How to choose the right fittings for PEX pipes - types and secrets of installation

Cross-linked polyethylene, abbreviated PEX, has been used in pipe production for a long time.These products have excellent technical and operational characteristics. But they have a drawback - a low melting point. Such material cannot be soldered or welded. Therefore, special fittings for PEX pipes are used for connection.

The content of the article:

Types of fittings

Types of fittings:

- compression, also known as crimp;

- press;

- flanged;

- electrodiffusion.

They are all made from different materials. You can buy brass products on the market. This is the most expensive option with improved technical characteristics. Hence the high quality of the joint. Using brass fittings, you can connect two polyethylene pipes to each other or a polymer product with a steel counterpart.

The second material often used for the production of connecting elements is polyvinyl sulfone with the abbreviation PPSU. This is a polymer with high strength, zero toxicity and electrical conductivity. Polyvinyl sulfone fittings are usually used in those pipe systems that operate in conditions of high humidity (outdoor open water supply or hidden piping system).

How to make a connection using fittings

There is still some debate about which type is better. Compression fittings for PEX pipes and press fittings are usually compared. To understand, you need to take into account not only the technical characteristics, but also the options for connecting parts of the pipeline using similar products.

Operating principle of a crimp connection

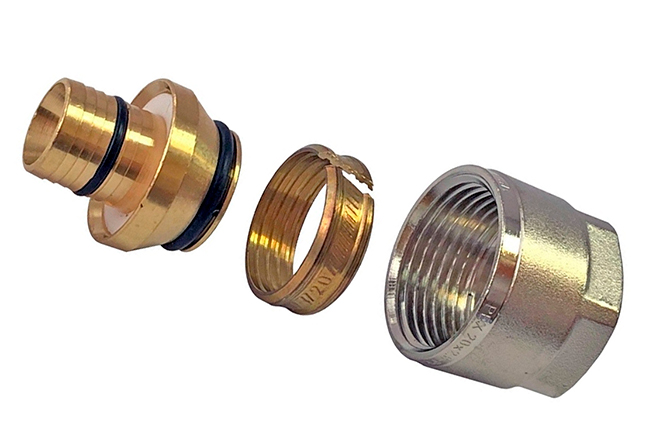

The crimp connector consists of three parts:

- nuts;

- ferrule ring;

- fitting to which the PEX product is attached.

Work technique:

- The fitting is disassembled.

- First a nut is placed on the end of the pipe, then a ferrule.

- This end fits onto the fitting pipe.

- A ring is placed over the PEX.

- The nut is screwed onto the external thread of the fitting, pressing the ring to the pipe. That, in turn, presses the outer surface of the pipe.

The clamp is so tight that there is no gap or gap left between the pipe and the pipe. One hundred percent tightness.

Crimp analogues belong to the category of “serviced connections”. This means that such joints must be periodically maintained - once a year the connecting element, consisting of two connecting parts, is “tightened”.

Hot water expands the metal, cold water contracts it. Therefore, when the heating is turned off or when the hot water supply is turned off, physical processes occur at the joint, which affect the joint density. Such fittings begin to leak. To prevent this from happening, you need to tighten the two parts of the device, sealing the connection.

What do you pay attention to when choosing a compression fitting for PEX products:

- It is necessary to put the pipe on the entire length of the pipe.

- The nut is tightened until it stops.

- The pipeline must not be subjected to tensile loads.

These are three components of high-quality and long-term operation of connections.

Compression fittings with integrated fitting

This is exactly the same element as the previous one. But there is a difference in its design - the length of the pipe. It is 4-5 mm larger than the width of the crimp nut. This was done on purpose.This is the way to solve the problem of PEX pipe kinking at the point of its connection with the fitting.

Threaded Crimping Adapters

These are standard fittings for PEX. But their purpose is to connect pipes with devices for various purposes:

Therefore, the design of the fitting has a pipe on one side and an external thread on the other. The latter depends on the diameter of the hole to which the fitting is attached. That is, the standard size of elements of this type is also wide.

Manufacturers today offer adapters with either a flat seal or a cone seal. The first has one o-ring, the second has two or more. Therefore, the conical version provides better sealing of the joint.

The advantages of all types of crimp connectors are the ability to disassemble them, replace the seals, reassemble them and reuse them in the piping system.

Difference from fittings for metal-plastic pipes

To understand what the difference is, you need to understand the press fittings that are used to connect metal-plastic pipes. And only after this can conclusions be drawn.

Press connectors

The press version differs significantly from crimp models. Firstly, the design contains two parts: a fitting and a bushing, with the help of which the pipe inserted into the fitting is crimped. Secondly, to carry out the work you will need a special tool - a press.

The resulting joint is not serviceable. It guarantees 100% tightness for the entire service life.

Connection technique:

- The pipe is put on the fitting.

- A sleeve is placed on top of it.

- The latter is inserted into a press, which compresses it evenly around the circumference.

In this way, the pipe is also clamped over the fitting pipe. The connection does not leak during its entire service life.

Metal-plastic analogs have an aluminum frame, which is responsible for reducing the coefficient of linear thermal expansion. It is aluminum that reacts with hot water that begins to corrode. This results in a decrease in the quality of the joint and a decrease in service life. Therefore, a gasket made of dielectric material and EPDM is added to the fitting, which guarantee maximum tightness.

Press fittings are cheaper. But to use them you need equipment - a press. In this regard, crimp models for PEX products are simpler - everything is done manually using two wrenches. But their disadvantage is their gradual weakening, which leads to leaks.

How to attach fittings

This process is described above. But the quality of the docking depends on several factors. It is important to insert the pipe into the fitting correctly. And although PEX products differ from other analogues in their more plastic structure, placing them on a pipe is not always easy.

The technology for fastening the fitting depends on the brand of the product and the thickness of its wall. For example, type “b”, which can withstand temperatures of no more than +45 ℃. It is used in a “warm floor” heating system. Wall thickness – 2 mm.

To connect parts of the pipeline, a press version is used. A pipe is inserted into the assembled fitting on one side, which fits into the gap between the pipe and the sleeve. After which the sleeve is compressed using a press. The same procedure is carried out on the other side of the fitting, inserting a second PEX pipe.

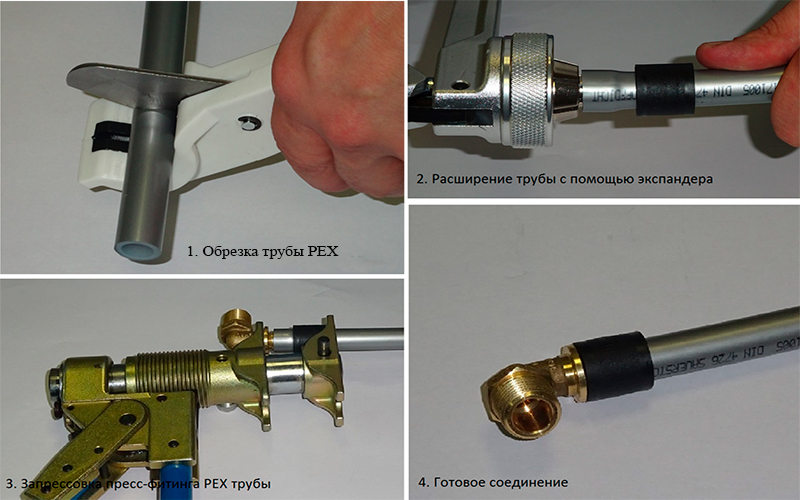

If a product of brand “a” is used with a wall thickness of 2.2 mm, which can withstand temperatures up to +95 ℃ (it is used in both hot water supply and radiator heating), then the connection process is carried out using a compression fitting, or rather, a push-in fitting. This is a fitting and a bushing. The crimping technology is carried out differently:

- A sleeve is placed on the pipe.

- The pipe end is expanded with a special tool.

- The pipe is put on the fitting.

- The sleeve is pulled onto the pipe surface, squeezing both it and the fitting.

Connecting PEX pipes using fittings is a simple process. But, as in all technological operations, strict adherence to the sequence of procedures and knowledge of the nuances is required. This is the only way to achieve high quality joints.

Have you ever done similar work? Share your experience in the comments. Save the article to bookmarks and repost it on social networks.

The whole truth about PEX pipes - fittings.

Sources:

- https://santehstandart.com/poleznye-materialy/fitingi-dlya-trub-pex

- https://vseotrube.ru/fitingi-i-zaglushki/dla-sshitogo-polietilena

- https://www.sdvor.com/articles/truby-i-fitingi-iz-sshitogo-polietilena

It is very important to choose the right PEX. Each variety has its own characteristics. Particular attention should be paid to the temperature that the material can withstand. As for the fitting, a crimp fitting is the best option.

Don't tell me. Press is more reliable. Set it once and that’s it – for all time.