Drain hose for a washing machine: types, recommendations for connection and operation

When buying household appliances, a washing machine or a washing machine, it would be right to think in advance where to place the equipment, how to connect it to water, and most importantly - to the sewerage system. As a rule, there are no problems with the supply of electricity and water, but the situation with drains may be different.

As practice shows, most future owners simply plan to use the drain hose for the washing machine included with the purchase. Only after installing the washing machine do you have to select a more suitable model or even extend the drain pipe.

The content of the article:

Types of hoses

Almost all washing machine manufacturing companies try to make drain hoses for their equipment according to approximately the same pattern. On the one hand, this simplifies maintenance or replacement.

On the other hand, it reduces costs, since small, insignificant fittings and consumables can be ordered from a third-party manufacturer.

To connect the washing machine to the sewer drain collector, three types of hoses are used:

- Outlet hose-pipe. Needed to connect to the outlet pipe of the pump inside the washing machine.

- Drain hose extension. It is used to increase the length of the waste channel to the sewer pipe.

- Corrugated polypropylene hoses in coils. Needed to increase the length of the drain.Can be used in washing machines for any model of almost all well-known brands.

The drain hose is based on a corrugated polypropylene pipe. If the filler can be made of PP or PVC with reinforcement with polyester or nylon thread, then for the drain you need a corrugation made of heat-resistant polypropylene.

This polymer is best suited for discharging hot water with high detergent content. In addition, polypropylene has a higher resistance to abrasion and deformation when hot.

Polyethylene drain hoses cannot withstand mechanical loads, while polyvinyl chloride ones “flow” when heated, and leaks appear under the fittings and connecting pipes.

Outlet drain hose

As a rule, the corrugation is installed at the stage of assembling the washing machine, but some manufacturing companies save money and can simply include it in a set of accessories and consumables.

On the one hand, this is convenient, since you can immediately install a drain of the required length on the washing machine without extension corrugations with intermediate connections.

On the other hand, to install the drain hose you have to resort to the services of a service center technician. It is better not to install it yourself, so as not to lose the warranty.

The length of the starting hose does not exceed 150 cm. The diameter of the fittings at the ends can be 19 mm, 22 mm for household models, 24 mm or 28 mm for semi-professional washing machines.

The color of the corrugation can be different - from white or light brown to bluish-gray. This does not affect performance characteristics.

Peculiarities:

- corrugation is dense;

- the thickness of the hose walls is greater than that of extensions;

- soft, bends well, but does not stretch.

This device was specially chosen, since the drain hose is routed through a hole in the back wall of the washing machine. The edges of the latter are covered with a rubber pad.

This scheme makes it possible to tightly and softly fix the corrugated pipe on the body of the washing machine. In this case, vibrations during rotation of the drum do not in any way affect the operation of the drainage tract.

Extension Cords

Since the washing machine drain pipe is designed to operate at atmospheric pressure, extensions are made from thinner polypropylene. This allows the hose to stretch and bend without collapsing the walls.

Extension corrugations are used to lay the waste pipe in an optimal way. Often, a corrugated drain is hidden behind kitchen furniture or even under floor skirting boards. This makes it possible to place the washing machine at a distance from the sink siphon or connector on the wall of the sewer pipe.

The connecting pipes at the ends of the extension hose are made of soft plastic. This makes it possible to splice two corrugations mechanically using a fitting, without the use of soldering. Depending on the connection diagram, a straight or L-shaped pipe can be installed at the second end.

Some washing machine manufacturing companies, such as Electrolux, produce extension cords with internal inserts after the fittings. Thanks to this, the drain hose, even in a highly stretched state, does not break or deform when bent.

What should be the length of the drain hose?

The size of the outlet corrugation attached to the body of the washing machine, as a rule, does not exceed 80-100 cm.This is enough to check the operation of the SM at an enterprise or service center, but not enough to properly connect the equipment to the sewer system.

Extension hoses can be stretched up to 4-5 m, while the corrugation remains operational. But it is not worth laying the corrugated hose to its maximum length, since this greatly reduces the strength of the walls.

It would be optimal to stretch the corrugation by 70-80%, no more. For example, the size of an extension hose marked 1.2-4 m when stretched is 3-3.2 m. This is enough to connect the washing machine drain to the siphon of a sink located 2-3 m away.

If you connect without a siphon, directly into the sewer pipe, then you need to additionally add another 70-80 cm to form a loop (water seal). Otherwise, odors from the drains will penetrate into the corrugated hose and into the pump, and the fittings and metal will rust over time. In general, the length of the washing machine drain hose will be equal to the distance to the drain plus another 80 cm for forming a loop.

How to install a drain hose

There are several options for laying a corrugated hose from the washing machine to the sewer. The specific installation method depends on where the washing machine is located and how far away the drain is from it.

Popular schemes:

- connection to the sink siphon through a rubber adapter coupling;

- connection to one of the pipes of the sewer tee installed below the siphon.

If the SM is in the bathroom, and it is not possible to connect the corrugation directly to the sewer, then the output of the corrugated hose is routed to the bathtub drainage device.

In a hopeless situation, the corrugation can simply be thrown into the bathtub.This is what many housewives did when using conventional activator washing machines, even before the advent of automatic models.

You will only need to use the drain hose holder (it is included with the machine). At the end of the work, the bath is washed to remove traces of dirty water and detergents.

How to connect the drain hose of a washing machine to the sewer without a siphon

Manufacturing companies do not equip their products with holders to drain dirty water into the bathroom. The device is necessary for correctly connecting the corrugated hose to the sewer pipe.

The connection diagram needs to be thought out in advance. To do this, a section with a Y-tee is cut into the sewer pipe. One of the side pipes with a rubber cuff will be used to drain water from the sink.

You can try to simply stick the end of the corrugated hose into the pipe, but such a connection will not work for long. After the first pumping of water from the machine, the corrugation will become heavy and sag under its own weight. Since this is an extension hose, the tube will partially collapse, dirt will begin to accumulate, and a plug will form.

Therefore, connecting the extension hose directly to the sewer must be done using a rubber coupling-holder, which must be inserted into the pipe and secured to the wall.

If the holder is mounted on the wall, then it is enough to insert the rubber coupling-cuff so that the fitting fits into the pipe without kinks.

It is necessary to form a loop on the corrugated hose. The installation height is determined according to the equipment passport. It differs for washing machines of different brands, maybe 30 cm, 50 cm, 80 cm. In any case, the installation height must be maintained exactly according to the passport.

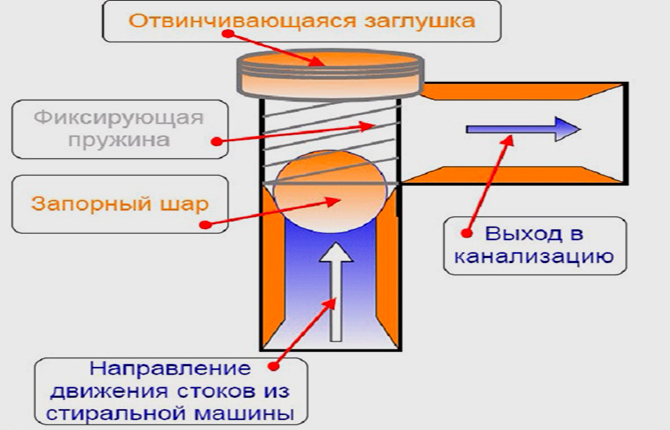

If the extension hose is not used, and the length of the outlet corrugation is sufficient, then it can be connected to the sewer without a holder. For this, a special valve with a polystyrene foam ball is used.

Valve circuits are used primarily when connecting the washing machine to vertical sewer risers.

How to connect the drain hose to a washing machine via a siphon

Most modern models of kitchen sinks are equipped with a siphon valve with a built-in connection point for the corrugated hose of a washing machine or dishwasher.

The unit consists of a fitting and an adapter-fitting with a union threaded nut. We press the adapter into the corrugated hose, do not forget to put on the nut first, and screw it onto the thread of the fitting.

Since the flow area of the extension corrugation has decreased, the connection must be additionally compressed with a threaded clamp. Otherwise, due to the increased water pressure inside the extension, the hose may be torn off the mounting.

This scheme is considered more reliable; it is recommended to use it in cases where the drain hose is long or was assembled from several extension sections.

How to extend the drain hose of a washing machine

In most cases, the washing machine has to be connected via an extension hose. The first solution is to connect the fittings of the outlet corrugation of the washing machine and the extension cord.

If they are the same size, they will easily fit into each other. Some “craftsmen” manage to additionally wrap the joint with tape so that it does not squeeze out under pressure when pumping out water.

Such a joint begins to undermine after the first starts of the washing machine. As contaminants accumulate inside the drain hose, pressure increases and at some point the fittings are forced out of the connection.Accordingly, the kitchen floor is flooded with dirty water.

More savvy craftsmen extend the outlet hose of the washing machine using a PVC tube of the appropriate diameter. Vinyl hose is purchased immediately at the required length.

The end is slightly heated in boiling water, after which it is put on the fitting and secured with a metal worm clamp. The connection is strong.

Despite its unpresentable appearance, this extension scheme has its advantages:

- The drain pipe from the washing machine to the sewerage connection point is obtained without inserts that reduce the flow area. It is in these places that the largest amount of dirt collects.

- PVC pipes have a wall thickness of 2.5-3 mm. This is several times more than that of ordinary polypropylene corrugation. Less risk of damage, longer service life.

- A PVC hose, unlike a standard corrugated hose, has a smooth inner surface. There is practically no dirt deposited on polished walls. The washing machine pump operates with less load.

The PVC extension hose requires virtually no cleaning. If a problem arises, just rinse with hot water or rub it with your hand in the place where the dirt plug has formed.

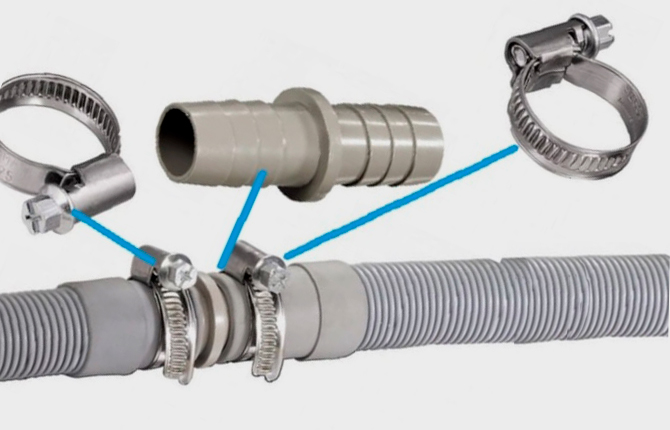

Fans of standard extension solutions use a ready-made polypropylene fitting. It is enough to pull the ends of the drain hose and extension onto the tube and secure with clamps.

The joint is strong and reliable.

Replacing the drain hose

Vibrations of the washing machine body and the small thickness of the corrugated walls cause the appearance of fistulas or transverse cracks. Often the owners step on a drain hose, carelessly thrown on the kitchen floor, and the legs of chairs get caught. All this leads to premature damage to the corrugation.

Replacing the outlet drain hose on a washing machine is performed in the following sequence:

- Turn off the water at the inlet hose.

- Raise the junction of the outlet corrugation with the extension cord to a height of 70-80 cm and disassemble the joint.

- Place the end of the hose on the washing machine into a liter jar (water will drain out). Holding the end of the extension cord suspended, we gradually lift it along its entire length so that the water flows into the sewer.

- We replace the corrugated extension with a new one and assemble the drain line in the reverse order.

Replacing the outlet drain hose on a washing machine is a little more complicated. It only needs to be replaced with a similar corrugation, preferably from the same manufacturer, or with any corrugated hose for SM that is suitable in size. It is important that the replacement is of good quality.

You should not try to splice/repair corrugation or change corrugated to regular PVC. If a leak occurs, you only need to change the hose.

First of all, you should unscrew filter at the bottom of the washing machine. At the same time, the water remaining in the pump volute will finally drain. At the same time, you can clean the mesh from adhering fibers and detergent flakes.

The next step is to remove the back wall on the housing, carefully pull the drain hose through the hole and carefully inspect it. Typically, cracks appear near the nozzle on the pump volute.

To replace the corrugation, you need to loosen the spring clamp and remove the drain hose. We install the new one in the reverse order.

How to Clean a Drain Hose

Most of the contaminants settle on the walls inside the extension hose. The reason for this is the horizontal arrangement and ribbed surface. Therefore, it is mainly the extension cord that has to be cleaned.

There are two types of contaminants to remove:

- Deposition of a mixture of undissolved powdered water softener, detergent and dust. All this is collected inside and cemented to a hard crust.

- Fiber and hair plugs. There are few fibers and hairs in the drained water, but they can accumulate at the outlet of the drain hose, forming a dense, lumpy mass.

As soon as the washing machine periodically begins to display the message “filter is clogged”, the water is downloaded slowly and not in full, you need to disconnect the hose for cleaning.

First you need to remove the plug. Sometimes it is visible in the corrugation from the side of the end connected to the sewer pipe. In this case, it can be removed with tweezers or a wire hook.

There may be several plugs inside the drain hose, so the extension cord must be rinsed with a stream of water under high pressure. For example, remove the gooseneck from the faucet in the bathroom, press one end to the fitting and turn on the water. Usually the cork is washed out or squeezed out by pressure.

To remove the remaining washing powder, the corrugation is rolled into a coil and immersed in water for 10-12 hours. After half a day, the water is drained from the hose, after which the walls are tapped with a wooden plank. All that remains is to rinse the corrugated hose under pressure to wash out from the inside everything that has peeled off from the walls.

There is no point in saving on a drain hose for a washing machine. You need to immediately buy high-quality corrugation from a well-known brand. The durability and reliability of the drain system depends on this.

Share your experience in maintaining extension cords, installing and repairing them. How can we improve the system for discharging dirty water into the sewer system and make it more reliable? Tell us in the comments.Save the material in your bookmarks so that you can return to it at any time.

Simply rinse the drum, tank, and pump with clean water after washing. When you’ve finished washing, take some water, heat it to 40°C and put it on pumping. Everything will be washed, from the pump to the sewer. This is what you should always do if you want to keep your car.

Place the car closer to the sewer; the shorter the length of the drain, the better. You can even determine the place where the traffic jam appeared by its appearance. Due to the bursting pressure at the moment of pumping, you can directly see how the distance between the ribs of the corrugation increases.