Wire connectors: the best types of connectors + what to look for when choosing a connector

The electrical network of a single house is a complex system of wires, electrical installations and a protective automatic group. The most vulnerable points are the places where two or more conductors are switched.

The task of the electrician is to select and correctly install wire connectors that will best suit the characteristics, perform their function perfectly and, most importantly, ensure reliability and safety.

Let's figure out what types of connectors are most often used in everyday life, for what work certain switching devices are suitable, and what are the features of their installation. In addition, we will provide practical recommendations for choosing the appropriate connector type.

The content of the article:

GOST classifications and requirements

Wire connectors are any devices that serve to close/open an electrical circuit. These can be electrical installation products - sockets, switches, as well as metal bars and plates, lugs, terminals and terminal blocks - blocks with several sockets.

We will focus on connectors in a narrower sense - on elements that create detachable and non-separable connections and ensure their reliability and functionality - that is, on all kinds of terminals, terminal blocks and sleeves.

Terminals are called both metal elements for decorating the ends of single- and multi-core wires, and small plates inside connecting devices - sockets, terminal blocks, patch panels.

The classification of electrical connectors is presented in GOST 10434-82, where information is provided on division into classes (1, 2, 3) and groups (A, B). Also, according to standards, contact connections are divided into detachable and permanent, requiring stabilization or working without it.

Some recommendations may be useful not only to professionals, but also to home craftsmen who install their own electrical wiring.

For example, it talks about the most preferred methods of connecting aluminum plates - soldering or welding and aluminum tips - crimping or welding.

Popular types of connectors in everyday life

Switching wires by soldering or welding in everyday life is done less and less often. They have been replaced by special devices that facilitate the installation process and reduce work time. Their main advantage is their accessibility for amateurs.

For example, to connect two conductors with a Vago terminal block, you do not need to know its design or operating principle - it is important to carry out the installation correctly.

Let's look at the features of products that may be useful if necessary. connecting wires without soldering during wiring or electrical repairs.

Cable terminal type

To quickly make detachable connections, cable terminals are installed on the conductors on one or both sides.

They are involved in various electrical procedures:

- when connecting inductive coils;

- in power supplies, generators and starters;

- in the windings of transformers and motors, etc.

The material and number of cores does not matter: they are installed on single- and multi-core wires made of aluminum or copper. At the same time, the elements themselves are produced to a greater extent from copper, nickel, brass or bronze.

Let's look at 4 types of terminals that are in demand for assembling electrical circuits.

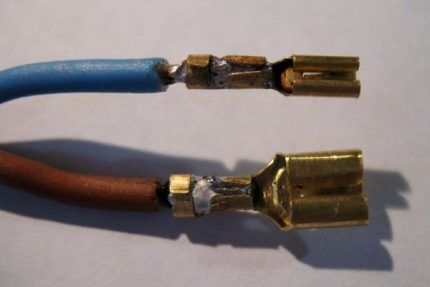

Option #1 - knife

On sale you can find a variety of tips made of brass and nickel, non-insulated and insulated. The simplest and cheaper are non-insulated products, their cost starts from 0.2 rubles. a piece.

This type is not used to equip power wiring, for example, in assembly of electrical panels they don't participate. Most often, stranded wires with a cross-section of no more than 6 mm² are crimped with knife tips.

The shell of insulated products differs in color, which depends on the rated power of the connecting block or other terminal block.

Option #2 - ring

The shape of the elements is reflected in the name - they resemble a closed ring. Like the previous option, they can be insulated or non-insulated. The flat part of the former is placed inside the polymer winding.

The mounting screw is inserted into the “circle” of the terminal, the nut is screwed on the reverse side, after which the likelihood of the conductor slipping out of the connection is reduced to zero.

Materials of manufacture: aluminum, nickel, copper, brass. Ring products are used not only in low-current, but also in high-power power lines of large cross-section, for a bolt of 27 mm or more. They are connected to conductors by soldering, welding or crimping.

Option #3 - fork

Switching of both power and secondary circuits is also carried out using fork lugs, shaped like a fork with two rounded teeth. The terminals are secured either to devices or to busbars with a screw connection.

However, the connection itself is no less reliable than a ring connection; the contact, thanks to the tightened screw, is quite tight. Fork-shaped lugs are suitable for wires with a cross-section of up to 6 mm², the fastening method is crimping.

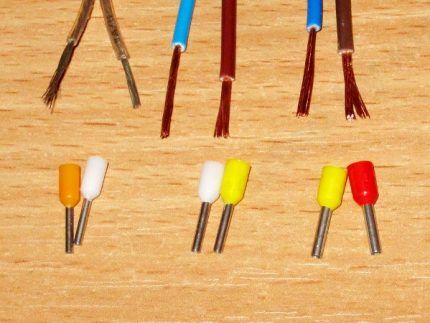

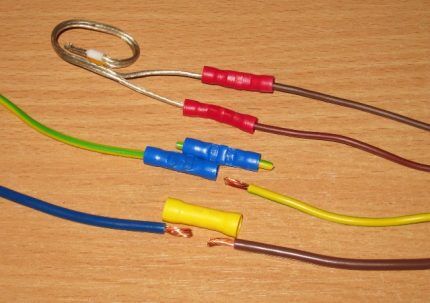

Option #4 - pin

Pin-shaped lugs are used in detachable connections, which are distinguished by markings: the plug is designated by the letter “A”, and the socket by “B”. Suitable for conductor cross-sections up to approx. 6.5 mm².

The color of the insulating shell is tied to the cross-section: for example, for some manufacturers, the polymer part of terminals with a cross-section of up to 2 mm² is blue, and with a larger cross-section - yellow.

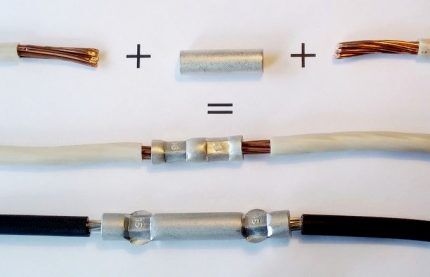

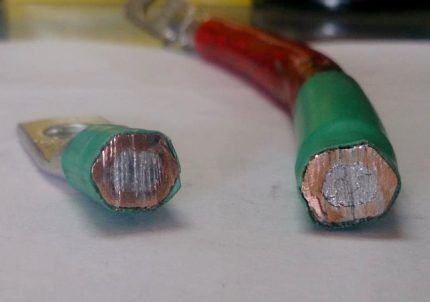

Sleeves for crimping

Excellent contact between two or more conductors is ensured by the crimping method, which is produced using metal sleeves of various diameters.

As a result of the pressing operation with a special tool, the cores are transformed into a monolithic, but permanent connection.

If it is necessary to disconnect spliced conductors, then mechanical cutting should be done and the sleeve removed - it cannot be reused. On the one hand, disposable use and non-detachability are disadvantages.

Sleeves as connectors have some advantages:

- do not destroy conductors, like the same screw terminals, but make the connection as strong as possible, without burning out;

- protect copper conductors as much as possible from contact with moisture and air, that is, from oxidation;

- create a reliable connection from a mechanical point of view - it cannot be accidentally broken.

For crimping, a special crimping tool is used - pliers, which are also called a crimper. In addition, they may be useful insulation stripper and trimming pliers.

Procedure for using sleeves:

As a result, we obtain durable, highly conductive permanent connections that do not deform when heated and do not melt during voltage surges in the network.

Recognized as the most reliable GM – copper sleeves without additional processing and GML – tinned copper sleeves coated with an alloy of bismuth and tin. The second option is more reliable, since the protective layer protects against corrosion and oxidation.

Both types of sleeves are not suitable for connecting aluminum conductors. For this purpose there are special GA – aluminum sleeves. Used for joining copper and aluminum GAM.

The size of the sleeve is selected depending on the total value of the conductors. The choice is large - for example, the market offers GML for wires with a cross-section from 2.5 mm² to 300 mm².

Terminal blocks - switching devices

Terminal blocks are not part of the wires like terminals, but rather switching devices.

They can connect different types of wires:

- in isolation;

- with insulation removed;

- with installed terminals.

There is a large assortment of species, we will focus only on the most common, affordable and widely represented in stores.

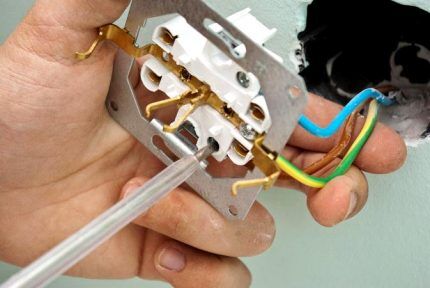

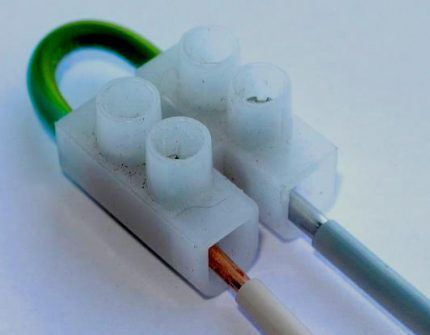

Option #1 - screw pads

Electrical installation products designed to connect paired conductors are called blocks.

They are a dielectric durable plastic housing, inside of which there are sockets with terminals and screw fastening devices for conductors.

The pads are sold in large blocks, which can be reduced if necessary. To do this, you need to cut off the required number of paired cells with a construction knife. For example, to connect three pairs of wires in a junction box, you will need a section with 3 pairs of sockets.

The disadvantage of using pads is that they do not provide a reliable connection. Over time, the screw fastening becomes loose, causing the connection to weaken.

If copper can withstand this situation, then aluminum will overheat and spark. The solution is regular inspection and tightening of screw fasteners.

Advantages of the products: “adjustment” in terms of the number of connections, quick installation, only a screwdriver is required from the tools.

What to do if you need to connect several stranded pairs, but only pads are at hand? You can make switching using wire connectors - install terminals at the ends.

Crimped pin ends of a diameter suitable for the cells are ideal.

Option #2 - spring terminal blocks

Connectors with a spring mechanism clamp one or more conductors and hold them without reducing the pressure.

There are two types of “springs”:

- disposable, providing permanent connection;

- reusable, which can be disassembled if necessary.

The design of the product is simple: inside a polyamide or polycarbonate body that can withstand high temperatures, a steel spring treated with chromium-nickel alloy is fixed. The terminal to which the connection is made is made of tinned copper.

One of the varieties of spring terminal blocks is designed specifically for installation under a DIN rail, that is, for equipping electrical panels and cabinets.

Product advantages:

- provide a reliable connection;

- carry out switching of conductors from different materials;

- have low resistance;

- do not require the use of special tools;

- reusable without loss of functionality.

The disadvantage of spring elements is their inability to support powerful lines of force; only small currents are available.

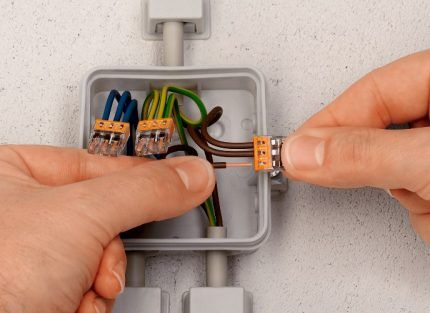

Option #3 - self-clamping connectors

Expensive, but extremely easy to install switching devices. Inside the case there is a pressure plate, which is activated if the conductor is inserted according to the instructions - all the way. The exposed part of the core is pressed against the tinned busbar.

The disadvantage of most self-clamping devices is their one-time use. However, there are products with levers that can be used several times.

In the product line connectors Wago There are several types of self-clamping terminal blocks that have proven themselves to be the best.

In addition to the listed connectors for electrical wires, use:

- knife terminal blocks — suitable for switching conductors without stripping the insulation;

- couplings - fastened with a screw.

The latter version of the device is used less frequently.

How to choose the right connector?

When choosing the right type of connector, everything is important: the brand, the material of manufacture, the diameter of the switched conductors. Don’t forget about the current load - even the most reliable terminal blocks have limitations.

Professional installers clearly know which connectors to use in a given situation, while amateurs can make a mistake and install the wrong connector. Let's look at cases that cause difficulties in choosing.

If you need to place the connected section in water, then it is better to make the connection by soldering, then fill everything with hot glue and cover it with heat shrink on top.

Conclusions and useful video on the topic

Instructions on the use of various types of connectors:

Details about sleeves and crimping pliers:

What are the benefits of self-clamping terminal blocks:

The correct choice of terminals and connectors ensures safety, without which any electrical network cannot exist. If you have a tool, you can connect the wires yourself using the appropriate type of connector.

VAGO connectors are especially easy to install, however, provided that the switching instructions are followed.

Do you have experience connecting wires? Or do you want to ask questions about the selection and use of connectors? Please comment on the post and participate in discussions. The feedback block is located below.

Vagos are, of course, easy to use. It is also convenient that they can be connected and disconnected many times. I made lamps for a friend of mine on their country veranda so that they could be removed for the winter. But there are low-power LED lamps, I’m not worried about them. But it’s scary to connect a large load - a stove or microwave - to the Vago. The contact area there is too small, it would not heat up.

Which connection is best to use for powerful equipment? They say that ordinary wire twisting will not work, why?

As I like to say, it wasn’t me who came up with it, but I heard it from my teacher: “Good twisting is better than bad soldering.” And this has been confirmed in practice more than once! But now there are so many different terminals that you can easily connect wires of different materials and different cross-sections. Without special terminals, a regular nut, bolt and washer will help to connect copper and aluminum wires.

If you have no experience in soldering, then twisting will be more reliable; for example, I will attach a photo of high-quality twisting of wires. Plus an example of terminals and twisting of copper and aluminum using improvised means.

Can you tell me how to connect the phase wires of the motor-wheel of an electric scooter with the controller wires?