How to hang a heating radiator on brackets - expert advice

Choosing equipment for home heating, few people think about ways to attach heating batteries. Most often, the old-fashioned way is to rely on what comes with the radiators. Meanwhile, the correctly selected type of bracket for a heating radiator can help improve heat transfer and at the same time make the mount safer.

The content of the article:

How to choose wall brackets

It is not necessary to use the fasteners from the kit to the purchased heating radiator.

You can find a lot of bracket options on sale:

- with adjustment of installation parameters;

- reinforced - for batteries with heavy weight;

- decorative;

- floor;

- wall-mounted, at least two dozen more devices.

They are available in any construction supermarket, in Leroy Merlin, Epicenter. It’s even better to contact a specialized heating equipment salon, for example, Rifar, where there are examples of installed brackets with radiators.

Do you like to do everything at home with your own hands?

When choosing a bracket you need to consider:

- Fastening strength. You need to make a choice, choose a wall or floor installation option. The weight of the body with water is quite considerable, even for aluminum models. Therefore, if the walls in the house are finished with plasterboard, then it is better to choose a floor model;

- Difficult to install.The radiator bracket should not be too difficult to install and adjust, otherwise it will be difficult to correctly align the position of the heating battery relative to the water drain line;

- Possibility of adjusting the distance of the heating surface of the radiator from the wall and window sill board.

Experts call the last condition the most important of all those given. Maximum heat transfer is achieved only if the distance provides the best flow rate of warm air in the gap between the wall and the rear surface of the radiator. It is not always possible to align the radiator relative to the wall correctly the first time. Therefore, the problem is solved with the help of adjustable brackets.

When planning to hang on wall brackets, it is necessary to leave a gap between the top edge of the radiator and the base of the window. For aluminum and bimetallic models, the gap must be at least 100 mm, for cast iron batteries - up to 20 mm.

The gap between the wall and the heating surface is recommended within 30-50 mm, selected individually. If the coolant temperature is no more than 60 OFor example, when using an individual heating boiler, the gap is reduced to 20 mm. The higher the temperature of the battery, the greater the distance from the wall should be.

Bracket for cast iron radiators

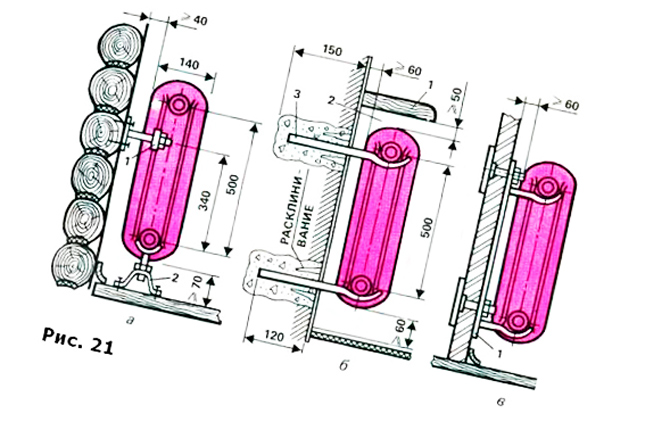

Cast iron batteries traditionally hung on hooks made of forged or stamped reinforcement. They were driven into the brick wall at least 20-30 cm, which ensured reliable fixation of the radiators. Although such brackets looked rough, they were able to withstand the record weight of a cast-iron radiator without subsidence.

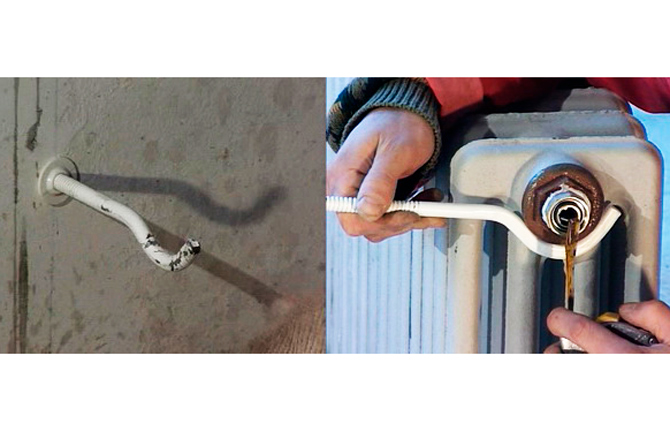

Installing the drive-in brackets required skill and experience.Each hook was driven into the wall according to preliminary markings so that the battery rested with the necks of the registers on its concave part without sagging. It was difficult to do this, so each hook had to be wedged. The slope of the drain line was adjusted in the same way.

Anchor hooks

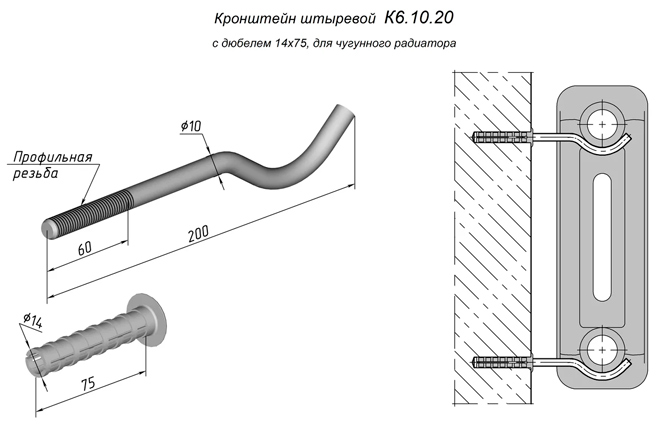

In houses with concrete walls, cast iron radiators are placed on anchor brackets. They are no longer driven in, but threaded into a dowel driven into the wall.

This scheme makes it possible to position the cast-iron radiator more accurately and, if necessary, turn the brackets so that the heating surface of the radiator is parallel to the wall.

Anchor brackets are used to attach all types of radiators, so when purchasing you need to pay attention to the material of the hook and the maximum load. For cast iron batteries, forged steel models with a diameter of 10 mm and a working load of up to 50 kg are suitable.

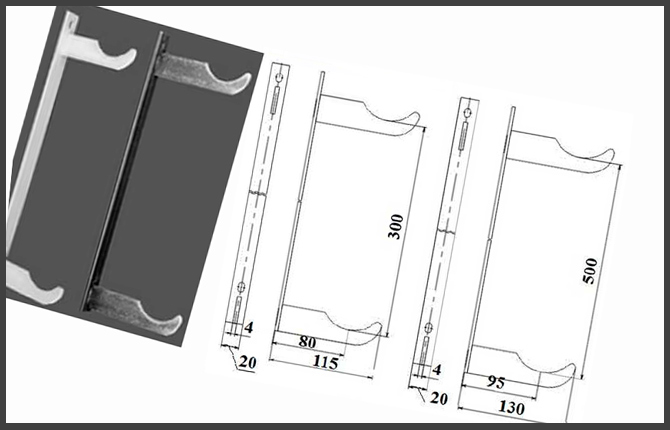

Wall Welded Brackets

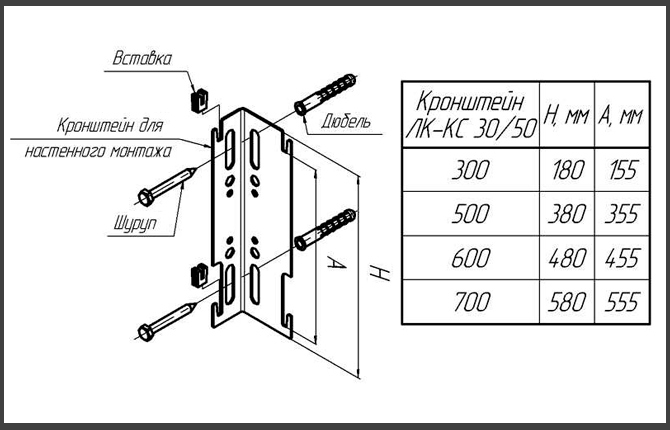

Each fastener is a mounting strip in the form of a pair of steel hooks, 4 mm thick, welded to a support strip 20 mm wide of the same metal. The distance between the supporting surfaces is 30 cm or 50 cm, the overhang of the supporting surface of the bracket is 80 mm and 95 mm.

Mounting strips can be installed on any type of wall; fastening is done using dowels or bolts. If it is a cast iron battery, it is mounted on a wall inside the room.

Fastening cast iron radiators with mounting strips has its nuances.

Namely:

- It is necessary to accurately mark the position of the brackets on the wall. If a mistake is made, both planks will need to be moved.

- After marking, the brackets are secured to the wall with dowels through the upper holes.

- The radiator is hung on the slats, its position is leveled, and only then the drilling locations on the wall for the lower holes are determined.

Any other methods of installing mounting strips require the use of a ready-made jig template. This option is used in residential construction.

Bracket for bimetallic radiators

The weight of bimetal batteries is several times less than cast iron registers, so there is no particular need to drive long, forged “crutches” of reinforcement into the wall. Bimetallic heating systems with a large number of registers are often secured using pin hooks.

This hook is similar in design to an anchor for a cast iron heating radiator, but its dimensions are smaller, and the depth of immersion in the wall is halved. The support arc is covered with plastic or silicone.

Bimetallic heating radiators are also installed on plate corners.

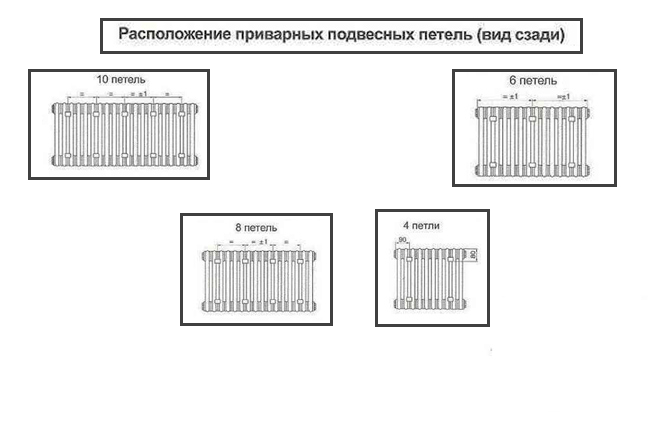

The mounting scheme for panel steel heating radiators is somewhat different. A standard steel panel is attached by hanging loops welded to the back of the radiator to several steel brackets pre-sewn to the wall with dowels. The number of brackets and hinges depends on the length of the heating radiator.

bracket steel radiator – This is a steel corner with perforated mounting holes. During installation, the heating panel is laid in loops on the teeth with inserts. Oval holes for dowels allow you to adjust the position of the dowels, and different sizes of corner shelves make it possible, if necessary, to unfold the fasteners and place the body at different distances from the load-bearing wall.

Bracket for aluminum radiators

For lightweight heating systems made of aluminum, corner types of fasteners are used.This can be a regular stamped steel corner or a more complex welded version with a height-adjustable supporting surface.

As a rule, aluminum radiators are supplied with universal brackets with a double arc. This scheme makes it possible to install batteries on any walls, without restrictions. But the strength of universal systems is noticeably lower than custom-made steel angles.

The manufacturer limits the load per point to 30 kg. Therefore, before assembling the heating system, you need to recalculate the total weight of the registers. If the battery is too long, you have to order additional fasteners or use special floor brackets for heating radiators.

When to Use Floor Brackets

The heating system of the house is planned in such a way that the radiators are located around the perimeter of the room, blocking heat loss through window openings, balcony doors, and main walls. But it is not always possible to use walls as a load-bearing surface for fastening.

In such cases, floor fasteners are used:

- the use of panoramic windows from ceiling to floor in the room;

- if the walls are lined with lightweight materials that cannot be used as a supporting base for heating radiators;

- for temporary placement of a heating system.

The last case is the most common. Major renovations in a room are impossible without a properly functioning heating system. To plaster the walls, you have to remove the heating system. But the plaster will not dry if the water heating system does not maintain 18-20 OFrom throughout the week.

Floor brackets are used for modern cast iron batteries due to their heavy weight or due to the specific interior of the room. In this case, the fastenings are structurally combined with the supply of the heating system.

How to hang a heating radiator on brackets

Installation can begin only after the final assembly of the radiator. The finished body will help determine the anchor points of the hooks.

Determine the drilling points on the wall for the hook-brackets. You can transfer the markings to the wall using a template or through the gap between the registers. We attach it to the wall and note the risks of connecting the heating system pipes. It is best to install the case on a temporary stand.

Using a building level, you will need to set the drain slope and transfer the line to the wall. We remove the body and mark the drilling points for the dowels on the line.

We drill holes to a depth of at least 70 mm, hammer in the plugs and screw in the brackets.

All that remains is to hang the heating radiator and make sure that the slope of the housing corresponds to the previously marked drain line.

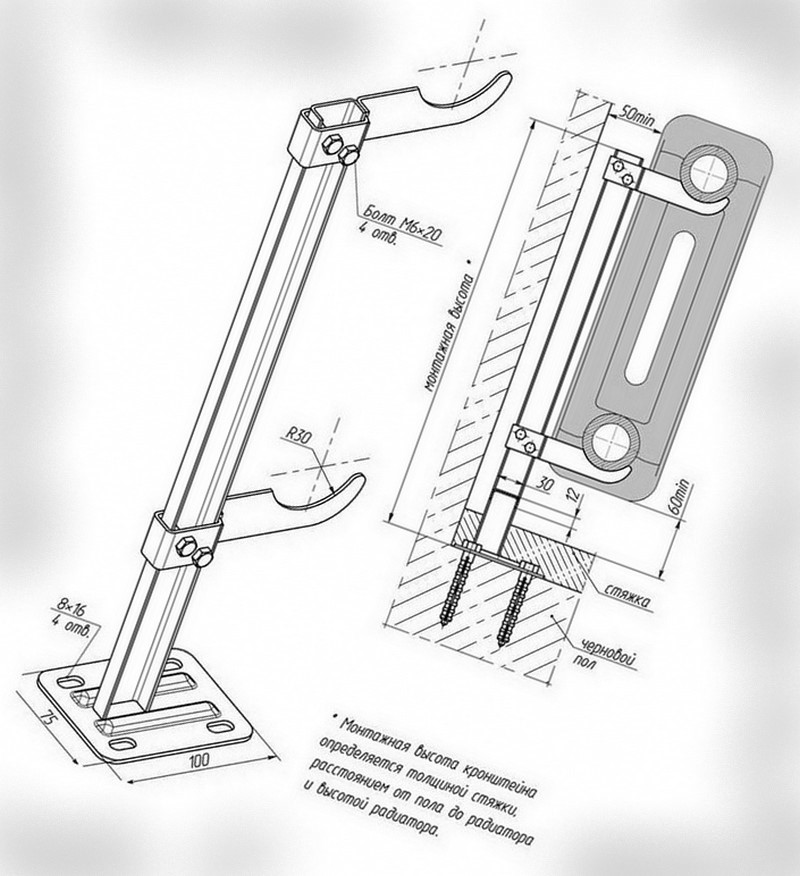

Floor mounting of radiators

Before installing the battery on the finished floor bracket, you will need to perform rough floor preparation. The concrete is cleaned using a grinder. It will be necessary to get two perfectly flat “patches” 100x75 mm, otherwise the position of the rack and heating registers will be unstable.

After cleaning, we put the fasteners in place and level them vertically using a building level. If required, washers must be placed under the support pads. We fasten the racks with dowels to the floor. You can hang the case.The only small thing left is to use a hammer and a wooden spacer to knock down the vertical post of each bracket so that the distance to the wall is the same for all attachment points.

Fill the screed, tighten the fixing bolts, and you can connect the pipes.

The correct choice of bracket for a heating radiator is a guarantee that the heating circuit will not fail or depressurize at the most inopportune moment.

Installation of aluminum or bimetallic heating radiators: video

What type of battery mount would you prefer? Tell us - did you have to repair the fasteners without removing the radiator? Save the article to your bookmarks and share it on social networks with your friends so that they can learn more about how to attach heating radiators.

I had a situation where new fasteners on a cast iron radiator fell out of the wall. I didn’t change anything - the heating season is in full swing, I just bought two stands with a chain, lifted it and placed the battery on them. This is the fourth year.

Problems with the bracket occur if the plastic connection to the heating radiator is made incorrectly. We hung the bimetal on hooks, and clamped the polypropylene pipe. It heated up and squeezed the body out of the mount. It should be sliding, then there is nothing to be afraid of.