Types of biofuels: comparison of the characteristics of solid, liquid and gaseous fuels

An alternative to traditional energy resources are various types of biofuel, the production of which uses plant or animal raw materials, industrial waste and the results of the vital activity of organisms.

We offer to understand the advantages and disadvantages of using such fuel, find out the production features, functional characteristics, and also evaluate the effectiveness of using different types of biological fuel. The information provided will help you navigate the choice of alternative sources of energy resources.

The content of the article:

What is biofuel

The most promising direction in the energy sector are technologies that involve the use of renewable resources, which include biological fuel.

As a raw material for its production, you can take biomass of plant/animal origin, including industrial waste or animal waste.

The processing of such substances is carried out by thermochemical or biological methods; in the latter case, fuel is obtained using various types of microorganisms.

Many countries have special programs to expand the share of biofuels in national and regional energy consumption. A number of states also have mandatory standards for the use of this energy source.

Advantages and disadvantages of biofuel

Biological fuels have their positive and negative sides. Interest in the use of this type of raw material is caused by its undoubted advantages.

These include:

- Budget cost. Although at the moment the prices for biofuel are almost the same as the cost of gasoline, biological substances are considered a more profitable type of fuel because they produce fewer emissions when burned. Biofuel is suitable for use in various conditions, and it can be adapted to engines of different designs. Another advantage is the optimization of engine operation, which stays clean longer due to the small amount of soot and exhaust gases.

- Mobility. Biological fuel differs from other alternative energy sources in its portability. Solar and wind installations usually include heavy batteries, so they are most often used permanently, while biofuels can be transported from one region to another without much hassle.

- Renewable energy source. Although researchers believe existing crude oil deposits will last for at least several hundred years, fossil reserves are still finite. Biofuels, made from plants and animal waste, are among the renewable resources that are not in danger of disappearing in the foreseeable future.

- Protecting the Earth's Atmosphere. A major disadvantage of traditional hydrocarbons is the high percentage of CO2, which is released when burned. This gas creates a greenhouse effect in the atmosphere of our planet, creating the conditions for global warming. When biological substances are burned, the amount of carbon dioxide is reduced to 65%. In addition, crops used in biofuel production consume carbon monoxide, reducing its share in the air.

- Economic security. Hydrocarbon reserves are distributed unevenly, so some states are forced to purchase oil or natural gas, spending large amounts of money on acquisition, transportation, and storage. Various types of biological fuel can be produced in almost any country. Since its production and processing will require the creation of new enterprises and, accordingly, jobs, this will benefit the national economy and have a positive impact on the well-being of people.

Improving technology and developing new methods can enhance the positive effects of biofuels. Thus, the development of technologies using plankton and algae will significantly reduce its price.

At the same time, at the present stage of development of science and technology, biofuel production is associated with a number of difficulties and inconveniences. First of all, these are natural limitations in growing plants.

For the growth of crops used for biomass production, a number of factors must be taken into account, namely:

- Water use. Agricultural plants consume a lot of water, which is a limited resource, especially in dry areas.

- Invasiveness. Crops grown for fuel are often aggressive.They choke out the authentic flora, which can cause the biodiversity and ecosystem of the region to suffer.

- Fertilizers. Many plants require additional nutrients to grow, which can harm other crops or the overall ecosystem.

- Climate. Certain climate zones (for example, desert or tundra) are not suitable for growing biofuel crops.

Active cultivation of agricultural plants is also associated with the depletion of agricultural resources. Failure to comply with the rules of agricultural technology can lead to a decrease in the content of useful soil components and, as a result, to their depletion, which will aggravate the food problem.

The ecosystem is disrupted. Biomass production usually requires expansion of agricultural areas.

Often, for this purpose, the territory is cleared, which leads to the destruction of the microecosystem (for example, forests), the death of plants and animals.

Problems arise with growing monocultures. To obtain larger biomass yields, producers often seed land with a specific plant. This practice is not very good for agricultural land, since monoculture leads to environmental changes.

Fields occupied by one type of plant are usually infested by special types of pests.An attempt to combat them with the help of insecticides and pesticides only leads to the development of resistance to these agents.

To avoid the problems described above, scientists advise not to neglect the biodiversity of crops by combining several plants in the fields, and also to use local varieties of flora.

Generations of alternative fuels

The wide range of plant raw materials used for biomass is usually divided into several generations.

First generation. This category includes agricultural crops that contain a high percentage of starch, sugars, and fats. These are such popular plants as corn, sugar beets, rapeseed, and soybeans.

Because growing these crops harms the climate and their removal from the market affects food prices, scientists are trying to replace them with other types of biomass.

Second generation. The biomass group includes wood, grass, and agricultural waste (shells, husks). Producing biofuel from such raw materials is expensive, but it allows solving the issue of recycling non-food residues with the simultaneous production of combustible materials.

A feature of the crops included in this variety is the presence of lignin and cellulose in them. Thanks to them, biomass can be burned and gasified, as well as subjected to pyrolysis to produce liquid fuel.

The main disadvantage of second-generation biomass is considered to be insufficient return per unit area, which is why significant land resources have to be allocated for such crops.

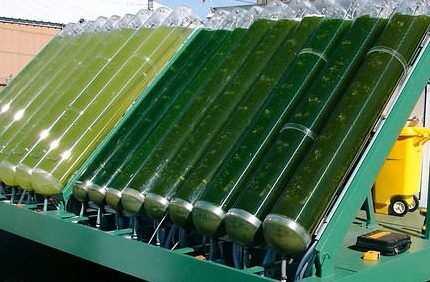

Third generation. The raw material for the production of biofuel is algae, which is grown on an industrial scale, for example, in open reservoirs.

This practice has great promise, but currently such technologies are only being developed. Scientists are also conducting research to create techniques that make it possible to obtain fourth and even fifth generation biofuels.

Three types of biofuels

Depending on the state of aggregation the substance is in, there are three main types of biofuel:

- Solid: firewood, peat, animal and agricultural waste.

- Liquid: biodiesel, dimethyl ether, bioethanol, biobutanol.

- Gaseous: biogas, methane, biohydrogen.

Each type of substance has its own specifics, which will be discussed below.

Type #1: hard

The most popular solid types of biological fuel include wood, peat, and animal waste.

Wood (firewood, chips, sawdust)

An ancient type of biofuel is the well-known firewood, which has long been used to heat houses and cook food. Until now, they are actively used in different countries to generate heat/electricity, in particular, a large Austrian thermal power plant with a capacity of 66 megawatts operates on wood.

At the same time, such raw materials have disadvantages. The energy value of firewood is relatively low: when burned, part of the substance settles in the form of soot, which is why fireplaces and stoves need to be cleaned regularly.In addition, it takes a certain time to replenish wood reserves - new trees will grow only after 15-20 years.

An excellent alternative to conventional firewood are pellets (granules), for the production of which substandard wood is used: bark, wood chips, pressed sawdust, bitch.

To produce fuel pellets, raw materials are ground into dust, which is then dried and pressed at high temperatures. Thanks to the lignin contained in wood, a sticky mass is formed, from which small cylinders with a length of 5-70 mm and a diameter of 6-10 mm are formed.

You can set up pellet production yourself by making press for fuel briquettes.

Wood chips are among the popular types of biofuels, which often serve as a source of energy in European thermal power plants. The production of these raw materials is carried out at logging sites or on special production lines equipped with shredder machines.

Swamp and forest fuel peat

It is a common type of biofuel that has been used for domestic and industrial purposes for centuries. Peat is a layer of moss that has not completely decomposed in swamp conditions, and is mined in many countries around the world: Russia, Belarus, Canada, Sweden, Indonesia and others.

To facilitate the production process, biomass is usually processed at the extraction site. The process consists of cleaning (sifting) the raw materials from extraneous inclusions, followed by drying and molding into briquettes or granules.

Fuel from agricultural waste

In agricultural production, as a rule, a large number of various plant wastes accumulate: outer shells of plants, nut shells, straw.

Such raw materials can also be pressed and granulated, producing fuel pellets, the characteristics of which are practically no different from pellets made from wood biomass.

Biofuels of animal origin

Along with firewood, in ancient times people began to use fuel of animal origin, namely dung - dried dung of domestic animals. Modern technologies for drying and processing such raw materials make it possible to obtain solid varieties of biofuel that are completely devoid of unpleasant odor.

Since livestock waste is currently accumulated on an industrial scale, the production of fuel from it simultaneously solves the issue of its disposal.

Type #2: liquid

Liquid biofuels, which are safe and environmentally friendly, are mostly used as a replacement for gasoline and other similar products.The most common options include bioethanol, biomethanol, biobutanol, biodiesel, and dimethyl ether.

Bioethanol from plant crops

It is a common liquid biofuel used to fuel cars. Although the pure substance is not used as a fuel, its addition to gasoline helps improve engine performance, increase its power, control engine heating, and reduce exhaust emissions.

Bioethanol was also appreciated by fireplace lovers. This substance has good heat transfer; moreover, when it burns, no soot or smoke is formed, and the amount of carbon dioxide released is minimized.

Thanks to these features, the fuel can even be used to fire hearths in apartment buildings. Read more about biofuel for fireplaces in this article.

Bioethanol is produced from first-generation raw materials containing starch or sugar. Cereals, corn, sugar cane, and beets are processed using alcohol fermentation technology.

Biobutanol for refueling cars

Biobutanol is a biologically derived analogue of butanol. A colorless liquid with a characteristic odor, it is widely used as a chemical raw material in industry, and can also be used as a transport fuel.

The energy intensity of butanol is close to that of gasoline, which makes it possible to partially replace the latter in fuel cells. Unlike bioethanol, biobutanol can be used independently, without the addition of traditional types of fuel.

The raw materials for the production of this biosubstance are a wide variety of plants: beets, cassava, wheat, corn.

Dimethyl ether (C2H6O)

It is also an environmentally friendly fuel. When it is burned, there are no sulfur compounds in the exhaust gases, and the content of nitrogen compounds is 90% lower than when burning gasoline.

Dimethyl ether can be used without special filters, but fundamental changes must be made to the design of the car (power system, engine ignition).

Without any modifications, you can use a combination fuel containing 30% dimethyl ether in cars that are equipped with LPG engines.

Liquid fuel can be produced from various raw materials: natural gas, coal dust, biomass and, above all, from pulp and paper production residues, which are transformed into liquid under low pressure.

Biomethanol from unicellular algae

This substance is an analogue of ordinary methanol, which is widely used for the production of a number of chemical compounds (acetic acid, formaldehyde), and is also used as an antifreeze and solvent.

The issue of producing this type of biofuel was first raised in the 1980s, when a group of scientists proposed producing a liquid substance through the biochemical transformation of marine phytoplankton, which would be cultivated in special reservoirs.

Biomethanol has a number of potential benefits:

- high energy efficiency — 14 for methane production, 7 for methanol production;

- excellent phytoplankton productivity — up to 100 tons per hectare per year;

- undemanding unicellular organisms, for the cultivation of which fresh water and fertile soils are not needed;

- conservation of agricultural resources, since phytoplankton is grown in ponds or sea bays.

Although the industrial production of biomethanol has not yet been established, persistent research and development of technologies are currently underway to develop the production of this type of alternative fuel.

Biodiesel as an alternative to transport fuel

This is a liquid motor biofuel consisting of a mixture of fatty acid esters. The substance is safe for people and animals, almost completely decomposes in the ground in 28 days, and also has a relatively high (<100) flash point.

Biodiesel reduces the percentage of harmful gas emissions and also extends the life of the engine, since it contains lubricating components.

The fuel is used to refuel car engines, both independently and in combination with conventional fuel. Only the short shelf life of the biological substance should be taken into account: after three months, the biological substance begins to decompose with a complete loss of properties.

For biodiesel, a special standard EN14214 has been adopted in EU countries. In a number of countries, the EN590 standard is also in force, allowing the addition of 5% biodiesel to other fuels.

Type #3: gaseous

The main types of gaseous biological fuels include biogas and biohydrogen.

Biogas as a replacement for natural gas

Biogas is an almost complete analogue of natural gas: it contains 13-50% CO2, 49-87% methane, as well as H impurities2 and H2S.If this substance is purified from carbon dioxide, biomethane can be obtained.

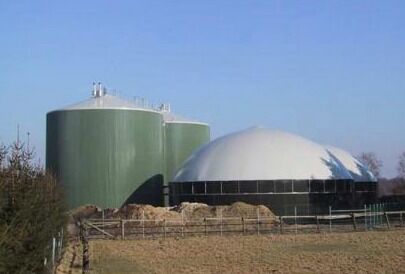

Gaseous biofuel is produced from biomass by hydrogen or methane fermentation. The latter is caused by three types of microorganisms: first, the raw material is exposed to hydrolytic bacteria, which are then replaced by acid-forming and methane-forming microbes.

A variety of materials can be used as raw materials: silage, manure, algae, wastewater, litter, fecal residues, household waste. The starting substance is brought into a homogeneous state, after which it is placed into the reactor using a loader.

There, a comfortable temperature of +35-38°C is maintained, necessary for the process of methane fermentation.

The raw material is constantly mixed, while the resulting gaseous product is discharged into a gas holder (storage unit), from where it enters the electric generator.

More information about obtaining biogas from manure and setting up a biogas plant is written in the articles:

- How to make biofuel with your own hands from manure at home

- Do-it-yourself biogas plant for a private home: recommendations for the device and an example of arranging a homemade product

Biohydrogen obtained by chemical method

A type of gaseous biofuel, which is an analogue of conventional hydrogen, is obtained from biomass using biochemical or thermochemical methods.

In the thermochemical method, prepared raw materials (for example, wood waste) are heated to a temperature of 500–800°C without oxygen, which releases H gases2,CO,CH4.

With the biochemical method, the raw materials are kept in comfortable conditions at normal pressure and a temperature of approximately 30°C.

Special microorganisms Enterobacter cloacae and Rodobacter speriodes are introduced into the biomass, which decompose the original product, releasing hydrogen. To speed up production using polysaccharides, enzymes can be added.

Conclusions and useful video on the topic

In the video below you can see the process of making a popular type of biofuel - wood briquettes:

Types of biological fuel differ not only in their state of aggregation, but also in their characteristics. When choosing such materials, it is necessary to take into account their intended use, effectiveness, functional properties and cost.

Do you have experience using alternative fuel? Or want to ask questions about biofuels? Please comment on the post and participate in discussions. The feedback block is located below.

I like the biofuel for which waste from the woodworking and other industries is processed - sawdust, substandard wood. This is a good approach to saving the planet's resources. Algae is also an option; they don’t need anything special and grow quickly.

But growing in fields seems anti-ecological - a lot of fresh water is wasted, but little useful product comes out.

I cannot understand why bioethanol is still not being widely sold in Russia; it is a purely environmentally friendly type of fuel, and raw materials for it can be found without much difficulty. Wood briquettes are also a good alternative. Who can answer clearly: is our Duma deliberately not passing the law on eco-fuels or is the Gazprom lobby involved here, I highly suspect...

Hello. We produce braces in good volumes, who said they don’t. As for the scale, the growth rate of bioenergy is increasing and a volume increase is planned, especially since it is a renewable resource, but, unfortunately, do not expect that this will be beneficial to anyone, most likely, the price of such fuel will be many times higher, given features of its immediate use.

In the meantime, they are mostly trying to implement this in agriculture in an autonomous form. However, according to statistics from one manufacturer of bioenergy installations, 10 thousand farms are interested in its product, only 3 farms use it. Why, because the economic payback of the equipment is unjustified.

The Gazprom lobby most likely has nothing to do with it. Which countries are developing this bioethanol? 90% of world production is from Brazil with their sugar cane and the USA with corn. What will we make it from?

Alex, we have a huge scale of logging. Even the fact that the waste will not rot in the forest, on plots, will be beneficial. And wood is processed into alcohol and biogas no worse than corn.