How to make a TV bracket with your own hands: popular homemade options

Plasma TV placement includes several options, one of which is to mount it on the wall using a bracket. This solution not only saves space, but also somewhat modernizes the interior. Despite their functionality, factory-made brackets have the only drawback - an unreasonably high price.

Agree, there is no point in overpaying for a design that you can make yourself. The rest of the article will provide step-by-step instructions that will allow you to make a do-it-yourself bracket for a TV of any model.

Depending on the degree of functionality, there are several types of construction, of which only two can be built independently. Next, you can familiarize yourself with the options for making homemade brackets from scrap materials, including step-by-step instructions for each of them.

The content of the article:

Plasma Mounting Requirements

Most of the TVs produced involve the use of VESA mounting.

All factory brackets are manufactured to match the mounting point spacing located on the rear of the unit. Typically these are four holes forming a square or elongated rectangle.

When bracket installation It is recommended to choose steel dowels for main walls. For walls made of foam block or cinder block, it is better to use propylene dowels. The diameter of the screws used must be at least 4 mm.

Depending on the type of load-bearing wall, the depth may be:

- 10 mm for concrete walls;

- 30 mm for brick walls;

- 50 mm for foam block walls.

The presented requirements do not apply to plasterboard walls, since they do not have good load-bearing capacity. If the sheets fit tightly to the capital wall, then the bracket is mounted directly on the wall.

If plasterboard sheets are fixed to the frame, and the thickness of the sheathing is less than 12 mm, it is not recommended to install the TV on such a wall. The only option is to mount the bracket directly on the frame, but in this case you need to know exactly its location under the sheet.

Choosing the right mounting location

Before starting the construction of a homemade bracket and its subsequent installation, it is important to decide where exactly the structure will be located.

When purchasing a TV with a large display, it is recommended to choose a wall with a large free area so that the equipment fits harmoniously into the interior.

The strength and load-bearing capacity of the wall material should also be taken into account. Friable materials include foam concrete and plasterboard, which have less strength than concrete, brick and wood. Ideally everything sockets should be located in close proximity to the TV, which will eliminate the need for extension cords.

The screen must be positioned in such a way that even with significant rearrangement it is in the area of normal visibility. In addition, the TV should be installed as far as possible from cabinets, chests of drawers and other furniture. Thus, due to the free space, the best cooling of equipment is ensured.

DIY TV bracket

The well-thought-out design of the bracket allows you to rotate, tilt and even zoom the screen to the optimal distance.

When building a DIY project, you only pay for the materials, many of which you can find around your home. In this case, it is important not to deviate from the instructions and strictly follow all the rules.

The modern market offers a huge selection of brackets, thanks to which you can adjust the equipment to your needs.

Among all the possible types, it is worth highlighting only two options that you can build yourself:

- Fixed. This bracket allows you to securely mount the plasma on the wall, without the ability to rotate or tilt it. This is the simplest mounting option, requiring a minimum of holes and screws.

- Swing-out. Using this bracket, you can rotate the screen in any direction and bring it closer if necessary. In this case, a more complex design is used, with many connections.

The cost of the latter design is especially high, so by building a swing-and-slide bracket yourself, you can save a large amount of money. By the way, the cost of a factory mount directly depends on the number of inches of plasma purchased.

Option No. 1 - fixed wall bracket

One of the simplest types of design is a fixed bracket. Its mounting system is as simple as possible, but it is not designed to tilt or rotate the screen.

You can build a fixed TV bracket from components that can be easily found in any building materials store.

In the first option, the fixed mount is made of wood. To do this you will need: two wooden planks, self-tapping screws with a ring, hooks and plastic dowels. It is better to give preference to hardwood planks, since they have the highest strength.

Take strips no longer than 10-15 centimeters, that is, their dimensions should not exceed the length of the TV body. The top bar should be slightly thicker than the bottom bar, which will allow for a slight tilt of the screen. Next, you need to screw two self-tapping screws with a ring to the top edge of each plank.

Using the bolts that you will need to screw into the special holes, secure the strips to the back wall of the TV. One bar is located at the top, the other at the bottom. In this case, you should rely on the mounting holes intended for the bracket.

Measure the distance between the rings horizontally and vertically and transfer them to the wall. Next, based on the marks, you need to drill four holes in the wall and install dowels with hooks on which the plasma will be hung.

To make the second version of the fixed structure you will need: four aluminum corners, one bicycle spoke, bolts, screws and plastic dowels. If possible, it is better to take aluminum corners, since unlike steel, aluminum is easier to process.

The installation location, the size of dowels and holes are selected in accordance with the dimensions of the screen. Pre-drill two holes at each corner. Take two corners and attach them to the back cover with bolts. The second pair of corners will need to be attached to the wall with screws.

To do this, attach them to the wall and mark with a pencil the holes for the plastic dowels. To connect the corners together, you will need to drill another hole in the upper side of each corner.

It is important that one corner fits into the other, so it is better to make the distance between the wall corners a couple of millimeters smaller. Next, attach the TV to the wall and align the drilled holes in one line so that you can thread a bicycle spoke through them.

The spoke allows you to hold the body of the equipment in a vertical plane, and the corners prevent its accidental horizontal displacement. If you need to remove the device from the wall, just remove the spoke and the connection will be disconnected.

Option No. 2 - swing-and-slide design

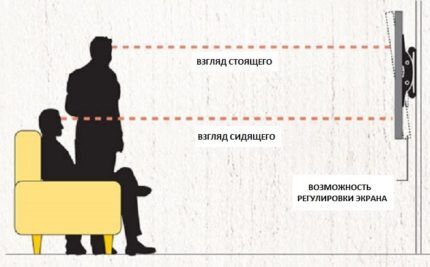

Using this bracket, you can rotate the screen in the desired direction and bring it closer if necessary. Some designs even allow you to adjust the angle of the screen, which is especially important when the TV is hung too high.

To independently construct a swing-and-slide structure, you will need two metal plates, a piece of square pipe, connecting bolts, screws, and dowels. First of all, take two 20x20 cm plates, attach one to the wall and the second to the back of the device. Each plate is equipped with two metal corners.

In order to ensure sufficient freedom of movement of the fastening, a piece of pipe is installed between the corners. Place it between the two corners, and connect them together using a long bolt, and screw it to the plate. The pipe should rotate freely without touching the plate.

The wall-mounted plate is equipped with corners that will need to be secured parallel to the floor. So, you can rotate the TV left and right.

The corners installed on the back of the TV are aligned perpendicular to the floor. Thanks to this, you can adjust the tilt of the screen depending on your needs.

To ensure that your TV lasts as long as possible, we recommend purchasing an uninterruptible power supply for it.Read about how to choose the right device in this material.

Conclusions and useful video on the topic

You can learn how to make a swing-and-slide bracket yourself from the following video:

The step-by-step process of making a rotating bracket with your own hands is presented in this video:

The article presents the basic requirements for installing a TV mount, tips for choosing a suitable location and several options for constructing brackets of different designs.

Based on step-by-step instructions for making a fixed and swing-out design, you can make your own bracket depending on your needs. So, you don’t have to spend money on buying a factory product.

If you have already tried to make a bracket for your TV yourself, then please share your experience with our readers. You may know the little-known secrets of making a durable design. If you wish, you can leave your comment in the special field immediately after the article.