LED lamp E40: device, characteristics, scope

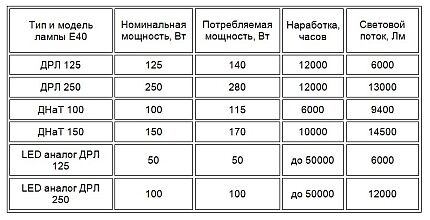

LEDs are methodically replacing not only household incandescent lamps, but also industrial lighting equipment.The desire to save money forces entrepreneurs and municipal authorities to look for less energy-consuming devices.

An excellent option for organizing lighting over a large area is the E40 LED lamp, the design of which is compatible with many lamps in use.

In this material we will talk about the design of LED lamps, their types and scope of application.

The content of the article:

LED lamp device

Due to the large diameter of the base, the E40 LED light bulb easily accommodates many electronic components inside it. And its increased body volume allows for even distribution of heat, preventing overheating of the product.

Thanks to its design features, the E40 LED lamp receives many other advantages.

General structural elements

E40 LED lamps can vary quite a bit in appearance. All of them are united only by the type of screw base, the diameter of which is 40mm. Despite the external differences, the design of such light bulbs has common features.

Their main components are as follows:

- Diffuser. It is a matte volumetric plastic shell located around the LEDs. It ensures the most uniform distribution of light across the entire circumference of the lamp.

- LED crystals, which are direct light emitters. They are located on a printed circuit board and can be of three types: SMD, COB, Filament.

- Printed circuit board. It has the form of a heat-conducting metal plate, which facilitates the transfer of heat from operating LED crystals to the radiator.

- Aluminum or metal-plastic radiator. It is usually located between the base and the bulb, and has a ribbed shape designed to increase the heat transfer area of the light bulb.

- Driver. It is a microcircuit that provides low voltage and constant current to LED crystals. A high-quality driver should not cause the lamp to blink during operation.

- Dielectric plastic or ceramic liner, which separates the energized base from the remaining structural elements of the LED light bulb.

- Screw metal base E40, with a diameter of 40 mm. It serves to mount the lamp in the lamp and ensures the transmission of current from the socket to the driver.

If the base of an E40 type LED lamp is always the same, then the external shape of the bulb and radiator can vary greatly.

The powerful light-emitting crystal generates a lot of waste heat. To maintain an acceptable operating temperature inside the housing of such lamps, a heatsink with a large surface area is required.

Therefore, the size and shape of LED devices is largely determined by their power and other technical characteristics.

Features of the Edison base

The letter E in the marking of the threaded base owes its origin to the inventor of lamps, Thomas Edison, who patented this engineering solution more than 100 years ago.

Its design has not changed over a century due to a number of advantages:

- simplicity and durability of installation;

- large contact area with the inner surface of the cartridge;

- ease of production;

- possibility of installing additional parts inside the base.

The most common screw base formats are E14, E27 and E40. The two-digit number in the marking indicates their outer diameter.

The E40 base was previously used in mercury arc lamps and incandescent light bulbs. Its large size was due to the need to increase the contact area with the cartridge, as well as the desire to reduce the heating of the glass base in a narrow place.

E40 LED lamps are manufactured only to ensure compatibility with older luminaires. There are currently no objective reasons for using such large plinths.

Circuit diagrams

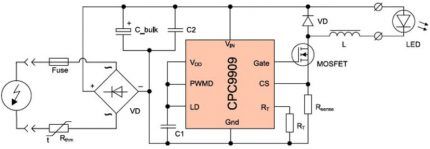

The cost and reliability of E40 LED lamps largely depends on the quantity and quality of driver parts. And it is based on a microcircuit that can be manufactured in various functional versions.

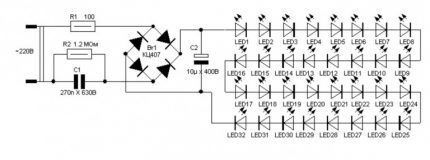

In its simplest form, the driver consists of a small capacitor and a voltage rectifier. The load current limiter is an SMD resistor located on the LED board. This elementary circuit does not even contain a transformer, which forces it to use a strictly defined number of LEDs.

In such a cheap option, the light of the lamp will pulsate, which can negatively affect the general health of people nearby.

The most difficult LED light bulb drivers include the following structural elements:

- bridge voltage rectifier with capacitive ballast that limits the input current;

- several high-capacity capacitors located at different levels of the circuit;

- a feedback system that allows you to adjust voltage and current parameters;

- dimming circuit, which makes it possible to smoothly control the lamp luminosity.

A high-quality driver completely eliminates the ripple of the LED lamp and stabilizes the voltage supplied to the LEDs.

This increases the overall service life of the product and increases its efficiency. Complex schemes also have disadvantages:

- big size;

- difficulty of repair;

- high cost.

In addition to the two electrical circuits discussed, there are many intermediate options for the internal design of the driver. Consumers demand light bulbs of various designs. For example, for night lighting of deserted industrial sites, a lamp with a simple driver will be sufficient.

Varieties of E40 LED lamps

Industrial lighting equipment is structurally much more diverse than household lighting equipment. Accordingly, it requires different lamp characteristics. The direction of light, the ability to operate in continuous mode and the security of the housing are of great importance.

Manufacturers follow demand and offer consumers the following modifications of LED lamps:

- dust- and moisture-proof;

- with operating voltage 110 or 220 V;

- illumination angle from 120 to 360 degrees;

- power from 10 to 500 W;

- made of plastic, aluminum, heat-resistant materials;

- with a matte, transparent bulb, with open LEDs;

- with light and motion sensors;

- dimmable;

- vibration-resistant, explosion-proof.

For little-known manufacturers of LED lamps, additional options may be more of a marketing ploy than a real advantage. Therefore, priority when purchasing should be given to lighting products from well-known brands.

Features of industrial LED lamps

Lighting devices with E40 socket are used only in industrial and public areas. Household products of this design are simply not produced.

Industrial lamps are subject to increased requirements for reliability and resistance to external factors. Therefore, the E40 LED lamps operating in them also have a number of features:

- The power factor value is 0.9-0.95, and for household light bulbs it is 0.7-0.9.

- LEDs often have individual lenses that change the direction of the light flux.

- Extended operating temperature range. The driver in E40 bulbs is designed to heat up to 110-120 °C and cool down to -50 °C below zero.

- Increased service life - up to 10 years of continuous glow.

- The housing often has anti-vandal protection to prevent mechanical damage to the LEDs.

- The placement of LEDs on the board suggests the possibility of replacing them during repairs.

- Most E40 lamps are protected from wind, rain and dust.

- A reinforced radiator allows for active heat removal during round-the-clock operation.

- Increased color rendering coefficient.

- Unlike mercury lamps, LED lamps do not require the installation of additional starting devices.

The above advantages significantly increase the cost of LED lamps with E40 socket. But due to increased reliability and extended service life, such products reduce the operating costs of enterprises.Once you install these LED bulbs in your lamps, you won’t have to worry about them for several years.

Lighting equipment with E40 socket is being replaced by modern models rather slowly. The reason is the lack of new alternative standards for connecting removable LED lamps. Another obstacle to equipment renewal is the indifference of industrial consumers to the design and obsolescence of devices.

Areas of application for E40 lamps

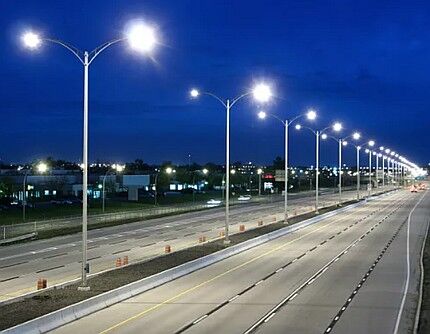

The niche of devices with directional light flux in the industrial sector has long been occupied by LED spotlights. Bulbs with an E40 socket are assigned a niche for diffused lighting of large areas and rooms.

The main places of their use are:

- Street territory of industrial facilities, warehouses, transport bases, public institutions.

- Roadside lamp posts.

- Yards of private houses, dachas.

- Shopping and entertainment centers.

- Production workshops with high ceilings.

- Stadiums.

- Hangars.

- Playgrounds.

In winter, LED lamps are good because when snow gets on them, it does not create a temperature difference in different parts of the body. Thanks to this, the strength characteristics of their flasks are not compromised.

The E40 base is a relic of the past, so it is unlikely to be used in new applications in the future.

Conclusions and useful video on the topic

The videos demonstrate E40 LED light bulbs in action and also look at their internal structure.

Comparison of LED lamps with different bases:

Overview and internal structure of the E40 LED light bulb:

Testing of high-power LED corn lamps E40:

The native E40 base in LED light bulbs is being used less and less. The reason for this is the desire of manufacturers to please the maximum number of consumers. Often they simply complete E27 format products with an adapter for a larger diameter. However, this does not prevent LED lamps with a forty-millimeter base diameter from providing high-quality lighting for large rooms and saving money for municipal and commercial enterprises.

Do you have any questions about the topic of this article? You can set them in the comments block, which is located under the article. You also have the opportunity to supplement this material with interesting information and facts that you know about E40 LED lamps.

We have been using LED light bulbs in everyday life for a long time. They really save the family budget. It’s interesting that there were also some not very successful lamps. The lamp socket, for example, worked for no more than a week after purchase. The design of the chandelier involves the operation of 5 light bulbs, we install all the same ones. And after a week one starts blinking, and then all the lights go out. The electrician looked at it and said that one of the bulbs was defective, but this is rare. The edge of the base has acquired a brownish color, and the melting process has begun. The master also went through the socket and wires where this lamp was installed, and it was necessary to change what had burned out there. He stated that the wiring was not at fault.

I don’t understand when they talk about the morally outdated base of a light bulb. What difference does it make how this same light bulb contacts the socket? Will it be screwed in or inserted? For me, I don’t really care. And to be absolutely objective, new contact groups will appear only when a fundamentally new source of lighting is invented, but not before.

Daniil, I generally think that E bases are one of the most convenient and practical. They have all the advantages: standardization, simplicity, reliability. Why come up with anything else?