Choke for fluorescent lamps: device, purpose + connection diagram

Agree: there is no need to buy and install unnecessary devices, without which the lighting system can work. Such questionable devices include a choke for fluorescent lamps.You don’t know whether it is needed in the connection diagram or whether you can do without it?

We will help you resolve the issue that has arisen. The article discusses in detail the features, purpose of the throttle and the functions it performs. There is a photo and a connection diagram that will help you assemble the fluorescent lamp yourself and start it up by correctly connecting all the components into the electrical circuit.

To help the home craftsman, we have selected a number of videos containing recommendations on connecting fluorescent light bulbs, as well as on choosing the right inductor depending on the type of lamp.

The content of the article:

Purpose and design of the throttle

Discharge lamps, of which the fluorescent variety is a representative, cannot be lit as usual, providing power supply. They simply won't work. To obtain the glow of this type of source, you will need to additionally use a ballast.

Purpose of ballast in the connection circuit

It turns out that for a fluorescent light bulb to function, it is necessary not only to ensure the flow of current, but also to apply voltage to it.

Therefore, the switching circuit uses ballast - resistance. It is connected in series with the lamp and is designed to limit the current flowing through its electrodes.

Its role can be performed by various electrical components:

- in the case of direct current, these are resistors;

- with variable - inductor, capacitor and resistor.

Among these devices, the most successful option is the throttle.It has reactance without generating excessive heat. Capable of limiting the current, preventing its avalanche-like increase when connected to the power grid.

The choke is not only an integral element in the starter circuit, it performs the following functions:

- helps create a safe and sufficient current for a particular light bulb, which ensures prompt heating of its electrodes when ignited;

- an increased voltage pulse generated in the winding contributes to the occurrence of a discharge in the luminescent bulb;

- ensures stabilization of the discharge at the rated value of the electric current;

- promotes trouble-free operation of the light bulb despite voltage fluctuations that periodically occur in the network.

Essential for functioning fluorescent light sources has the inductance of the choke. Therefore, when purchasing this electromechanical component, you should pay attention to the technical parameters, which must correspond to the characteristics of the light bulb.

What does a ballast consist of?

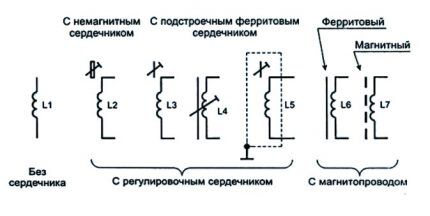

The inductor used in circuits for switching on fluorescent light bulbs is nothing more than winding a wire on a core - an inductor. It is its industrial design that is called a choke in electrical engineering, which literally translates as “limiter.”

A choke with the required technical characteristics is produced in an industrial environment, so the consumer will not have problems selecting the right option that matches the parameters of the connected light bulb.

Moreover, having the skills to assemble various electrical devices, the appropriate components and power tools, you can try to independently build a coil with the required inductance.

The throttle consists of the following elements:

- wire in insulating material;

- core – most often of the ferrite type or from other materials;

- potting compound, compound - it contains substances that are resistant to combustion, which provides additional insulation of the turns of the winding wire;

- frame, in which the winding is placed - it is made from heat-resistant polymers.

The presence of the last element depends on the features and characteristics of the specific current limiter model.

The starter circuit is imperfect, although it shows excellent results. But the flickering of the light bulb, the noise of the throttle and its large size, as well as a false start due to an unreliable starter led to the invention of a more advanced version of the ballast - electronic.

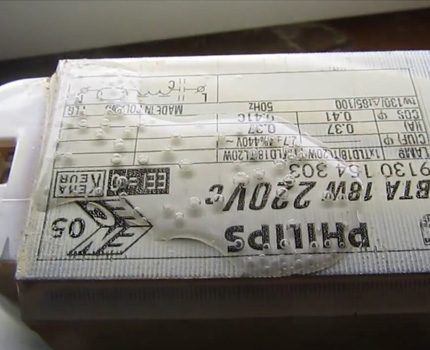

During operation, electronic ballasts help reduce power losses by up to 50% and eliminate flashing lights. Their use made it possible to reduce the mass of the chokes, as well as significantly increase the output of the lighting device.

True, the cost of electronic ballast is significantly higher than electronic ballast, and you need to purchase it from manufacturers with an excellent reputation - such as Philips, Osram, Tridonic, and others.

Scheme + independent connection

You can’t just turn on a fluorescent light bulb - it requires an ignitor and a current limiter. In miniature models, the manufacturer has prudently built all these elements into the body and the consumer can only screw the product into a suitable lamp/chandelier socket and flip the switch.

And for larger products you will need ballasts, which comes in both electromechanical and electronic types. In order to connect it correctly, ensuring trouble-free operation of the device, you need to know the order in which individual elements are connected to the electrical circuit.

True, having a diagram, but not having practical experience in performing this kind of work, it will be difficult to cope with the task. Moreover, if the connection needs to be made outside the home - in the corridor of an educational institution or other public institution - then unauthorized interference with the operation of the electrical network can lead to problems.

To do this, the establishments must have an electrician on staff who works on a permanent basis or serves the establishment as the need for its services arises.

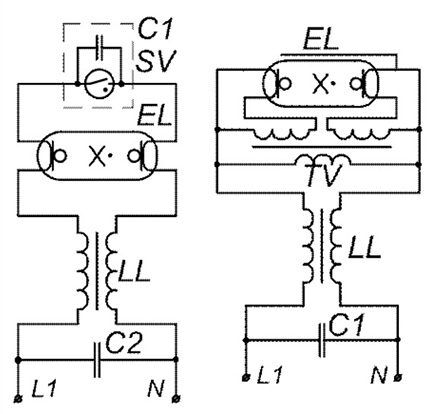

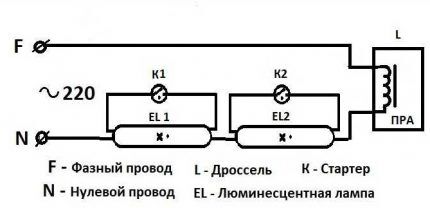

Let's consider the step-by-step connection of two tubular LLs to the electrical network using a starter circuit. For this you will need 2 starters, a throttling component, the type of which must necessarily match the type of light bulbs.

You should also pay attention to the total power of the starters, which should not exceed this parameter at the inductor.

When connecting the power cable to the lamp, it is important to remember that the inductor is responsible for limiting the current.

This means that the phase conductor must be connected through it, and the neutral wire must be connected to the light bulb.

A similar connection diagram is relevant for large lighting fixtures. As for compact models, they are equipped with a built-in starting and adjustment mechanism - miniature electronic ballasts, mounted inside the product body.

Throttle overheating and possible consequences

Using light bulbs that have reached the end of their service life and occasionally experience various breakdowns can result in a fire. Learn more about how to dispose of used fluorescent devices. written here.

Regular inspection of the condition of lighting fixtures - visual inspection, checking of main components - will help to avoid the occurrence of a fire hazard.

If used incorrectly, the flask may explode mercury lamp. The smallest particles can scatter within a radius of three meters. Moreover, they retain their incendiary abilities even if they fall from the ceiling to the floor.

The danger is posed by overheating of the inductor winding - the device consists of various types of materials, each of which has its own characteristics. For example, manufacturers impregnate insulating gaskets with complex compounds, individual elements of which have different flammability and ability to generate smoke.

In addition to overheating of the throttling element, there are other situations with fluorescent lighting that pose a fire hazard.

It can be:

- problems caused by violations of ballast manufacturing technology, which affected the final quality of the device;

- poor material of the lighting fixture diffuser;

- ignition circuit - with or without a starter, the fire hazard is the same.

It should be remembered that problems can be caused by negligence when making connections, poor quality of contacts or circuit components, which most often occurs when using very cheap devices purchased from unknown manufacturers.

Conscientious companies provide a guarantee for their products, and the technical parameters of the devices indicated on the case or packaging correspond to reality. This fact directly affects the service life of both the ballast itself and HID light bulbs, the features of the device and operation of which will be introduced in our recommended article.

Conclusions and useful video on the topic

Subtleties of assembling a circuit of two LLs with serial connection:

Video about what a throttle is and why it is needed:

Checking the throttle for damage:

About the rules for choosing a choke depending on the type of discharge lamp:

Having familiarized yourself with the purpose and design of the chokes used to start fluorescent light bulbs, you can arm yourself with a connection diagram and try to implement it yourself. True, this is true for the home.

In public institutions, the solution to such issues should be entrusted to electricians who have a special permit for electrical installation work.

Please write comments in the block below, post photos related to the topic of the article, and ask questions. Tell us about how you selected and connected the choke. Share useful information on aspects of device selection and installation technology.

During my work as an electrician, I hung an enormous number of these lamps. The choke is the heaviest element of a fluorescent lamp. Usually, before installing the lamp, the inductor is checked with a multimeter or simply a “control” (this is an LED connected to a AA battery). If there is no break, the LED lights up, which means the throttle is working.

Good afternoon, Victor. You can, of course, use an LED control, but a control with an incandescent lamp will be more informative. Let me explain: if the lamp does not light up when checking, it means there is a break in the ballast; if it burns brightly, the interturn is short; If the brightness is half incandescent, then the throttle is working. I have attached a screenshot of the diagram.

Of course, the surest way to find the location of the damage is to use a multimeter.