Air conditioner rotation unit: device, connection rules and module settings

A breakdown of the air conditioner in the office does not entail the cessation of staff work, does it? The situation is completely different with server rooms, where uninterrupted air cooling is necessary.By including an air conditioner rotation unit in the system, even short-term exceeding of temperature limits is eliminated.

This solution prevents the failure of server equipment and creates conditions for the stable execution of service tasks. We'll talk about how to organize a rotation block. We will explain how to reserve air conditioners and show you how to install and configure the device.

The content of the article:

- Air temperature indicators in the server room

- Purpose and structure of the rotation block

- Air conditioner redundancy schemes

- Features of installation using the example of BURR-1

- Operating principle of the rotation unit

- How to set up

- Equipment care rules

- Selection factors and additional functionality

- Conclusions and useful video on the topic

Air temperature indicators in the server room

Rotation units are installed in the air conditioning systems of many laboratories, data centers, and production workshops in high-tech industries. This is an integral element of equipping server rooms, which are found in almost every serious organization.

In the age of information technology, even new, developing companies strive to use their own server equipment to process, store and exchange data with partners and clients.

A separate technological room, the so-called server room, is allocated for server equipment, where it is necessary to maintain the operating conditions specified in the technical documentation by the manufacturer. In particular, one of the most important parameters is air temperature.

According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), the temperature in server rooms should be between 18 °C and 27 °C. Most specialized companies, for example, those providing hosting services, do not allow the air temperature to rise above 24 °C.

Such strict temperature limits are due to the operational features of server computers. Local overheating of certain devices included in the server leads to their breakdown. In the end, it all comes down to the loss of important information, disruptions in production, commercial, and logistics processes and, as a consequence, loss of reputation and profit.

A modern server is equipped with an internal heat dissipation system. All internal components that generate heat during operation are cooled. But it is impossible to completely avoid heat exchange due to the leakage of the housing. Despite radiators and even liquid cooling, the temperature inside the case will be close to the ambient temperature.

The following components are most sensitive to climatic operating conditions:

- CPU;

- HDD;

- RAM.

As the temperature rises, the materials from which the hard drive components are made expand. This leads to failure of magnetic disks, heads, and positioning systems. Problems with your hard drive can lead to the loss of important information.

Modern servers are equipped with random access memory devices equipped with their own passive cooling system (radiators). But this does not change the situation. Radiators can save RAM only with a very short-term and slight increase in temperature. But when the air heats up more strongly, they are ineffective.

The processor protection system is automatically triggered by overheating, which leads to the shutdown of the server and the impossibility of its normal, uninterrupted operation. Many microchips do not tolerate high temperatures, in particular on the south and north bridges.

You should not assume that if the outside (street) temperature is in an acceptable range, you can refuse to cool the air in the server room. It is necessary to take into account all indicators of heat release and heat gain. Thus, the thermal power of servers is 80-90% of the consumed electrical power and often exceeds 1 kW.

So, the use of expensive and important equipment for solving business problems, sensitive to temperature increases and fluctuations, requires properly organized air conditioning, in which each split system should work smoothly.

Purpose and structure of the rotation block

Organizing a cooling system by installing not only the main ones, but also spare, backup, air conditioners in itself does not save the situation.

It is necessary to coordinate the operation of all devices in such a way that the temperature in the room remains stable under any conditions. For this purpose, specialized complexes are used, which are often simply called matchers.

The standard complex includes a control unit and executive units. Together they perform the following basic functions:

- monitoring the operation of the system;

- switching air conditioners in case of breakdowns;

- ensuring alternate operation;

- uniform distribution of working hours.

A reliable server room air conditioning system consists of at least two air conditioners: the main one and the backup one. Each of them, according to its technical characteristics, must be able to maintain the required temperature conditions in the server room.

If one air conditioner breaks down, the rotation unit quickly turns on the second, working unit. When performing this function, thermal sensors are used that measure the temperature and react to its slightest increase. The backup function helps not only in emergency situations, but also, for example, during scheduled maintenance and repair of air conditioners.

The implementation of such a solution allows you to change filters, charge air conditioners with refrigerant, and perform more complex operations at any convenient time, while continuing to maintain an optimal microclimate in the server room.

The rotation unit also provides alternating operation air conditioners and split systems and as a result, their total operating time is approximately the same. As a result, the time between repairs and the operational life of the cooling equipment are extended.

Air conditioner redundancy schemes

It is possible to implement various redundancy schemes, which are conventionally designated as N+1 and 2N, where N is the number of air conditioners that perform a similar function in the system (from the English “Need” - “Necessity”).

The simplest scheme, which involves the use of only one backup air conditioner, is N+1. If a rotation system is not configured, the backup air conditioner turns on only in emergency situations and takes on the entire load.

The system can have several main working air conditioners and each of them has a backup air conditioner, which is designated as 2N and means 100% redundancy. It is clear that the more backup air conditioners, the higher the fault tolerance of the system.

Features of installation using the example of BURR-1

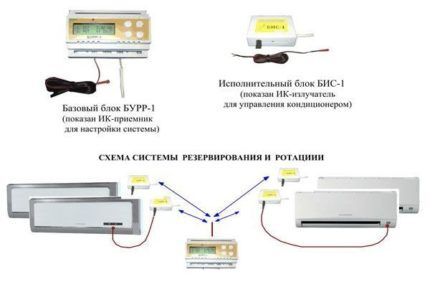

We will show how installation is performed using a specific example. In Russia, rotation and reservation control units BURR-1 are widely used, working together with specialized executive units BIS-1. The number of execution units may vary depending on the total number of air conditioners in the system.

In addition to the device itself, the BURR-1 package includes a temperature sensor. Executing units are purchased for each air conditioner. They are equipped with an IR probe and a double-sided self-adhesive gasket for its fixation. The temperature sensor is purchased separately.

Note that the configuration of the matchers depends on the manufacturer and often includes the entire necessary set of temperature sensors and auxiliary accessories.

Before starting installation work, the equipment is de-energized and other safety requirements are observed.

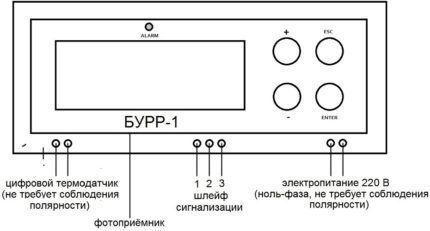

BURR-1 has a plastic case, convenient for installation on a special metal profile - DIN rail, which is placed on the electrical panel, next to the circuit breakers. A 3.5 cm long DIN rail is suitable for this purpose.

BIS-1 is installed above the air conditioner or directly on the air conditioner body with fixation on a self-adhesive double-sided gasket. A temperature sensor is fixed in the entry area of the blind guides. It is here that he will be able to sense the flow of cold air and determine that the air conditioner is in working condition.

The system also requires one common remote temperature sensor, which is installed in a holder on the wall in the server room at an equal distance from the air conditioners. This sensor should not be exposed to external thermal influences, for example, coming from heating radiators.

If it is possible to organize electrical wiring, the BURR-1 control unit can be installed outside the switchboard, for example, on the wall or even in an adjacent room.

The emitter probe is installed in such a way that it “looks” into the photodetector of the air conditioner from a distance of no more than 10 cm with a permissible deflection angle of 45-60 degrees.

The transmission range of a stable radio signal is 50 meters. That is, this is the maximum distance between the main and executive blocks. It is advisable to reduce it to reduce the level of interference coming from third-party equipment.

The following installation features should be highlighted:

- lack of cable lines;

- possibility of system expansion;

- implementation of different redundancy schemes.

When connecting an air conditioner rotation unit, you will not have to run a cable to transmit control signals, which, among other things, saves space in the server room. The composition of the air conditioning system is variable.

It can include a different number of air conditioners, differing in their power. By developing and increasing the equipment of the server room, the company can add new air conditioners to the system as needed (up to 15 units in total).

Operating principle of the rotation unit

In the process of working with BURR-1, commands are transmitted via radio signals at a frequency of 433 MHz to executive units, which turn air conditioners on and off using infrared emitters, in accordance with the established settings. Air conditioners must be equipped with photodetectors. Most modern models, including those for household use, meet this requirement.

Thermal sensors are continuously monitored. By comparing the received data, the condition of each air conditioner is determined. If the air conditioner is turned on and the sensor installed on its blinds shows that the output temperature change is less than 2 C, reserve power is turned on and an emergency signal is given.

How to set up

Based on the settings of the rotation control module set by the user, the air conditioners are turned on and off. In this case, a certain sequence and specified time intervals are observed.

To enter the control unit settings menu, press “Enter”. If the settings change during operation, the moment this button is pressed, the unit can transmit commands using a previously specified protocol. In this case, you will have to wait a little while continuing to press “Enter”.

The settings menu items are combined into several groups, including registration of execution units, time and temperature parameters. Information about the operation of the system is displayed on the display of the control unit. It is presented in the form of clearly formulated phrases and symbols. On the display you can see the type of command being transmitted and its current status, which facilitates the setup and subsequent operation of BURR-1.

Using the control panel, each air conditioner is assigned a number and its purpose is determined. Air conditioners are grouped depending on their purpose: reserve, rotation participants, etc.

Using the data input panel, set maximum permissible temperature values in the server room, connection temperature, disconnection temperature, alarm temperature, as well as time parameters related to collaboration and rotation.

The operating mode of the execution unit is determined by the change in color and blinking frequency of the diode located at the bottom of the housing. For example, when the execution unit is in normal mode and is waiting for a command from the control unit, its LED slowly blinks green.

When such a command is received, a yellow light comes on for 1-2 seconds. The execution of the power-on command is accompanied by rapid green flashing. If a shutdown occurs, the LED lights up red and also blinks rapidly.

Having set the settings and wanting to exit the menu, press the “ESC” button. If you do not press the buttons for 4 minutes, that is, completely idle, the exit will be performed automatically.

If there are no button presses because a command is being recorded and an IR signal is being awaited, there will be no automatic exit. Please note that when performing some operations, pressing “ESC” will exit the menu and the changes made to the settings will not be saved.

When the unit is in setting mode, the rotation control is suspended, although all timers are running, counting the operating time of each group of air conditioners and the rotation time.

The process of setting up the rotation control module is described in detail in the instructions supplied with it.

Equipment care rules

To ensure normal operation and long service life, the control and execution units are regularly maintained. Once every 3-4 months, the reliability of fastening, the quality of connections, and the serviceability of connectors are checked. Terminal blocks and external surfaces of housings must be cleaned of dust as they become dirty, preventing debris and foreign objects from getting on them.

Selection factors and additional functionality

There are different models and modifications of rotating and redundant air conditioner units on the market, differing from each other:

- by characteristics;

- by set of functions;

- by installation method;

- by type of control.

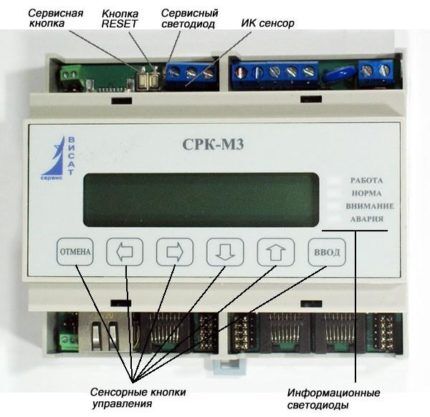

The control signal can be transmitted not only via an infrared channel, like in BURR-1, but also via wires. The equipment differs in the number of temperature sensors. The sensors themselves may operate with varying degrees of error, which to a certain extent determines the response speed of the rotation unit. Also pay attention to the timer error. These and other data must be indicated in the accompanying documentation.

When choosing a matcher, the requirements for the air conditioning system, its composition and configuration are taken into account. So, for air conditioners without photodetectors, you can choose devices with a wired control type. An important criterion is the functionality of the device.

Today you can buy rotation units with a wide range of functions.In addition to performing their main tasks, these devices automatically restart air conditioners whose operation was stopped due to a lack of power. It is not allowed to turn off air conditioners if a person accidentally gives such a command from the remote control.

When alarm loops are connected, messages about emergency situations are transmitted. For example, a fire message is sent if the temperature in the server room rises above a certain value (usually 69º C). The signal can be sent to the fire department control panel, and it is also possible to notify personnel via SMS.

Events and data from temperature sensors are recorded in non-volatile logs. The possibility of remote control via RS485 and Ethernet interface is provided. The industrial communication protocol Modbus is supported.

After reading the description and technical characteristics of the device, you should make sure of the significance of its functionality in order to make an informed, economically feasible choice.

It must be taken into account that uninterrupted cooling depends not only on the backup unit, but also on the air conditioners themselves. In server rooms they use precision, channel and wall-mounted inverter split systems. The latter option is most in demand, since such devices are much cheaper and take up less space.

When choosing a wall-mounted air conditioner, pay attention to the cooling capacity, which must correspond to the excess heat to be neutralized.

The air conditioning system must function in the server room regardless of the time of year. If the lower limit of the operating temperature of air conditioners is limited to -10 C, additional low-temperature kits are purchased.

Conclusions and useful video on the topic

Commissioning of an air conditioning system with a matcher in the server room:

Unpacking and review of the rotation unit for two air conditioners:

To ensure uninterrupted, round-the-clock cooling of the server room and to avoid equipment failures, rotation and redundancy units are used, which turn air conditioners on and off according to a given algorithm. If one of the air conditioners fails or lacks power, the backup air conditioner immediately turns on. Due to variable operation, the service life of air conditioners is increased.

Please leave comments in the block below. Tell us about your own experience in installing and configuring a rotation unit for an air conditioning system. Share useful information and photographs on the topic of the article, ask questions.

The article does not contain a wiring diagram for BURR-1m. In words everything is clear, but in reality I look at it and not a single terminal is signed. I opened the lid and the same thing happened.