How to sheathe the outside of a wooden house: the best types of materials and technologies for their installation

The external cladding of a wooden house performs several important functions - it protects the walls from atmospheric influences, insulates the building, and gives it a more aesthetic appearance. Even at the design stage, you should think about how to cover the outside of a wooden house so that the finishing meets the technical requirements and financial capabilities.

Let's look at popular cladding options and find out which ones are best suited for cladding houses made of wood.

The content of the article:

Why is external cladding needed?

Wooden houses to this day remain the most environmentally friendly, breathable, healthy and comfortable to live in. However, wood is a short-lived material and therefore requires mandatory protection.

In addition, due to its softness and friability, the wood is attractive to rodents, bugs and other living creatures.

But protection becomes more effective if the top of the façade of a wooden house is covered with cladding - reliable, beautiful, and heat-insulating.

There are no universal rules for choosing a facing material, but preference is given to finishing that has the following characteristics:

- is a heater;

- has vapor permeability;

- easy to install;

- has a low cost;

- does not require constant painting.

Of course, wooden types of cladding win - lining, block house, planken, imitation timber. They have the same characteristics as the main building material and preserve the naturalness and environmental friendliness of the building.

But other materials are often used that are more practical and do not require constant maintenance - for example, vinyl siding.

You should also take care when choosing insulation for your home. You can read about which material is better to give your preference in this material.

Review of materials for home decoration

Often, when purchasing, they focus only on the cost of the facing material. This is the wrong approach, since cheap finishing requires additional investment.

It is also wrong to purchase expensive material that does not meet the technical parameters. Therefore, it is necessary to take into account all aspects - cost, characteristics, compliance with the climatic zone.

The modern market provides the opportunity to choose exactly the cladding that fits perfectly in all respects. Popular types of finishes include four types made of wood, and four more from other natural and synthetic materials.

In addition to the listed materials, corrugated sheets are used for finishing log and timber houses - steel sheets coated with a layer of polymer. Most often they are decorated and imitate stone, wood or brick cladding.

Each material for finishing wooden houses differs in its technical characteristics, conditions, installation method, and cost. Polymer materials that do not allow air and steam to pass through require the installation of a ventilated façade.

And now - in more detail about the materials themselves and the technology of their installation.

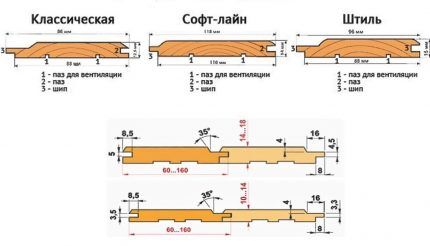

Option #1 - wooden lining

Conventional lining is characterized by its low cost, availability, and easy installation. This is one of those materials that can be used for DIY house siding.

When choosing a material, you can rely on the standards specified in GOST 8242-88. There are also more stringent standards - DIN 68126/86, which set out the requirements for the so-called “eurolining”.

Before use, the slats are dried to a certain extent - 10-15%.This provides additional protection against deformation, as well as against the effects of excessive moisture - rot, mold.

To decorate a house, more expensive wooden cladding is often used, and ordinary lining is used for interior work or cladding of seasonal cottages.

There are many technologies for installing lining; below we will take a closer look at one of them.

The materials are attached to the wall of a wooden house in the following sequence:

- lathing for insulation;

- thermal insulation layer;

- wind protection;

- counter-lattice;

- lining.

Sometimes the first layer is a vapor barrier, which is attached to the beam directly onto the brackets. But wooden lining is a natural material, so there is no need for vapor barrier.

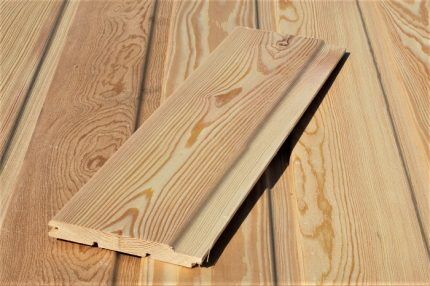

Option #2 - block house

Many consider a block house to be a subtype of lining, but it is a completely different material - more durable, reliable and warm. It is made mainly from spruce and pine. They are sold already processed.

To give the wood a particular shade, it is treated with glaze, stain and glaze solution. You can also change the color using protective varnish or impregnation.

Before installing the cladding from the block house, the logs are treated with antiseptic impregnation, the crowns of the log house are reinforced, and the cracks are caulked.

Work order:

- Fixing roll or sheet vapor barrier with an overlap of 10-15 cm.

- Fastening the vertical sheathing in increments of 0.4-0.6 m.

- Installation of insulation boards into the sheathing using dowels and nails.

- Covering the thermal insulation with a windproof membrane.

- Installation of the second layer of sheathing.

- Block house cladding.

The slats are secured with clamps, screws or nails. To avoid corrosion, it is better to use galvanized or anodized fasteners.

Block house refers to those types of cladding that require treatment every 3-4 years. To ensure that the wood retains its original appearance and characteristics, it is coated with an antiseptic or acrylic varnish.

Option #3 - imitation timber

Wooden boards that imitate timber also belong to prefabricated cladding and resemble lining. If you make the finishing from high-quality material, then externally the house will look as if it was built from timber.

When purchasing material, you can choose lamellas of the desired length - from 2 to 4 m. Also, the boards differ in thickness - 2.0-3.5 mm, in width - 10.5-17.5 cm.

According to the production method, there are solid lamellas, and there are glued ones from several slats. Prefabricated parts are practically no different from solid parts in terms of characteristics.

The technology for installing false beams is the same as for lining or a block house.

Option #4 - planken

Compared to the listed sheathings, planken is a relatively new prefabricated material. It is installed in different ways, but more often - overlapping or in a tenon.

There are several types of plank: straight, beveled, with grooves. Installation methods differ. The straight one is attached with gaps between the lamellas using spacers, the beveled one is overlapped, and with grooves it is connected like a lining. Before installation, it is necessary to make a sheathing from the profile.

Installation procedure for straight plank:

- We fix the vertical timber sheathing.

- We secure the first element at the bottom using countersunk screws.

- We install the PlanFix fastening element - with one screw in the sheathing joist, the second in the lamella.

- We put a couple of spacers on the board to even out the gap.

- We install the next element - hammer it onto the PlanFix tenons.

- We continue to install the slats in the same way.

- We secure the last board with self-tapping screws.

- We take out the spacers.

Straight plank is not intended for insulation - it performs only a decorative function, so additional care should be taken about thermal insulation.

Option #5 - vinyl siding

Siding was created specifically for cladding wooden, brick, panel, and block houses. The slats have special locks and holes for self-tapping screws, with the help of which they are connected to each other and attached to the base.

To install vinyl siding, you need to build a frame. Lightweight lamellas do not require serious support; slatted sheathing is sufficient. Vinyl does not allow steam to pass through, therefore, the facade must be ventilated.

The installation procedure for different types of siding is the same, so the instructions also apply to other types: metal, fiber cement.

Operating procedure:

- Assembly and installation of a frame made of wooden beams or metal profiles. If you plan to provide thermal insulation, then the slabs or rolls are secured under the sheathing.

- Installation of the starting profile at the bottom of the facade, near the foundation.

- Installation of external and internal corner profiles.

- Installation of profiles for framing door and window openings.

- Installation of siding, starting with the starting profile.

Lastly, we sheathe the area under the roof and the gable. We do not specially punch holes for self-tapping screws; we use only factory ones.

Option #6 - metal siding

The main distinguishing feature of siding made of metal is its long service life, up to 50 years.

It is made from rolled steel, sheet thickness is 0.40-0.65 mm. Finished parts have a complex configuration, made by bending on special equipment.

When purchasing, you can select panels of the required length - from 0.5 m to 6 m. The standard width is 20-25 cm. To allow air to circulate, lamellas with perforations are produced, which are usually placed on gables, for finishing slopes and cornices.

The color range is wide. In addition to plain siding, products “like stone” or “like wood” are available. Sheathing with metal siding can be done both in winter and summer, regardless of temperature and other weather conditions.

Option #7 - fiber cement panels

No less popular are panels or siding made of cement and synthetic fibers - fiber that plays the role of a reinforcing component. From the outside, the panels resemble stone or brickwork, finished with boards.

Cement-based cladding material does not fade in the sun, is not subject to fire, is lighter in weight than its metal counterpart, wear-resistant and low hygroscopic.

However, working with fiber cement parts is more difficult than with polymer parts and requires special drilling and cutting skills.

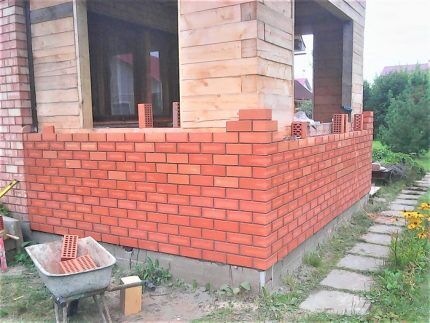

Option #8 - facing brick

Sheathing wooden buildings with stone, clinker or brick is very rarely done, as this is due to the complexity of installation. However, this method of cladding is practiced due to its outstanding decorative effect. And the house becomes much warmer after such “cladding”.

One of the conditions for using stone or brick cladding is a strong cement foundation that can support the weight of the finishing material.

It is also necessary to provide a gap between the wooden wall and the cladding - at least 5 mm. Finishing can begin only after the house has settled.

Conclusions and useful video on the topic

Recommendations for choosing cladding:

Practical application of imitation timber:

Tips for installing siding:

When choosing cladding for a wooden house, try to take into account everything: from the nuances of installation to the rules for subsequent operation.

Don’t forget that saving on material can result in subsequent regular expenses for caring for it. Try to find a compromise between the technical and aesthetic sides to make living in the house comfortable and pleasant.

What material did you choose for cladding a wooden house? What were your reasons for doing this and are you satisfied with the result? Please tell other visitors to our site about this. Leave your comments in the block below. There you can ask questions about the topic of the article.

One of the most budget-friendly options is covering the house with siding. This material can be selected to suit every taste and budget. For example, I chose imitation natural wood for my dacha. My parents’ house had completely lost its appearance, but thanks to cosmetic renovations it found a second life. Only a true professional can distinguish siding from natural wood. And if you wish, you can always change the material.

Of all the listed options for covering a wooden (and not only wooden) house, the best option is vinyl siding. Covering with this material allows you to do the job once and forget about the problem for a long time. All other options require periodic painting, gluing, fireproofing and other work, depending on the material.

Vinyl siding is cheap, but we struggled with it when we started decorating the house in the fall. The material is such that it changes, albeit slightly, size at different temperatures. It is better to cut in a warm place; at first we tried on the spot, but the siding did not cut, but broke. The problem was not with the jigsaw. When they brought building materials into the garage, things went better.And we had to drill it ourselves. Only this must be done at low speeds.

Compared to wood siding, siding has the advantage that it requires no maintenance. From time to time, it is enough to simply wash it with clean water or any household detergent without abrasive additives. When considering what material to cover the outside of a wooden house, you must pay attention to this feature. No varnishes or paints are required. Having paid once for the material and installation, you can have peace of mind for the appearance and condition of the facades for 15–20 years.

Plastic siding also looks cheap and is easily damaged. This should also be taken into account when choosing finishes for your home. Therefore, if you want your home to look presentable, choose a different material.