages:

- low price for natural gas;

- high calorific value;

- possibility of fast and cheap transportation;

- small amount of harmful emissions into the air during combustion;

- full automation of combustion.

Gas outperforms other types of fuel due to the fact that its supply is mainly carried out through pipelines.

This allows owners of industrial enterprises to free up territory intended for solid fuels and their waste. There is also no need to have vehicles to constantly transport large volumes of fuel.

Types of gas supply systems

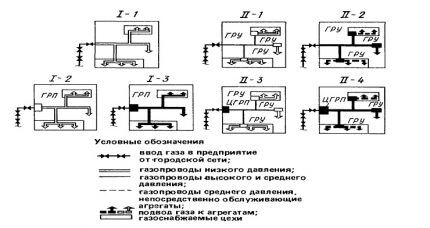

Industrial enterprises can be gasified using several schemes, which differ depending on the design conditions of each individual facility.

Single stage gas supply systems are designed in cases where:

- it is planned to connect the enterprise to the city gas pipeline with a low pressure level;

- it is planned to connect an industrial enterprise to the city gas network through a central gas control point if it is necessary to ensure low pressure in the gas pipeline of the facility;

- The connection of an industrial facility to city networks is being developed by connecting to the central system through a gas distribution point with a future average level of gas pressure in the pipes.

Installation of two-stage systems is provided in the following cases:

- when connecting workshop gas distribution installations of an industrial facility to the city gas pipeline through medium and low pressure distribution points in workshop gas pipelines;

- when connecting workshop gas distribution installations of an industrial enterprise to the city medium-pressure gas network at an average level of pressure in the workshop gas pipelines;

- when connecting shop gas distribution units to the central gas distribution point of city networks at an average pressure level in inter-shop gas pipelines and a low pressure level in shop gas pipelines;

- when connecting workshop gas distribution units to the central gas distribution point of city networks at an average level gas pressure in inter-shop gas pipelines and at an average level of pressure in shop gas pipelines.

When designing a gas supply system for a separate industrial enterprise, engineers are often faced with the need to combine circuit diagrams for the specific conditions of the gasified facility.

Centralized gasification of industrial enterprises

Industrial gas supply systems include a number of components.

The main components include:

- gas pipeline entries into the organization’s territory;

- network of intershop gas pipelines;

- in-shop gas supply system;

- regulatory points and installations;

- devices that measure gas flow;

- piping gas pipelines for gas consuming devices.

Gasification by connecting to the main gas pipeline is typical for the largest plants - the flagships of industrial production. The vast majority of small and medium-sized industry representatives use the services of city gas supply.

Industrial facilities are supplied with gas from a looped distribution network. There are three pressure levels: high, medium and low. Most plants and factories are powered by high and medium pressure air defense systems. And only a small number of small urban industrial facilities have enough low pressure.

Large industrial facilities are supplied with two inlet pipelines from different mains, which are then combined within the facility area. Pipelines transporting gas to a facility are made above ground or underground.

Overhead pipelines are a more popular option because they are easier to inspect and maintain. In case of gas leaks, such pipelines are not so dangerous. They are also not subject to constant corrosion.

They are installed on supports or carried along fire-resistant external walls and structures. The height of the gasket is regulated by regulatory documents.

Several taps or valves with a lens compensator are installed along the pipe: one outside the industrial building and several, depending on the needs of the enterprise, directly on the site.

At large plants, each inter-shop gas pipeline has its own separately developed diagram, which is compiled depending on the level of gas consumption. Schemes of inter-shop gas pipelines differ by and large in the number, location and type of gas control points.

Small factories powered by a low-pressure loop distribution network usually do not install gas control points, but installation of a gas flow metering point is required.

If the pressure level is higher than necessary, then a central gas distribution point is installed on the territory of the industrial facility. The device reduces the pressure to the level required by the enterprise.

If it is necessary in some workshop to provide a different pressure value, a gas distribution unit is installed in it, with the help of which the pressure indicators can be adjusted.

If each workshop in an enterprise requires an individual pressure level, then it is possible to run a gas pipeline to each separate workshop.To do this, a gas distribution installation must first be installed.

Gas consumption at different enterprises is uneven and depends on many factors. Typically, increased resource consumption occurs during the daytime, when the main technological processes in plants and factories are carried out.

On weekdays, most industrial enterprises consume more gas than on weekends. However, some factories operate without technological downtime.

To calculate gas consumption, it is important to take into account seasonality. In winter in cold regions, resource consumption is several times higher than in summer. Due to uneven gas consumption, a number of problems arise.

In summer, remote gas pipelines do not operate at full capacity, and in winter, there is a need to reduce or completely stop gas supply to certain areas.

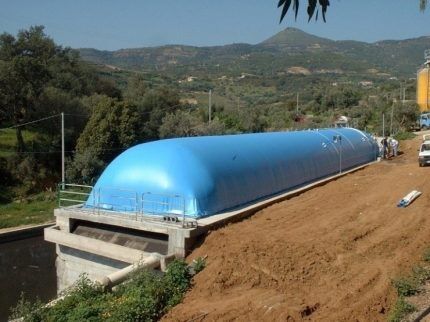

In the construction of autonomous gas supply networks for enterprises located in areas inaccessible to laying a gas pipeline, special containers are used - gas tanks intended for industrial facilities. This option is also used if organizing a standard gas pipeline is unprofitable.

In order to fully utilize the resource in the summer, buffer consumers are installed that can operate on several types of fuel. They are designed for a quick transition of the unit from consuming one resource to another.

Autonomous gas supply to organizations

If an entrepreneur is wondering how to gasify his enterprise, one of the possible solutions is to join a centralized gas supply. However, the legislation also provides for the possibility of using autonomous gas sources.

The advantages of autonomous gasification include a reduction in gas consumption from the general network. The costs of installing an autonomous gas storage facility, as well as gas tank installation cost on a suburban area, significantly lower than the costs of laying pipes and connecting to a centralized main line.

Such systems are used for the following purposes:

- providing cogeneration plants with the necessary fuel for efficient generation of electrical and thermal energy;

- fuel supply to gas infrared heaters;

- ensuring continuous operation of gas generators;

- Providing the necessary resources for gas-fired boiler houses.

At industrial enterprises, gas can be used as the main energy carrier or as a resource to ensure the operation of a backup energy supply scheme. In the second case, gas tanks are purchased, which should be installed strictly in accordance with GOST and SNiP standards.

The gas tank bodies are covered with a protective layer that prevents electrochemical corrosion processes.

Among the necessary equipment for installing an autonomous gas system at a facility are:

- Liquid or electric evaporators, which are additionally equipped with a regulatory group. They improve design productivity.

- Mixers installed on pipelines of enterprises connected to the central pipeline;

- Drain unit that allows you to remove condensate;

- Gas pipelines for various phases of gas mixtures;

- Condensate collectors that collect and discharge condensate from the pipeline to evaporators or disposal devices;

- A control complex designed to automate control over the operation of a tank farm.

Tank installations have the following operating diagram:

- Filling with liquid gas;

- Storage of liquid fuel under pressure in a tank;

- Supply of liquid phase to the evaporator;

- Conversion of liquid phase into vapor phase;

- Supply of steam phase to equipment and burners.

Gas is supplied to the evaporator using pumps. The tank complex must be equipped with an automatic control system.

The procedure for gasification of an industrial enterprise does not depend on whether gas is used as the main energy carrier or as a fuel for backup energy supply. To gasify an organization, it is necessary to carry out a number of sequential measures.

Even at the design stage, the concept of “enterprise gasification” is clarified and specified. Thus, the documentation indicates sequentially gasified: equipment, communication systems, workshop and enterprise.

First of all, you should submit an application to the design institute. There, thermal engineering calculations are carried out and the fuel requirement of the gasified facility is determined depending on the technological conditions at the enterprise.

The next step is to send a letter to the gas distribution organization of the region. It must contain a request for the issuance of a certificate confirming the technical ability to connect the industrial facility to regional gas networks.

The listed set of papers should be accompanied by a situation plan and a thermal engineering calculation carried out at the design institute.

The regional gas distribution organization also receives a certificate of technical ability to connect the enterprise to gas distribution networks.

To obtain technical specifications For gasification, it is necessary to obtain permission to use natural gas as fuel from the design and technical department of the design organization developing the project and estimate.

A tripartite agreement is also signed between the gas supplier, consumer and gas distribution organization. After receiving all documents and permits, all systems and equipment are installed and installed and the gas is started directly.

Gasification service costs

The use of natural gas is economical, uninterrupted supply and highly environmentally friendly.When owners and decision-makers of industrial enterprises, plants, and factories realize the future benefits of gasification, they ask themselves about the cost of gas pipeline services.

Similar questions are asked by owners of private households, whom connection cost worries no less than managers and boards of directors of enterprises. In essence, the cost items for private and commercial consumers are similar; the difference mainly lies in tariff rates.

On the one hand, the necessary documentation can be collected in person. In this case, you will have to face the problems of documentation, spend personal time, money and delve into all the processes. The actual installation of gas systems must be carried out in accordance with the norms and regulations approved by government agencies.

Only companies specializing in the installation of gas pipeline communications will be able to carry out such work. You can use the services of small teams, contractors or teams of large services.

On the other hand, there are a number of companies operating on the market that provide comprehensive services for installing gas supplies to industrial and commercial enterprises. Such organizations, for a pre-agreed amount, will carry out the entire range of work, including documentation, purchase of equipment and installation of all systems.

Of course, the services of such companies will not be cheap. However, they guarantee high quality work and fulfill orders in the shortest possible time.

The cost of services of specialized companies varies depending on a number of factors:

- power of the installed equipment, measured in kW;

- the number of facilities on the territory of the enterprise that will be gasified;

- presence and number of technological gas consuming devices;

- the designed length of the gas pipeline, measured in meters;

- geological conditions of the route along which the gas pipeline will be laid.

In order to save on gasification, it is recommended to adhere to the following tips:

- insulation of gas-conducting structures reduces heat loss from heated objects and the required power of equipment;

- installation of modern heating systems pays for itself in a short time due to their high energy efficiency;

- if there are industrial facilities in the neighborhood, it is worth considering the joint design of gas supply routes;

- calculate the most optimal route and method of laying gas routes.

On average, it takes from 12 to 15 months to complete all stages from design to launch of gas supply systems.

Conclusions and useful video on the topic

How to select and install a gas tank:

Laying a gas pipeline underground:

Installing a gas pipeline and adjacent gas systems to industrial facilities is a complex and multi-stage process. For its successful implementation, many nuances and features should be taken into account. It will also require significant financial investments to purchase equipment and pay for installation work.

However, the money spent will pay off in the near future. This is due to the inexpensive cost of natural gas, good price-quality ratio and high environmental friendliness. The enterprise will not need to purchase expensive filtering equipment in order not to pollute the environment.

There are several possible problems that the enterprise will have to face. Difficulties may arise in obtaining agreements and licenses. It is also necessary to obtain the consent of the owners of the land on which the pipeline will be laid. All problems can be easily solved if you choose the right approach.

Since working with gas is primarily a responsibility and qualification, it is important to choose a good contractor. It is recommended to cooperate with companies that have positive experience in laying gas communications. The company must know all the intricacies of the work and be aware of its responsibility.

In difficult situations, you have to cooperate with government supervisory authorities and comply with their requirements and recommendations. It is also possible to make adjustments during the laying and installation process.