What is better to choose for your home: an electric boiler or a convector - comparative characteristics

For new wooden houses, heating with electricity has long become a real alternative to heating with wood or domestic gas. Connecting to electrical networks is much easier and cheaper than bringing gas into the house. Heating with electricity is more expensive. Therefore, the load on the family budget and the level of comfort in winter depend on how correctly the heating device is chosen, whether it is an electric boiler or a convector in a wooden house.

The content of the article:

- Electric boiler and convector - what is the operating principle of heating devices

- What makes convectors convenient for heating residential premises?

- What types of electric convectors are there?

- Types of electric boilers and their features

- Principles of constructing a heating system using convectors and electric boilers

- Features of using an electric boiler

- Economic component of heating system projects using an electric boiler and convectors

Electric boiler and convector - what is the operating principle of heating devices

The boiler method of heating a home is considered one of the most common and popular heating schemes. The boiler running on wood, gas or coal fuel was considered the most problematic part of the system. Servicing such devices was too much of a hassle.

Therefore, with the advent of modern models electric boilers Many owners of private houses, including wooden, log and aerated concrete buildings, have gladly switched to using electric boilers. In addition, inexpensive and efficient electric convectors have become available, which are easier and more comfortable to operate than boilers.

Therefore, owners of small-sized housing, wooden baths and cottages are switching en masse from bottled gas, coal and firewood to electric heating. All that remains is to make a choice whether to use convectors or an electric boiler in a wooden house.

What makes convectors convenient for heating residential premises?

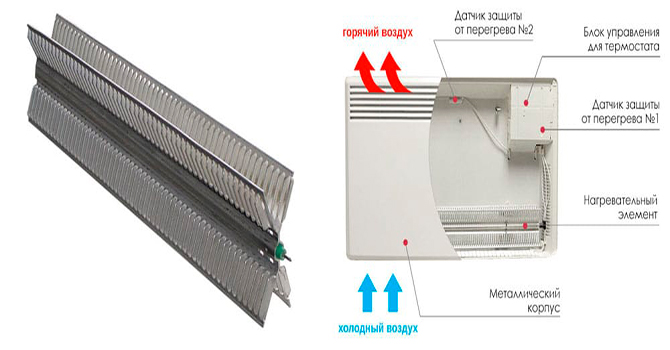

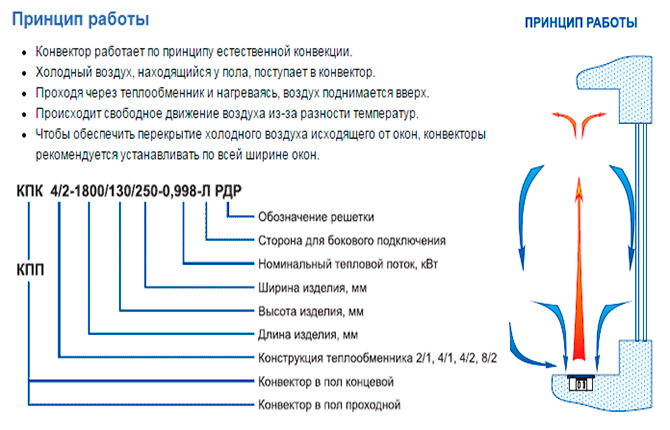

In a simplified sense electric convector It is a sheet metal housing with a lattice bottom and several rows of slots in the upper part of the metal box. A heating element is installed inside in the form of a package of plates, needle and wire heat exchangers. The air flow heated inside the convector rises and exits through the cracks, simultaneously sucking in a fresh portion of cold air.

The flow temperature is quite high, 100-120 °C, so heat is quickly transferred by convection upward to the ceiling. Part of the energy is transmitted through radiation from the walls of the convector; a temperature comfort zone is created at a distance of 50-60 cm from the body. Convectors are very convenient for country cottages and houses. In winter, when arriving at a frozen dacha, you can always settle down next to the heater and warm up without waiting for the heating system to thoroughly warm up the room.

Advantages of heating with electric convectors:

- A hot air stream rising upward effectively removes condensation from the windows and walls of a wooden house. For log houses and timber buildings, wet walls of a winter cottage have always been a problem. It is easy to dry a bathroom and even a bathhouse with a convector.

- All modern models of electric convectors contain built-in mechanical or electronic temperature control systems.Automation can be programmed or manually configured separately for each room and even a specific area of the room;

- Thanks to intense convection and increased air movement, natural supply and exhaust ventilation operates at its maximum potential.

Electric convectors also have disadvantages:

- firstly, to equip the heating system with convectors, you will need to make new wiring to each convector installation point;

- secondly, additional electric heaters, even when installed in a protective housing, remain a potential threat of fire in a wooden house or electric shock.

There is an opinion among ordinary consumers (reviews often confirm this) that convectors “burn through” the oxygen in the air, reduce the humidity of the atmosphere in the room, and saturate it with unpleasant odors of hot metal. All this applies to older models of heating convectors with open nichrome spirals. Metal heated to a high temperature burns not oxygen, but house dust. Because of this, the smell appears and the air humidity in the apartment or in a wooden house decreases.

Heating with convectors of a private house. The pros and cons of this heating method in the video.

What is attractive about a heating system based on an electric boiler?

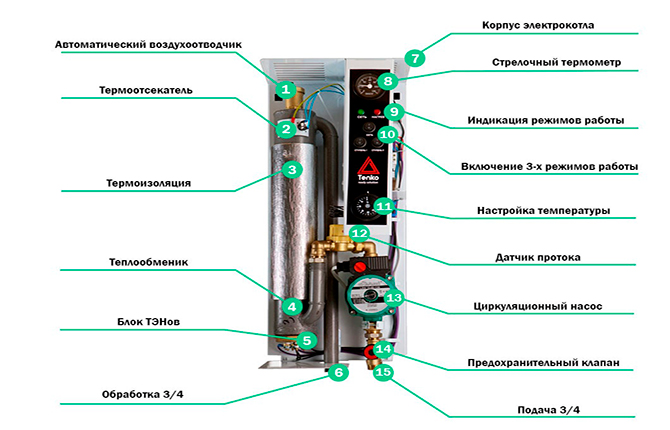

The design of the device is an insulated metal flask, inside of which there is a heating element. Depending on the circuit of the electric boiler, the current flows either directly through the water or the heating element in the heating element, heating it to a temperature of 85-92 °C. Circulation pump An electric boiler accelerates hot coolant through pipes and radiators in the same way as in any other water heating system.

Advantages of an electric boiler:

- the huge resource of the heating element is estimated at tens of years;

- the water heating zone in the electric boiler is completely insulated and grounded, so there is no risk of electric shock or boiling of the coolant due to excessive power;

- the entire heating part of the electric boiler is concentrated in one place, where there is no access for children, guests, or random people;

- there is no need to lay tens of meters of copper cable throughout the apartment, routing walls, wiring junction boxes or sockets.

Another huge advantage of an electric boiler is that you can use the old system of pipes and radiators left after disconnecting from centralized water heating.

The air temperature around the battery is lower, the heating intensity of the room is weaker, air flows move at a lower speed, and only a third of the energy is transferred by radiant heat. This means that when heating with an electric boiler, the windows in a frozen dacha thaw more slowly than in the case of a convector. But dust will not collect on curtains and curtains, and indoor plants will not dry out.

Compared to a convector, the rate at which an electric boiler warms up a room is lower, since there is inertia of heat transfer by water flow. On the other hand, if a wooden house is de-energized in winter due to an accident, the electric boiler will retain heat in the living quarters for another hour and a half. When heating with a convector, the room cools down in 30 - 40 minutes.

What types of electric convectors are there?

To confidently navigate existing models of electric convectors, it is enough to pay attention to two basic characteristics of heaters. The first is the design of the convector body, the second is the installation method (floor and wall).

The first include more massive and powerful rooms that release heat into the atmosphere in all directions. They cannot be installed closer than 50 cm to wooden and plastic objects. They are connected to the electrical network with a separate cord, a heat-resistant Euro plug with a grounding terminal.

Wall convectors are manufactured in the form factor of a flat box. Heat release occurs on one side, so the device can be mounted on the wall.

The exceptions are log and wooden houses made of timber. The relatively low temperature of hot air is considered safe for wood. There is no risk of thermolysis or fire of wooden finishing, but under the influence of a dried air flow, the upper layers of a log or timber quickly lose moisture and dry out. As a result, microcracks form on the surface, and the crowns themselves can become deformed as the gaps and joints between the rows of timber increase.

To heat a wooden house, it is recommended to use floor convectors, and additionally coat the walls with a protective heat-resistant varnish.

To heat the air inside the convector, three main types of heating elements are used. The heating element for an electric convector is easy to distinguish from heaters for other devices by its characteristic shape. The design of the heating element is a horizontal block with a large number of needles, wire loops, and metal petals, with the help of which they increase the transfer of heat from the metal to the air flow.

In modern models of convectors, the heaters are made in the form of a monoblock made of aluminum, inside of which ceramic, oxide or graphite heaters are sealed.The service life of such heating elements is many times greater than that of wire models, but thanks to their specific design, electric heaters are resistant to shocks and falls on a hard surface. In case of burnout, they cannot be repaired.

Any convector model, regardless of its price or design, is equipped with a temperature controller. It could be:

- mechanical system based on a bimetallic plate. Low adjustment accuracy is compensated by durability and easy repairs;

- electronic circuit based on triacs and a rotary handle, characterized by reliability and high service life;

- programmable unit (it is often installed complete with an electronic control panel).

Convectors with mechanical adjustment can be connected to any electrical network, even if the voltage in the network changes during the day. Electric convectors with regulation of the second and third types are included in a stabilized network.

Types of electric boilers and their features

Majority models of electric boilers are produced in the form factor of a wall-mounted or floor-standing cabinet, inside which the parts and components necessary for the safe and stable operation of the heating system are assembled. The electric boiler itself is a seamless cylindrical container made of stainless steel, designed for high pressure of steam and hot water.

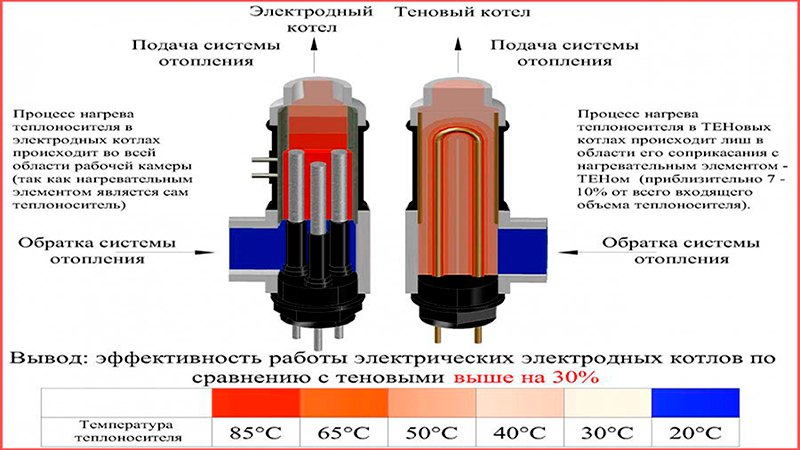

Depending on the model, water heating in an electric boiler can be carried out in three ways:

- by passing an electric current through a stream of water, two or three electrodes are installed inside the boiler;

- with the help of heating elements mounted in a steel flask, there can be several heating elements;

- induction of eddy currents onto the water flow using an additional electrical winding.

Electrode boilers are the easiest to use.The built-in protective magnesium electrode protects steel reinforcement from corrosion. The absence of additional windings and heating nichrome spirals guarantees high reliability of the design. The only negative is the accumulation of sludge in the heating system, so pipes and radiators must be flushed periodically.

An electric boiler with built-in heating elements provides precise control of the heating of the coolant. You can regulate the operation of the heating system manually by turning off the heating elements, and smoothly using a triac control unit.

Induction electric boilers have lower efficiency. Non-contact heating does not pollute the coolant, so the parameters of the heating system remain constant throughout the entire service life of the boiler equipment.

All types of electric boilers are equipped with automatic control of temperature and water pressure in the circuit. An expansion tank and a coolant level sensor are installed parallel to the heating unit in the heating system. The electric boiler will not start or will turn off at the sensor command in the following cases:

- water leaks or freezing in the heating system;

- clogging of the expansion tank;

- breakdown or jamming of the circulation pump;

- increased pressure in the electric boiler bulb.

All heating devices are installed and operated with circuit breakers, sometimes paired with an additional electricity consumption meter.

Principles of constructing a heating system using convectors and electric boilers

The decision about which heating method to choose is made based on basic criteria:

- the cost of the electric boiler or convector itself, estimates for refurbishment or initial installation of the heating system in the house/apartment;

- expected level of comfort and savings on electricity bills;

- the ability to use old infrastructure in the house - wiring, pipes, heating radiators.

The principles of planning a heating system using convectors and electric boilers are in many ways similar, there are only features associated with balancing the load across different rooms.

Features of using an electric boiler

The average power of an electric boiler is selected at the rate of 100 W/h for each square of housing area plus 10% reserve. For heating systems based on electrode and heating element models of electric boilers, it is recommended to increase the reservation to 15%; for induction models of electric boilers, the reservation need not be made.

While special coolants based on ethylene glycol are widely used in gas boilers, they are not used for electric boilers. In electrode and induction models they are useless; in designs with heating elements, such a coolant degrades, decomposition products clog heating radiators and are deposited on tubular heating elements.

Experts recommend pouring distilled water with additives into the heating circuit and changing it before the start of the season.

The second requirement relates to the use of a boiler; a 200 liter insulated barrel will help save on electricity, especially if the house has a meter with a night tariff. During the day, the temperature in the rooms can be maintained by a heat accumulator, and in the evening you can start an electric boiler in the heating system.

The third requirement relates to proper load balancing. To coordinate hydraulic resistance and heat transfer, the heating pipes are divided into two parallel circuits. The first includes a living room and bedroom, the second - a kitchen, bathroom and toilet.The output from the circulation pump of the electric boiler is fed to a tee, from which the pipes diverge into two circuits. You just need to adjust the water flow through each heating line using a tap. If the house has two or three floors, then it is best to install several low-power electric boilers for each heating tier.

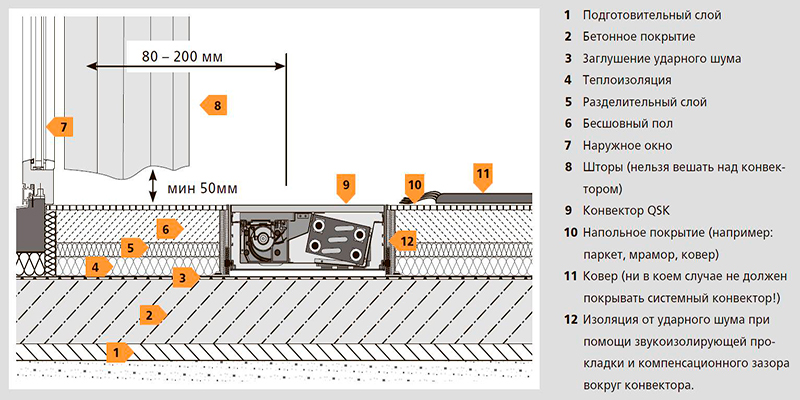

Principle of installation of convectors

Installing electric convectors in a house is easier than installing boilers. First, you need to determine where to install the convector in each room. For living quarters and kitchens, you can use models with protection level IP21, for bathrooms and toilets - IP24.

Secondly, for each convector you will need to lay your own cable with ground. We put the wiring in a heat-resistant channel and cover it with a plinth. In addition, each convector must have its own socket for a Euro plug with ground and a bag. The wire cross-section is selected according to the permissible constant load.

We collect all the wiring on a distribution panel with circuit breakers for each branch. Here you can install a programmable automatic machine that controls the operation of the convectors.

Economic component of heating system projects using an electric boiler and convectors

If you do not take into account the design and aesthetic problems of the design of the heating system, then there will not be much difference in the total costs of heating with a boiler and a convector. Purchasing an electric boiler, installing it and connecting it to the network, and wiring hydraulic circuits will cost only 10-15% more than purchasing and installing a convection heating system.

Operating costs and electricity payments are also approximately at the same level. Repair and periodic maintenance of electric boilers are more expensive.The service life of convectors is much shorter, so they will have to be replaced earlier and more often than for electric boiler components.

Significant cost savings can be achieved with an electric boiler only if it is possible to heat water at a night tariff. Electricity costs will be reduced by 25-30%. In addition, the efficiency of convector heating decreases sharply, and costs increase accordingly if the wooden house has very high ceilings, without ceilings. Due to intense convection, most of the heat is simply lost in the ventilation ducts.

Before you make a choice whether to install a convector or an electric boiler in a wooden house, you need to think about the issue of saving energy. If it is possible to install a meter with a double tariff, then the electric boiler will pay off. In other cases, it is optimal to use convectors on modern low-temperature heaters for heating.

What heating system do you prefer? Leave a comment under the article, save the information in bookmarks, share it via social networks.

Electric boiler or electric convectors - which is more profitable? Opinion of the author of the video.

Links to resources:

- https://teplo.guru/obogrevateli/elektroobogrevateli/elektrokonvektory-otopleniya.html

- https://baltgazservice.ru/stati/otoplenie/elektricheskij-konvektor/#1

- https://lucheeotoplenie.ru/podbor-otopleniya/keramicheskie-konvektory.html#keramicheskie-konvektory

- http://thermomir.ru/doc/all/electro_kotel