How to install a male tee - step-by-step instructions

The fitting is an important element when carrying out pipe laying work.Its main task is to connect individual elements of a pipe structure, including at its corners. There are types of fittings designed to create a branch or fit pipes with different diameters (from larger to smaller and vice versa). A tee with an external thread seals the pipe joint line.

The content of the article:

Types of male tee

Fitting play an important role in the process of laying a pipeline, therefore they must be made of durable materials that do not corrode and are resistant to temperature fluctuations.

Manufacturers produce fittings made from the following materials:

- stainless steel (stainless steel);

- carbon steel;

- brass;

- polypropylene.

Polypropylene is a material of artificial origin that is used for the manufacture of pipes and other structures. Feels good under temperature fluctuations (softening temperature is 140℃, and melts at 170℃), and is resistant to many chemicals. It has a low cost. Due to all these properties, it is widely used in the production of pipes. This is why the propylene tee with external thread has become such a popular fastener option.

Types of tees with external thread:

- equal passage. The tee has 3 outlets and they are all the same diameter. According to the type of production they can be welded, stamped-welded, stamped;

- transition tee. The adapter tee has 3 outlets, but 1 will differ in diameter.Its function is to connect pipes with different diameters, ensuring a high-quality connection;

- tee adapter for external thread. It can be used to create detachable connections. A distinctive feature of such models is the ability to install them on pipes made of different materials: metal-plastic, plastic, brass, steel, and so on;

- combined variations. There are two types of threads in the design of such fittings: external and internal. Classic arrangement: two external and one internal, and vice versa;

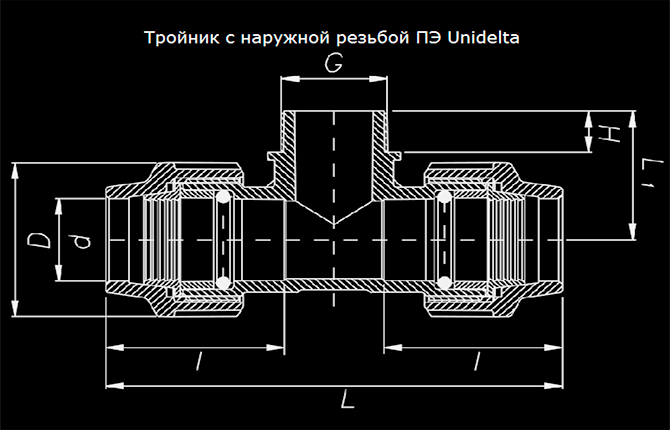

- models with external thread and collet connection;

- with external thread and crimp connection.

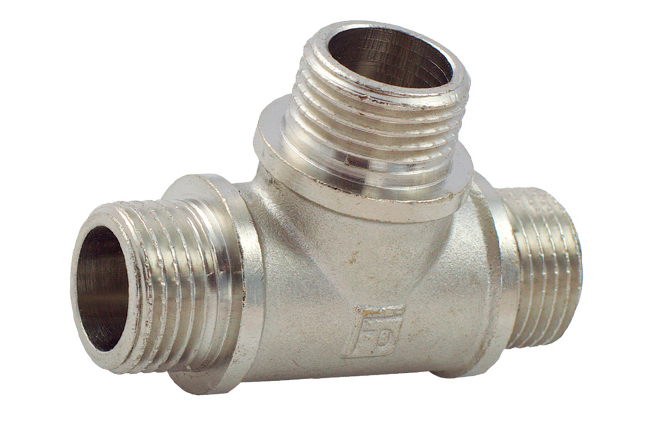

Brass male tee

The model that everyone knows. Brass tee – golden color. Made from brass, or more precisely, from alloys. Type of connection to the pipe - thread.

The main task is to connect another (additional) pipeline to the main line. Since there are many options for a brass tee, choosing the right one (connection angle) will not be a problem.

Brass fittings are good and in demand due to their properties:

- universal and suitable for different types of connections;

- large selection of modifications;

- easy to install;

- durable;

- the connections are reliable and sealed.

Stainless Steel Male Tee

Stainless steel models are used when laying drinking water pipelines. Stainless steel does not corrode and will not contaminate the water flowing through the system. In addition, stainless steel is strong, environmentally friendly and durable.

Such tee models are capable of withstanding extreme temperature fluctuations: from -70 to +450 ℃. The working pressure of such fittings is 16 MAP.

Tees with external threads are good for laying ornate and original pipelines and systems.Thanks to the abundance of modifications, you can realize incredible ideas and plans.

Male Tee with Stopcock

A distinctive feature of such fittings – the presence of an additional element (crane) in the structure. This option is especially useful, because it will be possible to shut off the system and water supply at any time in the event of a connection break or an accident.

Area of use: connecting household appliances to the pipeline (dishwashers, washing machines, etc.).

Design Features:

- rotation lever;

- presence of a rod;

- rubber seals;

- locking mechanism (ball);

- The body is made of brass with nickel plating.

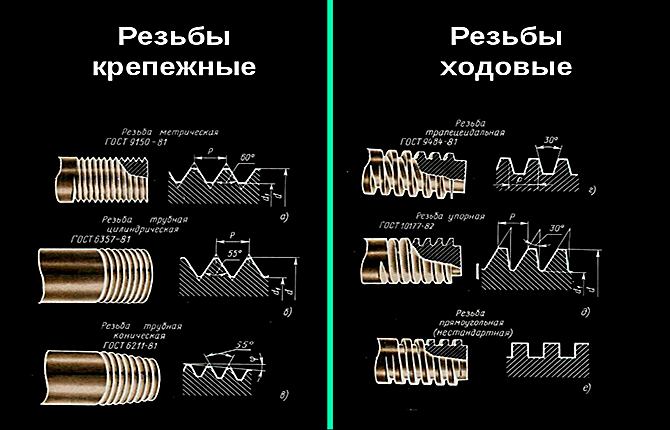

Types of threaded fasteners

Carving also has many types and sizes. There are 2 main types - pipe (inch) and metric.

Pipe is used in heating systems or pipelines (pumps, heating, filters). Water heaters and other appliances use this type of thread.

The metric type is found in gearboxes and pressure gauges. There are two types: fitting and nut (external and internal).

When installing and selecting pipes, fittings and other elements of the system, it is important to make sure that all components are available. The diameter of the pipe is measured from the outside. Many people forget about this, and then cannot connect the elements of the system together.

How to install a male tee

To install male tees, you need equipment designed for this type of work. Then the process will not cause difficulties and problems:

- Pipe section. The first thing to do is cut the pipe. The cut is made at an angle of 90 degrees to the axis. It is important to use a sharp tool during the cutting process. Do not allow deformation of the pipe body: clamps, kinks, etc. This can lead to a leaky joint and subsequent leaks/accidents.

- Calibration with sweep. Using a calibration device, the end of the pipe is centered and calibrated. To carry out the procedure, a steel sleeve is installed.

- Tee installation. By controlling the position of the pipe, the pressfitting tip is installed into the pipe. The fitting itself is inserted all the way with the sleeve.

- Pipe crimping. To do this you will need a press tool. The press part is inserted into its grooves. After pressing, three identical even stripes appear on the sleeve. It's important to do everything right the first time. Repeated pressing is not advisable.

A tee with external thread is an important element that is used when laying pipelines for any purpose. In order for the part to last for a long time, it is better to buy a model made of durable material that can withstand mechanical loads and temperature fluctuations.

Have you ever used a tee? How did you install it? Write in the comments. Save the article to bookmarks and share it on social networks.

I have a stainless steel tee installed on the water supply at home. So there are no problems with him. It’s already been 5 years since I assembled the system, but you can’t tell by looking at it. Looks like new. And it does its job perfectly.

I myself have never worked on pipelines. Let those who understand this do it. When we built the house, specialists supplied us with water and built a heating system.