How a recirculation hood works + typical ventilation schemes with air recirculation

While when using a flow hood, dirty air leaves the room through the air duct, a recirculation hood has a completely different principle of operation.

Here, there is no element such as an air duct, and the device itself is equipped with effective catch filters. When passing through them, the air is freed from all harmful microimpurities and unwanted odors, and then again supplied to the room.

In this material we will talk about the principles of operation of such equipment, outline the subtleties of selection and ventilation arrangement schemes.

The content of the article:

How does a recirculating hood work?

The recirculation type hood operates in a closed cycle. In fact, it can only be called an exhaust device conditionally, since it does not remove air from the room, but only cleans it and returns it back.

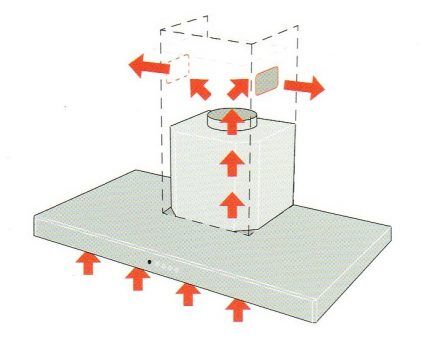

Contaminated air enters the device body under the influence of draft created by the fan blades rotating in a plane horizontal to the surface of the kitchen stove.

Moving along a given path, the air mass collides with the coarse filter. Having passed through it, it leaves fatty inclusions, particles of soot and dust on its fine mesh surface.

Next, the air flow, under the influence of pressure, passes through a fine filter, where it gets rid of odors and traces of the smallest particles, then returns to the room.

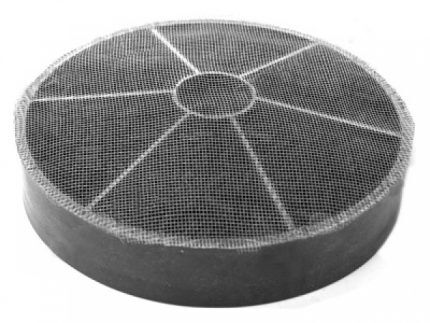

This filter is an ordinary cartridge filled with granular carbon. The carbon filter is a disposable product, so when it becomes dirty, it must be replaced.

Since this type of hood does not interact with the ventilation system, designers have developed telescopic hoods. During operation, they create a powerful lateral draft, due to which all dirty air masses are sucked in.

As soon as the need for this disappears, the device hides in the countertop. This solution is not only original, but also very convenient.

Positive and negative points

Although filter hoods have a low capacity, they have many advantages.

These include:

- ease of installation and operation;

- unlimited choice of placement of the stove, because a ventilation shaft is not needed for this;

- easy care.

These exhaust devices also have disadvantages. This is a small efficiency - up to 70%, the need for frequent replacement of disposable filters - 3-4 times in 24 months. The hood does not affect the humidity level in the room in any way. The electric drive of the device when turned on creates a certain noise.

Hoods of the latest releases, as a rule, can operate both in air mass removal mode and as recirculation mode. Such a device must have connection to the ventilation shaft.

Since a stand-alone hood does not provide fresh air, it is necessary to ventilate the room after turning it off.

Types of autonomous hoods

Depending on the mounting system, recirculating hoods are flat, mounted above the stove and have low capacity. There are also built-in hoodsand, integrated into furniture elements placed above the hob. They are compact and have greater productivity than the first ones.

Hanging hoods are placed under kitchen cabinets. In this category there are slider options with a working surface that extends forward. Corner hoods are placed at a certain angle to the mounting surface.

They are ergonomic, easy to use, highly efficient, and have a low noise level.

Depending on the location of installation, hoods are divided into wall, corner, and island. The first are used to complete zones located near the wall, the second - at the junction of walls. Island units are an ideal option for spacious kitchen spaces.

Features of choosing a hood

Basically, the hood is selected according to parameters such as depth and width. They are determined by the dimensions of the hob. Ideally, the unit should be several centimeters wider than the stove. This has a positive effect on the efficiency of exhaust air mass intake.

Different models of autonomous hoods differ in their range of functions. The more there are, the more expensive the equipment.Manufacturers equip them with electronic panels with displays for more convenient control and monitoring of the device’s operation. Sometimes there are programmable timers and sensors that automatically turn on the fan when humidity and temperature changes.

Special sensors can independently regulate the performance of the hood. The presence of a remote control in the kit allows you to start and turn off the unit without direct contact. When choosing, you should strive to ensure that the functionality of the model meets specific requirements as much as possible. It is irrational to pay for unused functions.

Filters for extractor hoods with recirculation

The quality of air recirculation depends on the number of filters in it. The latest models of hoods are equipped with two types of filters. The first, made of metal (aluminum or stainless steel), is called fat.

Its purpose is rough cleaning. As a necessary minimum, it is always included in the unit kit. Without it, any engine simply would not be able to function.

A metal grease filter is similar to a cassette. It includes a metal frame and the filter itself. The perforation of the filter element can be asymmetrical or symmetrical.

Caring for it involves periodic cleaning using household chemicals. Attach it to the outside of the cleaning device. It can be either disposable or reusable. The efficiency of work depends on the shape and size of the mesh cells.

You can read more about grease filters in this material.

After the grease filter comes the second filter - carbon. It cleans the air that has passed through the first filter, removing odors. These filters are not cleaned; when clogged, they are simply replaced with new ones. Special sensors notify you that it is time to change filters of the second type. Manufacturers are sure to equip their new models with them.

Additional filters that provide finer cleaning are:

- Acrylic, intended for reusable use. They have a very delicate structure, so they must be washed by hand and under no circumstances be wrung out, otherwise the fibers will change their original position.

- In the form of disposable inserts - padding polyester, paper or non-woven. When the existing pattern on them is not visible due to a layer of dirt, they are replaced with new ones.

- Coal, endowed with adsorbing properties. They are much denser than the first two and hold unpleasant odors well.

The first three are used in economy class hoods, called flat. Visually, these filters resemble a lightweight rug. Although some housewives wash them and then reuse them, this procedure does not return the synthetic material to its original properties. The quality of air purification then decreases.

Carbon filters have different densities. As it fills, air passes through it more and more slowly, so it is necessary to change cartridges in a timely manner. They are usually not included with the hood.

To extend the life of carbon filters, after using the hood, you need to leave it on for another five minutes.This short time is enough for the remaining moisture to leave the filter, which contributes to the caking of the coal and reduces its adsorbing ability.

The frequency of replacing cartridges with fine filters depends on how intensively the equipment is used. Typically, the instructions that manufacturers include with the product stipulate the frequency of such replacement.

When choosing filters for your recirculating hood, you should definitely check the parameters of the slots for the cassettes. If the sizes do not match, they will either not be inserted correctly, or gaps will form, which is unacceptable.

If the hood is used occasionally, you can use universal filters. They are made of polyester and impregnated with activated carbon. The fabric is able to absorb both fat and odors.

How to replace the carbon filter?

If the carbon filter has reached the end of its useful life, it must be replaced. To do this, the exhaust device is disconnected from the electrical network, otherwise the electric motor may accidentally turn on spontaneously.

Next, dismantle the grease filters and remove the cassette with the deteriorated carbon filter from the housing.

The new filter is inserted into the cassette, then the latter is closed and placed in the appropriate place on the hood. A correctly performed operation is indicated by a characteristic click. After this, the coarse filter is returned to its place, the device is connected to the electrical network and its functionality is checked.

As a rule, the manufacturer includes installation instructions for carbon filters. If the body of the carbon element is designed in such a way that it can be opened, this means that it is possible to replace its contents - replacing used granules with new ones.

Washing the grease filter

In order to wash the grease filter, it is removed from the device. The basin is filled with water, and a product used to remove fat is added. Afterwards, take a stiff brush and clean it from fatty deposits and soot.

If this method turns out to be ineffective, you should soak the filter in a solution consisting of laundry soap and soda for 3 hours. After soaking, the filter is cleaned, dried and put back in place.

Best filter samples

Grease filters are made by many manufacturers. Among the best is the Russian enterprise Lissant-Yug. They produce non-separable cassettes made of stainless steel or galvanized steel. The five-plate filter can withstand temperatures up to 70⁰.

Stainless steel filters are produced by Titan. The temperature of the working environment for them is 70 ⁰С. The thickness of the product is 0.5 mm. Up to 80 ⁰С is the maximum temperature for filters made of galvanized material or stainless steel produced by the manufacturer “Roven”.

The element includes from three to five plates. The best examples of carbon filters include elements produced by such well-known manufacturers as Electrolux, Gorenje, Folter, Hansa, Krona.

Ventilation with recirculation function

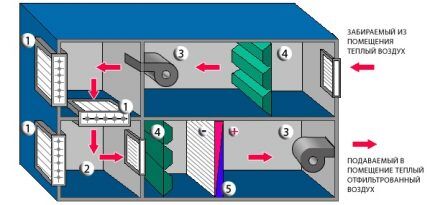

The very concept of ventilation with air recirculation means that the process is carried out with the return of all or part of the air removed from the room with the possible mixing of air coming from outside. The ratio in which air masses are mixed is determined by the design solution, taking into account specific circumstances.

Ventilation scheme with recirculation

Supply and exhaust ventilation with recirculation works according to a certain scheme. Air from the street enters the room through the shaft. After some time, the hood draws him in. Part of this air mass is thrown out, and the remainder goes into the mixing chamber, where it is mixed with a new influx.

Depending on how the system is configured, the air entering the chamber is heated or cooled. Its further path is an air conditioner or heater and return to the room.

Recirculation significantly reduces the load on systems designed to process air masses.

The air will always have characteristics that make it suitable for breathing if two main conditions are met:

- The minimum volume of air coming from the street is 10% of the volume processed by the air handling unit per unit of time.

- The air mass entering the room contains 30% of the permissible concentration of harmful impurities as a maximum.

With the participation of recirculation, the system operates with a constant consumption of thermal energy, as well as a constant speed of transported air flows, regardless of the time of year.This fact is a guarantee that the air entering the room will be evenly distributed throughout the entire volume.

Scheme implementation options

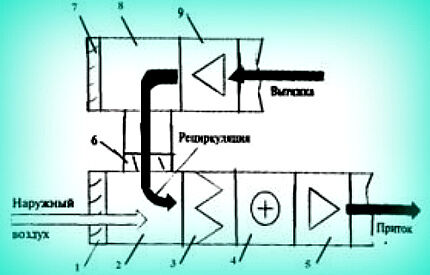

There are different options for implementing ventilation schemes with recirculation. This includes recirculation using a fan installed under the ceiling of the room, and through the ceiling duct, and through the central air supply unit. Air exchange in the first way can only conditionally be called recirculation.

There is no heat exchanger, but if you connect it to a fan and separate them into a separate unit, you get a fan coil or a fan closer. In the heat exchanger, in this case, the recirculating air is cooled or heated. Outside air enters separately and has its own individual parameters.

Removal of harmful substances occurs only through the outside air. In ventilation systems fan coil units not used often, because they do not ventilate the room, but only affect the internal temperature.

When recirculating according to the second option, through the ceiling duct, the length of the air ducts is insignificant. Sometimes a heat exchanger and a fan are placed in the channel. This is a standard scheme for air conditioners with a ducted indoor unit and used in rooms with medium and small volumes.

If in the main air supply unit with recirculation before the heater, close the valve that lets air in from the outside, you will get complete recirculation. The ventilation system in this case is used as air heating.The units inside split air conditioners and fan coil units are often designed to allow outside air to be mixed in.

In this case, the air flow with the required temperature enters the room through the same air distributors. Air conditioning units are designed according to this principle. This scheme is not suitable for large rooms, because... there is little power, there is no mixing chamber, no automation, and there is no heat recovery.

Ventilation of fairly large rooms is carried out using large-scale central installations, including a large set of equipment. The recirculation scheme used here ensures economical operation through flexible system control. Maintaining the required ratio of the amount of outside and exhaust air is carried out by means of valves.

When the recirculation valve is closed and the exhaust and flow valves are open, there is no recirculation. If you close the last two valves and open the first, complete recirculation is observed.

Disadvantages of ventilation with recirculation

The use of air recirculation is limited by SNiP 41-01-2003. It does not allow its use from premises where substances of hazard classes 1-2 are emitted and the flow of outdoor air is regulated by their mass.

Recirculation should also not be used where the concentration of fungi and bacteria in the air exceeds the norm or where there are clearly pronounced unpleasant odors.Laboratory premises where work with flammable or hazardous gases is carried out are not suitable for recycling.

Conclusions and useful video on the topic

Video about a flat kitchen hood:

About installing a carbon filter in a kitchen hood:

Hoods that operate on air recirculation eliminate the need to connect them to the ventilation shaft. With the help of integrated filters they effectively clean the exhaust air. In this case, it is necessary to replenish the supply of fresh air in the room through the vents.

Perhaps you have experience using recirculating hoods? Tell us what device you use and are you satisfied with its performance? Please leave your comments at the bottom of the article.

We have a hood like this at home. The seller in the store praised it very much, so we bought it. In principle, it’s not bad, but it’s not suitable for those who cook a lot and often, as the filters have to be changed too often. Although it is stated that once every six months, I have enough for 3 months maximum. Maybe try using other filters, non-native ones? The main thing is that the size fits. Who puts what kind in such hoods?

You should check exactly what kind of hood you have; the material lists models with different filters. If we are talking about coal ones, then according to the instructions they work for just 3 months.

Good day, Elena.

Carefully study the hood's passport - you may find a section dedicated to the interchangeability of filters. Another option is to go to the store with a filter. The seller may offer replacement options.

Carbon filters from the FTR line are popular on the Internet, which, according to the manufacturer, can be adapted to any hood.

Recommend a hood in recirculation mode with good power, low noise level and a stainless steel filter.. There is no talk of price yet.

I want to install a range hood in the kitchen. Which one should you buy for an apartment? I would like it to work silently, but at the same time have sufficient retraction power. Well, it didn’t look completely ugly. Although modern hoods all look about the same. I know that Bosh produces good hoods, but they are also quite expensive, I would like something cheaper.

Yes, Bosch has a hefty price. Another good one is Siemens, they are cheaper, but not much. If you want a completely budget-friendly one, then look towards KRONAsteel and Elikor.

Good afternoon, Olga.

Take a flow-through one if the ventilation duct allows - you won’t need to systematically change the carbon filter. It is worth taking the latest models - the technology is constantly being improved.

Among the TOP hoods, experts mention Electrolux products (noise level 50 dB), the cost reaches ₽8500. Recirculating hoods have low noise levels. For example, models of the German Krona generate 36 dB and cost only ₽3500.