How to increase draft in ventilation: a review of methods and devices for increasing draft

Clean air is vital for any person, and it is completely natural to want to use technological advances and the experience of craftsmen to build an ideal ventilation system in your home. And as a result, every owner is faced with the question of how to increase ventilation draft so that polluted exhaust air easily gives way to fresh air flows.

If you have ventilation problems or are just building a new home, use the advice of our experts and the list of draft accelerators they prepared, and the ventilation in your home will be normalized.

The content of the article:

What is ventilation?

People, while in their apartment, cook, clean, wash and simply breathe during the day, thereby saturating the air with excess moisture and odors, polluting it with carbon dioxide. During the process of replacing air masses, all this happens unnoticed with normally functioning ventilation, but results in considerable problems in the event of a failure of the air exchange system.

Without proper ventilation, the corners of the apartment become moldy, there is dampness, condensation on the windows, and a musty smell.

You can check the performance of the channel in a simple and effective way: by deflecting or moving a small piece of paper near ventilation grille, or the absence of dirt and dust on it with a smoked ceiling and walls.

Air exchange and types of ventilation

Air exchange - directed movement different temperatures air masses, which occurs due to draft in the exhaust ducts.

Air movement is carried out according to two elementary rules:

- air moves to an area of lower pressure;

- heated air moves upward.

Traditional natural ventilation becomes less and less effective over time due to the different nature of the materials used in the construction of modern buildings.

Instead of “breathing” wood and brick, foam concrete, artificial thermal insulation and finishing materials reign in the houses, soundproofing doors and metal-plastic window. As a result, air is not able to circulate freely and easily through the rooms; therefore, multifunctional ventilation complexes took the palm.

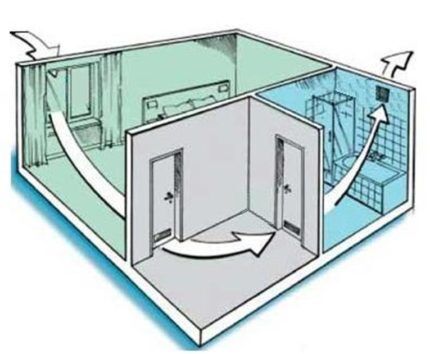

In the supply part, in the absence of infiltration, it is possible to install supply valves and a fan. Doors with bars will help to achieve flow; exhaust devices are necessary in bathrooms and kitchens.

In addition to conventional classical ventilation, mechanical air exchange methods are used for full functioning. The most popular and in demand method of arranging ventilation is considered supply and exhaust system, which not only removes used air, but also prepares incoming air (filters, warms or cools, purifies).

Factors influencing traction force

Regardless of the type of device, the main indicator of the effective operation of the system is traction, the intensity of which depends on a number of reasons.

The directional movement of air masses from the room to the outside naturally depends on uncontrolled weather conditions:

- numerical difference in temperature indicators in the room and at the outlet of the channel (in cold weather the draft increases, and in the summer it disappears);

- atmospheric pressure;

- wind direction and speed.

However, there are ways to influence the strength and speed of air currents.

Therefore, in the process of planning a ventilation system or its reconstruction, it is necessary to pay due attention to the following factors:

- height of the outlet pipe on the roof;

- dimensions and internal surface of the ventilation duct;

- channel layout;

- installation of deflector type devices.

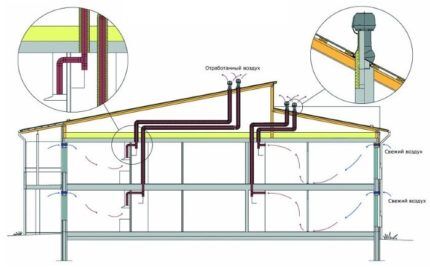

As everyone knows, air gravity in air ducts occurs due to differences in temperature and pressure at the inlet and outlet. For the stability of this process, it makes sense to place ventilation pipes at least in order to maintain the required temperature. intra-wall space, and ideally next to warm pipes or insulated.

In addition, there are a number ofrules and requirements to the placement height. The used air must leave the building above the roof, and the height of the exhaust pipe above the roof cannot be less than half a meter.

The resulting difference in height leads to normalization operation of the ventilation system and increased draft, which residents of the top floors of multi-storey buildings with a flat roof lack - they have problems with air exchange.

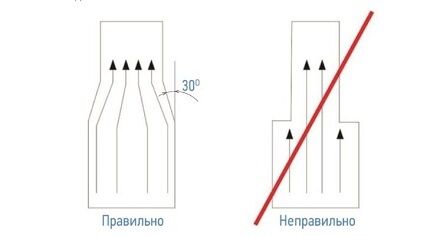

For traction force, not only the height of the ventilation duct, but also the direction of its laying is of great importance. It is advisable to place it only vertically with the least number of turns (each one reduces traction by 10%).

If possible, a pipe of the same diameter is used along the entire length; if a connection is necessary, the deviation angle is no more than 30 degrees.

The most popular type of ventilation pipe is considered to be a round rigid air duct; due to lower resistance and good air flow intensity, it is ahead of the economical rectangular and flexible corrugated ones.

When choosing parameters, it is recommended to use pipes with a cross-section of at least 16 sq. cm - if made of stainless steel, and with a channel side of at least 10 cm, but most often a size of 14 cm is used.

Increasing the pipe parameters will entail increased traction, therefore, it is more profitable to use the maximum possible dimensions of diameter and length. In cases where it is not possible to install channels with the same length, they resort to installing ventilation grilles in all rooms of the building.

Using a deflector for ventilation

One of the most effective ways to solve ventilation problems is the installation of draft accelerators for ventilation, for example, deflectors. Unlike the methods discussed above for increasing traction, which are more convenient to use during construction or major repairs, installation of a device such as a deflector can be done at any convenient time.

In addition, the installation allows you to neutralize the consequences of such difficult-to-correct actions as insufficient channel diameter, small height, difficult weather conditions or poor location.

The deflector is mounted on the exhaust ventilation duct above the roof of the building, its size depends on the amount of air emitted and the diameter of the duct. Available in standard sizes, many manufacturers work to order according to individual parameters.

The most common manufacturing materials are plastic and metals - aluminum, galvanized and stainless steel.

Plastic deflectors look much more advantageous in appearance due to their varied designs and colors; they are also much cheaper, but you need to take into account that their service life is short due to their instability to high temperatures.

The usual model of a ventilation deflector consists of a pipe, a diffuser and a cap with or without a return cylinder. Installation of the device is simple; you can install a standard deflector yourself easily and simply.

The lower pipe, the diffuser and the cap are alternately attached to the pipe head; connections are made with clamps, bolts and brackets. It is important that the cap is larger than the diameter of the diffuser to protect against slanting rain.

The mechanism of action of the deflector is based on the elementary rules of physics. The wind entering the device body is cut through diffuser, a rarefied zone appears and air masses, becoming more active, rush from the ventilation duct into the area of low pressure.

In addition to its main function, the deflector also solves a number of other problems:

- protection from debris;

- reducing the influence of negative natural conditions;

- increasing the efficiency of the ventilation system by 20%;

- the risk of backdraft is reduced.

They choose a deflector based on design and price, usually choosing well-known, well-proven models - TsAGI, Grigorovich, Astato, weather vane, H-shaped model.

Such a simple device as a deflector will help cope with a common ventilation problem - weak exhaust draft. However, we should not forget that the exhaust will not work fully without a supply ventilation system.

[adinserter name=»desktop: insert in text – 15]

And when checking the exit to the roof of the exhaust shafts, it is necessary to remember about the intake grilles to allow fresh air masses to enter. Their height above the ground must be at least 2 meters.

Conclusions and useful video on the topic

The video will talk about how to make a ventilation deflector yourself:

What needs to be done to increase ventilation draft:So, for the full functioning of the ventilation system, it is recommended to extend the air duct above the roof level and check the vertical location of smooth, hard, wide ventilation pipes.

It is also necessary to check the operation of the supply ventilation or fix the nozzle on the head of the shaft - the simplest models of the deflector can be made independently, each master chooses a suitable method for increasing traction.

Have you ever encountered insufficient draft in the ventilation duct and how did you manage to cope with this problem? Please share your experience with other visitors to our site. The communication block is located below.