Why does a gas boiler go out? Review of typical faults and methods for their elimination

The prospect of being left without heat in the cool autumn and frosty winter period will not please anyone.If this happens, then in the best case, the room can return to a comfortable temperature within a few hours. After all, it takes time for the master to arrive when called.

To quickly resolve the problem, it would be a good idea to learn how to identify and eliminate the cause of operational irregularities yourself. You need to figure out why the gas boiler goes out and try to get rid of at least basic faults yourself. We'll tell you how to find them.

Of course, no one forces you to dismantle equipment or change a part yourself if you have neither the tools nor the training to do so. However, information about simple and affordable repair operations will come in handy. In addition, they will help monitor the actions of gas workers, not all of whom are quite experienced and competent.

The content of the article:

Why might the burner go out at all?

The boiler extinguishes as a result of the operation of the device’s automation, which responds to the following disturbances in the operation of the system:

- the draft in the chimney has decreased or disappeared;

- the gas pressure in the supply line has dropped;

- The flame in the burner has gone out.

Moreover, these processes can occur both due to internal failure and due to the influence of external factors.

If we consider floor models (manufacturers: Danko, Aton, ROSS, Zhitomir), then they have a primitive internal design. Therefore, if you look into them, there is nothing special to break in them. Attenuation in this case occurs most often due to strong wind outside or other external factors.

But wall-mounted gas boilers in their design already resemble an autonomous mini-boiler room, and therefore there may be more options for stopping the operation of a gas boiler:

- the coolant circulation was interrupted or did not start after repairing the circuit (the flow sensor reacts);

- The air supply has decreased/stopped (the pressure switch is triggered);

- voltage drops occur;

- power outage.

If a mounted heat generator goes out, it is not easy to restore its operation. However, it is still quite possible to eliminate some malfunctions on your own. Find out how to do this below.

Main causes of attenuation

If the equipment was working properly before, but now the automatic valve begins to shut off the gas supply, there may be several reasons. Depending on them, the ways to eliminate them will be different.

Decreased/disappeared cravings

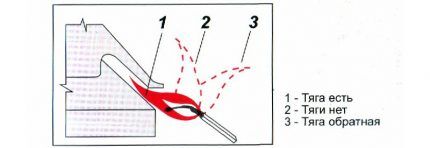

Rule #1 in case of fading atmospheric boiler: Check traction. This can be done with a match or lighter, which should be brought to the viewing window.

Further actions depend on the behavior of the flame:

- if it deviates towards the combustion chamber, there is draft - everything is in order;

- if remains vertical, there is no thrust.

It is important to remember to close the gas supply valve well. But that's not all.

Remove the part of the pipe that is connected to the outlet pipe and check the draft now in the chimney:

- if there is one, you need to clean the boiler channels;

- if not, you can limit yourself to cleaning the chimney.

What exactly needs to be cleaned? Where does pollution come from in the chimney? Natural combustion products accumulate in it in the form of soot and soot deposits, fallen leaves, and sometimes even the boiler goes out due to a flying bird!

If a blockage has formed at the inlet, it will not be difficult to clean it yourself. But if it’s at the top of the pipe, you’ll have to wait for a technician with tools (you may have to use access from the roof).

There is a backdraft in the chimney

Sometimes the boiler may go out due to reverse draft. This means that due to blowing out a gas boiler with the wind, the smoke does not escape from the chimney to the street, but returns back to the firebox, thereby knocking out the flame.

There may be an alternative solution to the problem:

- Install a protective cap at the end of the chimney (popularly called a deflector, popularly called a “mushroom”).

- Increase the chimney pipe itself by 1–2 m if, due to the height and location of nearby buildings, there is a disturbance in the circulation of air masses.

Cornice-type caps are currently prohibited according to SNiP II-35 and SNiP 02.04.05.However, in some cases, their installation may be the only way out - so it is still better to consult with gas workers.

Burner nozzle or filter clogged

If the pilot light does not light when the boiler is turned on, this is a sure sign that the starting elements are clogged. Namely, you will have to clean the igniter nozzle nozzles, the fine-mesh inlet filter or the pilot burner filter. You can do this yourself using handy tools.

For example, filters are easy to blow (even just blowing is enough, but if you have a hand-held vacuum cleaner or a pneumatic spray, it will, of course, be more convenient). You will have to tinker with the nozzles - scrape off carbon deposits with a thin copper wire until the original diameter of the nozzles “returns”.

The pressure in the gas line has decreased

Turning off the burner is the very first sign of a drop in pressure in the gas supply line, while the pilot flame does not go out when the boiler stops operating.

First of all, evaluate how gas flows through the pipeline. To do this, unwind the hose of the pipes and open the valve completely, and then see:

- if there is a strong hiss and the smell of methane is released, everything is fine with the supply;

- if the signs are almost invisible or absent, the problem is in the gas supply system.

After this, immediately close the shut-off valve, return the hose to its original position and check the tightness of the joints with a soap solution (if it foams at the joint, this is a 100% leak).

If there is no leak, look into the meter: after repair, scale or rust may remain in it, which will make it difficult for gas to flow through. "Clogged" flow meter shows incorrect data.

However, you cannot clean the gas flow meter yourself according to Decree No. 261-FZ. This should only be done by gas service representatives with the appropriate license.

There is not enough oxygen to burn the gas

Poor ventilation can also be a reason for boiler extinguishing. Let's try to figure out what this means.

Insufficient air supply is most often caused by the following conditions:

- tightness of plastic windows;

- insulated, transparent interior doors;

- boiler room layout with violations;

- excessively powerful hood in the kitchen;

- forced ventilation in the bathroom and toilet.

You can check for oxygen deficiency by opening the window and turning on the gas burner. If the flame has stabilized, the situation could not be clearer.

The problem is solved as follows: install supply valves on the windows or organize a system of forced air intake from the street by installing supply ventilation valve in the wall.

Electrical faults

Due to a breakdown in communication with the thermocouple, incorrect no-flame signals are sent to the solenoid valve. Because of this, the gas supply stops.

When the boiler goes out immediately after a short period of operation or after selecting a different mode, this is already a signal of problems in the electrical circuit:

- rupture of contacts of the thermostat, thermocouple or vacuum sensor;

- the thermocouple does not enter the flame zone or does not provide the required voltage;

- breakdown of the thermostat, electromagnet coil or thermocouple.

All these problems can also be solved without calling a specialist. The main thing is to stick to the algorithm.

To avoid losing track of the correct sequence of actions, do the following step by step:

- check the resistance on the sensors and connecting devices one by one - normally 0.3–0.5 Ohm;

- clean all “oxidized” areas with fine sandpaper, tighten loose contacts;

- disconnect the thermocouple from the main unit, connect the tester and, pressing the start button, turn on the pilot burner;

- measure the voltage - normal is 10–50 mV.

If everything is fine, return everything to its place and adjust the position of the thermocouple. If there is no voltage, remove the top cover of the main unit, heat the thermocouple with a torch, press the safety valve, and then release.

If the valve still holds, remove the contact block and apply voltage (220 V power) to the coil, bypassing the thermostat.

After these manipulations, you can start the boiler. If the problem is not solved, then the old thermocouple and solenoid valve coil cannot be repaired. Need new parts.

Typical problems with turbo boilers

The problems described above also occur with turbocharged boilers. But in addition, given that boilers with a closed combustion chamber are equipped with additional elements, additional “troubles” can happen to them.

For example, during their operation you may encounter the following difficulties:

- icing coaxial chimney outside the home;

- failure of the built-in air blower.

Their design, of course, is more complex than that of models with an open combustion chamber. But at the same time, you can carry out all the same manipulations with them as with atmospheric boilers.

But let us dwell in more detail on the breakdowns characteristic of this type of equipment.

Icing of the hood or chimney

If you observe that the boiler goes out most often in frosty conditions, then most likely the chimney opening is blocked by an ice mass.

This may happen due to:

- formation and accumulation of condensate;

- snow accumulation.

As you can see, the reason is bad weather conditions. Therefore, the solution to the problem is to protect the chimney from external factors.

In this case, again, it is worth considering the option of installing a “fungus”, i.e. deflector. But this is a preventive measure. But what to do if the problem has already “ripened”, and weather conditions further aggravate the situation? There is a way out in this situation too.

Condensate settling in pipes is typical for convection boilers with a coaxial chimney. Plugs form in them due to the difference in temperature of the air flows drawn into the burner from the street and coming out. These ice jams block the path both into and out of the combustion chamber.

To remove the ice crust from a coaxial chimney, you may even need to dismantle its outer part. Dismantling will not affect the daily operation of the system, but it is still better not to let it happen. Sometimes, in order to prevent the accumulation of condensate in the gap between the pipes, a pair of holes are drilled in the outer contour.

Simply breaking the ice is not the solution. Moreover, the chimney may be damaged. It's better to buy a portable one gas burner with cartridge and “melt” the chimney with it. After the plug melts, the boiler will start working again. But to prevent such incidents from arising in the future, the pipes should be insulated.

The second prerequisite arises in cases of installation of eaves caps: they protect the chimney from precipitation, but in winter they cause more trouble than they are worth, impeding the outflow of flue gases.

Fan or turbine malfunction

When the wick of a gas boiler with a built-in supercharger suddenly goes out during operation or does not initially light up, listen to the sounds it makes.

During normal operation, the turbocharging system should hum steadily, so you should be wary of the appearance of extraneous noise.

If there are none during operation, the breakdown is obvious: that is, the automation does not allow the safety valve to open, so the wick does not light up.

In this case, we strongly recommend not to engage in amateur activities, but to immediately call the gas workers. In most cases, turbocharging cannot be repaired - most likely it will have to be replaced, and such work is associated with the risk of carbon monoxide spreading throughout the room.

Therefore, it is better if control over this process is carried out by a gas worker from the company with which the agreement is concluded. service contract equipment and gas supply.

Typical problems of double-circuit boilers

Double-circuit modifications of gas boilers, intended for the preparation of coolant and hot water, can also fade for all the reasons described above. But if there are no signs of the above breakdowns, perhaps the problem is caused by the specific features of the unit.

These include those that arise due to the operation of the water overheating protection system, namely:

- mixing hot and cold running water;

- thinning of the walls of the gearbox membrane.

The instructions for boilers with an additional heat exchanger for domestic hot water usually warn that two taps cannot be opened at the same time. It is better to initially select the most suitable temperature for heating hot sanitary water in the settings.

The fact is that when cold water is turned on, the consumption of hot water decreases, and heat is generated in the same mode, overheating the heat exchanger. Due to overheating, the automatic system is activated, which shuts off the gas supply and blocks the operation of the boiler.

If operation is carried out according to the instructions, but the dual-circuit unit still turns off, you need to change the gasket of the water unit. Most likely it is worn out.

Conclusions and useful video on the topic

The following video will clearly show you the reasons why the burner of a gas boiler goes out:

Do not forget that the problems listed above may not arise if you monitor the condition of the gas equipment and carry out its preventive inspection.

At the same time, if you cannot determine the breakdown yourself or there is already a pronounced smell of carbon monoxide in the room, call a technician immediately.

Have you ever experienced a fading flame in a gas boiler burner? Share your own experiences and troubleshooting options. Please leave comments in the block below, post photos and ask questions about the topic of the article.