Why the heated floor does not work - the main reasons and solutions

Of all the possible problems with heating systems, this is perhaps the most difficult.And the point is not even why the warm floor does not work. There may be several reasons, but they can be established by brute force and checking all possible options.

More unpleasant is the fact that malfunctions can be associated directly with the heating film or cable hidden under the floor covering or covered with adhesive screed under the tiles.

The content of the article:

Why underfloor heating doesn't work - the main reasons

Diagnosing a water heater is easier. If the heating boiler is working properly, the valves and taps close normally, then the place of damage should be looked for at the point where the warm part of the floor ends and the cold, unheated part begins. In the worst case scenario, the problem can be found by a leak from the pipe and a spreading wet spot.

In a situation with an electric heated floor, the process of identifying a breakdown is complicated by the presence of a large number of components, each of which could potentially cause a circuit break.

There are many options:

- Human factor – violations of heated floor assembly technology.

- Defects in the thermostat.

- Lack of contact in couplings or terminal blocks.

- Incorrect wiring connection.

- Mechanical damage to the heating cable cores.

The situation is simplified if you initially purchased a high-quality cable or graphite film. At the same time, the installation of the heating base was carried out by a master, and not by a self-taught amateur.In this case, the reasons for the heated floor not working should be sought in the thermostat - check the contacts and the current voltage on the cable.

Initial installation problem

There are two basic schemes for electric heated floors, depending on the heating element used. The first option is a canvas in the form of a graphite film applied to a vinyl base. Two copper conductors are printed along the edges of the strip, connected to a remote power supply with a thermostat. When voltage is applied to the electrodes, heat is generated.

The second option is a high-resistance cable embedded under a screed.

When working with a heating film, it is important to correctly lay thermal insulation with a reflective layer under it, and a laminate backing on top of the heater. Thanks to the aluminum coating of the thermal insulation, all heat is reflected upward.

If the layers are mixed up during the installation process, the heated floor will not work. More precisely, there will be a feeling that it is not working, since all the heat will be redirected down into the concrete base.

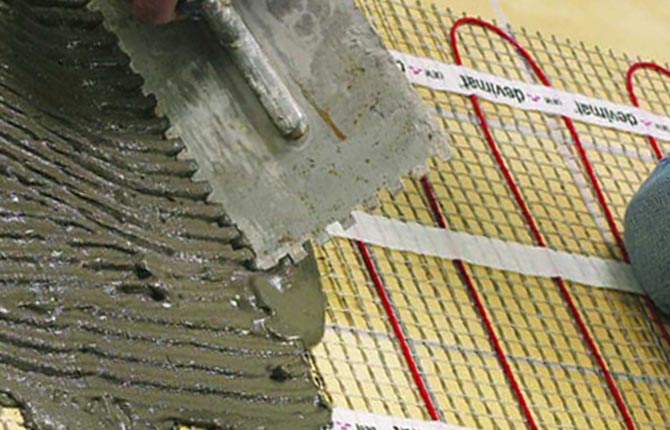

The second reason why a heated floor may not work is incorrect or unclear connection of the connectors to the contact tracks on the film. In the process of laying cords from the film mat to the power supply and thermostat, a terminal break may occur. Often the heater stops working if laminate, parquet or tiles are laid carelessly.

Usually, when laying lamellas, the master periodically checks whether the heated floor is working or whether a break has occurred.

Exactly the same problems occur with cable heated floors. For example, the cable may not be laid on holders or a polyethylene mat, but simply on concrete, even without thermal insulation.In such a situation, there will be a feeling that the system is working, but the lion's share of the heat goes inside, into the concrete slab.

Cable underfloor heating may not work due to improper crimping of the connectors (connecting chips). The worst case is if a contractor or worker mixed up the diagram and brand of cable, for example, he took the wiring for a single-core cable, but laid a double-core cable on the floor, and vice versa. For both cases, the symptoms of the “disease” will be the same. But the reasons why floor heating does not work are completely different.

Lack of power

One of the most common reasons why a heated floor may work unstably or not function at all. In this case, heating (if it works) will be uniform.

The heated floor may periodically fail to heat and just as unexpectedly resume its operation.

Symptoms such as these indicate unstable power supply or poor contact on the terminal blocks. If the heated floor stops working (turns itself off) synchronously with the indicator on the thermostat or power supply, then the problem is most likely in the cord or socket.

Check sequence:

- We check the voltage of the outlet with a multimeter. To make sure that the heated floor might not be working due to the plug or contacts, you can use a power extension cord (carrying cable) through which you connect the system to an outlet on another wiring branch.

- If the mains voltage is normal, then plug in the power cord and make sure there is supply voltage at the contacts of the block, which is plugged into the socket on the power supply.

- If the problem is not detected, then you need to check with a multimeter the presence of operating voltage at the input of the thermostat, on the output cable of the unit.

In 80% of cases, the cause of the lack of power is the wiring distribution box, socket or plug, or cord. The remaining 10% occurs in situations where the connection of the heated floor to the network is incorrectly planned.

For example, another powerful consumer of electricity (washing machine) is connected to one branch of the electrical wiring. If switched on at the same time, the mains voltage will drop below the operating limit and the floor will stop working.

Damage to the floor heating system

The most difficult situation is when individual parts or elements of the heating base are destroyed. For example, a film heated floor may stop working after an unsuccessful rearrangement of furniture, or if the laminate was laid without compensation gaps around the perimeter.

In theory, even too much deflection of the plywood or chipboard board of the rough base can damage the integrity of the contact tracks of the film heater.

Often, after removing the laminate and underlay, it turns out that the heated floor does not work due to a break in one of the contact tracks. In this case, you have to cut off the non-functional part and lay a new sheet, connecting to the remaining part using “crocodiles”.

Damage to cable heaters occurs less frequently, mainly due to careless handling of the cable. The main reason why a cable heated floor may not work is a broken wire or short circuit of the wires.

Failure of the thermostat

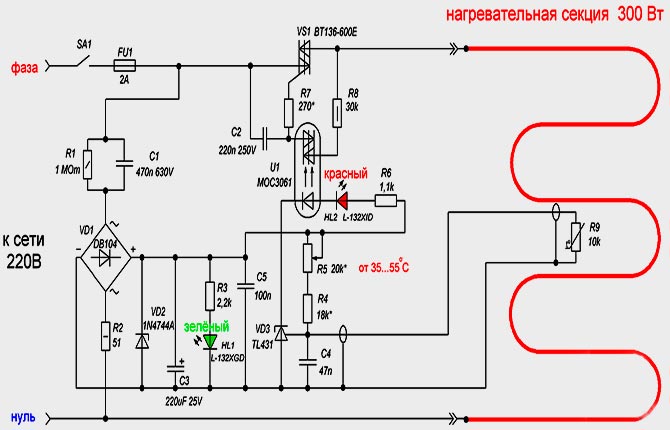

The device that controls and controls the heating process can be made on different element bases. But most inexpensive thermostats are assembled approximately according to the diagram below.

The most important parts, due to breakdown of which the heating does not work:

- thermistor (R9);

- triac (VS1);

- Zener diode (VD3).

The combustion of any of the listed elements leads to the thermostat either not working or incorrectly regulating the heating level of the heated floor. To check the parts, you need to unsolder the part and check it with a multimeter.

Thermostat circuits may differ, but not much. Usually most of them work on the same principle. Programmable and wireless regulator models are more likely to fail due to power surges. As a result, the heated floor will not work due to the failure of some capacitor at the input.

The design also has a variable resistance R5, with which the heating level of the heated floor is set. If you frequently adjust - rotate the potentiometer - then over time the graphite track inside the part may simply wear off.

In a worn regulator, the contact will periodically disappear or become stuck in one place. The warm floor will work, but at one power level. In any case, you will have to disassemble the box to understand why the heating level adjustment does not work.

It may happen that there is no thermostat circuit, and in addition, not all models (especially Chinese ones) can be soldered and repaired. The best way would be to replace the thermostat with the same device. It may not be new, but the main thing is that it is known to be in good working order. If the procedure did not give anything, and the floor did not start working, then, apparently, the reason is not in the thermostat.

The functionality of the thermostat can be checked by connecting a regular 150 W incandescent lamp to the output terminals (instead of the heating section of the cable). If turning the knob changes the heat of the spiral, it means that everything is fine with the regulator, and the floor is not working for another reason.

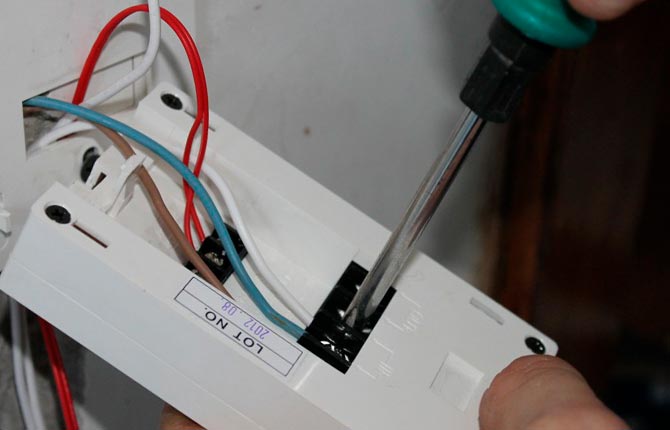

For reinsurance you need to check correct wire connection to the terminals on the thermostat or terminal box. Check to see if there are any burnt contacts and if all the retaining screws are tightened as far as possible.

In older models of heated floors, mechanical thermostats with a bimetallic temperature sensor mounted inside can be used. These devices are practically indestructible, but are very sensitive to dust. A frequent situation is when the heated floor does not work after renovation in the apartment due to dust on the contact, because construction dust acts as an insulator and blocks the contacts.

Damage and checking the temperature sensor

Almost all modern models of heated floors use a remote sensor with a negative temperature coefficient (NTC type). This means that when the temperature increases, the internal resistance of the thermistor decreases, and when it decreases, it increases.

In branded models, the sensor in the thermostat circuit is protected, so breaking the contact on the thermistor leads to the floor operating at maximum power or completely shutting down.

In relatively inexpensive and home-made models of heated floors, for example, with a thermostat assembled according to the above diagram, the sensor is unprotected, and a broken contact can lead to strong heating of the heated floor.

For a cable system this is not so bad, especially since most heated floors are covered with tiles. They dried up and continued working. But for graphite film the consequences can be unpleasant. The heater may become deformed, and it is unknown how long the entire heating system will work.

Check work temperature sensor You can use a multimeter on a heated floor.To do this, you need to disconnect the thermostat and cable. Next, disconnect the thermistor contacts on the switching box and connect the multimeter probes in resistance measurement mode. Until the floor cools down, the resistance should be quite low. As it cools, the readings on the device should increase.

You can simply test the new temperature sensor with a multimeter by measuring the internal resistance. On a working cold thermistor, the device will show 20-45 kOhm.

If you connect the probes of the device to the contacts of the sensor, and then hold it in your fist for several minutes, the resistance will drop to 6-7 kOhm. Just in case, you need to check the documentation for the maximum and minimum resistance for a specific temperature sensor model.

They try to place the temperature sensor as close as possible to the plane of the heating mat. To increase sensitivity, the thermistor is placed without a cover, only the contacts at the soldering site remain closed.

Often the sensor simply moves and comes into contact with the cable sheath. In this case, the information about the heating level turns out to be overestimated, so the heated floor does not work efficiently - it heats up to a maximum of 25 OWITH.

The thermostats of most modern models use a built-in indication of sensor operation (green-red LED). While the temperature sensor is working, it lights up green; if it doesn’t work, it lights up red. This allows you to quickly take action to eliminate problems before the heating cable system melts the mat substrate.

Damage to the heating cable and heating mat

The underfloor heating cable system can be single-core or double-core.In the first case, there is one high-resistance core inside the cable, and the supply voltage is supplied to the ends of the segment using additional copper wires. They do not heat up and are easy to replace if necessary. The connection is made with crimp sleeves.

The cable may not work only if the contact under the sleeve is broken or due to an internal wire break. For example, if a cold wire is severely bent in a loop due to frost.

In a two-core cable, two cores are insulated, so heating sections or mats are always made of a fixed length, for a certain thermal power and current consumption. A pair of stripped contacts is connected to the terminal box, and a jumper is soldered at the opposite end of the wire.

The most common type of damage to a two-core heating wire is damage to the internal insulation between the cores or the outer sheath on the side of one of the conductors.

In the first case, damage to the heated floor can be diagnosed only by uneven heating of the floor covering. The part of the floor adjacent to the thermostat will overheat greatly, the rest of the surface will not warm up well or remain cold. A warm floor will not work for a long time in this mode; the insulation and even the substrate panel may melt.

You can find the location of the short using a remote IR thermometer; you just need to find the hottest spot on the floor. If the installation diagram remains, then the location of the short circuit on the warm floor can be calculated by measuring the resistance of the closed cold cable.

You need to take the measurement by first disconnecting the cable from the thermostat. Knowing the resistance of a working and closed wire, you can use the parallel conductors formula to calculate the length of the heating section.

Cable burning and signal generator

A low level of thermal power produced by a heated floor with the regulator set to maximum indicates the presence of unstable contact at the junction between the main thread of the single-core cable and the additional copper wire.

If you use a multimeter signal generator and test the circuit for an open, the device will most likely show normal contact. As soon as the thermostat turns on the heating, the warm floor will begin to produce heat, but before it has time to warm up to operating temperature, it stops working.

The essence of the problem is that the two ends of the wire at the break point diverge when heated, although when cold they can touch each other.

You can fix the problem by burning the chain. For this, a magneto from a two-stroke scooter engine or a HDTV with a scanner from an old (tube) TV can be used. Magneto is considered a safer option, although it is not the best solution, it almost always works.

Before burning, unplug all electrical appliances from the outlet; the thermostat should work. We connect the wires from the magneto to the contacts on the cable and, using an electric drill (screwdriver), untwist the generator shaft for a few seconds. The ends of the cores at the point of uncertain contact must be welded.

The heated floor may not work due to water getting into the junction of the conductors. In this case, neither a magneto nor a high-frequency frequency can be used. First, the cable will need to be connected to a low-voltage (20-25 V) pulsed current source and the core will need to be heated in short pulses for several hours.

Broken heating cable core

Violation of the integrity of a high-resistance conductor is considered a severe type of damage. The warm floor does not work and does not even start.The gap can only be repaired by opening the base and sealing the break.

You can determine the point of destruction of the heating wire using a special cable tester or using an oscilloscope by changing the capacitance - inductance of the two-core cable. But this should be done by a specialist.

Determining the reasons why a heated floor does not work is not so difficult. Before inviting a technician, make a diagram of all possible options for yourself and consistently check the functionality of the heating circuit components.

Tell us about your experience in diagnosing and repairing heated floors - how difficult was it to determine the cause, and how was the cable heater restored to its functionality? Save the article in your bookmarks so as not to lose it.

Once we tried to look for a gap using a TV block. On a dry floor in the dark, a glow is visible at the breaking point, but even on a slightly damp floor the effect disappears, in addition, you can get an electric shock on your hands.

Do not buy a heated floor with a bimetallic thermostat. The first year it worked, but during the second year I had to periodically click on the box with my finger - the contact got stuck somewhere. If possible, replace it with an electronic or mechanical one, but an older model.