Installation of swing gates: nuances of choice + tips for installing gates and setting up automation

The selection and installation of swing gates are critical stages in organizing access to a personal plot, enterprise territory, or garage. After all, the reliability and functionality of the entry group depends on this. Do you agree?

But how to choose and install the right gate? This is exactly what we will talk about in our article. We will consider important criteria that influence the choice, and also provide instructions on installing gates and setting up automation. We will provide the presented material with visual photos and detailed video recommendations.

The content of the article:

What to consider when choosing a gate?

In order for swing gates to become the optimal solution, and to serve for a long time and without breakdowns, it is necessary to take into account a number of important features. Moreover, even before the selection begins, and even more so before the purchase and installation of the gate.

Otherwise, ignoring this rule may lead to financial losses. For example, this can happen when the characteristics of support poles and electric drives turn out to be incompatible.

To avoid problems you should pay attention to:

- location;

- dimensions;

- space to open;

- wind load;

- type of gate;

- number of doors;

- presence of a gate;

- selection of automation;

- architectural design;

- material of manufacture;

- price.

The listed features directly affect the functionality of the gate, its durability and ease of use.

Criterion #1 - location of gate installation

The design of the entrance group should begin with an inspection of the future location of the gate - at this stage it is determined whether the structure can have the required functionality.

Why is it determined on the ground:

- ease of entry/exit of vehicles - will a car be able to drive up to the gate, drive through it, and then park in the garage or lot;

- the cost of eliminating deficiencies that interfere with access;

- legal grounds.

The last point suggests that the presence of any restrictions will make installing a gate in a particular location impossible. For example, you cannot worsen the living conditions of your neighbors, block the path of fire trucks, or use someone else’s territory.

During design, you should make sure that the doors can be opened to the desired angle (90-120°) and closed after parking the car.

You should also take into account that in winter you will need to remove snow somewhere, a significant amount of which usually prevents the doors from opening. That is, there should be additional space next to the gate.

Criterion #2 - design dimensions

When designing the design of swing gates, you should pay attention to a number of parameters in order to properly organize the planned access regime and the comfort of entry/exit to the territory.

Therefore, you should accurately calculate the dimensions:

- the entire gate structure;

- roadway;

- valves;

- column

It should be taken into account that the entry group should allow the passage not only of the existing vehicle, but also of larger ones. For example, a fire truck or a large car (purchased in the future).

Criterion #3 - type and wind load

As for the type, there are two main types of entrance doors: deaf And lattice.

In the first case, the entire area of the gate is covered with cladding made of various materials. This option is the most popular if owners want to exclude outsiders from viewing their territory.

Lattice gates are a design with separately located leaves, so the space behind them is visible.

Blind gates, due to the peculiarities of their design, have a high windage capacity.Which is a significant disadvantage in strong winds. For example, if electric drives are selected incorrectly, then they will not be able to close the gate or their wear will be significantly accelerated. And this will lead to early breakdown of this expensive equipment.

To avoid these problems, even at the gate design stage, you should calculate the wind load. This step will help you choose the best electric drive option.

To perform the calculation, the area of the blind gate should be multiplied by the wind pressure relevant for the desired region. This parameter can be obtained from specialists from organizations involved in the installation of gates. But in many cases the wind pressure can reach 60 kg/m².

Let's consider an example of calculating the load for a gate with an area of 5 m²: 5m² x 60 = 300 kg.

Then the resulting value must be divided by the number of valves.

So, for example, if there are 2 of them, then we get: 300 / 2 = 150 kg - this is exactly the load that will act on each half of the gate, if their area is equal.

As a result of the calculations performed, we learn that in order to automatically control each leaf, you should purchase an electric drive capable of handling a load of 150 kg. But it is more practical to add 15% power reserve, or even better 50%. In the latter case, the drive motor will not be subjected to maximum loads, which will extend its durability, and significantly (by 2 times).

Criterion #4 - number of doors and gate

Consumers most often stop at one- And bivalve entrance group designs. In this case, the doors can be folded in half or like an accordion. Such features are in demand when space is limited.

A device such as a gate is often an element of the gate design - it can be part of the design solution. Or it can be used as a separate structure.

Criterion #5 - automation efficiency

At the gate design stage, you should decide how they will be controlled. That is manually or automated (using electric drives). The design of the entry group is different in both cases.

If at the time of installation of the gate there is not enough money, but in the future it is planned to install automation, then an interim decision should be made. That is, to install an entrance group, the design of which will allow the installation of electric drives in the future without any alterations or additional costs.

Criterion #6 - structural design

For modern swing gates, it is not enough for them to be reliable and durable. Consumers are increasingly paying attention to aesthetic characteristics. Design is especially important for owners of private houses.

As a result, the architectural plan must be comprehensive, which will create a harmonious residential complex.

Criterion #7 - material of manufacture

The frame of swing gates is most often made of steel pipes of various sections. The profile of which can be round or square.In rare cases, the frame is made of wood. It is beautiful and environmentally friendly, but the durability and strength qualities of this material are inferior to its steel counterparts.

The materials used to manufacture swing gates are most often metal profiles, sheet steel, as well as various forged elements, various types of plastic, including transparent, opaque, and sandwich panels. But wood paneling (shown in the photo below) is again becoming more and more in demand.

When choosing a manufacturing material, you should pay attention to its weight. Since the power of the electric drives that will need to be installed depends on it, the convenience of manual opening.

Criterion #8 - gate cost

The range of entry groups is rich in different price categories. Therefore, purchasing a gate at a price acceptable to the buyer will not be difficult.

It should also be taken into account that expensive gates usually have considerable operating and repair costs.

Stages of installing swing gates

The main stage is the installation of support pillars. To which the gate leaves are subsequently attached.

The materials for manufacturing support pillars can be:

- steel pipes — products are usually used whose cross-section is 60X60 mm or 80X80 mm;

- concrete;

- brick;

- stone.

To ensure sufficient strength characteristics of the structure, all types of poles, except those made of steel pipes, are equipped with a metal base - a core.

Installation of support pillars

The material of manufacture affects the amount of work during installation. So steel pipes are enough drive in or concrete. If necessary, they can be installed in a combined way.

The pipes are driven in to a depth of 1.5 m. For this purpose it is necessary to first prepare the well. The driving procedure can be carried out using a sledgehammer and a wooden spacer. But this is the most time-consuming method. Therefore, special devices are most often used, for example, pile drivers.

Leveling is then carried out using a hydraulic level. Next, the support pillars are connected to the fence and to each other. What are special removable strips used for?

Concreting the pillars is a more reliable method, because the entire structure of the entrance group will be more stable. It is no more difficult than driving in.

So concreting consists of several stages:

- well drilling;

- installation and alignment;

- pouring concrete mortar.

In this case, the well depth is usually no more than 1.5 m. The installation of support pipes is carried out in a reinforced glass or without it.A hydraulic level is used for leveling.

The solution is not filled with the entire well, but only part of it. For example, if the depth is 1.5 m, then only the lower 50 cm are concreted. The rest of the space is covered with crushed stone and soil.

Installation of hinges and hanging of gates

Regardless of the method of installing the support pillars, the hanging hinges should then be welded. After which the swing gate leaves are hung.

Support pillars with a steel core are installed in the same way as their steel counterparts until they are covered with brick or other popular material.

But it should be remembered that hinged loops and an overlay plate should be welded to each core. This is necessary for attaching the sash and the electric drive.

When the gate is not planned to be automated, there is no need for overhead plates. If circumstances change, they can be attached to the support posts using chemical anchors or welding. The last method is more reliable.

We recommend that you read manual on electric welding for beginners.

In any case, the plate should not be mounted below 50 cm from the ground level - the lower, the more moisture affects it. So, in winter the electric drive will be covered with snow, which can result in premature failure.

The gate leaves can be opened in any direction, but it is more practical if outward. This will save space on your territory.

Features of installation and configuration of automation

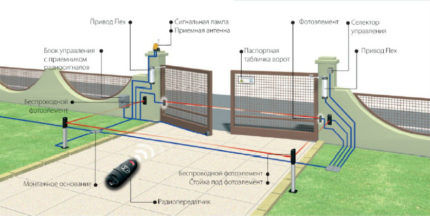

The set of gate control systems includes a significant number of elements that ensure their efficient and safe operation:

- Electric drives of various types (lever, linear). Each sash is equipped with one such device.

- Control block.

- Photocells. They are not a mandatory design element, that is, the automation can easily cope with closing/opening the gate without them. Photocells allow you to instantly identify an obstacle - a child, an animal, an unsuccessfully approaching car. Then give a command to stop moving the valves.

- Wires.

- Control panels.

- Distribution boxes.

The gate automation operates on 220 V.

If the owner plans to install the automation himself, then he should choose an electric drive model for which the warranty will not be lost after installation with his own hands.

Requirements for placement of the electric drive

An important point when setting up the design elements of the gate leaf control system is their correct placement:

- Photocells must be located strictly opposite each other. This is necessary so that nothing interferes with the receiver receiving the command signal from the transmitter.

- When installing electric drives, the manufacturer's requirements and recommendations should be taken into account.You should almost always strictly adhere to the requirements regarding the distance between the hinges and the angle of the support post. It is critical that the electric drive bracket is at the required distance (the value is indicated in the instructions) from the corner of the pole.

If the listed requirements are ignored, the gate simply will not open.

When attaching the electric drive bracket to the mounting plate using welding, tack is initially performed. After that, measurements are taken, as well as a test opening/closing of the sash, and only then scalding is carried out. In this case, if any shortcomings are identified, the bracket can be moved to a new location without any particular difficulties or losses.

The electric drive rod must be attached to the frame of the sash, and not to the leaf, even if it is rigid. The control unit is placed on a vertical surface, no lower than half a meter from the ground, and preferably higher. This element of the system is sealed, but it is correct if the rubber gasket is periodically replaced. This will reduce the likelihood of damage to the expensive board, batteries, and transformer located inside.

Connection and setup nuances

The automation is connected to power supply after all elements of the system are installed. Initially, the wires are connected to the control unit. And then to the drive motor and other devices.

To connect automation, it is advisable to use copper PVA wires. They should be protected with corrugated pipes.If the cable will pass under the roadway, then it is better to take plastic water pipes, which will prevent damage even under significant load.

The laying of wires should be carried out hidden, that is, they should be hidden inside support pipes, in a fence, etc. If this is not possible, then materials that are resistant to ultraviolet radiation must be used for insulation.

To reduce the load on the electric drive, clamps for the extreme positions of the sashes should be used. They reduce the negative impact on the gear motor during wind and people swinging the sashes. Which significantly increases their service life.

You can unlock the gate in the absence of electricity using a special key. It is included with each electric drive.

Conclusions and useful video on the topic

The video will help you understand how to install automation:

Modern swing gates can effectively prevent unauthorized entry into the territory. And also significantly increase the comfort and safety of travel for the entry group. But for this you need to choose and install the gates and automation correctly.

Do you have experience in installing gates yourself, installing and connecting automation? Tell our readers about it - the comment block is located below. Also here you can upload original photos of your gates, ask questions or leave recommendations for your choice.