Hydrogen heating boiler: device + operating principle + selection criteria

The principles of alternative energy are increasingly gaining the attention of consumers.This is largely due to the increase in tariffs on traditional energy resources, as well as periodic disruptions in the services market.

In these circumstances, a hydrogen heating boiler is considered one of the most promising types of devices operating on renewable fuel, which is H gas2.

Before deciding to purchase such a unit, you need to familiarize yourself with the principle of its operation and evaluate the advantages and disadvantages of using hydrogen as a fuel. These issues have been studied by us and described in detail in the article.

In addition, we identified parameters that should be taken into account when choosing a boiler, provided operating tips and prepared a review of the best factory-made hydrogen generators. Fans of homemade products will find the instructions for assembling the unit with their own hands useful.

The content of the article:

- Properties of hydrogen as a fuel

- Advantages and disadvantages of hydrogen boilers

- Operating principle of the heating unit

- Components of a hydrogen plant

- Generator selection criteria

- Tips for using the boiler

- Top 5 Factory Hydrogen Generators

- How to make a boiler yourself

- Which water is better - regular or distilled?

- Conclusions and useful video on the topic

Properties of hydrogen as a fuel

As mentioned above, the fuel for such units is hydrogen, the lightest gas in nature, colorless and odorless. Among its advantages are the large amount of heat that is released during the combustion of H2 (121 MJ/kg, while propane combustion releases only 40 MJ/kg).

Under normal conditions, hydrogen burns at a temperature of +2000°C, but with the help of a catalyst it can be reduced to +300°C.This allows boilers to be made from inexpensive steel rather than from expensive rare earth metals.

Hydrogen is non-toxic, which makes it safe to use in everyday life. When this substance is burned, water vapor is produced, which improves the indoor microclimate and does not require chimneys.

Disadvantages include the increased explosiveness of hydrogen, especially when it is mixed with air or oxygen, which leads to the formation of detonating gas.

Advantages and disadvantages of hydrogen boilers

The strengths of such devices are:

- Completely environmentally friendly. Water decomposition products do not harm the atmosphere; they are completely safe for the health of people and pets.

- High level of efficiency, which can reach 96%. This is significantly higher than the efficiency of diesel, natural gas or coal.

- Saving natural resources through the use alternative energy sources.

- Low price calories received. For such devices, water and a little electricity are enough.

At the same time, such devices also have weaknesses.

The disadvantages include the following nuances:

- Maintenance requirements. For the highest possible H production2, the metal plates must be replaced every year. In addition to replacing the electrodes, a catalyst must be added regularly to produce the planned amount of energy. The frequency of this procedure depends on the power, as well as on the features of a particular model.

- High cost — factory installation will cost no less than 35-40 thousand rubles.

- Explosion hazard when the normalized pressure in the boiler increases.

- Shortage of hydrogen cylinders - They are quite rarely found on sale.

- Limited choice. Since such heating devices are not very common on the Russian market, it is not always possible to quickly find a suitable model, as well as find competent specialists for installation and repair of equipment.

- The need for communications. To operate the device, you need a constant connection to the power supply to carry out the electrolysis reaction, as well as to a source of water, the flow of which depends on the power of the device.

It is necessary to mention that manufacturers pay great attention to new technologies and strive to improve hydrogen boilers, eliminating or minimizing disadvantages.

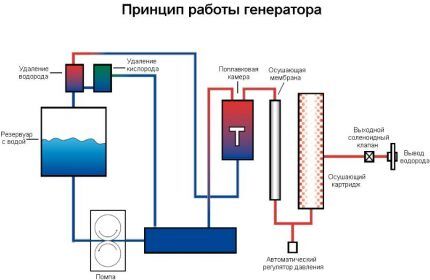

Operating principle of the heating unit

Due to its activity H2 It is not found in nature in its pure form, but it is quite easy to isolate it from ordinary water by electrolysis, which also releases oxygen gas.

For the heating device to function, it is first necessary to obtain H2. This happens in a special compartment reserved for such a reaction. Liquid is poured into the container, into which metal plates are immersed.

They are supplied with an electric current of specially selected purity, under the influence of which H is released2 and about2, as well as water vapor as a by-product.

The resulting mixture is passed through a special device - a chemical separator, with the help of which it is possible to isolate hydrogen, separating it from other impurities. The purified gas is supplied to the burner, on which a valve is installed.

It prevents movement H2 in the other direction, which prevents an explosion. In this case, oxygen and water vapor are released into a special container through another system.

Next, hydrogen gas passes through the protection unit and enters the combustion chamber. Here it reacts with gas in the presence of a catalyst, resulting in the formation of heat, which enters the home heating system through a heat exchanger.

The water vapor released in the chamber is returned through a specially designated channel to the reservoir with the electrolyte, thus using the recycling process.

Power adjustment is carried out using specially equipped channels, the number of which can reach six. Each of these devices contains a catalyst inside, due to which, when turned on, the process of generating heat starts.

The gas flow, heated to a temperature of 40°C, begins to move towards the heat exchanger located in the combustion chamber.

Thanks to separate designs, the channels can operate independently of each other, which allows you to turn on only part of them.

Modern models are also equipped with various devices, for example, water level indicators and pressure sensors, which allows them to operate automatically and respond urgently in unforeseen situations.

Components of a hydrogen plant

The design of a heating system operating on hydrogen is quite simple.

Boiler, which plays the role of a heat exchanger, is the main element where hydrogen production occurs.

Electrolyser - the main active part of the boiler, where the electrolytic reaction occurs, leading to the decomposition of water into H2 and about2. The element is a reservoir filled with water into which metal electrodes are placed that have maximum current conductivity.

The plates are connected to wires through which electricity is supplied.

Burner - a device that helps heat the coolant in the heating system. Located in the combustion chamber, a spark is supplied to ignite it.

Burner valve - a special part located at the top of the device. Thanks to this detail H2, rising to the top, easily overcomes the barrier inaccessible to other released substances and enters directly into the burner.

Pipeline - communications that extend from the unit and are used to supply heat to all rooms of the house. Used for strapping heating pipes diameter 25-32 mm. When laying, the fundamental rule is observed: the diameter of each subsequent branch should be smaller than that of the previous one.

Generator selection criteria

When deciding to purchase such equipment, it is important to pay attention to the following criteria.

Power. With modern devices, the value of this indicator can vary significantly, which allows you to choose the best option for both a small house and a two- or three-story building.

Number of circuits. On devices operating on hydrogen, a heating circuit is usually installed. Some models also provide additional installation of a second (heating) circuit.

Electricity consumption level. Today's technologies make it possible to achieve excellent heat performance while using a minimum of electricity. The energy consumption of different types of generators varies from 1.2 to 3 kW per 1 hour.

Low energy consumption is achieved due to the fact that the hydrogen boiler does not operate continuously, but only to maintain a certain temperature in the room.

Power supply. All types of hydrogen generators can be divided into two large categories: one runs on gas, the other runs on electricity.

Manufacturer. It is better to prefer proven manufacturers (Italy, USA). You should be wary of low-quality products offered by dubious companies at extremely low prices.

Tips for using the boiler

To improve the functionality of the unit, it is important to follow the included instructions. You can improve the operation of the device by adding additional parts (you must strictly follow safety rules).

You can install special sensors into the inside of the heat exchanger to monitor the increase in water heating rates, as well as supplement the burner design with shut-off valves.

Simply connect it directly to temperature sensorso that the boiler automatically turns off as soon as the heating reaches the set point.

It is also useful to install a device for normalized boiler cooling.

If operating standards are observed, a hydrogen-powered unit will serve for decades. Although the warranty period for such devices is 15 years, in practice they can work efficiently for 20-30 years.

Repairing such devices will not be difficult for an experienced technician, since the basic design of a hydrogen boiler is not too different from analogues operating on other types of fuel.

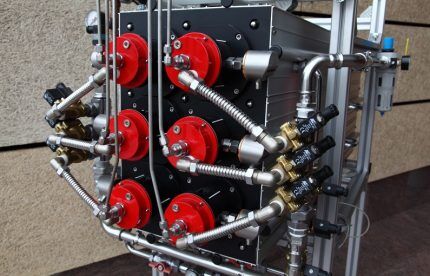

Top 5 Factory Hydrogen Generators

The first company to manufacture and patent the technology for manufacturing a hydrogen fuel boiler was an Italian company Giacomini. It specializes in devices based on environmentally friendly methods of generating energy: geothermal pumps, solar panels and others.

Currently, similar models are manufactured by American, Chinese, and European companies, but their range is not very wide compared to boilers operating on other types of fuel.

The best factory models of hydrogen systems

Among the most popular models we note:

- MegaTank100 – a generator running on electricity from the network. It has a reliable multi-level protection system against overheating and short circuiting, which guarantees safe and productive operation. The cost of the model depends on its configuration.

- STAR-2000 – an expensive unit (>200,000 rubles) has excellent technical characteristics. Despite the fact that this generator consumes minimal energy, it is capable of heating a room of 251-300 square meters.

- Kingkar – a mains-powered device with excellent performance properties. The cost of the model is quite high - about 100 thousand rubles, but it is offset by economical energy consumption.

- H2-2 – Italian “extra” class equipment at a high price (approximately 250,000 rubles). allowing air to be heated in large spaces (from 300 m3 and above) with minimal electricity consumption.

- Free Energy – high-quality devices at an affordable price in the range of 15-35 thousand rubles (the price depends on the power and other characteristics). Equipped with a control unit that automates many processes, a multi-level voltage and pressure regulation sensor.

There are also other models in different price categories.

How to make a boiler yourself

Heating generators have a fairly lightweight design. With a certain level of skill, you can assemble the device yourself. At the same time, due to the explosiveness of the hydrogen mixture, such work requires extreme responsibility, knowledge of safety precautions and experience in installing such devices.

The process of making a hydrogen boiler with your own hands can be divided into several stages.

Step #1 — execution of the drawing and preparation of materials. First of all, you should find similar projects on the Internet in order to use them to think about a device that would meet all conditions and capabilities.

It is necessary to accurately calculate all the indicators, and above all, the required power, and also decide on the materials that will be used to make the boiler. Ferromagnetic alloys are considered the best option, but a container made of stainless steel is quite suitable.

Although heating hydrogen generators may have different designs, the following details remain unchanged:

- 12-volt power source;

- the tank where the structure will be located;

- PWM controller with a power of at least 30 A;

- several tubes of different diameters made of stainless steel;

- steel sheet;

- hacksaw for metal;

- gas-burner - better prepared, purchased in a store.

Step 2 — creation of electrolytes. To make the plates with which the electrolyzer will be equipped, you need to take a sheet of steel of medium thickness.Using metal scissors, a hacksaw or another tool, it is cut into equal strips of 18 or more pieces (the number must be even).

On the other hand, in each of them it is necessary to drill holes for the bolts that will be needed to hold these elements completely motionless in the electrolyte.

We divide all plates into anodes and cathodes; depending on this division, wires are connected to them, respectively transmitting positive and negative charges.

Using direct current is more efficient than using alternating current. It is best to use a PWM type generator as its source.

Step #3 — electrolyzer assembly. The best material for the manufacture of this element is stainless steel. A reliable rectangular or square-shaped structure is welded from metal, after which water or a mixture of H is poured into it2O with the catalyst, and prepared plates with connected wiring are also placed.

Step #4 — burner connection. A burner is mounted at the top of the device - it is better to use a purchased model, which can be purchased at a specialized store.

Step #5 — installation and connection of the separator, which is necessary to separate hydrogen gases from a mixture.

Finally, a tube is laid through which H2 will rise to the burner, and elements that remove heat and distribute it throughout the house are also connected.

Which water is better - regular or distilled?

One of the questions that owners of hydrogen boilers often ask concerns the water used to operate the devices.

According to experts, factory or home-made devices demonstrate the best performance when working with distilled water, to which very little sodium hydroxide has been added (one tablespoon per 10 liters of H2O).

However, a hydrogen boiler can also operate successfully on tap water, the main thing is that it does not contain heavy metal salts.

Conclusions and useful video on the topic

In the video below you will see an overview of a model of a gas boiler running on hydrogen fuel, produced by the famous Korean company DAEWOO.

Hydrogen is not without reason called the fuel of the future: this gas can become an almost limitless resource of cheap, environmentally friendly fuel that can be used in various installations.

A hydrogen fuel boiler, manufactured in a factory or independently, will allow you to create an autonomous heating system. This will help to significantly reduce payments in housing and communal services, and will solve the issue of maintaining a comfortable temperature in living rooms and utility rooms.

Any experience using hydrogen as a fuel? Do you want to ask questions on the topic or talk about your invention? Please comment on the post, participate in discussions and leave photos of your homemade products. The feedback block is located below.