Rollers for shower cabins: criteria for choosing door fittings, installation and replacement instructions

Such a popular plumbing device as a shower stall is most often equipped with sliding doors, the movement of which is helped by special mechanisms - rollers for shower stalls.

The correct choice of fittings to replace a damaged or worn-out sliding mechanism will help restore the operation of your shower stall to its previous mode. How to choose rollers and perform the replacement correctly - we will consider these issues in detail in our article.

We will also pay attention to the device and the reasons for their breakdowns. In addition to the instructions for replacing the rollers, we will add visual photos and video tips for dismantling and installing new fittings.

The content of the article:

Types and technical features of rollers

Rollers for glass showers are replaceable fittings made from plastic, rubber and metal elements in a wide variety of standard configurations. They are used not only in purchased booth models, but can be useful when production of shower cubicles with your own hands if the owner decides to equip his homemade product with sliding doors.

The main functionality of the rollers is stability in the smooth opening/closing of hydrobox door leaves.The “heart” of the roller is the ball bearing, because the service life of this product directly depends on its quality. By type, bearings are divided into 2 types: rolling and sliding. They are made of ceramics, bronze, stainless steel.

The body of the parts consists of ABS plastic or brass; the design of the rollers is:

- Eccentric. The main elements in them are an eccentric with a rotor on which a bearing is attached. Eccentric rollers are available in single and double versions. They replace each other and are divided into upper and lower.

- tension. They contain special slides, a rolling bearing, mounting and adjusting screws. Tension models come with one and two wheels, lower and upper.

Options for attaching roller supports may also differ, depending on the shape of the door panels: straight ones will require regular fixation, and for rounded ones, you need to purchase products equipped with a rotating mechanism.

When installing roller mechanisms, you must adhere to their factory dimensions, because in practice, incorrect selection of these products or surface mounting can lead to the fact that the fastening of the moving elements will be either too tight or too loose.

In these cases, mechanical damage to the roller housing and its bearings cannot be avoided.

Incorrectly installed rollers and overtightened mounting screws 100% guarantee distortion and deformation of the moving product, which can lead to careless operation of the shower stall.

Classic causes of roller mechanism failures

Rollers are installed in the upper and lower parts of the shower door panels. The doors are fixed to the guide elements and move using small wheels.

The owners often use the hydromassage shower box and cabin, so subsequent replacements of worn-out rollers with new ones will be inevitable.

Reason #1 - active use of the shower stall

According to numerous reviews and statistics, a family of three can open shower doors at least eight times within 24 hours, which is considered evidence of possible rapid wear of parts.

Movable door fittings often break down during active and prolonged use of the shower stall, regardless of whether the plumbing was carefully maintained or not.

Reason #2 - hard water and aggressive products

Tap water in modern urban infrastructure and water from private wells are usually hard in chemical composition. Detergents and hygiene products, inaccurate and sudden opening/closing of doors - all these factors can negatively affect the material of the rollers, wash out the lubricant, and contribute to the appearance of corrosion defects in the bearings.

Hard water with a lot of impurities can have a negative impact not only on the rollers, but also on the faucet, which will lead to breakdown shower cartridge cartridge. As a result, repairs will be required.

The most aggressive components include chlorine-containing preparations and alcohol-based products, sediments of calcium and magnesium salts contained in water with increased hardness.

After 2-3 months, you will notice their appearance on the rollers of the cabin: salt crystals will begin to clog small holes on the doors, forming a difficult-to-wash off deposit not only on the fittings, but also on the surface of the walls and doors. More care will be required clean the shower stall, selecting more effective means.

Over time, the rollers will begin to move the doors with noticeable tension, creating discomfort for users of the shower room, and then immediate replacement of the entire set of moving elements will be required.

You can carry out such work either with the involvement of specialists or on your own; the main thing here is to wisely select the necessary rollers for a specific model of shower cabin and responsibly follow the technology for their installation.

Recommendations for choosing spare parts

If you want to replace jammed or cracked rollers that are mounted on shower doors so that they are exactly the same as the “original” fittings, then you need to visit the store. The market offers a wide range of installation mobile mechanisms.

Externally similar models, as a rule, may differ in different design parameters, so it would be best to take one of the rollers with you for a sample.And if your shower stall has upper and lower rollers of different sizes, you will have to use two mechanisms.

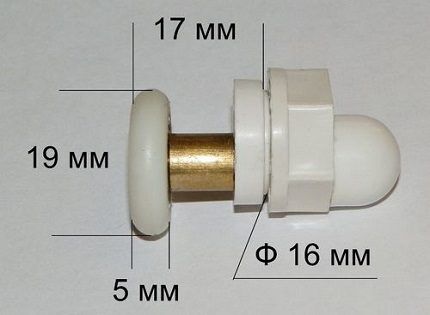

To purchase videos remotely, you need to measure their parameters yourself:

- Roller wheel diameter. If the store does not have the required size, then it makes sense to order a product with a slightly smaller diameter, but no more than 2-3 mm. You cannot take wheels of a larger diameter, even if the difference is only a couple of millimeters, because the parts supplied by the original manufacturer of the shower stall do not provide a margin for width. When replacing, large wheels will not fit accurately into the guide elements.

- Size of holes on the door leaf (leaves). Here, the diameter of the sleeve can also be 2-3 mm smaller than the diameter of the hole in the door, but in no case more. If there is a roller with 2 fasteners, then measure the distance between them and between the holes in the doors. The parameters must be similar, matching exactly down to the millimeter, so that later the mechanism can be secured without problems.

- Roller extension length. It is important for the semicircular design of the booths: if the length of the extension in the new rollers differs from the length of the old ones, then the doors will constantly jam, unnerving the owners of the house.

It is worth considering the thickness of the casement glasses. Of course, roller manufacturers produce their products that are suitable in all respects for standard shower enclosure doors. But if they have thick glass, then it would still be a good idea to clarify the dimensions of the rollers, based on this fact.

You should be aware of the advantages of truly high-quality and functional rollers, which play an important role as a mobile device for the shower door leaf.

They have:

- waterproof bearing, characterized by high working potential;

- free wheel movement;

- exact dimensions, corresponding to the standard parameters of these products;

- wear-resistant housing - cast and impact-resistant, with no visible defects.

An additional aspect in favor of a truly reliable roller will be the most effective adjustment of doors, fitting parts that have worn out over time to it, so that, if necessary, the moving element can be optimally quickly selected.

The most ideal bearings for roller mechanisms are single-row radial bearings, preferably made of bronze or ceramic. Steel ones will quickly rust, and ceramic ones are suitable for both strength and aesthetic characteristics, but their price is still high for the mass buyer.

Closed bronze bearings equipped with a plastic casing are the optimal, affordable and quality option for replacing worn-out rollers.

If you prefer to take bearings separately from the rollers, then measure the width, outer and inner diameters of the old bearing. We recommend that users purchase rollers with nickel-plated brass axles.

Guide to replacing faulty hardware

For work you will need:

- new videos;

- a 10mm wrench, if you can’t find one, then pliers will do;

- flat screwdriver.

At the very beginning, care should be taken to ensure that the surface of the glass or plastic doors of the shower box, depending on its configuration, does not suffer from possible mechanical damage.

Take thick cardboard or a rug and lay it on the floor. The space around the booth needs to be cleared, as it is inconvenient to work in cramped spaces. You can damage both the door leaves themselves and the glass walls. If such a problem has occurred and you need new glass for your shower, we recommend that you familiarize yourself with glass selection rules and the nuances of its installation.

Step No. 1 - dismantling the upper and lower rollers

First you have to remove the lower rollers while inside the cabin. Carefully holding the top of the door, press the button on the roller all the way until you hear a characteristic click. If the cabin originally had eccentric rollers, then they need to be turned down all the way.

Then you need to remove the upper rollers with the guide element, lift the door and remove it from the guide runners. The door must be very carefully placed near the wall in a vertical position; it is advisable to place rags and other soft material under it.

When dismantling the rollers yourself, you need to remember that the door edges and corners will be quite vulnerable here. The shower doors are made of durable tempered glass, but this fact does not negate the possibility of accidental damage to the door when replacing/removing the rollers.

Never place a glass shower door directly on a tile or concrete floor; in addition, it should also not be lifted or carried by the handle: it is not structurally designed to withstand such forces and may come off.

Next, use a screwdriver and wrench to unscrew the rollers from the door. Rusted and jammed parts that cannot be removed must be carefully broken into small pieces with pliers.

Step No. 2 - cleaning the door surface

Now it’s time to thoroughly clean the glass surface of the doors from dirt, salt deposits and rust located in the mounting circuit of the moving mechanisms. An ordinary synthetic detergent solution is quite suitable as a cleaning agent, preferably without the inclusion of abrasive particles.

Next, the glass and plastic doors should be rinsed clean and wiped well with a dry soft material, after which you need to start cleaning the dirt, plaque and grease residues that remain in the cavities of all the guides. Take the trouble to thoroughly clean the door runners: the future smoothness of the cabin door leaf on them will depend on the final result.

Step No. 3 - installation of new videos

For this stage of work, you need to unscrew the fasteners installed at the back of the roller housing. Performed on both upper and lower rollers.Then you should carefully move the fasteners apart and put them on the glass so that the bushings simultaneously fit into the corresponding fastening holes.

Be extremely careful to avoid any confusion. You can confuse the place for the lower roller with the place for the upper one: then, alas, your mechanisms will not work for long and will soon break down.

When all the rollers are aligned, screw the screws back in without tightening them too tightly. It’s better to play it safe and not inadvertently damage the expensive glass of the shower stall.

Step No. 4 - installing the door and adjusting it

The next step is to carefully lift the door and position the top rollers into the guide rail. Next, the operation is repeated, but with the lower rollers: a button is pressed on them and they are also placed in the guide runners.

After installation, adjust the position of the cabin door to the most convenient position for you. To do this, either tighten the screws on the rollers or loosen their clamp. The final stage consists of additionally lubricating the internal surfaces of the guide elements to ensure that both doors move virtually smoothly and move without the slightest difficulty.

Service specialists and shower cabin manufacturers advise replacing all rollers at the same time. Some individual parts of the rollers, for example, wheels or bearings, may also be faulty, but the housing itself remains intact and unharmed.

Then they act in the following sequence: remove the doors, dismantle the rollers and replace the damaged elements in them. Repaired parts can be reinstalled in their original places. This technique is quite economical: individual spare parts from the roller mechanism are an order of magnitude cheaper than a new set of fittings.

You can extend the life of the rollers for a long time if you wash the shower stall and its fittings more often, inspect the runners with guide elements weekly, removing dirt from them. Add lubricant to the rollers, preferably silicone, and they will not let you down!

If you encounter other types of malfunctions, we recommend that you familiarize yourself with the list of popular shower stall breakdown and methods for their repair.

Conclusions and useful video on the topic

The video describes in sufficient detail the most popular modifications of rollers that can be found on the Russian plumbing fittings market.

We invite you to watch another useful video with a story about repairing a shower stall, or rather, with detailed video instructions for replacing roller mechanisms that have become unusable.

For efficient and safe operation of the movable rollers that modern shower cabins are equipped with, you need to take care of hygienic and preventive care of these plumbing devices.

Even the absolutely correct choice and technologically competent installation cannot always guarantee users impeccable service of roller mechanisms.

Are you planning to replace the sticky rollers on your shower door yourself? Maybe you still have questions after reading our article that we did not pay attention to? Ask them in the comments below - our experts will try to clarify any unclear points.

Or maybe you would like to supplement our material with recommendations for choosing the best videos or tell us about your own experience of editing them? Write your opinion about the videos you purchased - are you satisfied with their quality? Was it difficult for you to install them?

And even though we take very good care of our shower stall: we constantly wipe and clean excess water so that it doesn’t rust anywhere, but the rollers still become unusable over time. 3-4 months, that's all. They no longer glide so smoothly, and sometimes they creak unpleasantly. All because of the water quality. It is too hard with calcium content - so plaque appears no matter how you clean it. I change the rollers myself, taking the old one with me to the store as an example. You can find it in almost any store that sells plumbing supplies. The most important thing is to be careful with the canvases so as not to damage them.

Sergey, your videos break very often. You need to take care of them, and not just wipe them with water. This action alone will not help much. At home, I regularly lubricate the rollers and guides with special lubricant. About once a month, but this is more for reinsurance, because... Every time I see from the condition of the rollers that this could be done less often, but lubricating it is easier than bothering with replacement. Or rather, the replacement itself is not so scary, but this fiddling with the doors, supporting them, placing temporary supports is too many unnecessary movements.I lubricate the rollers with Teflon sanitary grease. Ask around in specialized stores. I know that people also use Vaseline, but I would not recommend it - it is quickly washed out with water. And by the way, I don’t bother wiping off some water every time after a shower.

Can you recommend any specific brand of lubricant? Because this is the first time I've heard about Teflon sanitary lubricant.

Hello! Please tell me how to remove the roller with the eccentric from the glass door of the Delight shower enclosure and where to buy a new roller?

Hello. I understand that you are interested in replacing the bottom cam from the Delight glass shower enclosure door. Since this type of eccentric is quite common, finding a similar replacement will not be so difficult.

Here you just need to correctly navigate the dimensions, in particular the diameter of the roller itself. Since there are absolutely identical eccentrics, but they may differ in roller diameter. What exactly was broken? If the eccentric is collapsible and the roller is broken, then you can simply buy a roller of the required diameter and replace it.

It is better to search in specialized stores on the Internet so as not to waste time traveling to hardware stores, where the required eccentric model may not be in stock. Take several pieces at once so that you have a reserve for the future.

I'm sure they'll fall apart anyway.

Shower cabin Cezares, made in the Czech Republic. Installed in 2010. Plain water with calcium - the glass gets dirty quickly. One of the rollers has just failed, i.e. after operation for 9 years.During this time, I never cleaned or lubricated the rollers. Buy cabins and components of normal quality and you will be happy, instead of dancing with grease and constant replacement.