Bathroom made of plastic panels: types of panels + brief guide to finishing

Renovating a bathroom requires a lot of effort and serious financial investment.Replacing pipes, purchasing plumbing fixtures, preparing walls and purchasing finishing materials can cost homeowners a very large sum. You definitely shouldn’t skimp on the quality of the mixer and the services of craftsmen: these are key cost items on which the outcome of the entire repair largely depends.

However, the rough preparation of the walls and their finishing can still be done more cost-effectively, but at the same time quite aesthetically pleasing. Modern materials, which are distinguished by both a more favorable price and less demanding requirements for basic surface treatment, will help reduce costs.

A spectacular bathroom made of plastic panels with proper selection of good PVC materials is not visually inferior to a room in which tiles were used. At the same time, plastic slats will cost much less, and to assemble them you do not need to level the walls so carefully and use a lot of additional building materials. With the proper skill, you can finish covering your bathroom walls with panels in just one or two days.

In this material we will talk about the types of plastic panels that can be used to transform a bathroom, consider the best ways to install lamellas on the wall surface and reveal the intricacies of finishing a room with this material.

The content of the article:

Types and features of plastic panels

Polyvinyl chloride is justifiably conquering the building materials market.Due to their cost, lightness, and temperature resistance, PVC products are especially popular when creating budget but stylish renovations. It is quite possible to use plastic panels to decorate a bathroom: in this room such material looks appropriate and organic.

Manufacturers offer panels with different textures, which can imitate both natural materials, such as wood, and artificial ones, repeating the tile pattern. A rich color palette makes it possible to choose the optimal shade for interior decoration, and thanks to printing, even from PVC panels you can create a spectacular panel.

But in addition to the aesthetic component, when choosing panels for finishing a bathroom, you should pay more attention to the types of lamellas. Conventionally, they are divided into two broad subcategories: sheet and sectional.

Leafy panels for decorative wall decoration are good for working with perfectly smooth walls, as they are often mounted in a frameless manner. The minimum thickness of such a panel can be only 0.4 mm, so the material is convenient for finishing surfaces with a complex configuration, for example, arches or doorways.

The main advantage of decorating walls with this type of panel is the ability seamless fastening of sheets.

Sectional plastic panels are used much more often due to their lower cost and ease of assembly - the cladding is mounted on a pre-created frame.

There are two types of products.

- Lining - the most inexpensive type of plastic panels, which are secured to each other with a European locking connection.The presence of a groove and a tongue contributes to maximum seam density, but the junction of the lamellas remains very noticeable. Therefore, lining is used less often in the interior, as it looks less aesthetically pleasing.

- Wall panels made of PVC are a better option for interior decoration and are often used for bathroom renovations. If the installation technology is strictly followed, the joint remains almost invisible.

The shade, various patterns and surface texture depend on the type of panels. So, laminated The panels receive color and texture thanks to the covering with thick PVC film. A offset are painted using a printer, after which the design is covered with a layer of special varnish. Like laminated slats, offset slats can also replicate the texture of wood or stone.

Thermal transfer PVC panels are processed using film. Thermal transfer material is pressed to the surface of the lamella using a heated drum, after which the design is transferred to the product. Film and varnish act as image protection.

Thanks to the variety of shades and patterns, plastic panels practically do not limit owners in creating a modern and attractive bathroom design.

In addition to the walls, you can also decorate the ceiling with plastic panels. This solution will help hide the wires of lighting fixtures.

Advantages and disadvantages of paneling

Cladding walls with PVC panels has a number of advantages.

In addition to the attractive price, it is worth noting the following advantages of this material:

- ease;

- ease of trimming, which can be done with a stationery knife or Bulgarian, equipped with a thin disk for metal;

- ease of care;

- durability;

- resistance to external aggressive environment;

- low maintenance requirements;

- operational installation;

- the ability to hide communications under the main frame.

When calculating the required amount of material, it is worth remembering about trimming the panels. If you plan to use products with a complex pattern, increase the calculated number of sections by about 10-15% in advance.

However, like any other finishing material, plastic panels also have some negative features:

- products are extremely sensitive to pinpoint impacts, so through holes easily form on their surface;

- When exposed to sunlight, the pattern on the panel may fade;

- PVC is a completely fire-hazardous material: the plastic can withstand fairly high temperatures, but during the melting process it releases extremely toxic substances;

- For true connoisseurs of quality materials, the texture and appearance of plastic panels may not be attractive enough.

The disadvantages of plastic slats when finishing a bathroom are minor. Therefore, budget material is so often used to speed up and reduce the cost of repair work in this particular room.

Methods for installing plastic panels

There are two methods for installing plastic panels on the walls and ceiling in the bathroom: framed and frameless. Each of them has its own characteristics and is optimally suited for certain types of panels.

Option #1 - frameless fastening of panels

It is most appropriate to carry out installation without a frame using glue if sheet panels are chosen for finishing.

An important condition for high-quality work is the preliminary preparation of the wall: leveling the surface, eliminating bulges and depressions.

The advantage of this method is almost seamless wall cladding, provided that large sheets are purchased. In addition to more thorough preparation of the wall than when using the frame method, the disadvantages include the inability to delicately hide wiring or even pipes under the cladding.

When choosing an adhesive, it is very important to take into account its features and aggressiveness towards plastic. Choose only products suitable for PVC, as glue for other finishing materials can cause deformation of the panel.

Option #2 - mounting panels on a frame

A frame in the form of a lathing is an excellent way to hide possible unevenness in the wall and securely fasten sectional plastic panels. An additional bonus will be the opportunity to replace the wiring in the bathroom without gating the walls: thanks to the presence of space under the future cladding, the cable can be run directly over the wall. In the same niches under the false panel it is permissible to leave the distribution of water pipes.

Preparation of walls for the frame is more aimed at treating with antiseptic drugs that prevent the formation fungus.

The direct leveling of the wall can be taken more superficially, by filling only obvious depressions with putty and slightly grinding off the protrusions.It is necessary to set the ideal plane of the future cladding surface at the stage of installation of the sheathing: each of its elements is fixed to the wall with dowels or self-tapping screws after preliminary adjustment of the parts using a level.

To make the frame, you can use wooden slats or a metal profile, which is intended for installing drywall:

- Wooden sheathing remains the cheaper option. However, high humidity in the bathroom can negatively affect the natural material, so the wood must be treated with an antiseptic and protective liquids.

- Metal profile frame will cost a little more, but this design is less susceptible to deformation. To avoid corrosion processes for as long as possible, it is better to use galvanized metals for installation.

The position of the elements in the frame can be vertical or horizontal and depends on the direction of laying out the panels themselves. Most often, the lathing is mounted horizontally, since the PVC slats are fixed vertically on it. The step between the slats of the sheathing or frame should not exceed 30-40 cm.

You can fasten the panels to the frame with a construction stapler or small self-tapping screws if the structure is made of wooden slats. Self-tapping screws are used to attach the lamellas to the metal profile.

Additional elements for sectional installation

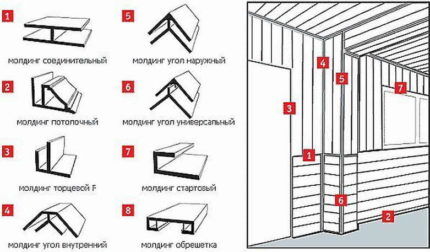

In addition to the sectional panels themselves, additional plastic elements will be needed for high-quality installation.

A variety of corners, profiles and moldings allow you to securely and aesthetically fasten the panels to the frame:

- Universal corner will be required for finishing internal and external corners in the bathroom.

- Outer corner used to hide panel joints at external corners.

- Ceiling And floor skirting boards have a more complex configuration. The inner part of the product is fixed under the panels, and the outer part covers their cut.

- Connecting profile makes it possible to fasten the lamellas together when their length is not sufficient to completely cover the wall surface.

- Starting And finishing profiles are used to finish the first and last sheet of the panel and can be replaced with universal corners.

The use of other profiles depends on the number of corners and breaks on the wall surface.

Subtleties of assembling panels onto a frame

Assembly of the entire structure is quite simple and quick and in many ways resembles folding a puzzle:

- The first panel is inserted into the starting profile and fixed to the frame.

- The second panel is connected to the first using a built-in lock mechanism.

- After fixing the second panel to the sheathing, the third lamella is mounted.

- The process continues to the corner of the wall, which is pre-equipped with a corner profile.

After finishing the cladding of the first wall, you need to move on to finishing the next one, inserting a new panel into the corner profile.

In fact, for independent and high-quality assembly of sectional elements, the owner must fulfill several important conditions. First, slightly level the surface of the walls and treat them with a deep penetration primer, antiseptic and antifungal agents.

Then build the sheathing or frame strictly according to the level and secure the additional profile elements for high-quality installation.

Compliance with this technology will make it possible to obtain an even coating without obvious joints.

Conclusions and useful video on the topic

The repair and finishing specialist shows in this video a finished project of a bathroom lined with plastic panels. The spectacular interior was created in one day:

Step-by-step instructions for decorating walls with plastic panels are presented by the master in the following video. A professional demonstrates all stages of repair work from creating a frame to installing sections:

Covering the walls and ceiling of a bathroom with plastic panels is a quick and inexpensive way to create an impressive and durable finish. The cheapness of the material, the variety of colors and installation, which does not require special skills, make it possible to quickly complete repairs and refresh the room without special expenses.

If desired, homeowners can periodically radically change the interior, because dismantling the panels is simple, and the previously assembled frame is suitable for fixing new slats.

Do you still have questions about installing plastic panels? Or would you like to tell us how you assembled PVC slats on a frame with your own hands and what difficulties you encountered? Share your personal experience, ask questions to our experts, add original photos of your bathroom decorated with plastic panels in the comments section. It is located below, under this publication.