Trays for surface drainage - classification with characteristics

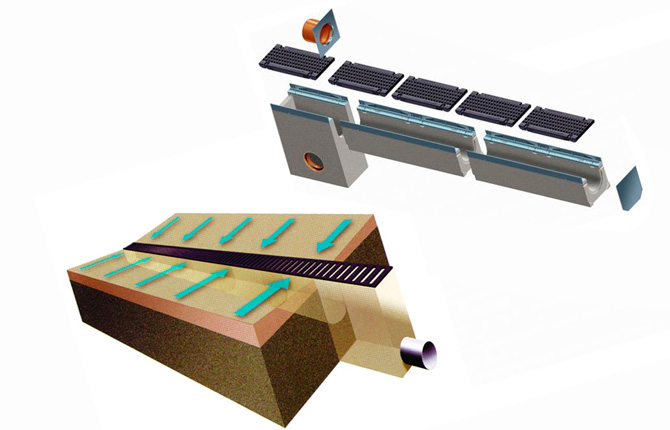

Rain and melt water is one of the reasons for the destruction of residential buildings and utility structures.Therefore, they are trying to get rid of it, and quickly, moving it away from the foundations. Typically, such water is discharged into storm drains or outside the site: ravine, river, lake and other bodies of water. Trays assembled into one structure are called surface drainage or a surface drainage system.

The content of the article:

Where used, design features

Drainage trays have a wide range of applications. They are installed:

- along roads, sidewalks and alleys;

- around sites of various types and suburban areas;

- around buildings and structures, airfields, parking spaces.

The main task is to create a system of canals through which water will be drained.

Purely structurally, the tray for surface drainage is a U-shaped, U-shaped gutter. The cross-section is trapezoidal or triangle. Can be telescopic. The second element is a grid laid on top of the tray. Its task is not to allow debris to pass through, which could clog the drainage system, rendering its operation useless.

But even a grille cannot protect the channels one hundred percent. Therefore, they must be cleaned periodically. That is, the grates are removed and debris is removed by hand or with garden tools. After which the protection is placed in its place.

Classification

There are several parameters on which the classification of trays is based. And the first class is usually the load that the gutters must withstand. This is an important parameter on which the service life of the drainage system depends.

There are six groups:

- A15. Not the most durable model. Therefore, trays of this type are laid along pedestrian areas, around areas of private houses, sports grounds, inside public gardens, and along bicycle routes.

- B125. A more powerful design that is installed along roads with low traffic volumes. It is important that only passenger cars and not the heaviest vehicles travel on these highways.

- C250. Drainage trays can be installed along roads where traffic intensity is average. They are also installed inside car services and car washes.

- D400. Intended for industrial zones and highways along which vehicles of different classes travel. At the same time, the traffic intensity is maximum.

- E600. Factories, factories, warehouses, loading terminals.

- F900. Airfields and airports.

The second parameter by which trays for surface drainage are classified is slope. It is clear that water can move through channels by gravity if they are located at a certain angle. For a surface drainage system, the slope is 7-10 mm per meter of drainage line length.

Manufacturers today offer two types of trays:

- straight;

- with a slope inside.

The first ones have to be set at the required angle, which is not always easy, especially in areas with uneven terrain. That is, each gutter is mounted with an inclination towards drainage.

The second are ready-made products, inside of which the cavity is made with a slope. Such trays are installed on a flat surface.

It is necessary to note that the angle of inclination of the surface drainage system is an important engineering indicator.If it does not comply with the parameters indicated above, then the drainage network simply will not function. The water in the gutters will stagnate and dirt will accumulate.

And the third parameter by which surface drainage trays are classified is the raw material.

Concrete trays

These products are manufactured in accordance with GOST number 32955-2014. This regulatory document clearly states that a tray of this type is equipped with a grate made of gray cast iron of the SCh-20 grade. At the same time, there are much more design types here than in other model ranges.

Concrete channels can be:

- U or U-shaped;

- slotted;

- ring;

- curbs and others.

They can be produced both at concrete factories and directly at the construction site at the place of installation. The latter are called monolithic. The main thing is to use reinforced concrete of a grade not lower than M300.

In this case, other characteristics of the mixture must be taken into account. Namely:

- water resistance – no less than W8;

- frost resistance – no less than F300.

Working with concrete mortar is difficult, but not difficult in terms of obtaining the required product, no matter how complex it is in shape and size.

This GOST does not strictly regulate the dimensional parameters of products. Therefore, they are represented quite widely on the market. Eg:

- length within 400-4000 mm;

- height from 200 mm and above;

- width is not defined.

Some manufacturers offer tray sizes that differ from GOST standards. And this is not prohibited by law, because non-standard solutions sometimes help improve drainage system designs.

Polymer sand trays

Products of this type use polymer as a binder.Most often these are ester resins or high-density polyethylene. That is, the solution includes a binder polymer material and filler: sand, stone chips and others.

The technology for manufacturing surface drainage trays of this type is complex and labor-intensive, so the price is higher in comparison with other models.

The correct choice of polymer type affects the technical and operational characteristics of gutters. It's all about the source material itself.

There are two types of polymer:

- saturated, which includes polyethylene;

- unsaturated – these include essential resins.

The difference is that the first has fewer intermolecular bonds than the second. Hence the low adhesive properties. That is, the adhesion of polyethylene to the same sand is poor. This leads to delamination of concrete during operation. This happens especially quickly at the ends of the trays. It is in these areas that they crack.

Therefore, when choosing trays for surface drainage made from sand concrete, it is better to purchase those that contain ether resins as a binder.

Polyethylene is a material that cannot withstand high temperatures. It has low heat resistance. At a temperature of +60 ℃ it begins to lose its strength characteristics. Therefore, in the southern regions, where the temperature of the road surface reaches +80 ℃, it is prohibited to install trays of this type.

In addition, under the influence of ultraviolet sunlight, the polymer undergoes thermal aging. Scientifically, this process is called thermal-oxidative destruction. Under its influence, the material is destroyed. Many manufacturers, in order to avoid all these troubles, increase the sand content in the solution.This helps, but the density of the mixture decreases, which means its strength.

Polymer concrete trays

One of the varieties of concrete products. But instead of cement, polymer is used here, hence the name. Ester resins are usually used as a binder, but epoxy is still more often used. This material gives products certain qualities and properties. Here are some of them:

- low specific gravity;

- smooth surface, which increases water permeability;

- zero water absorption;

- belongs to load class A15-C25.

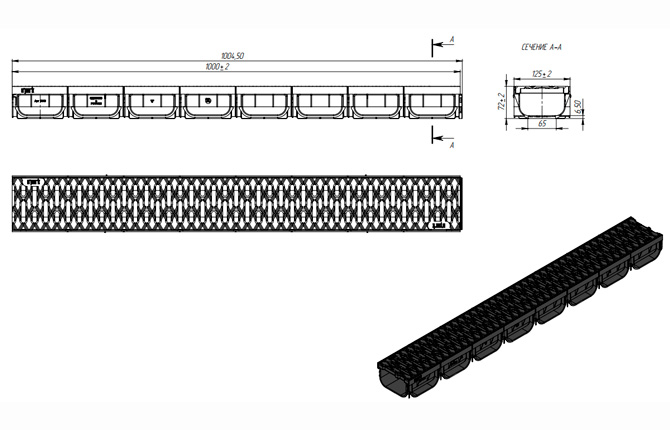

Manufacturers today offer polymer concrete trays for surface drainage in different sizes:

- standard length - 1 m, larger or smaller sizes are rarely found;

- width varies in the range of 138-248 mm;

- height – 60-243 mm.

Depending on the dimensional parameters, the weight of the gutters is from 6.3 to 13.4 kg.

The characteristics of this type of trays have made them popular. Their advantages:

- The weight of the trays is light, which makes their installation simple. No heavy lifting equipment required.

- Strength is high due to the absence of mineral impurities. Even point loads cannot break polymer concrete channels.

- Maintenance is carried out much less frequently. The reason is the smooth surface.

- Easily tolerate low temperatures.

- Increased inertness to aggressive environments.

- Service life - at least 30 years.

Polymer concrete gutters for surface drainage, just like concrete ones, are produced in accordance with GOST 32955-2014. The document specifies which polymers and other components need to be used in the technology.

Synthetic resins used:

- polyester;

- furano-epoxy;

- methyl;

- furfural acetone.

The resins themselves cannot exhibit astringent functions. Hardeners are added to them:

- polyethylene polyamine;

- benzenesulfonic acid;

- isopropylbenzene and others.

About fillers - crushed stone 8-20 mm in size and sand of medium or coarse fraction.

Plastic trays

There is no GOST that would define the technology for the production of products of this type. Therefore, manufacturers use technical specifications (TS), which they develop themselves, taking into account their own technical and technological realities of production. This document also passes all authorities, like the state standard. That is, it is the law for production.

But there is GOST, which determines the quality of the raw materials used. Its number is 26996-86. That is, if the manufacturer used a polymer that complies with this regulatory document, then the final product is of high quality.

Plastic surface drainage trays have many advantages:

- Low price compared to other models.

- Low specific gravity, which reduces the cost and complexity of the installation process.

- They are easy to process. For example, a plastic gutter can be easily cut to the required length, which is impossible to do with other analogues.

- Their design contains stiffening ribs that maximize strength. And this characteristic is not inferior to concrete analogues.

- Service life – more than 50 years.

- Withstands temperatures ranging from -40℃ to +95℃.

- They do not change their qualities and properties under the influence of sunlight and aggressive environments.

- A smooth surface creates conditions for maximum water permeability, which is important for a surface drainage system.

One of the disadvantages is not the highest strength compared to concrete or metal channels.But under operating conditions, it is unlikely that surface drainage will be affected by serious loads that would damage the polymer product.

Manufacturers today offer different models depending on possible loads. Therefore, you need to choose correctly, taking this indicator into account.

However, surface-type polymer drainage trays are not recommended for installation in areas subject to high loads. For example, in an industrial production area or an airport. And for household use this is a good option. It will last for many years without problems.

Fiberglass trays

This is a type of polymer product. The raw material used is polypropylene, which contains fiberglass. The latter serves as a reinforcing frame, hence the increased strength. Therefore, trays of this type can be used for surface drainage systems located in areas with high load.

All the advantages of plastic are present in these models. They are inferior in strength to concrete ones, so they try not to install them near airports and military bases. Trays of this type belong to classes A15-E600. Ordinary plastic ones - for A15-C250.

Metal trays

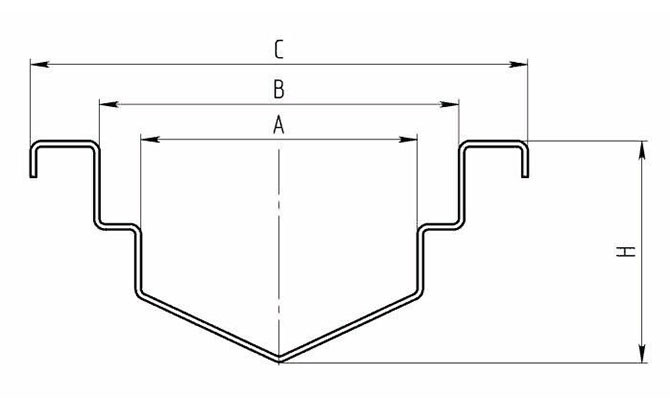

More precisely, it must be said that this category includes trays that are installed inside objects where, due to technological necessity, it is necessary to collect industrial waste. Therefore, gutters are made of stainless steel. Such a surface drainage system is called linear. And they install it in rooms with a large area.

Stainless steel trays are made from sheets with a thickness of either 1.5 or 2 mm AISI 304.If the load on the drainage system does not exceed 2 tons, then use the first option; if it exceeds, then the second.

What you need to pay attention to when choosing trays of this type:

- section, which is based on the width of the product (A);

- width for the grille, it is called landing (B);

- installation width (C);

- channel depth (N).

These chutes are mainly used in the following industrial plants:

- processing of animals, fish, poultry;

- places of their slaughter;

- milk processing;

- production of liquid drinks of any kind;

- production of confectionery products;

- pharmaceuticals;

- chemical plants;

- catering kitchens;

- showers and swimming pools.

The standard length of the trays is 2 m. But at the request of the customer, they are made in longer lengths.

Manufacturers today offer a surface drainage system of the so-called slot type. It can be installed not only indoors, but also outdoors. Design features make it possible to operate such gutters without a grate.

Installation of stainless steel trays is carried out using bolted connections with the installation of sealing gaskets. If the assembly is carried out correctly, then two parameters can be equalized: the load on the trays with the loads on the surface.

Advantages of stainless steel channels:

- long service life;

- no metal corrosion;

- anti-vandal design;

- easy to clean and hygienic;

- aesthetic appearance.

Cross-country ability calculation

Typically, the calculation is carried out by designers, and this document is part of the overall design of the surface drainage system.The calculation is complex; it requires selecting special values of certain coefficients from tables.

But there is a so-called simplified calculation, consisting of one formula. It uses three indicators that are multiplied among themselves:

- F is the area of the territory from which rain and melt water will be collected into the drainage system. It is measured in hectares (Ha).

- q20 – precipitation intensity coefficient. Rain is usually taken into account. The value of this indicator differs by region. For example, in Moscow – 80, in St. Petersburg – 60. The value is in a table.

- φ – absorption coefficient. This refers to absorption by the material from the surface of which water is drained into the trays. For example, from asphalt paths or platforms the coefficient is 0.95. From the ground – 0.4. The denser the material, the higher the coefficient and the lower the water absorption. From them, more water will flow into the gutters, which means their cross-section should also be larger.

After multiplying the data, the value of the volume of water that the surface drainage trays can contain and be moved by gravity to its destination is obtained. Next, in a special table, find the brands of gutters that correspond to the result obtained.

Installation

This is one of the simplest construction processes, which includes several stages:

- marking;

- carrying out excavation work - digging trenches according to markings;

- leveling the bottom of the trench with sand;

- installation of channels with the required slope with sealing of connecting joints;

- filling trays on all sides.

Despite its apparent simplicity, it is necessary to take into account a large number of nuances:

- First of all, the density of the soil and its type are taken into account. The denser, the lower the water absorption.

- Installation begins from the lowest point of the drainage main - from the place where water is collected into the sewer or discharged outside the territory.

- The depth and width of the trench should be 10-15 cm greater than the same parameters of the channels themselves.

- Grids of the surface drainage system should be located 3-5 cm below the final finishing of the territory (below asphalt, paving slabs and other materials).

- Installation of plastic channels is carried out together with gratings. This is how the shape of the products is preserved.

- Before installation begins, a thread is stretched over the trenches to determine the slope of the channels. To do this, several pegs are driven into the ground, to which the thread is attached.

- Heavy gutters are lowered into the trench using lifting equipment. Lightweight by hand.

- Sealants are laid between the elements of the drainage line to ensure sealing of the connections. For plastic ones, a polyurethane sealant similar to an adhesive composition is used. Concrete ones are connected with cement-sand mortar or special gaskets, round in cross-section. The latter are also used in joining metal elements.

- To increase the stability of the location of surface drainage trays, they are sprinkled on both sides with semi-dry concrete mortar, which subsequently becomes the basis for finishing the adjacent area.

- Installation is carried out strictly along the tensioned thread. Each channel is additionally checked with a building level to control the installation level.

- If large-sized concrete trays are being installed, the bottom of the trench is thoroughly prepared. A sand cushion 10-15 cm thick is poured in, and a concrete base for the channels 10 cm thick is formed on it. It is this that is laid at the required slope, so as not to align the gutters themselves to the angle of inclination.

The variety of surface drainage trays made it possible to expand the choice. After all, surface drainage is part of not only public places and industrial facilities. Today it is part of the landscape design of suburban areas, which is subject to functional loads. Therefore, the appearance of plastic trays on the market solved many of the problems of country developers.

Have you installed trays for surface drainage on your site? Which type did you choose? Write in the comments. Share the article on social networks and save it to your bookmarks.

Information sources:

- https://gs16.ru/dacha/razmery-vodootvodnyh-lotkov-2.html

- https://opzt.ru/wp-content/uploads/2019/08/GOST-R-Lotki-ZHB-1-red.-04.24.2019.pdf

- https://stroy-podskazka.ru/drenazhnaya-sistema/lotki/#h3_282336

- https://gk-azimut.ru/blog/obzory-tovarov/tipy-vodootvodnykh-lotkov-i-ikh-razlichiya

- https://septikexpert.com/ochistnye-sooruzheniya/drenazh-i-livnevaya-kanalizaciya/lotok-vodootvodnoj

- https://www.standartpark.uz/info/articles/polimerpeschanaya-ili-polimerbetonnaya-tekhnologiya

- https://strojdvor.ru/kanalizaciya/lotki-vodootvodnye-polimerbetonnye

- https://septicov.net/lotki/plastikovye-lotki/plastikovye-vodootvodnye-lotki.html

- https://www.drenag54.ru/articles/1375

- https://www.inoxpark.ru/catalog